Support

Share your projects and learn about our research!

Troubleshooting and How-Tos for your Gigabot!

Thank you for working with us.

Our dedicated support team is available to all Gigabot owners for the lifetime of their product, free of charge.

HELPFUL LINKS & REFERENCES

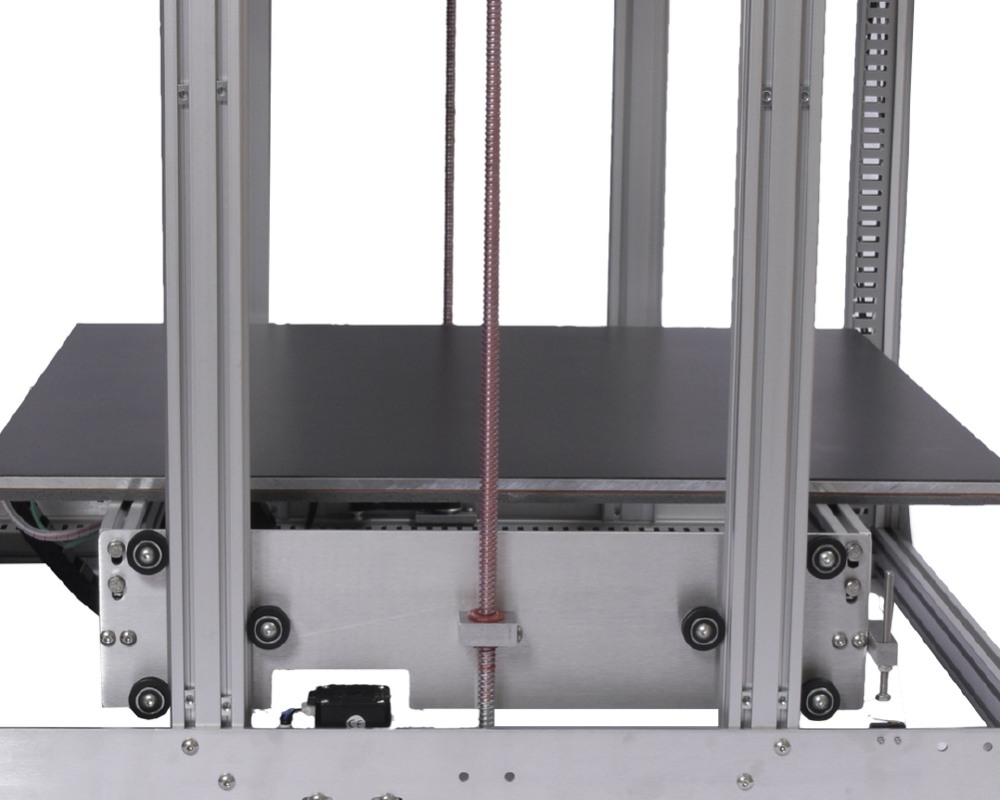

Your Gigabot Parts Kit should arrive in two boxes, one large box and one bed plate box. After reviewing the contents of the box, be sure to grab a friend and start assembling your Gigabot using our helpful docs.

