September 22, 2020 – LONDON – re:3D has been awarded a $100,000 grant in recognition of the exceptional work being undertaken in addressing the immediate and long term challenges resulting from the effects of the global pandemic.

The grant is designed to support and amplify the impact of the work re:3D is doing.

The Unreasonable Impact COVID-19 Response initiative was launched by Barclays and Unreasonable Group earlier this year and has already supported ten Unreasonable ventures that have pivoted their businesses to combat challenges related to COVID-19.

The initiative was launched as a direct response to the outbreak of COVID19 and is an extension of Unreasonable Impact, the unique multi-year partnership between the two companies supporting growth stage entrepreneurs across the Americas, Europe and Asia Pacific regions solving many of the world’s most pressing issues.

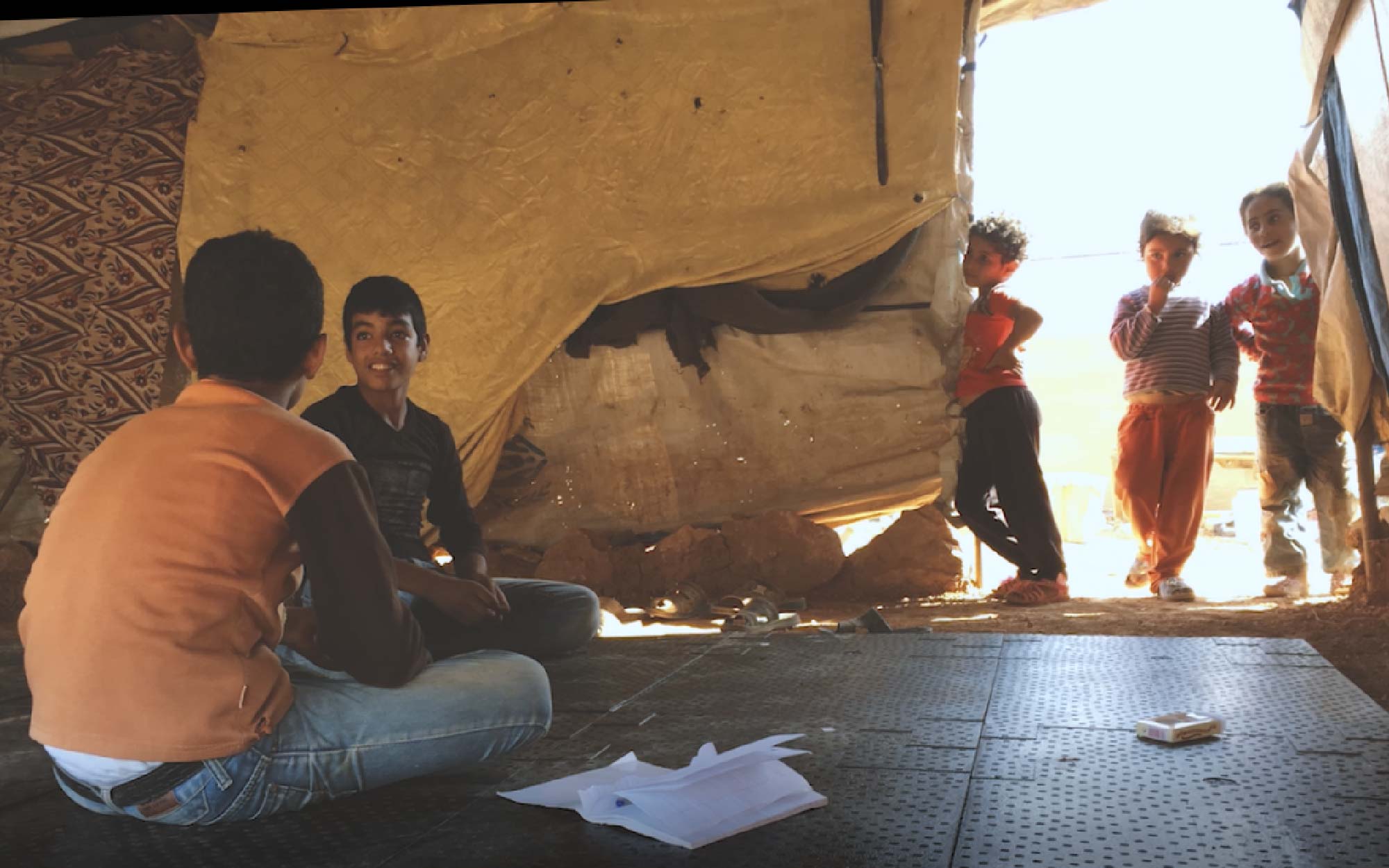

re:3D was chosen by a selection committee for the meaningful work they are doing to provide PPE to workers in minority and underserved areas who are at greater risk for critical illness from COVID-19. The program, PPE for the People, is fiscally sponsored by Impact Hub Houston, and has donated 3D printed face shields, ear savers and other PPE to help protect restaurant and food pantry workers, as well as organizations and small businesses that seek to reopen safely, like barbershops, nail salons, and