The exponential spread of the novel coronavirus across the globe led to overwhelming demand on supply chains and disruptions to traditional manufacturing and distribution systems. Because of societal lockdowns and stay-at-home orders, a dire need quickly arose for locally fabricated, specifically focused and creatively sourced solutions to equipment shortages and emergency supplies. At home and across the globe, designers and engineers quickly mobilized into online, open-source prototyping groups to solve the challenge of a lack of personal protective equipment (PPE), ventilators and medical device accessories. 3D printing and additive manufacturing was an obvious go-to, with the ability to rapidly prototype and iterate on the fly, teams could utilize 3D printers to supply healthcare providers with equipment now, as soon as there were designs to print. The intention and needs were obvious and clear – to aid humanity and fill the gaps in supply chains – however, organizing volunteers and streamlining the process to avoid duplicate efforts was a daunting task.

As a company with a wealth of R&D project experience and long used to working as a distributed team, re:3D put out the call that we would prototype – for free – any life-saving devices or PPE in order to expedite review by medical professionals. We are conscientious contributors to the open source design community for COVID-19 response. We take a First, Do No Harm approach to any design work we do for this effort, meaning that it needs to be designed with input from, and in partnership with, the individuals who will utilize any equipment we prototype. We will not create anything that gives a false sense of security, but is ineffective or harmful. Our medical providers on the front lines are in need, and we are honored to take on the challenge.

