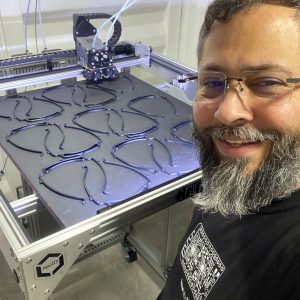

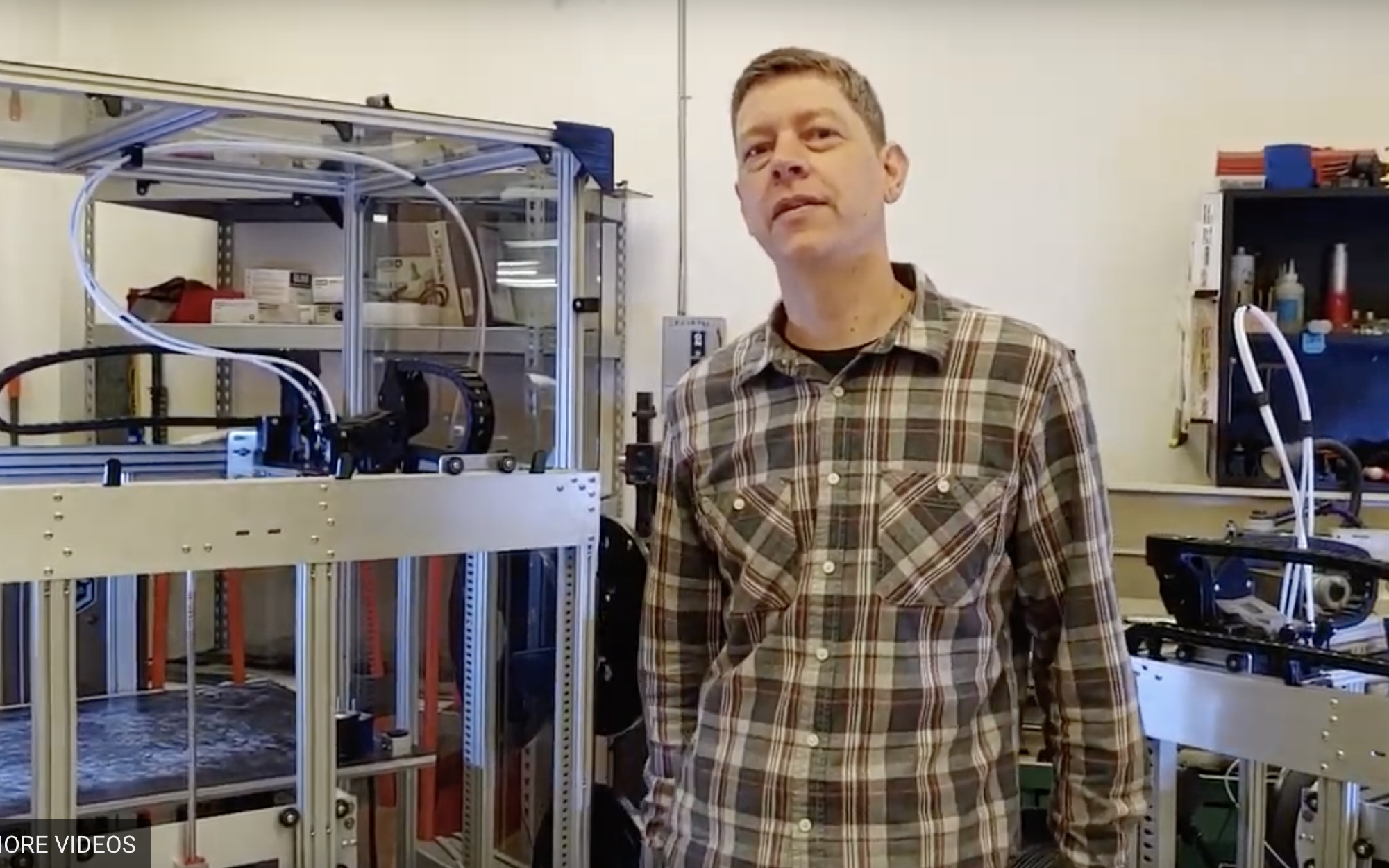

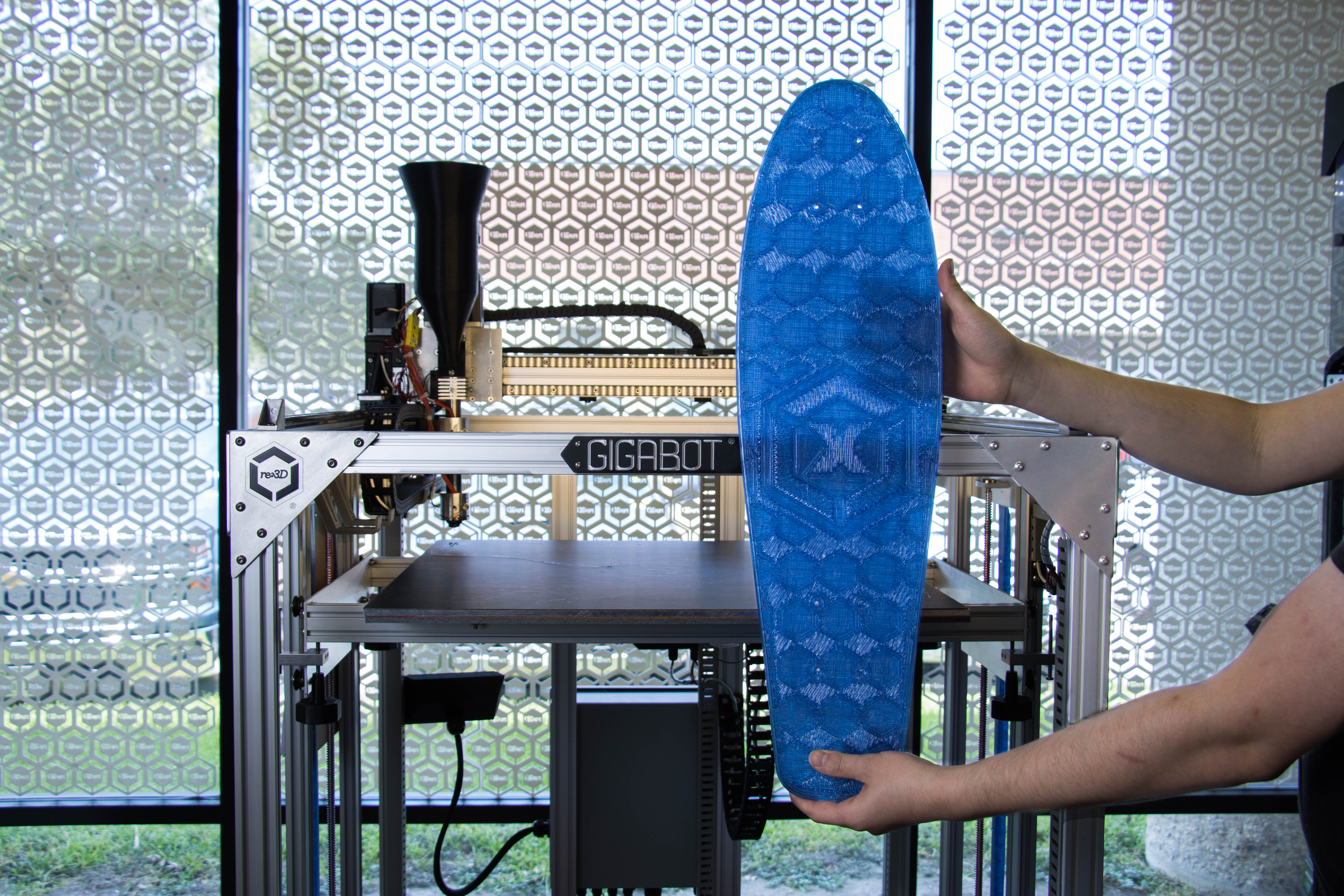

Mike Ogrinz is a maker through and through, deeply embedded in the re:3D community since backing the original Gigabot on Kickstarter in 2013. He originally purchased the Gigabot to 3D print the parts for his life-size replica of Robby the Robot. Over the years, Mike upgraded his Gigabot 2 to have a heated bed and dual-extruder capabilities. This has given Mike the ability to use the Gigabot for numerous projects, including making re:3D a life-size 3D printed Grogu (Baby Yoda) in exchange for our Series II All-Metal Body Extruder. You can read Mike’s blog post about how Grogu was created below, originally posted on his website, ogrinz.com.