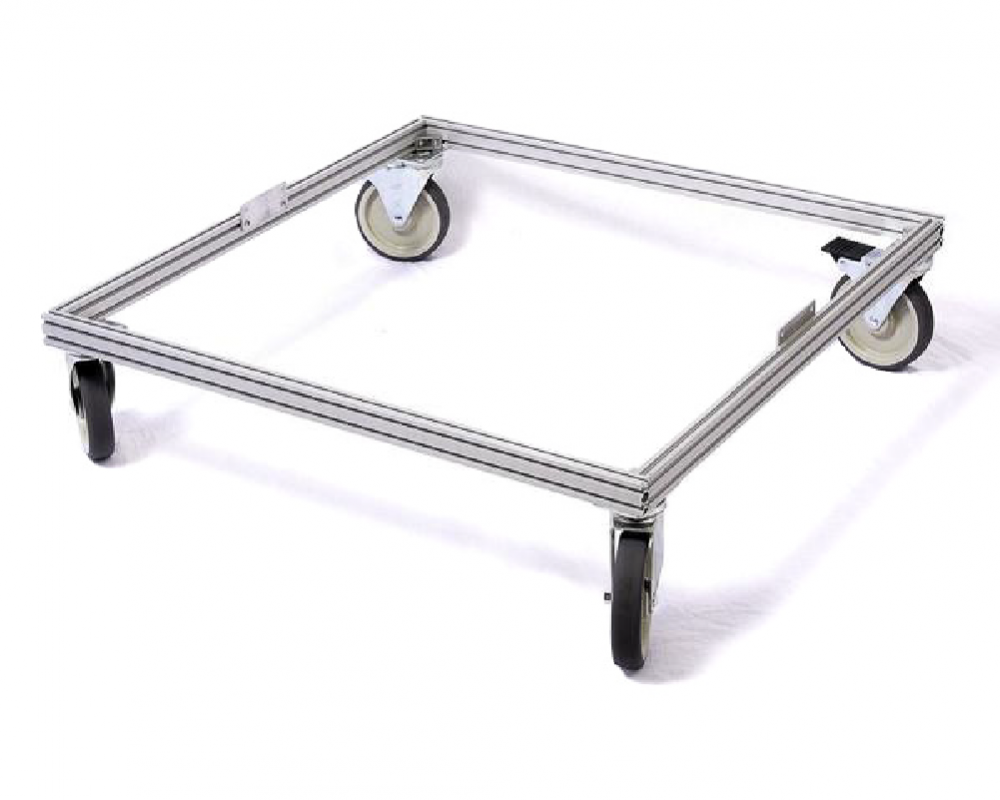

Your Fully Assembled Gigabot should arrive straight to your door in wooden crate, packaged on casters. Simply remove from the packaging, plugin, and follow calibration steps to start printing!

Technical Support | Service Packages

On-Site Training

If you’re new to 3D printing, start out on the right foot with on-site training for your team with a re:3D engineer. This hands-on workshop covers basic skills such as bed leveling, calibration, and the general 3D print workflow, as well as more advanced skills like how to identify and troubleshoot issues with your Gigabot to ensure you are achieving the highest-quality prints.

PARTS GUARANTEE

The re:3D Parts Guarantee covers replacement parts for your Gigabot due to damage and normal hardware wear and tear. By purchasing this guarantee, you won’t have to worry about maintenance of your Gigabot. Based on your needs, one, two, or three year plans are available. The Parts Guarantee package is available for purchase within 60 days of placing your Gigabot order.

REPLACEMENT PARTS BUNDLE

Looking to have a stash of backup parts on hand for your Gigabot? The Gigabot Replacement Parts Bundle includes all of the parts from your Gigabot that will need to be replaced due to normal wear and tear, so you have them when you need them. The bundle includes one extruder (two for dual extruder), one Azteeg x3, one Viki interface, two motor drivers, one single or dual heater, one thermocouple daughterboard, one X/Y Upright, one spare fan assembly, one left hot end (and one right for a dual extruder), jumper cables, one TC1 thermocouple (and a TC2 thermocouple for a dual extruder), and two Y and Y axis carrier supports.

FREQUENT FILAMENT PLAN

For our heavy filament users, we have a plan that keeps your Gigabot’s spool full without you having to think about it. With customized subscription plans, we provide for your filament needs that get filament delivered to your doorstep every month. To subscribe to the Frequent Filament Plan, your Gigabot must use three 5 lb. spools or two 15 lb. spools per month, for 3 months at minimum.

Gigabot® 3+ Upgrades

Still Troubleshooting?