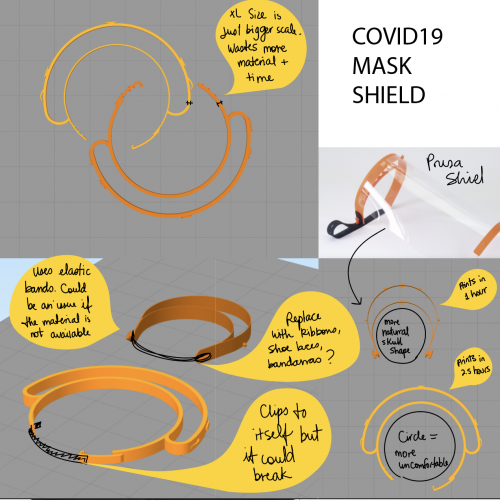

Face Shields

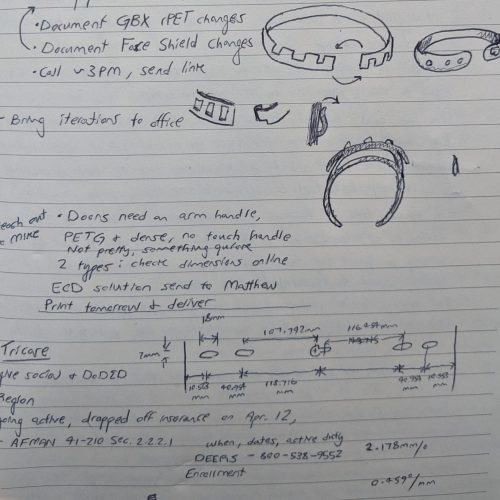

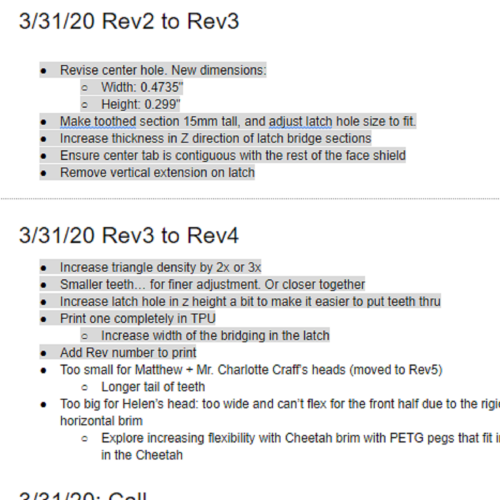

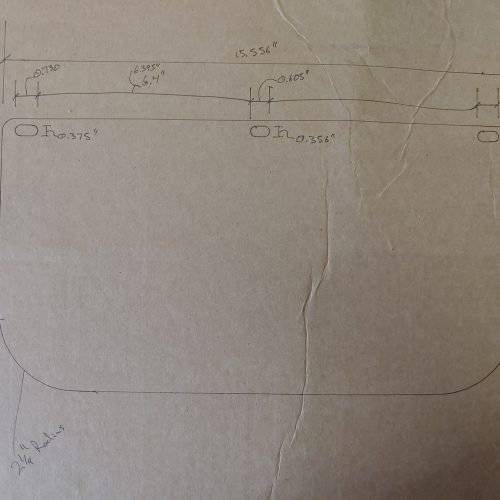

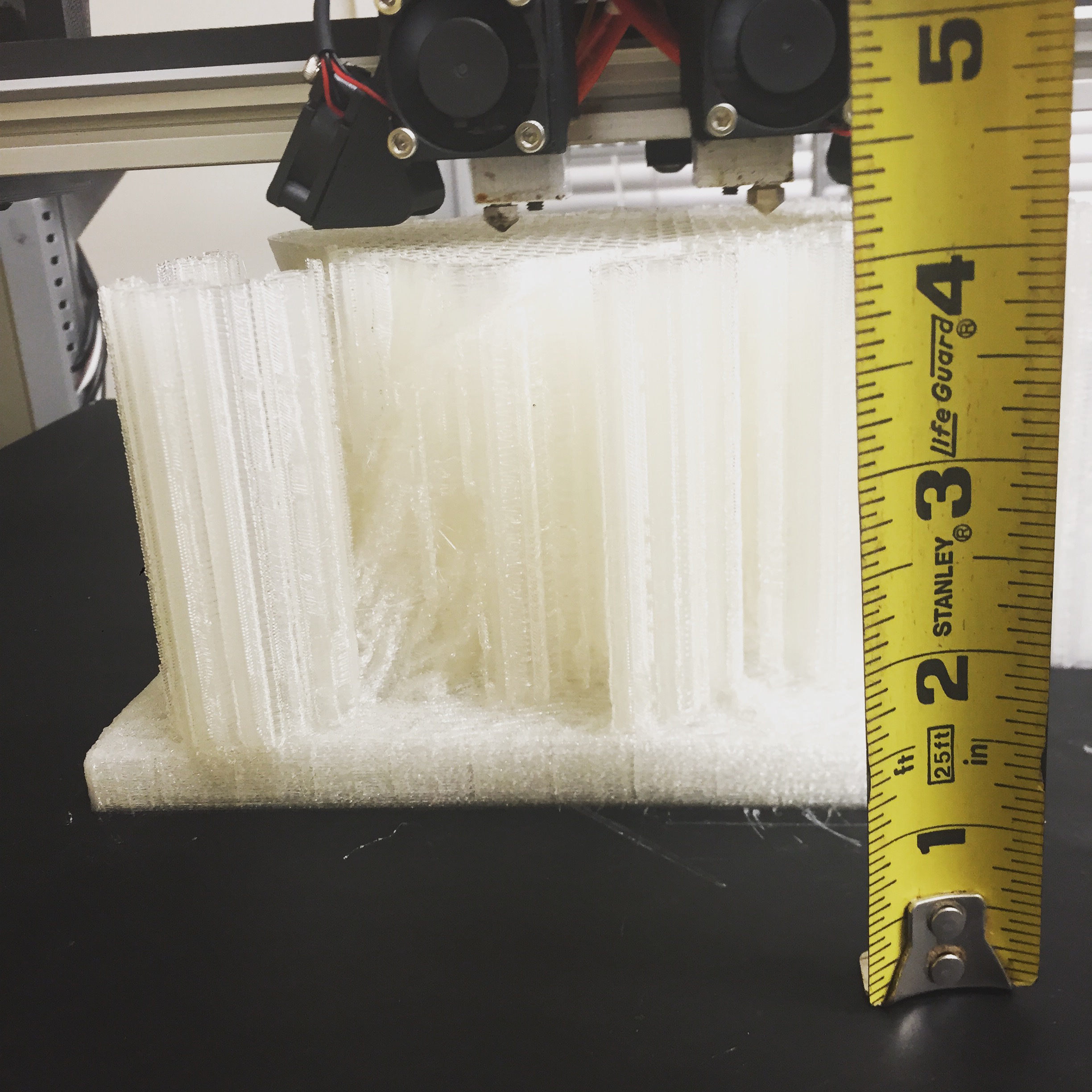

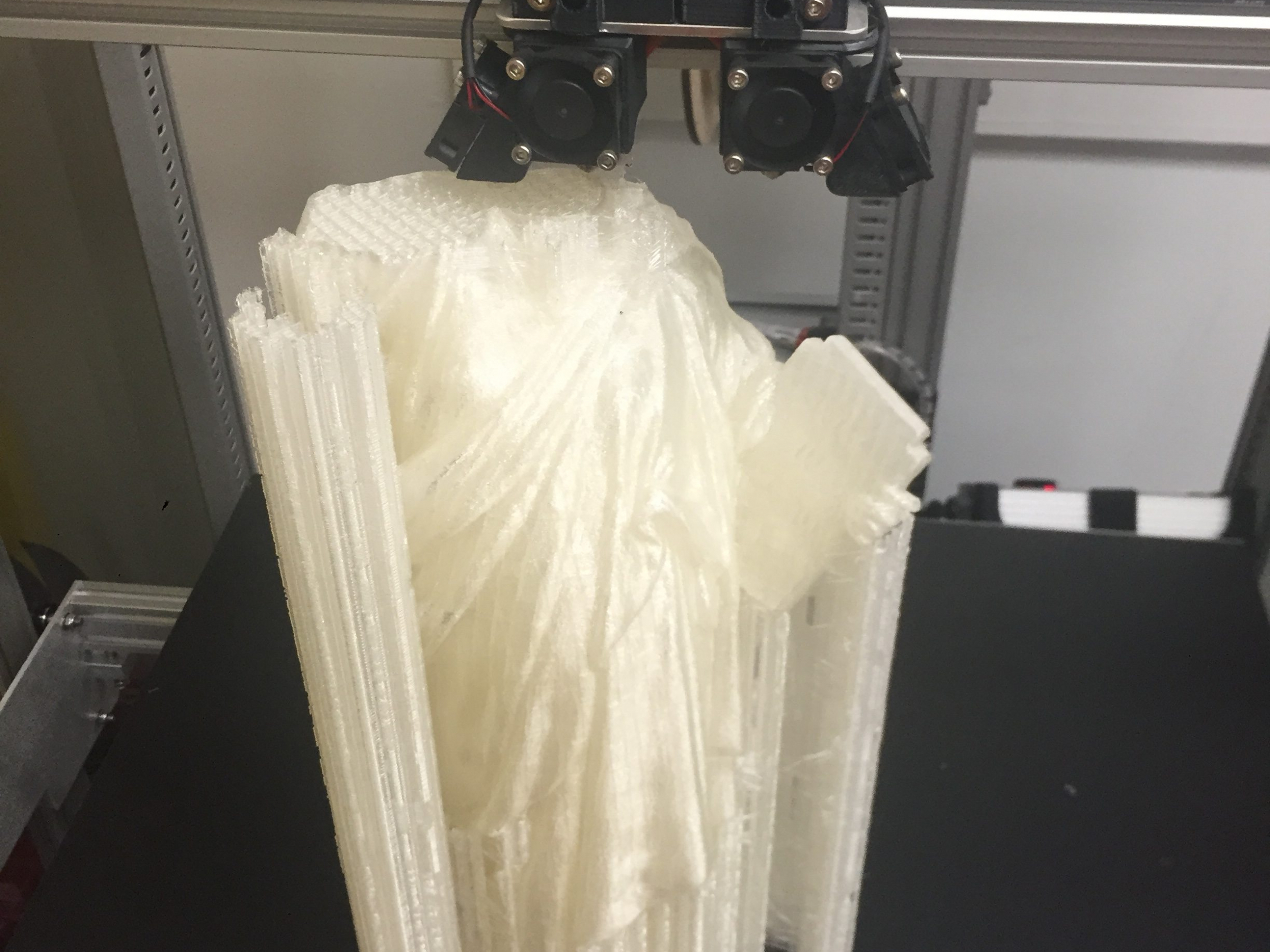

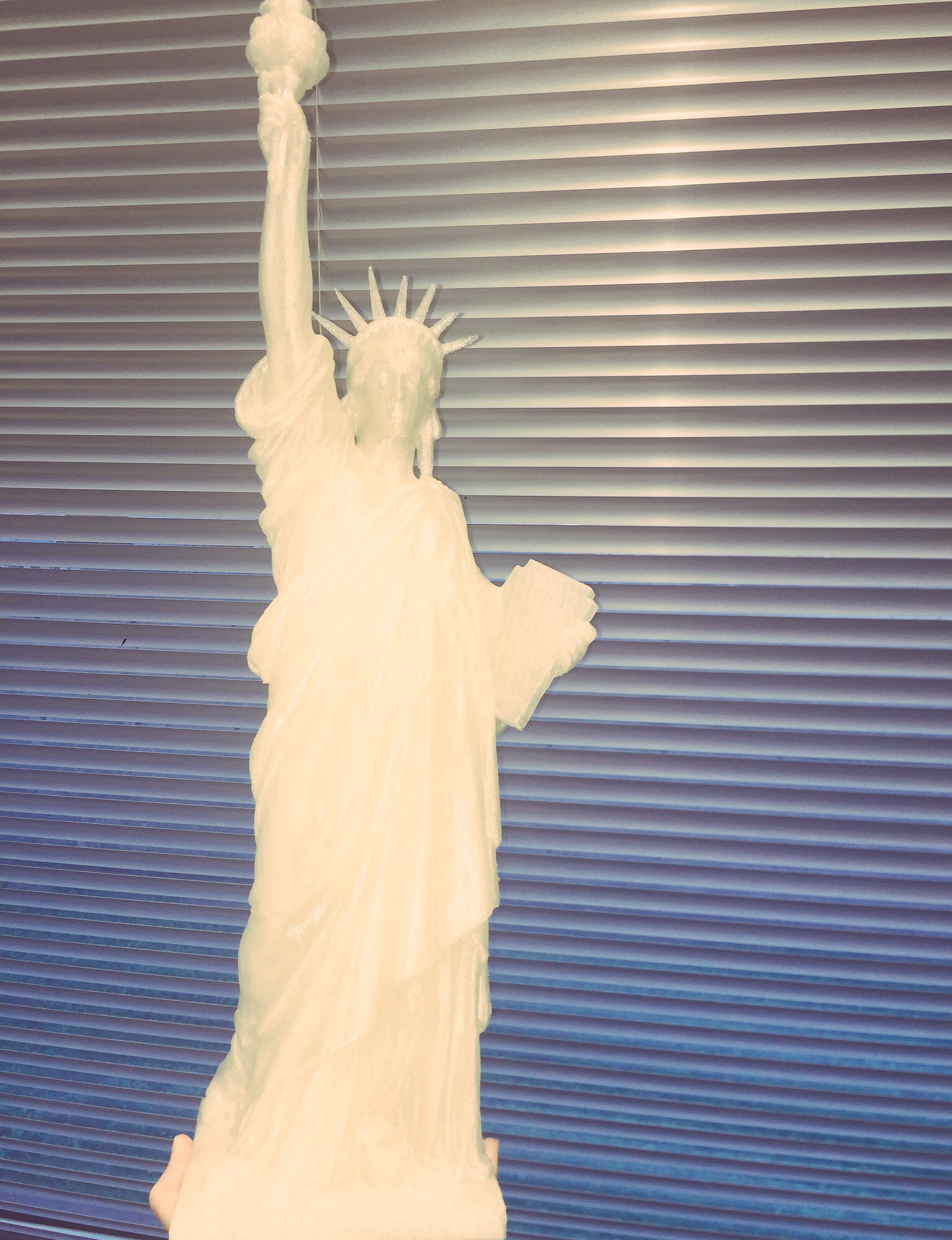

In two overlapping efforts, we prototyped a design for a 3D printed face shield with full visor coverage and an adjustable zip tie style latching mechanism. The inquiry started in Puerto Rico. Vicente Gascó, our friend and colleague from Tredé and Engine-4 shared he had a supply of 4000 clear plastic lenses for face shields, but no visor to which they would attach to the head. Armed with only the measurements of the lenses and aided by an idea from assembly guru and NASA technician Andrew Jica in Houston, Brian Duhaime, our mechanical engineer in Austin, and Alessandra Montano, our graphics designer in Puerto Rico, pumped out five different iterations of a face shield in only 48 hours.