I’ve had my Gigabot 3D printer for almost a decade now (wow) and every now and then the company behind it (re3D) have asked “Would you print something out for our in-house museum?” They’ve even offered to pay for the filament, shipping, etc. At one point, I *almost* sent them one of the spare heads from my Robby the Robot project, but the thought of all that sanding, priming, and painting scared me off.

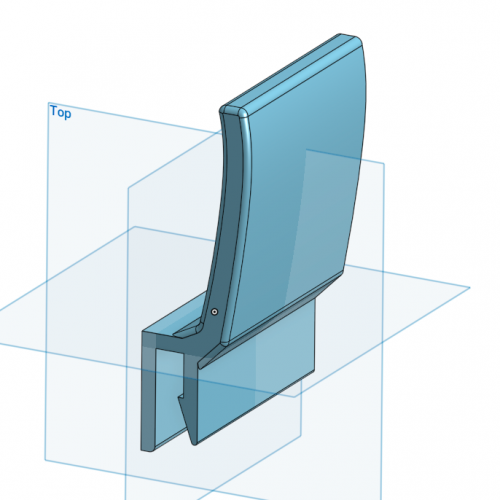

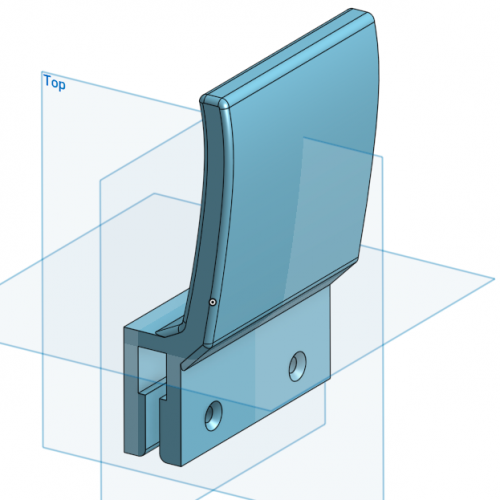

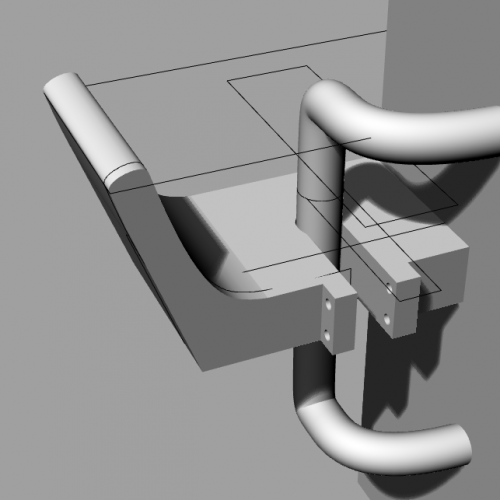

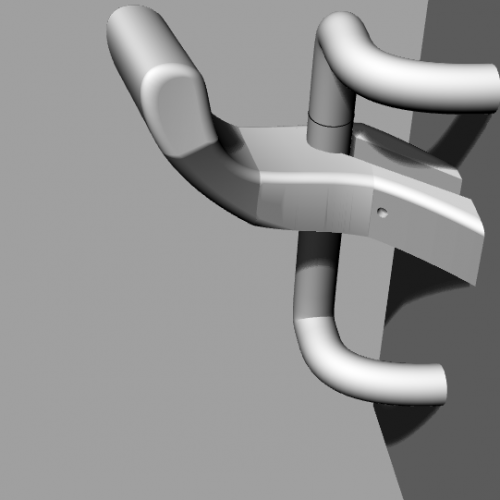

Then a few months ago Jennifer from re3D reached out again. She asked if I’d be interested in making something, and even offered me some credit in their store. Well, I did have my eye on a set up fully-machined dual aluminum extruders as an upgrade for my Gigabot…. So I asked, “What would I have to make you in exchange for those parts?”

