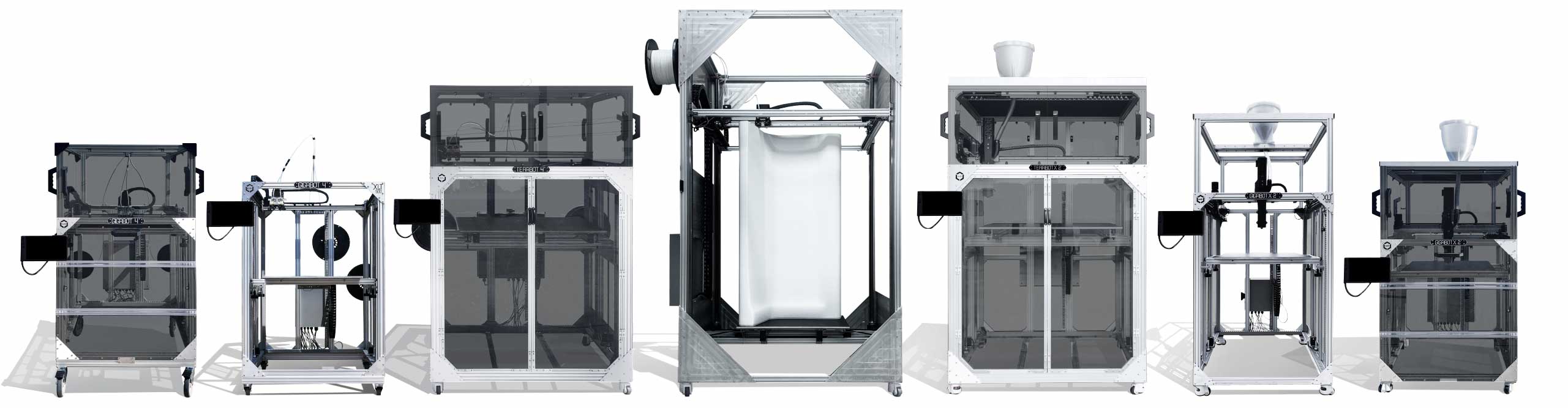

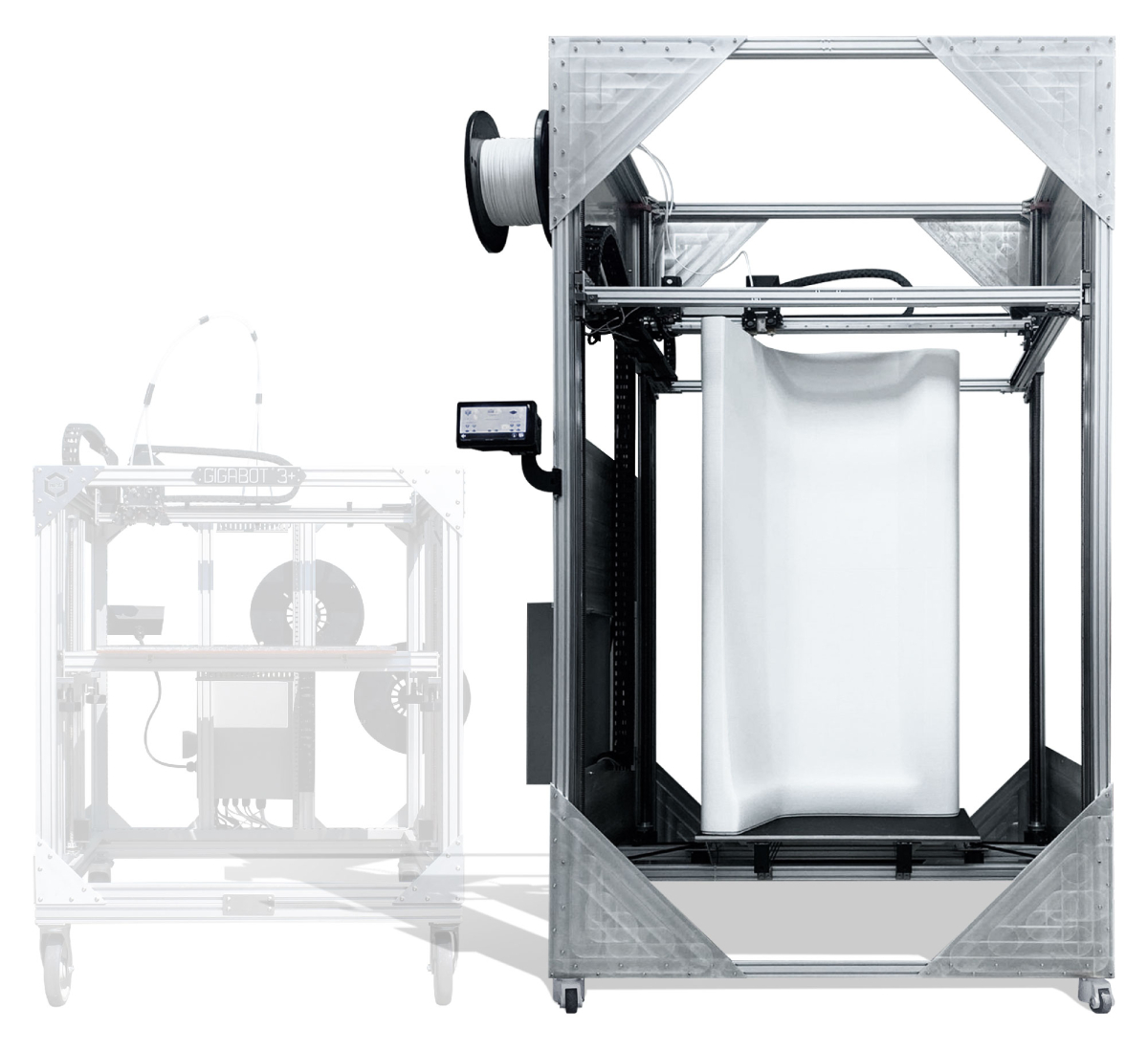

Left To Right: Gigabot 4 with Enclosure, Gigabot 4 XLT, Terabot 4, Exabot, TerabotX 2, GigabotX 2 XLT, GigabotX 2 with Enclosure

Introducing the Next Evolution of re:3D 3D Printers Featuring Klipper Firmware and ArchiMajor Control Boards

When deciding what changes to make on the next version of your Gigabot and Terabot 3D printers, your needs came first. The Gigabot family of customers has always inspired us to push this technology forward because it’s what you do with it that motivates us. Whether you’re teaching the next generation of change makers or innovating in advanced manufacturing, your feedback determines where we put our R&D focus.

The biggest visual change you’ll see on all versions of re:3D 3D printers is the front mounted 10” full color LCD touchscreen. The touchscreen includes temperature, and motion controls, temperature history graph and preset macros. The menu options add file management, gcode editing, command line input, and print history analytics and tracking. Also included is a webcam viewer for remote monitoring and an integrated USB port for loading gcode files directly on to your printer.

This touchscreen software is just one component of our new Klipper open-source software stack. We’ve transitioned from Marlin firmware to Klipper because it enables high precision stepper movement, smooth pressure advance and input shaping, and also an API server that enables opportunity for custom development. The Klipper web application runs the touchscreen from a Raspberry Pi and enables you to access the printer from your local network on desktop or mobile browsers with all the same control options you’re able to perform directly at the printer.