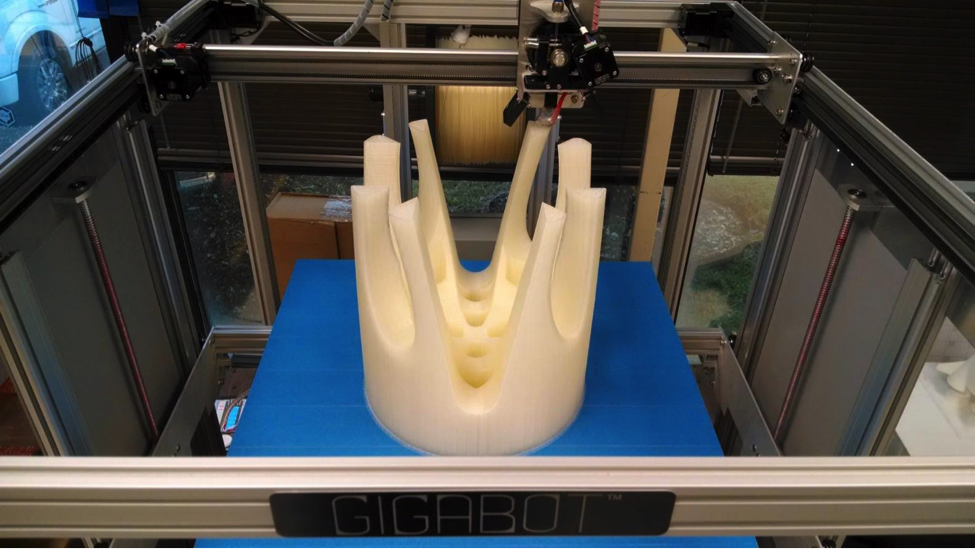

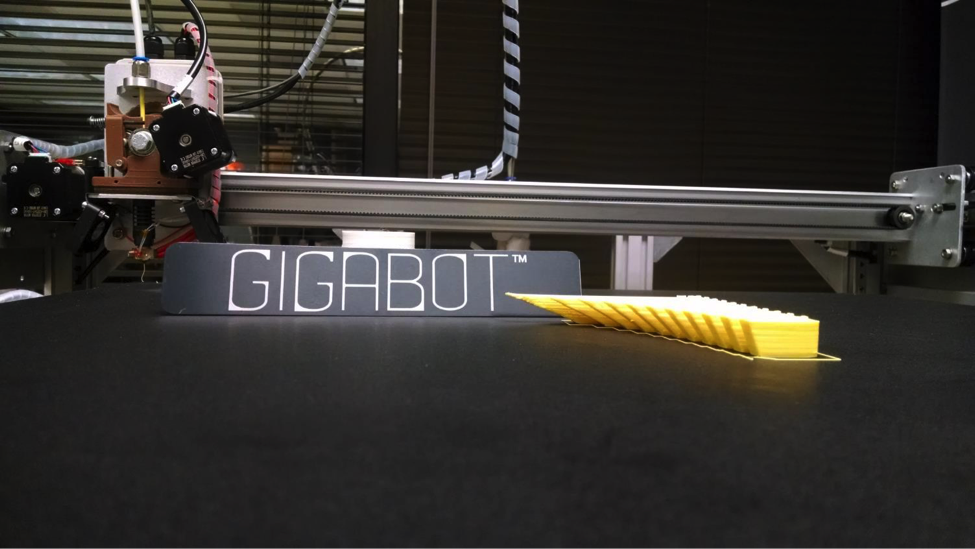

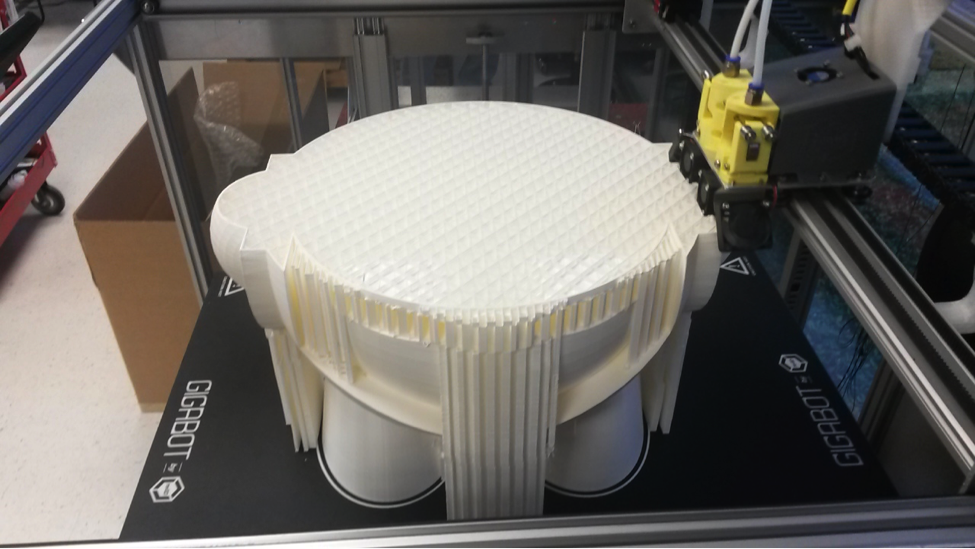

Vicente and Luis Torres, co-founder of Engine-4, pulled our Puerto Rico Gigabot out of Parallel-18 and added it to the existing Gigabot at Engine-4. Gigabots in Austin and in Puerto Rico printed out iterations of the designs for testing.

In Houston at the same time, CTO Matthew Fiedler, mechanical engineer Helen Little and community liaison Charlotte Craff were meeting with doctors from a local hospital to discuss their needs for a face shield. Knowing that vetted, open source face shield designs were already available, the group reviewed designs by Prusa, Lazarus3D, Budmen and Professional Plastics. The Houston team 3D printed existing options for the doctors to test, but the designs didn’t meet all of the doctors’ needs:

- Lightweight, fully closed top

- Reducing the air gap between lens and chin

- 180 degree lens coverage

- Limit number of parts to reduce need to source materials in short supply

Knowing that supply chains were disrupted and very little raw materials were available in a timely manner, re:3D conferred with Professional Plastics and determined that plastic sheeting supplies were well behind schedule, but that there were excess pre-cut face shield lenses available. Again, re:3D opted to prototype to existing, local supplies, keeping stress off of traditional supply chains and getting creative with what was available.

Over the next week, Helen built on the work done for the Puerto Rico design, integrated the needs of the doctors and iterated ten different versions of the face shield while working from home and rarely getting to hold a print in her hands. The result is a single print, face shield with an adjustable latching mechanism. It’s designed for 180 degrees of protection and comfort without the addition of foam padding. It has the approval of the hospital’s Infection Control and is currently available at the National Institutes of Health 3D Print exchange for COVID-19 Response. https://3dprint.nih.gov/discover/3dpx-013504