FAQ

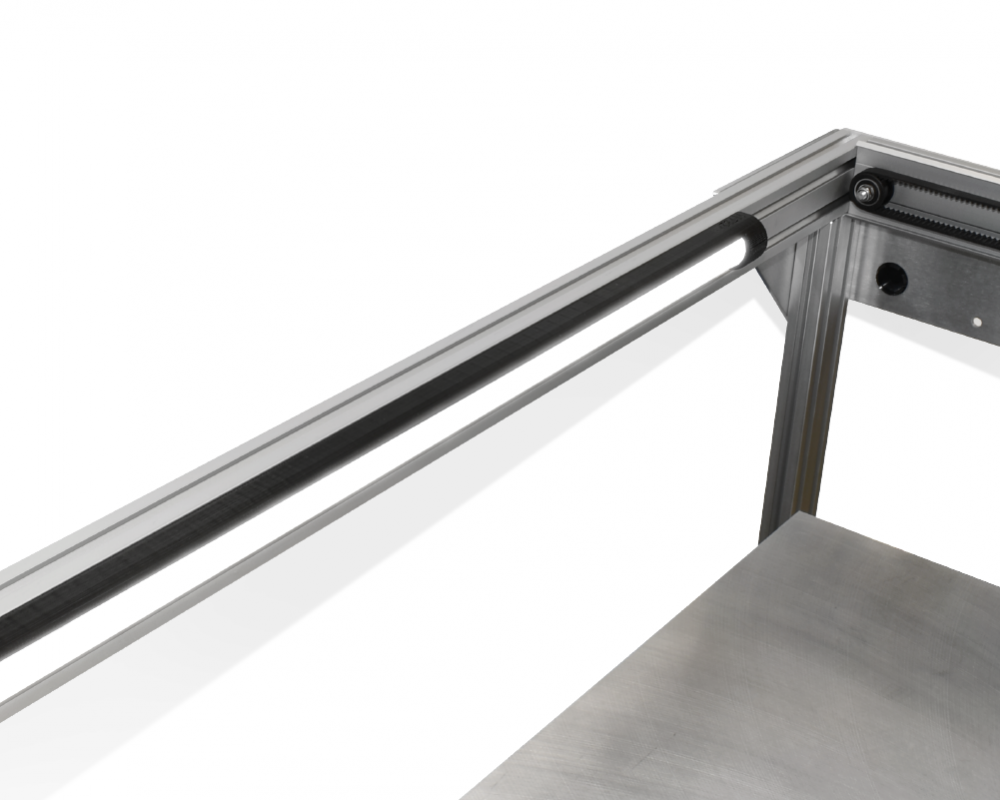

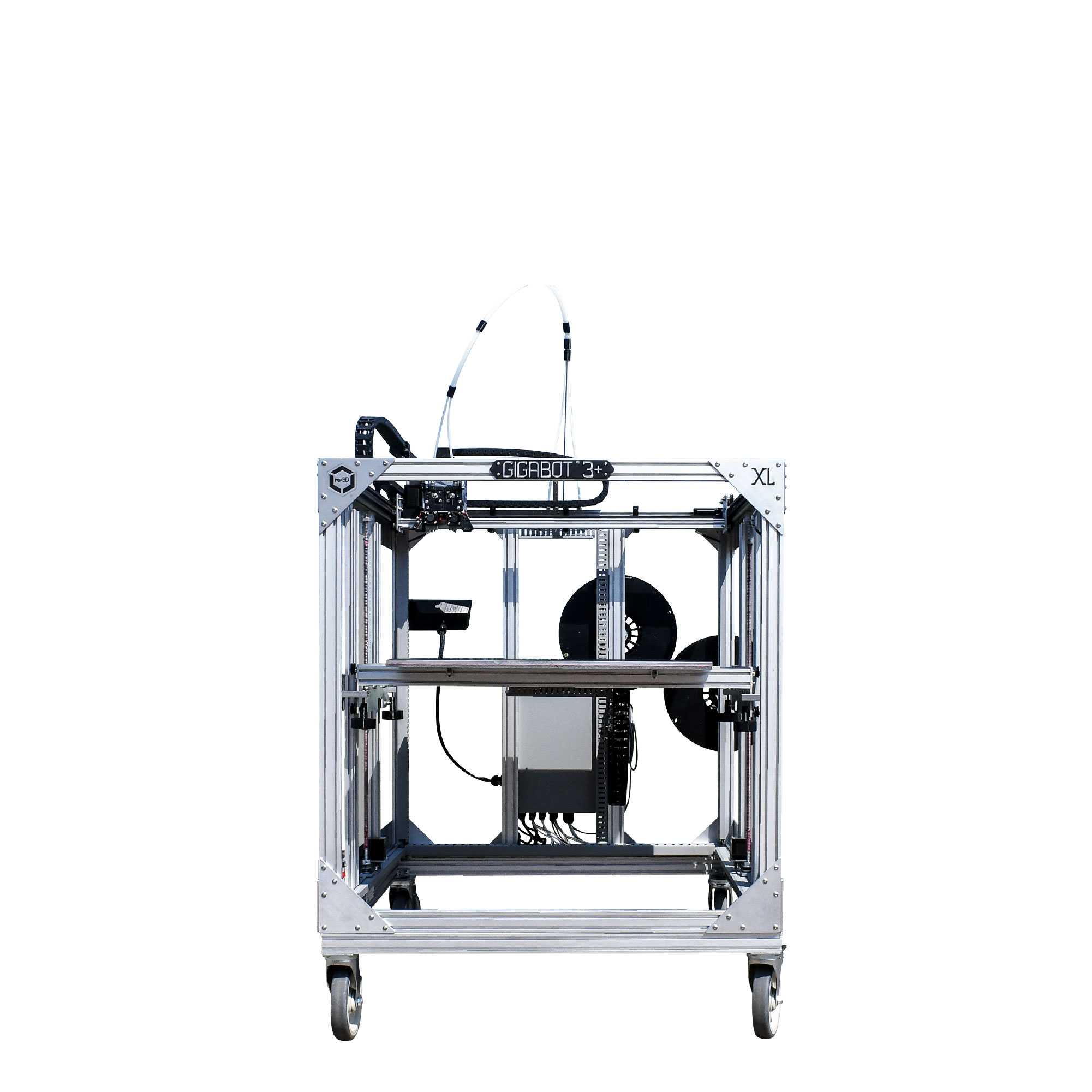

Gigabot has a massive build volume starting at 600mm3 and only gets larger from there. Check out our portfolio of large format industrial 3D printers to find the one that best fits your dreams to print huge!