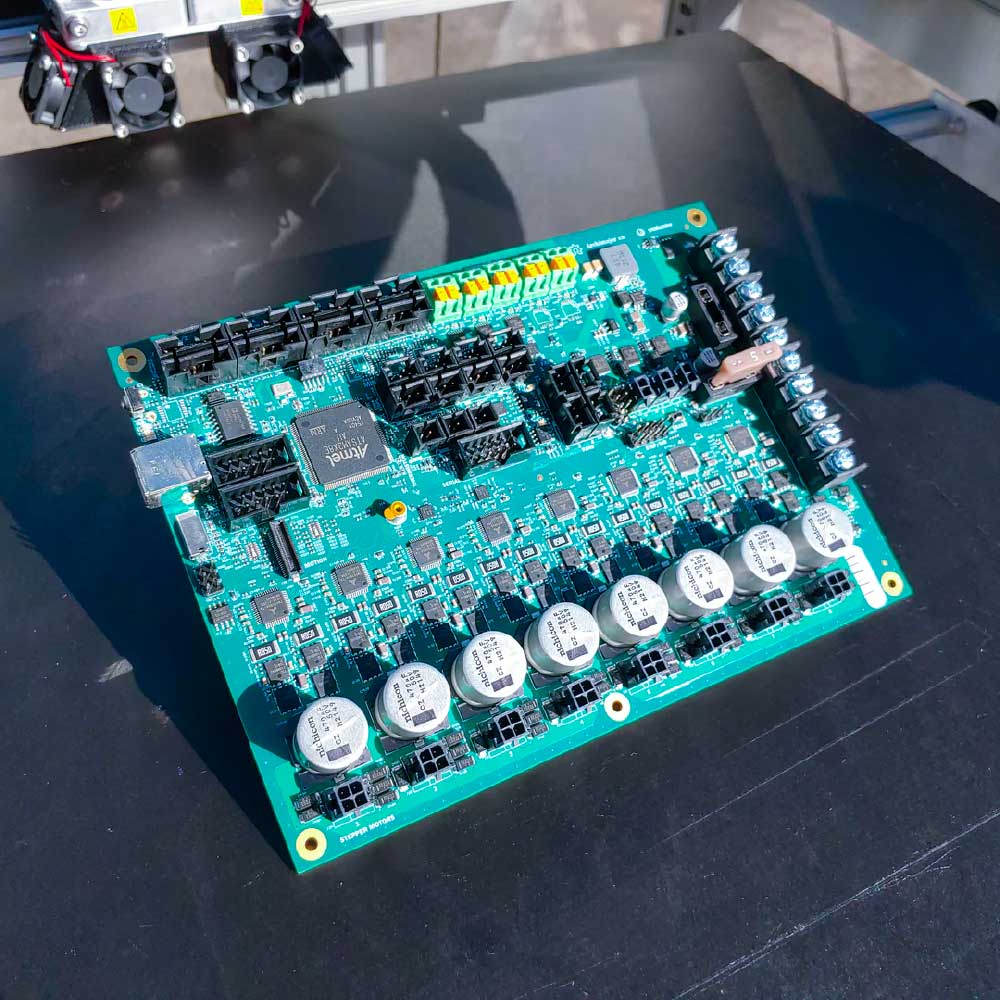

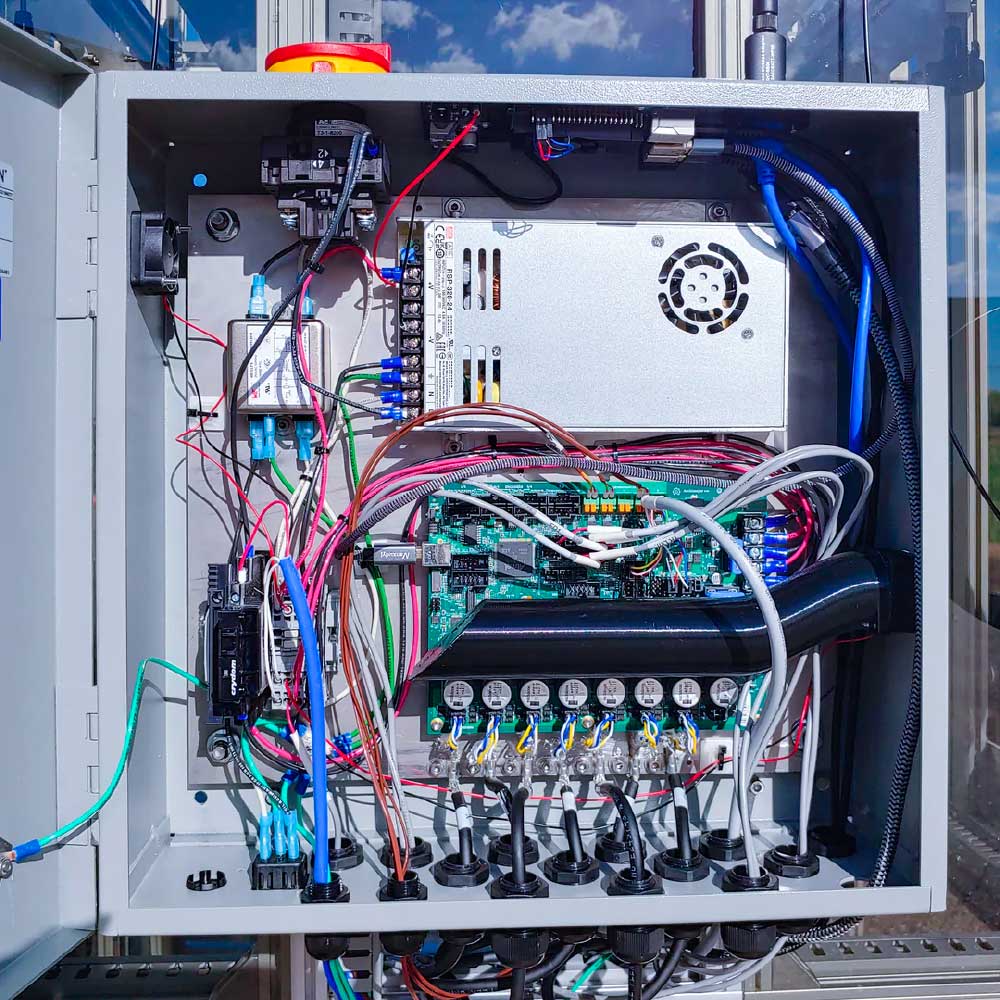

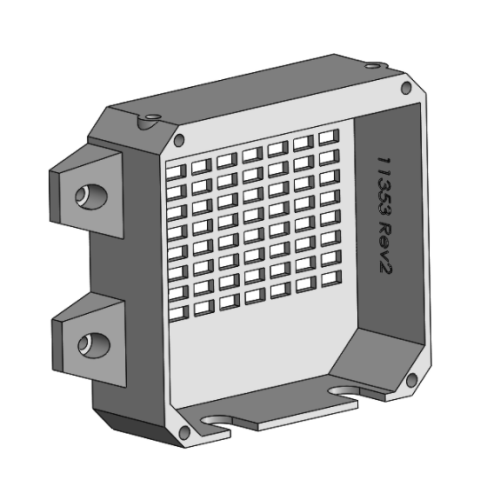

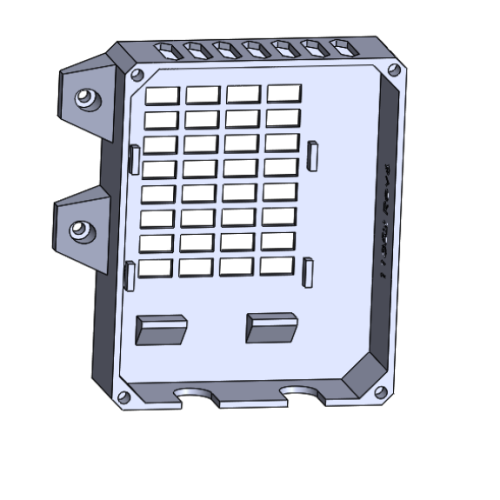

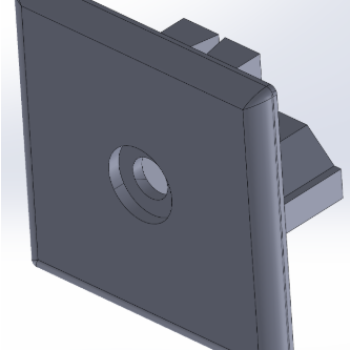

In order to successfully integrate this exciting new software stack, we’ve overhauled our electrical system starting with the control board. We partnered with US based manufacturer Ultimachine to design a custom 32bit ArchiMajor control board for your Gigabot. The advanced board features eight integrated stepper motor drivers, three heater outputs, five thermocouple inputs, four controllable fans and eight endstops. These provide flexibility to extend the functionality of your Gigabot, for example, adding an additional thermocouple or part cooling which is under development at re:3D. The new control board and the Raspberry Pi are now inside a 16” electrical enclosure with an integrated power switch, power filter and more durable flex rated cabling. Not only does this board increase your 3D printer’s processing power, but it allows us to better control our supply chain and electronics quality with a strong US manufacturer as our partner.