Hands-Free Door Pulls

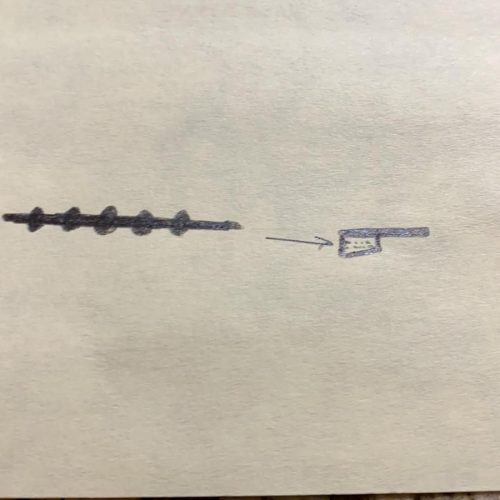

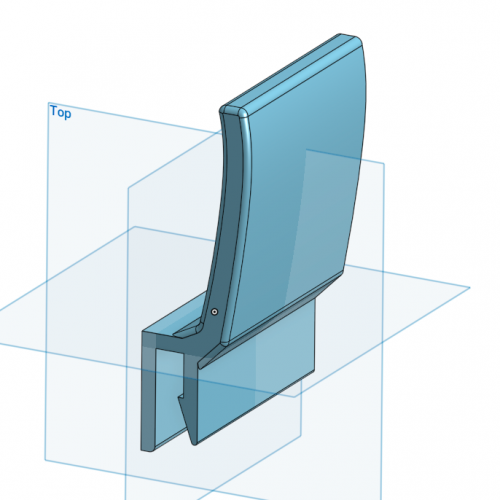

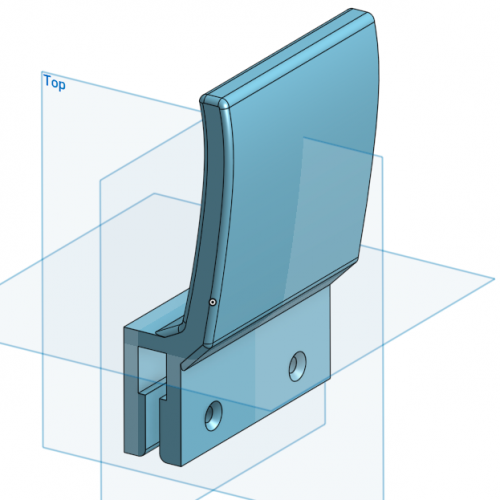

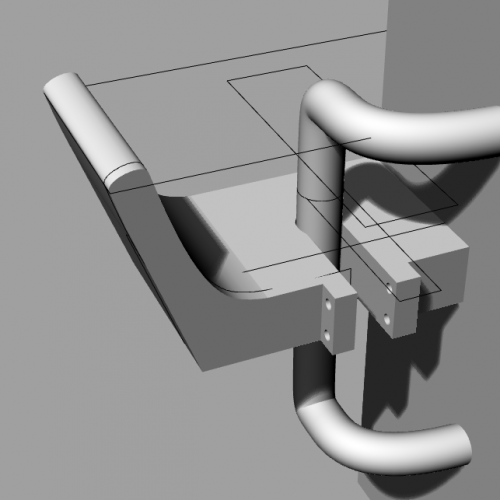

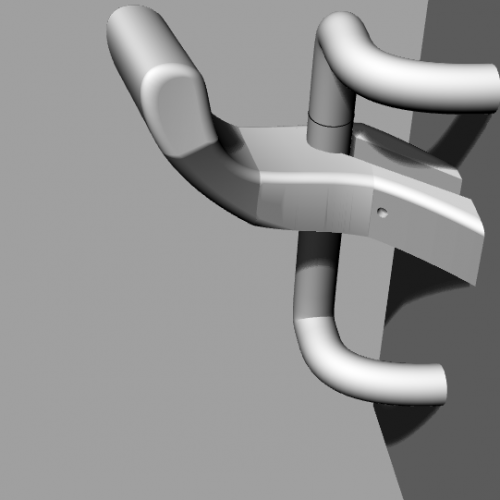

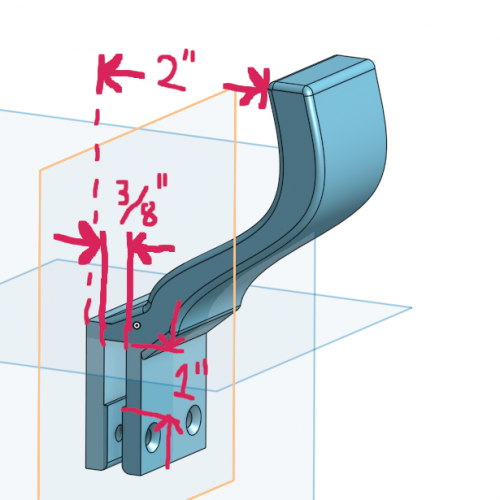

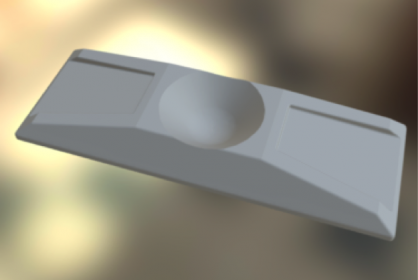

Eliminating unnecessary shared contact surfaces is imperative, especially in buildings where essential workers are operating to continue necessary services. Our team includes multiple military service members. One of our reservists was activated when she sent out a call back to our team to make some hands-free door pulls to use on the base. Aided by Matthew Fiedler, Mike Battaglia, our designer in Austin, and Brian Duhaime went to work prototyping hands-free door pulls for lever-style and bar-style door handles.

These designs were drafted before we had dimensions for either of the door styles, so had to be modeled in such a way to enable incremental dimensional adjustments while preserving the models’ shapes. During her free time, the service member sent feedback on the first versions via pictures and notes, and Brian and Mike iterated the changes remotely, melding organic shaped and attachment options into single print solutions.