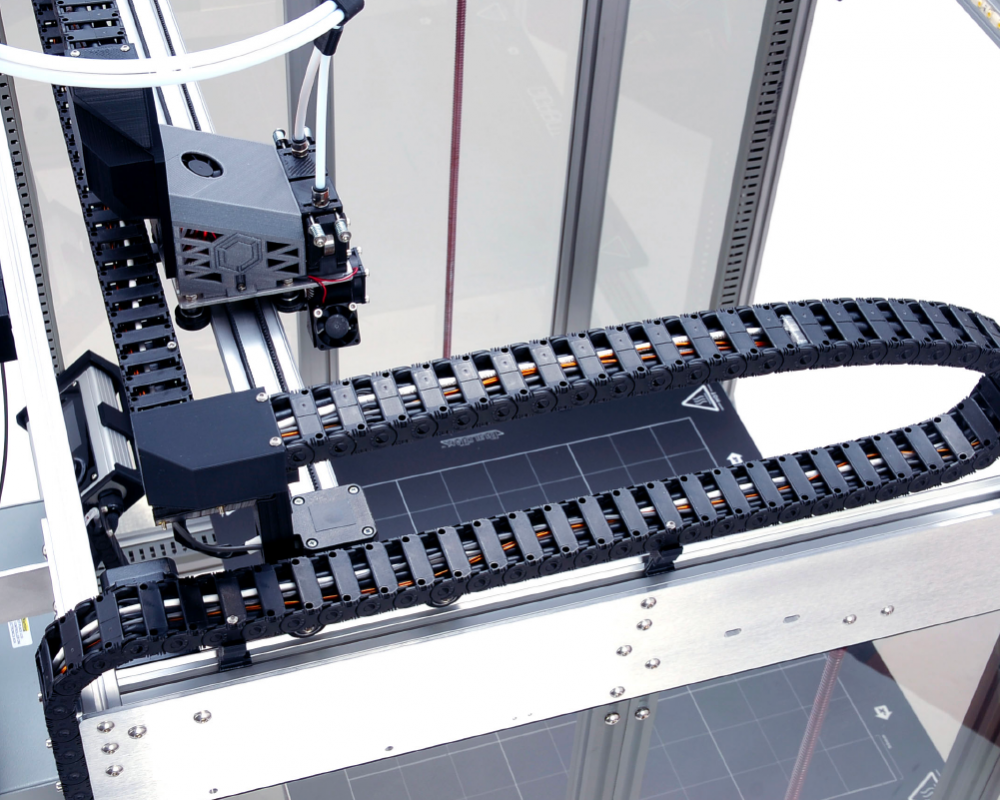

The Gigabot line of 3D printers has a dual extrusion system and 3D print with 2.85 mm diameter filament. The Gigabot X line of 3D printers has a single extrusion system and 3D print with pellets, flake and granulated plastics.