Platform-Wide Features

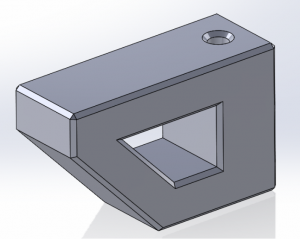

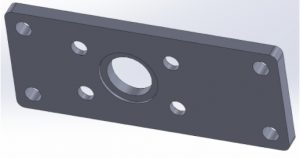

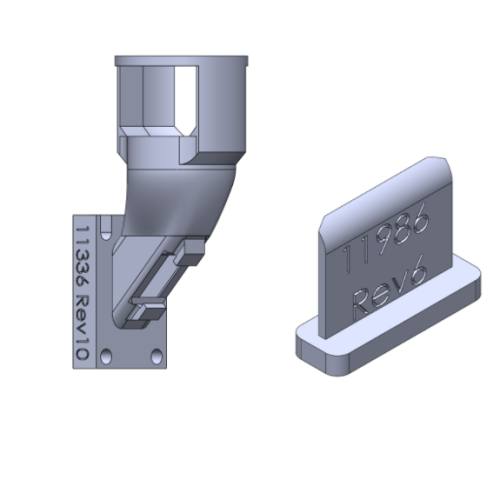

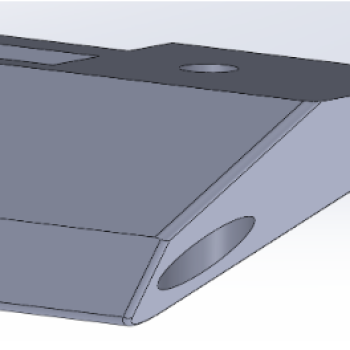

Stress tested in the re:3D factory, the new tube-style thermocouple is a more durable, consistent and accurate temperature reader for your Gigabot. We’ve added this improvement with a ½” thick aluminum bed plate, that is precision-blanchard ground flat and parallel to less than 0.005”. The bed is heated by a full-size silicone rubber heating pad, which allows the printing of high-temperature industrial materials. A robust cable carrier and cables rated for 1 million cycles of flexing protects all moving wires. Additionally, all unenclosed printers come standard with full side panels to protect electronics and cabling