The hands-free door pulls are now successfully in use on base, protecting our military personnel as they work to respond and aid COVID-19 efforts. These models are available for download here https://3dprint.nih.gov/discover/3dpx-013825 and here: https://3dprint.nih.gov/discover/3dpx-013822

From Intubation Box to Drape Stands

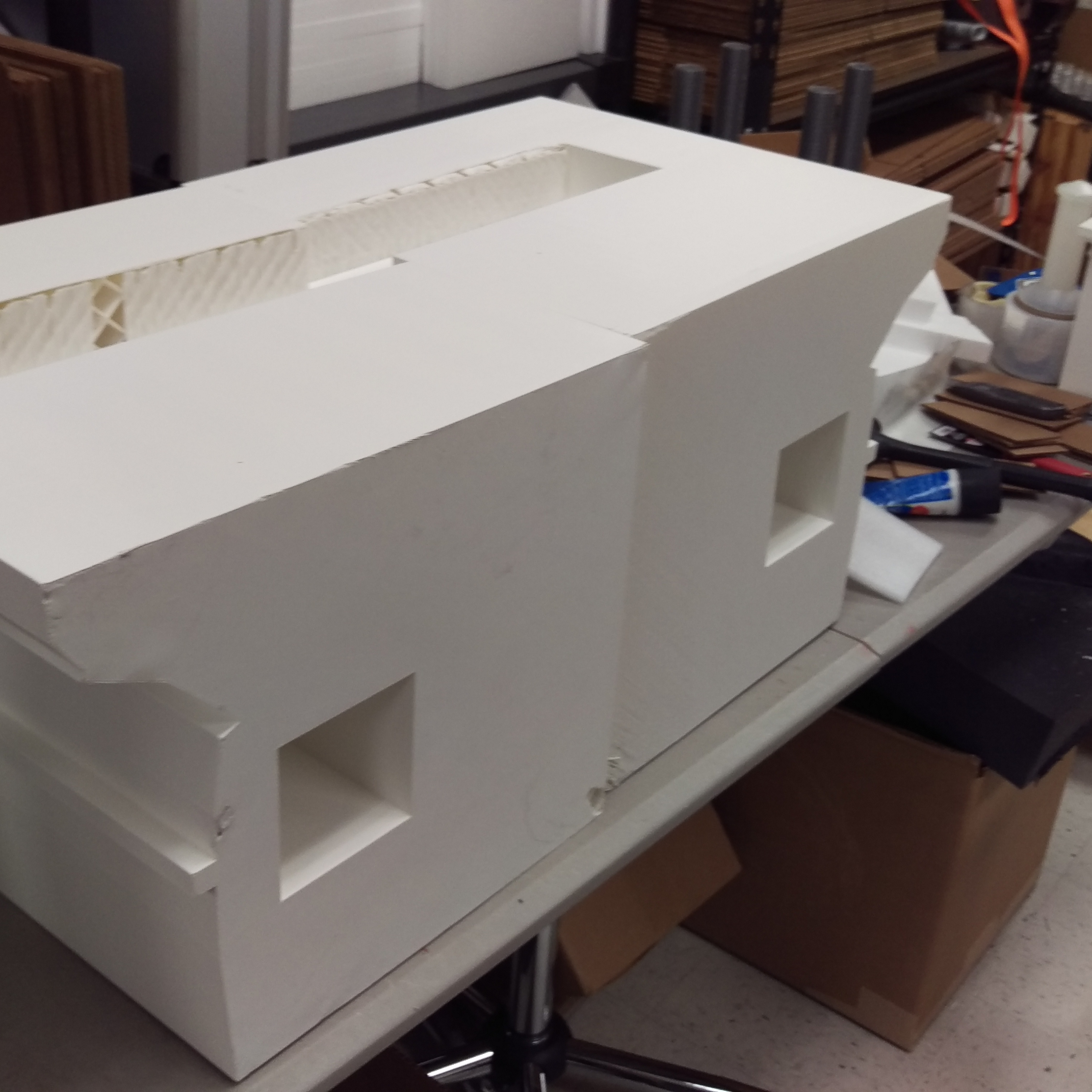

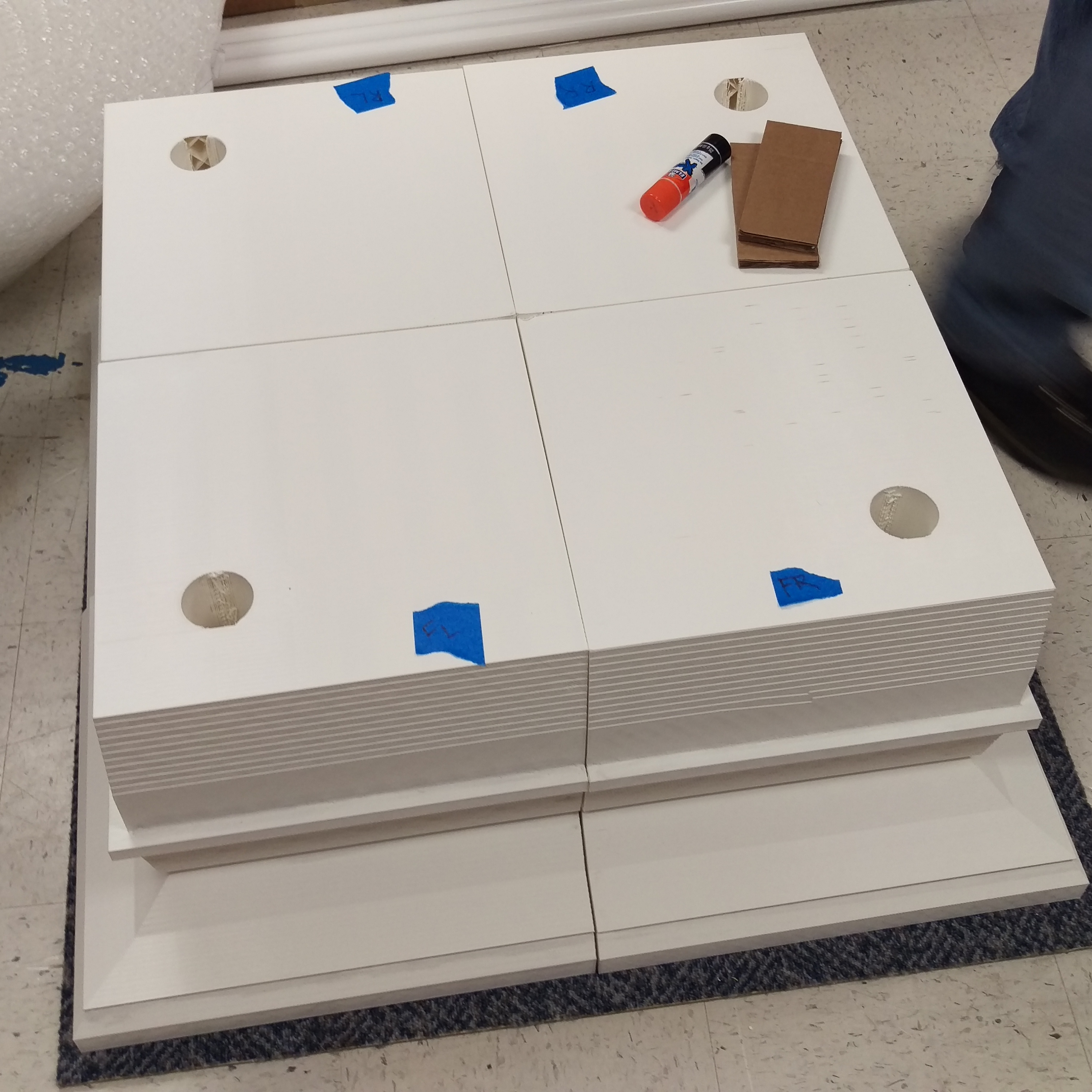

As a 3D printer manufacturer, we are understandably advocates of 3D printing use in manufacturing. However, we recognize that not all innovations require, or are best served by, an exclusively 3D printed solution. As we do much of our manufacturing in-house, including machining parts on our CNCs, we can apply rapid prototyping principals to traditional manufacturing methods. Take the example of an aerosol or intubation box:

We were contacted by an anesthesiologist based in Austin about modifying such a box, used to protect doctors and nurses from aerosols released when intubating a patient. The doctor’s main concerns were ability to clean and the need for a “helper” hole. This equipment needed a curved, clear surface rather than sharp corners where germs could hide. We offered to prototype using polycarbonate sheeting and an aluminum framework available in our machine shop. In this case, the request for aid evolved before we produced a prototype. The anesthesiologist reported that the existing boxes were unwieldy and took up too much space, so instead requested a solution for supporting clear plastic drapes to achieve the same purpose and be easy to store. Matthew Fiedler proposed a combined 3d printed base and a bent aluminum frame for the project. Design work is ongoing and we will update this post as the prototype develops.

Are you a healthcare professional needing a COVID-19 related equipment solution? Please reach out to us at info@re3d.org to begin coordination. Should you wish to purchase any of our COVID-19 designs. They’re available in our online store: https://shop.re3d.org/collections/covid-19

Interested in supporting existing efforts to fight COVID-19? See below for how to help in Austin, Houston and Puerto Rico.

- PETG is preferred, but PLA is completely acceptable if you don’t have PETG or are not able to print with it.

- 3-4 solid top/bottom layers

- .3mm layer height

- 5 Perimeters (AKA Shells or walls)

- 0% Infill

If you live outside of these areas and/or are seeking ways to contribute, A Form to Volunteer is Available Here. We will be responding to inquiries this weekend and doing our best to facilitate introductions:)

Charlotte craff

Blog Post Author