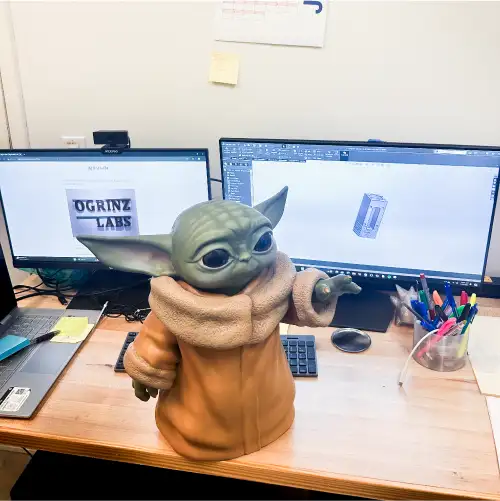

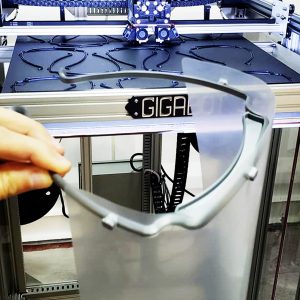

Jennifer almost immediately answered “Baby Yoda!” and the deal was struck. I figured with the filament cost probably coming in around $100, I was getting the better end of the deal. But of course, there was a lot of finish work required. And since Grogu has so many organic surfaces and details, it had to all be done by hand. I had to completely finish the replica too, which meant learning how to use an airbrush (well, it meant buying and airbrush and then learning how to use it). But I am extremely happy with how it came out. Now if I only could find the time to install those metal extruder mechanisms…

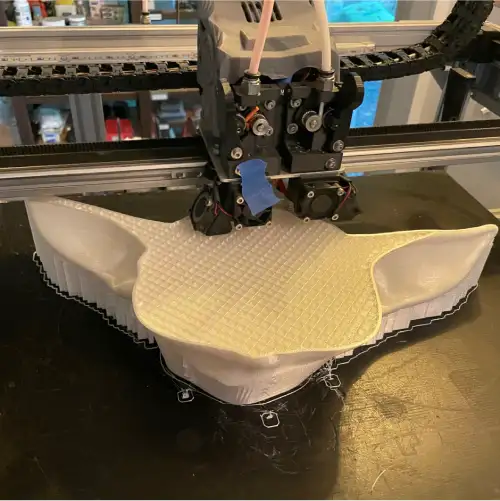

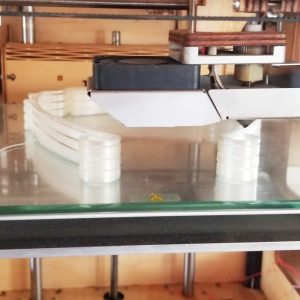

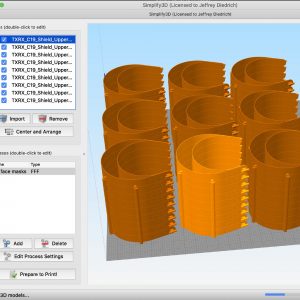

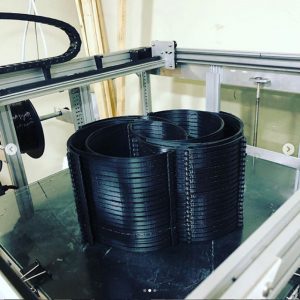

The 3D printed Grogu took 134 hours to print and used three rolls of PLA Silk filament.

The original Grogu file came from MarVin_Miniatures on Thingiverse. You can also follow them on Facebook, @MarVinMinis.

To learn more about Mike’s other projects click here. You can also check out Mike’s YouTube Channel, Ogrinz Labs, where he posts educational and informational videos on his awesome builds.

Jennifer Dennington

Blog Post Author