FFF Filament 3D Printer Features

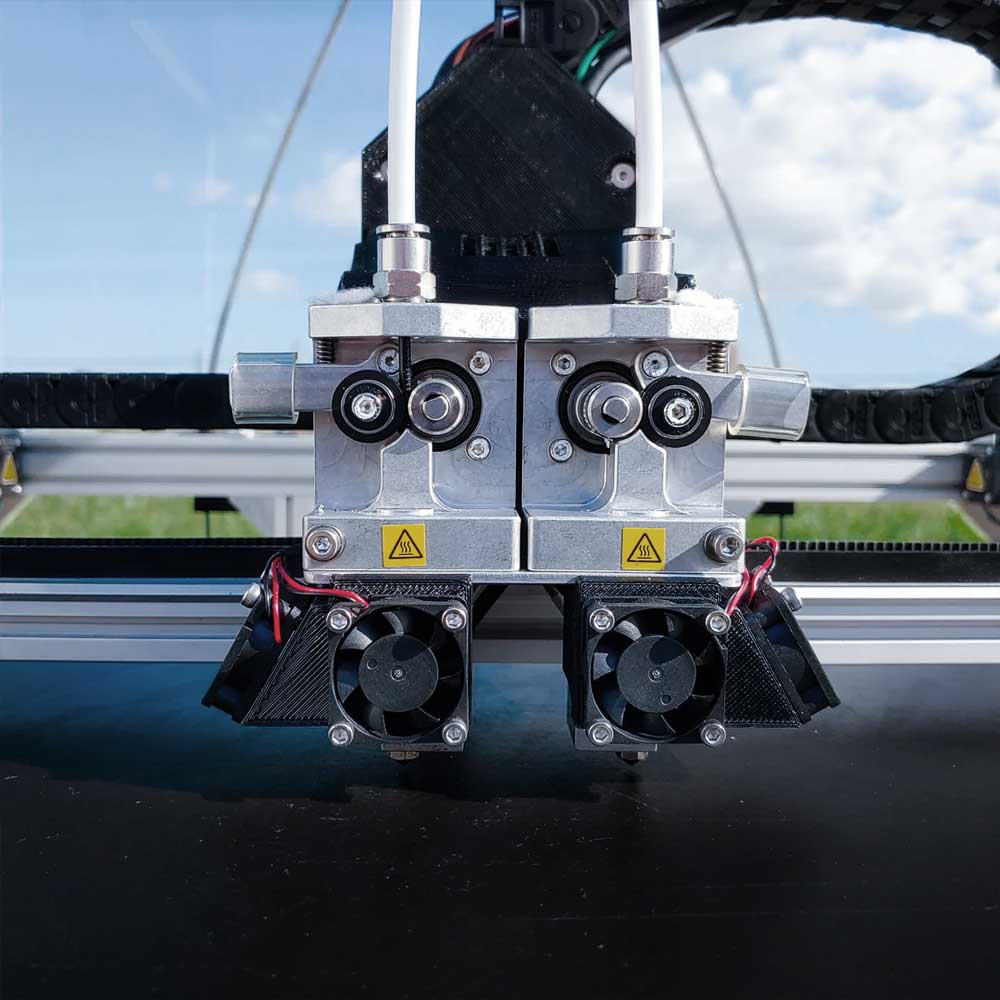

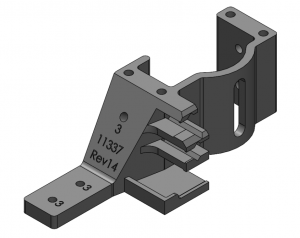

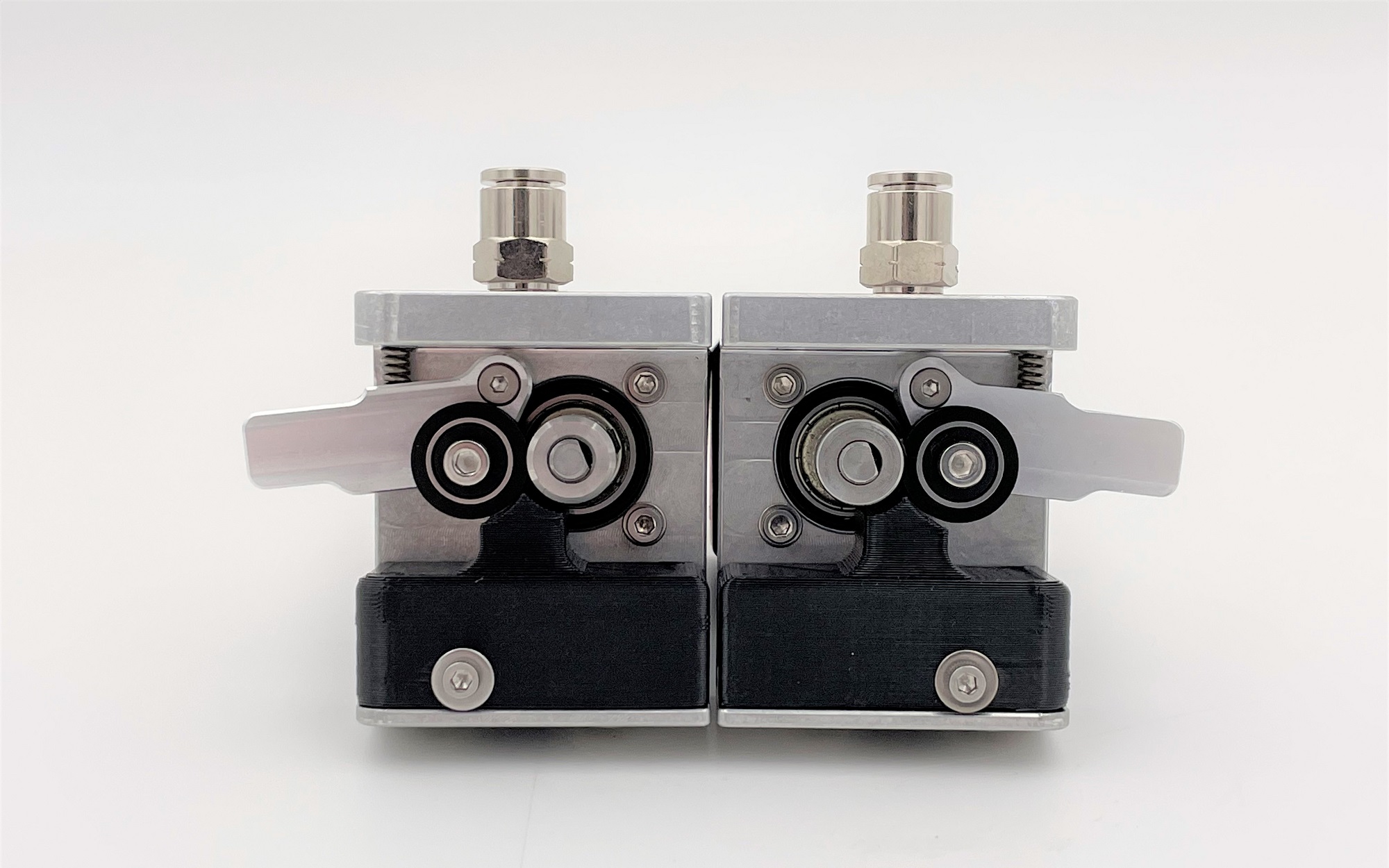

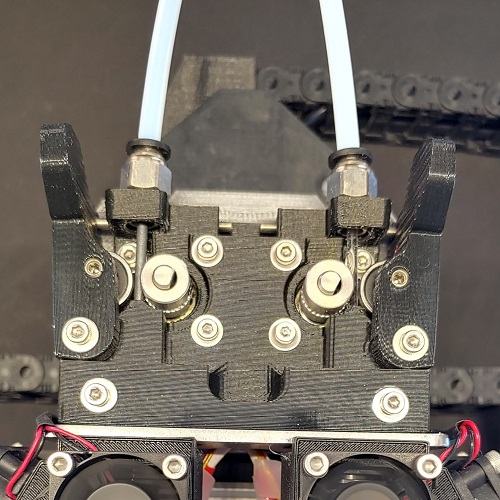

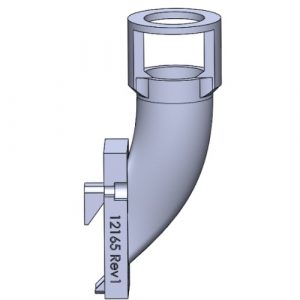

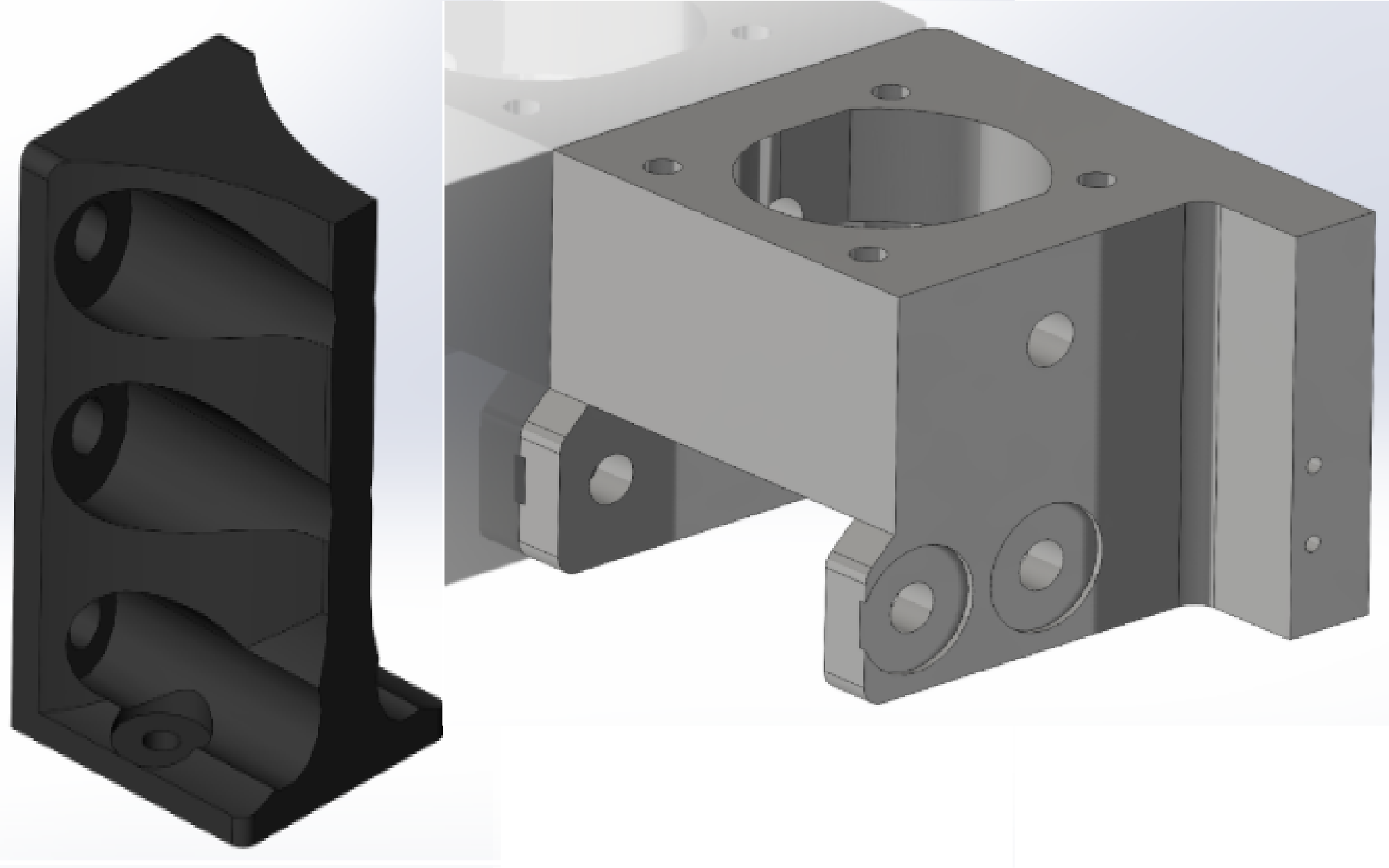

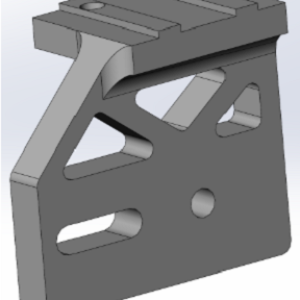

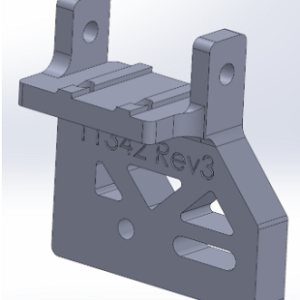

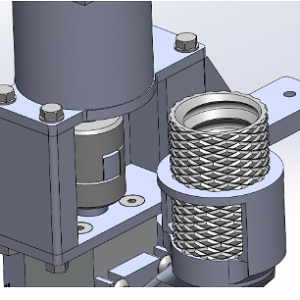

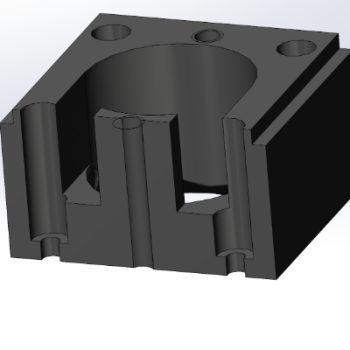

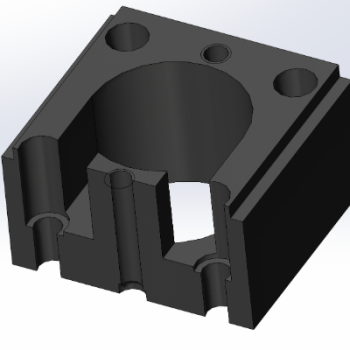

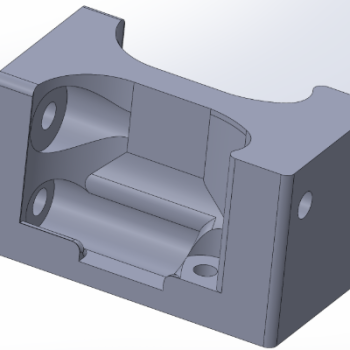

In the transition from Gigabot 3+ to Gigabot 4 we’ve pushed out some changes early as technology improvements have increased reliability and longevity for your printer. Many of these updates center around the extrusion system: The all metal extruder body, 20 Series Hot Ends for 0.8 nozzles and Terabot 4, tube style thermocouples and heater cartridges are all standard, combining to make the most robust, industrial extruder system ever on your Gigabot.

To keep Gigabot affordable you may still purchase a regular 600 mm cubed Gigabot 4 as a kit which ships in flatpack boxes, and the full enclosure is an optional add-on for pre-built Gigabot 4 and Gigabot 4 XLT sized 3D printers. Terabot 4, as before, comes with the enclosure standard. One change we’ve integrated as standard is the side panels on your Gigabot cover the full side on the left and right to provide better protection for the motors and electronic components.

As with the changes we made during Gigabot 3+’s lifespan, This is just the beginning. Gigabot 4 will continue to iterate and grow and change to meet your needs as the technology evolves. Plans are already in the works for a filament dry box, bed probing and even more robust build plate and frame improvements. Stay tuned!