Gigabot hardware and software is open source. This means you can modify Gigabot to suit your needs without voiding your warranty on the parts we make. We are also happy to share our product part files with you upon request.

Gigabot can 3D print with 2.85mm filament with print temperatures of 320ºC and below. This includes a wide range of standard 3D printing filament as well as specialty materials including composites and recycled filament.

re:3D does not restrict Gigabot users to a specific brand of materials. As an open source company, we want you to be free to use whichever material suits the projects you are working on. We have, however, validated a wide range of filament as proven to work on Gigabot via our robust materials testing rubric. Visit our Materials section to see the complete list of validated filaments.

Gigabot X can 3D print with thermoplastic pellets, flake and granules measuring up to 5 mm in diameter with print temperatures of 270ºC and below. With Gigabot X, you can use both virgin and recycled materials and a broader range of thermoplastics than those typically made into filament.

re:3D does not restrict Gigabot users to a specific brand of materials. As an open source company, we want you to be free to use whichever material suits the projects you are working on. We have, however, validated materials as proven to work on Gigabot X via our robust materials testing rubric. Visit our Materials section to see the complete list.

As an open source company, re:3D does not restrict you to only using one software for CAD or slicing. For modeling some options include: Autodesk Fusion 360, Solidworks, FreeCAD, SketchUp and more. Most slicer softwares work with CAD models exported in stl, obj, or 3mf format. Some of those slicers include Simplify3D, Ultimaker Cura, Octoprint, and PrusaSlicer.

We recommend using Simplify3D for its accuracy and speed for the very large prints made on Gigabot. re:3D shares slicer profiles for each of our printers and the various materials we have validated on them in our Knowledge Base.

Our smallest Gigabot 3D Printer is 35.9” by 41.6” by 41.2” when fully assembled. Please refer to the detailed specs of each of our 3D printers for the footprints of each machine.

Gigabot is hand-crafted with precision manufacturing and industrial components at our factory in Texas. It is built to last. We back up each 3D printer we make with life-time customer service and upgrade options so that your 3D printer lasts as long as you need it to. Every Gigabot is covered under warranty for 6 months, which means that all replacement parts are free of charge, whether it’s damage due to normal wear and tear, user error, or faulty parts. After this 6 month period, these extended warranty options will cover all your replacement parts for Gigabot. Extended warranty options and maintenance plans are available for up to 3 years. Purchase at shop.re3d.org.

Operating cost of the Gigabot 3+ is less than $1.00 / hour including the cost of the machine, maintenance and replacement parts for the life of the machine. Please refer to the detailed specs of our 3D printers for the power consumption information for each machine.

Gigabot can be configured to run on either 110v, 60Hz or 220v, 50Hz.

Current in-house assembly time is roughly 12 hours. We recommend that first time builders prepare for a week of assembly time. However, depending upon your mechanical aptitude and how many hands you have helping out the process could be completed in 12-20 hours.

Our robust Knowledge Base contains start-up guides, troubleshooting access, tips and tricks, software profiles, material guides for filament and granules and more. Can’t find the answer you are looking for? Contact our life-time customer support team.

We ship internationally all over the world. Gigabots are in fifty-five different countries and counting.

In addition to making your Gigabot large format industrial 3D printers, re:3D offers a complete line of 3D printing services including contract printing, design, material testing, 3D scanning and custom solutions.

Absolutely! Visitors are welcome at the Houston, Texas re:3D factory, just down the street from NASA – Johnson Space Center. Visit https://re3d.org/community/ to find out how you can tour the factory to get up close with our 3d printers and learn about our mission to 3D print with purpose.