FGF Pellet and Granule 3D Printer Features

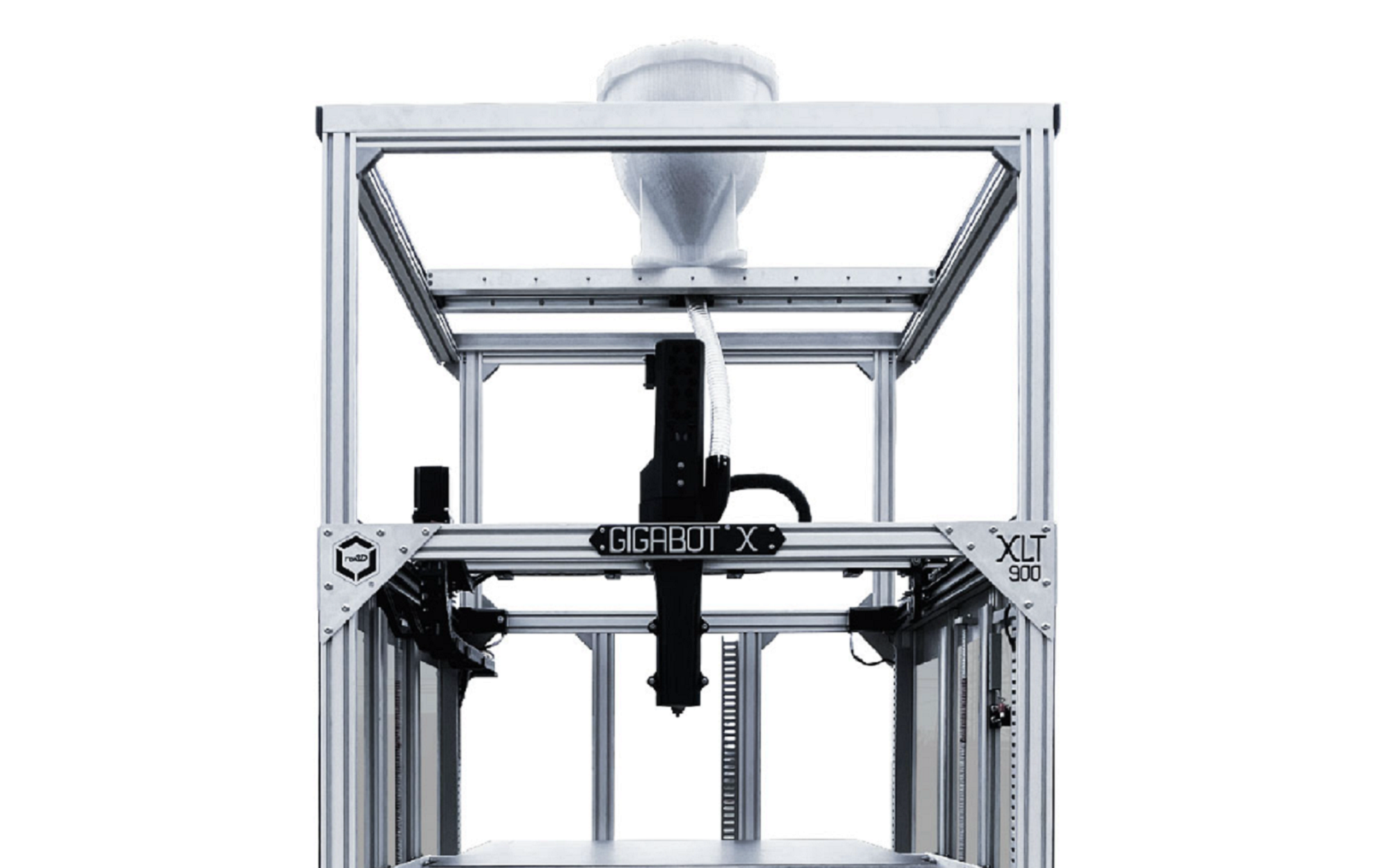

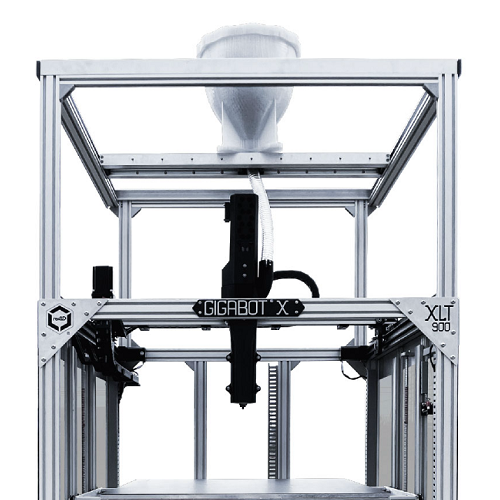

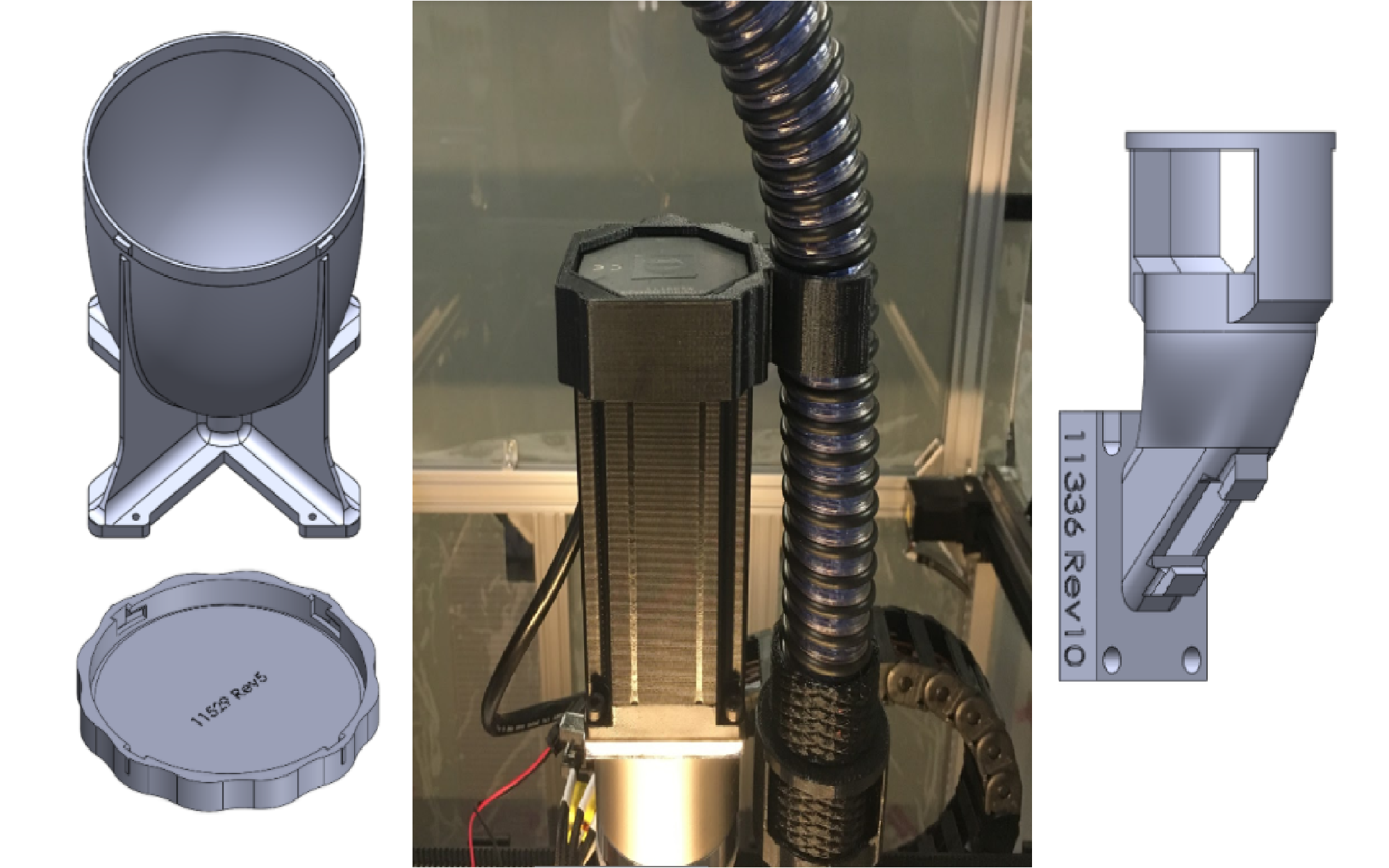

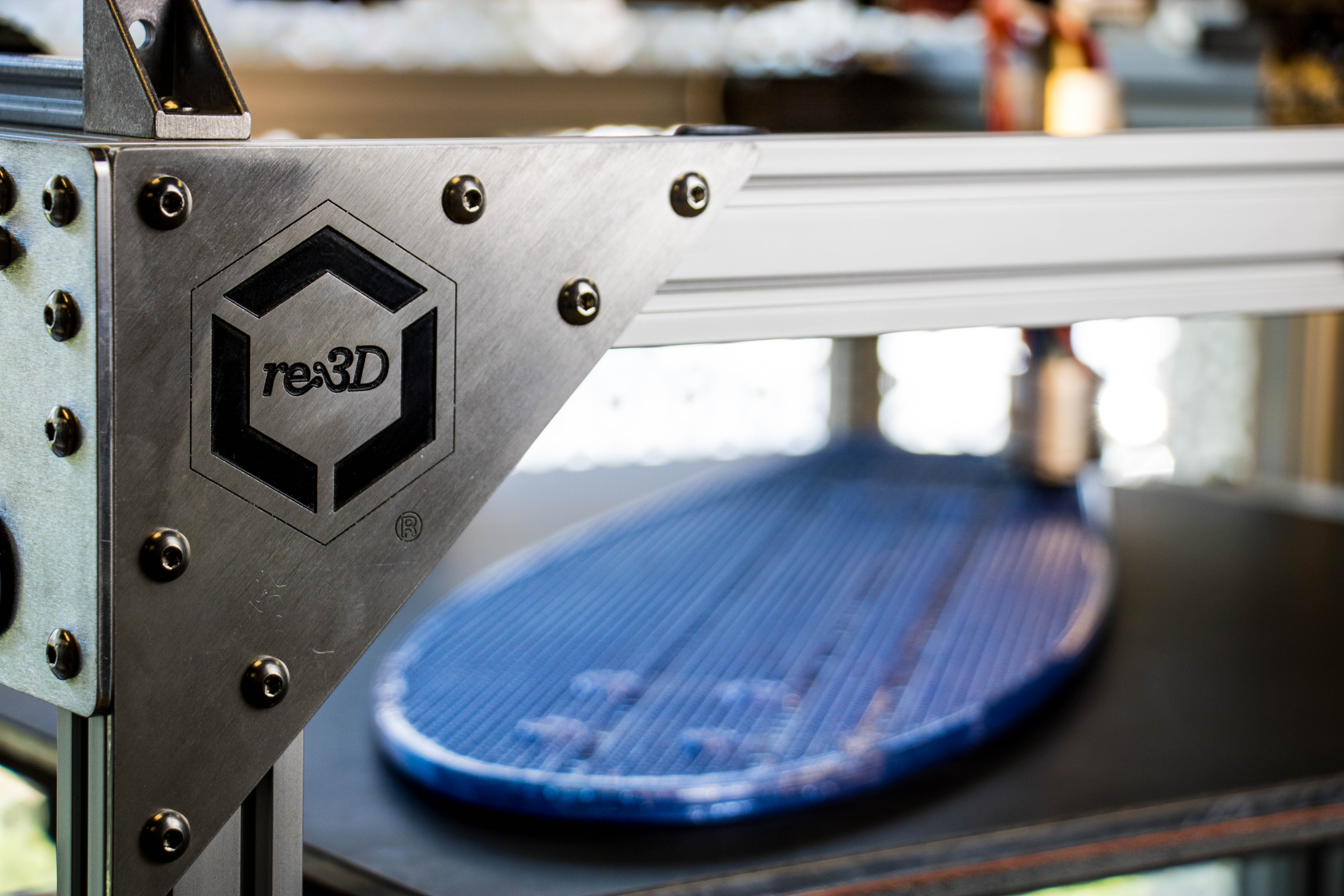

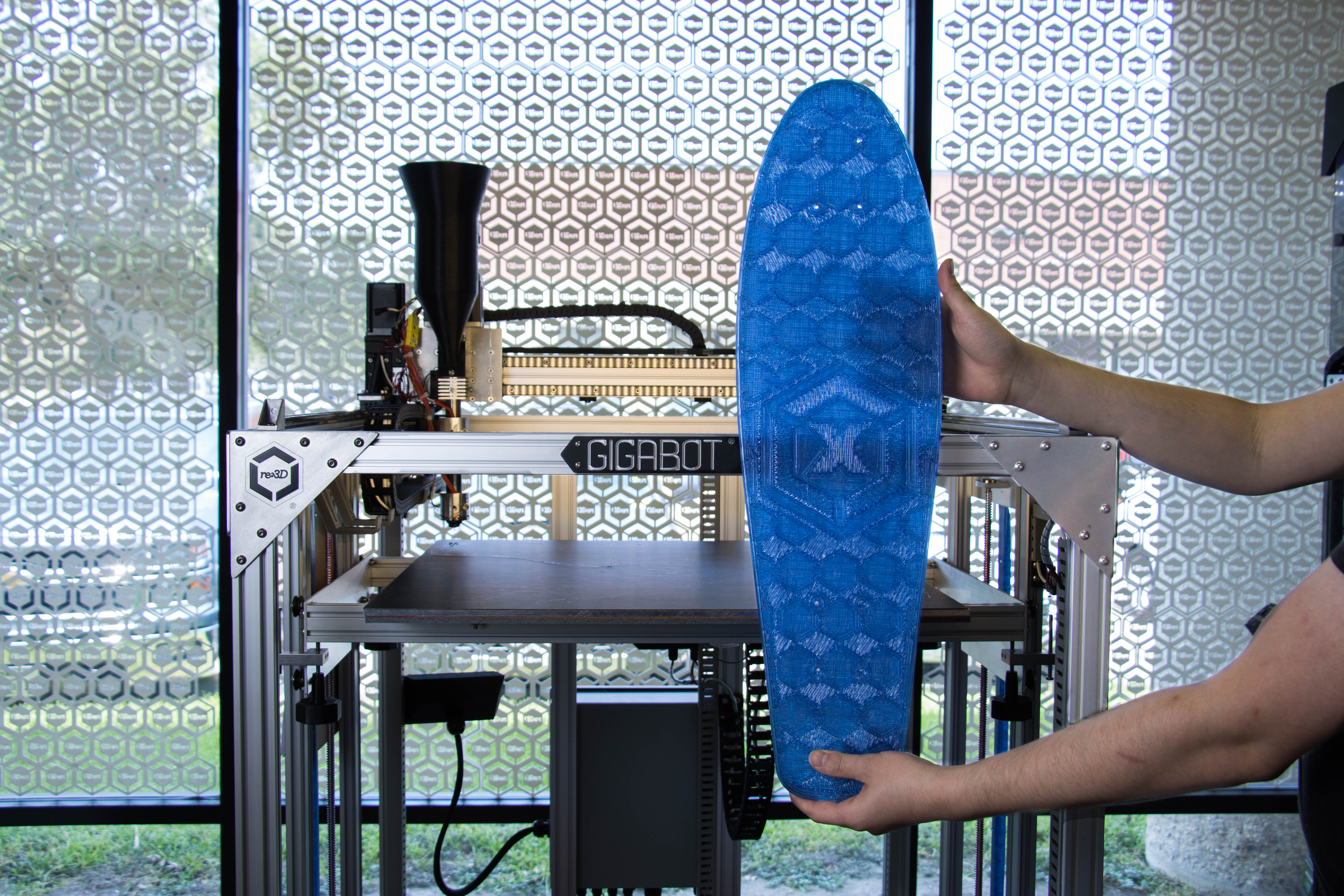

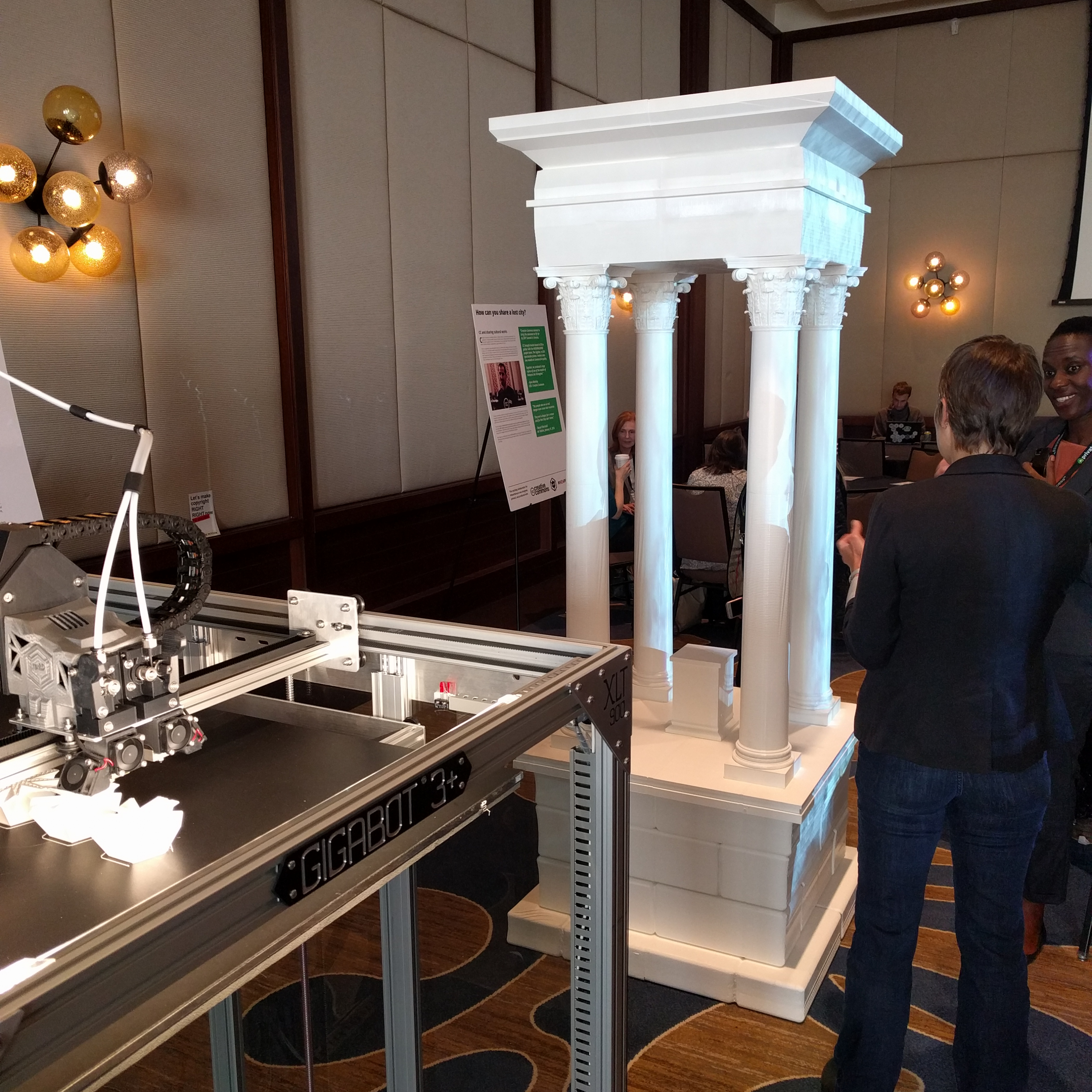

Since releasing the beta version of Gigabot X in 2018, re:3D invested significant R&D resources from community support to produce a more agile, advanced and capable fused granular fabrication 3D printer.

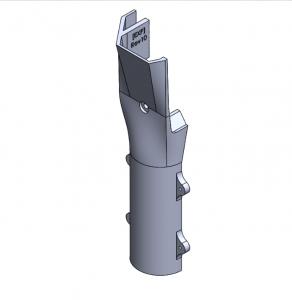

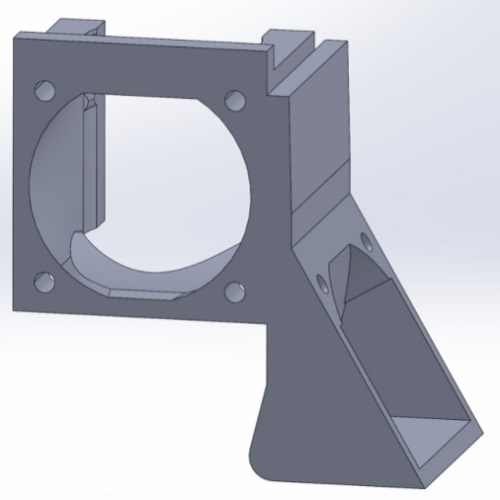

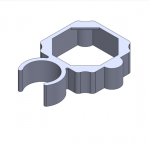

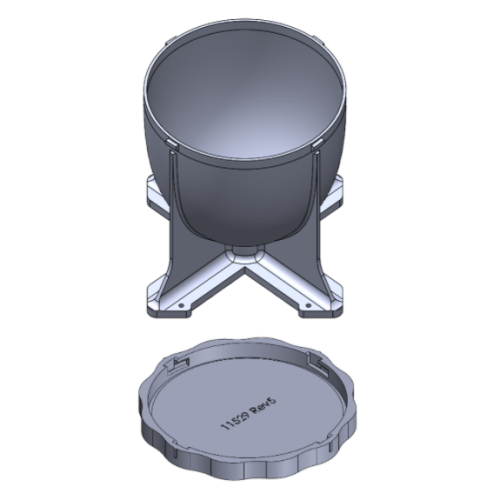

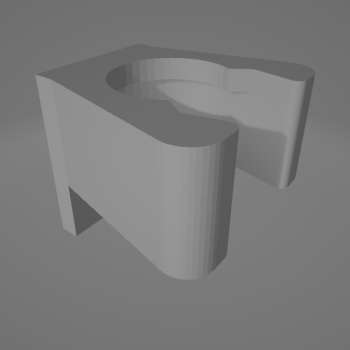

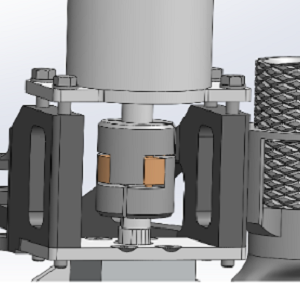

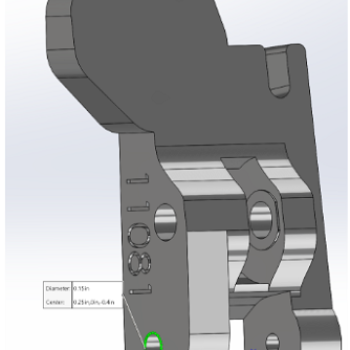

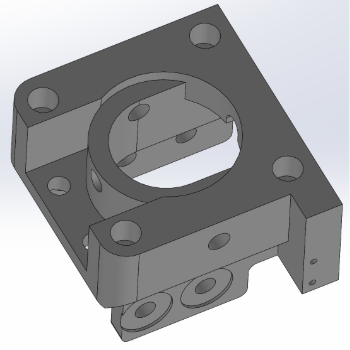

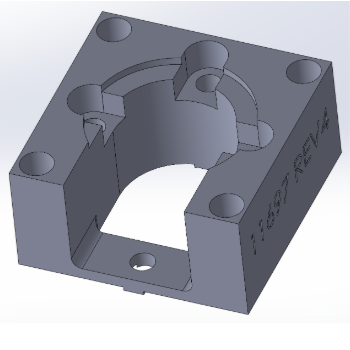

GigabotX 2 features a feeding and extrusion system precision engineered for processing pelletized and granular thermoplastics. Material is manually fed into the 24 hour capacity hopper which rides on an independent hopper gantry system, to allow a full and smooth range of motion and consistent feeding into the extruder.

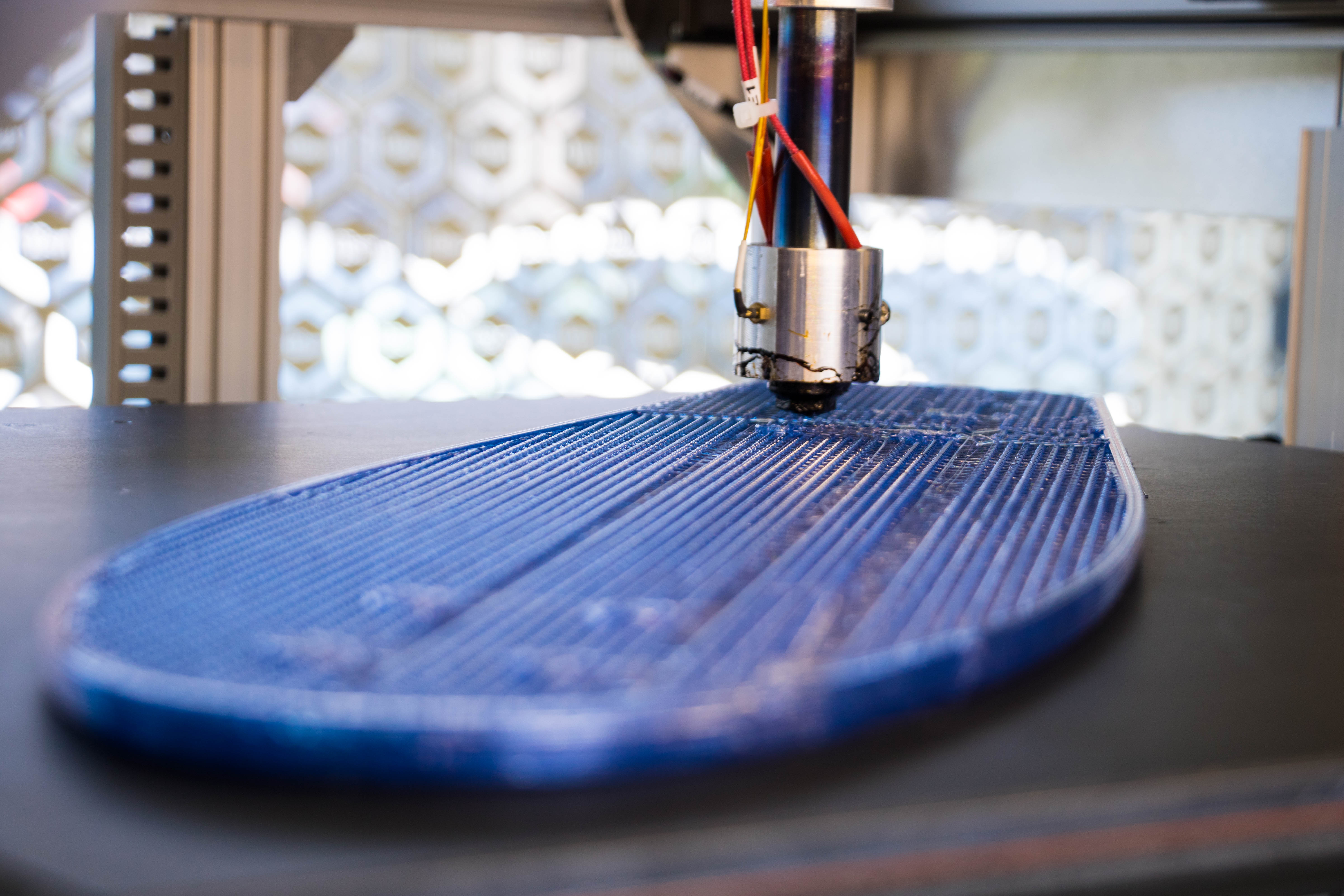

Print material flows from the hopper into the extruder via either the gravity fed feed throat or the optional active feeding system, or crammer, which includes a motorized auger that pushes material into the extruder with a user controllable feed rate.

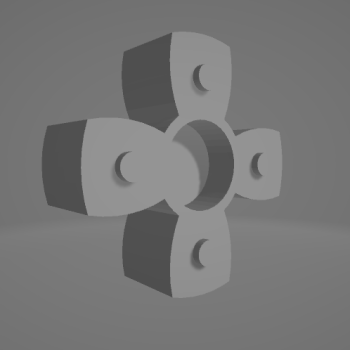

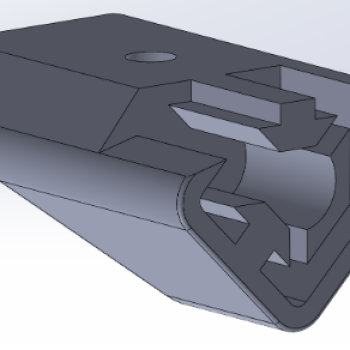

The GigabotX 2 extruder is powered by a 425 ozf*in NEMA 23 motor with planetary gear box to provide increased torque for flowing materials. The extruder is a solid steel ⅝” screw with 16:1 L/D ratio designed with our partners specifically for consistent throughput for thermoplastics. Three independently controllable heaters are mounted on the extruder barrel allowing for extrusion temperatures up to 270°C. Interchangeable nozzles between 0.4mm and 2.85mm in diameter can be used to control resolution and extrusion width.

GigabotX 2 is the culmination of our mission to enable more users to 3D print directly from novel and waste plastics, but we’re not stopping here. Research is currently underway to integrate a granulator, dryer and automatic feeding system with GigabotX 2 to make machine operation even more efficient and user friendly and enable anyone anywhere any time to be the problem solvers for their community.

Charlotte craff

Blog Post Author