veterinary clinics. PPE for the People partners include: Baker Ripley, Creatorspace, West Houston Institute IDEAStudio, Leidos, McDermott, Stand Behind and 3DPPE. “We are actively seeking businesses and organizations looking for this protective equipment. Please share this opportunity with those in need,” said re:3D Community Ambassador, Charlotte Craff.

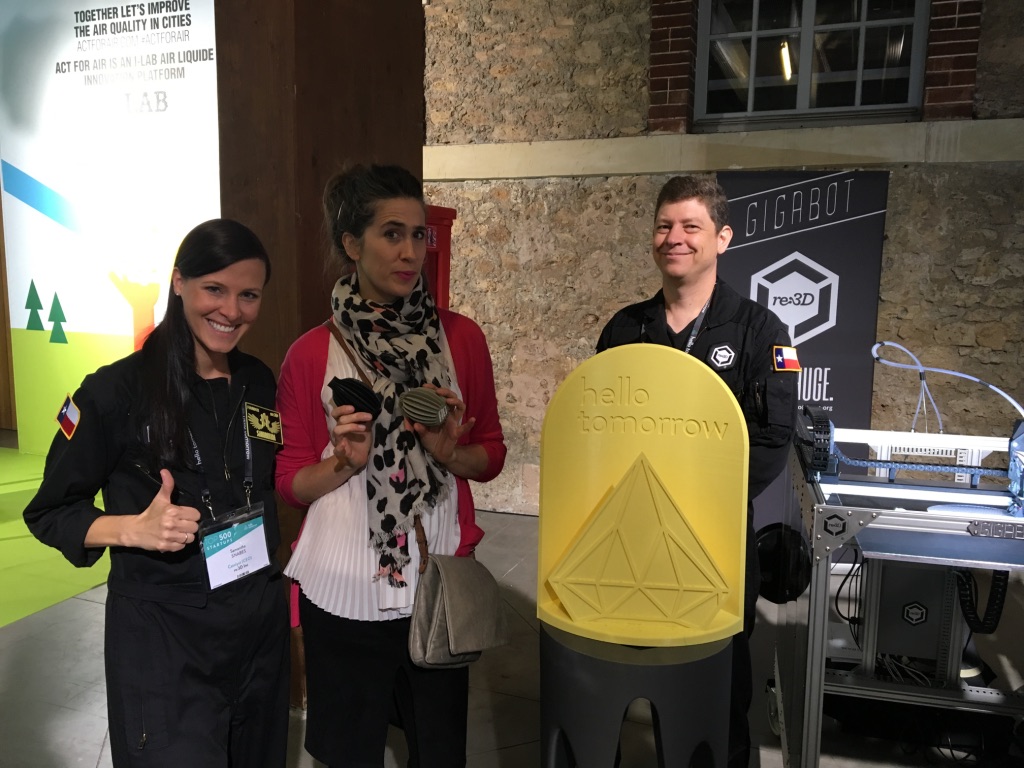

re:3D Co-Founder and Catalyst, Samantha Snabes and Charlotte Craff will join the 12 other grantees at a virtual event, The Unreasonable Impact COVID19 Response Exclusive Summit, created with Barclays on September 29th, where they will have a chance to share re:3D’s exceptional work with a global audience.

Joe McGrath, Barclays’ Global Head of Banking, commented, “Through Unreasonable Impact we set out to offer advice, expertise, and support to entrepreneurs so that they can more quickly increase the scale and impact of their businesses. These entrepreneurs have been recognized for their ingenious approaches to tackling almost impossible-sounding challenges, especially in some of the most challenged communities across the globe. When COVID-19 took hold this year we knew that Unreasonable Impact entrepreneurs would be among the first to pivot their talent and drive towards responding to the impacts of the pandemic – and we’re in awe of the speed with which they did just that, and of the scale of the positive impact that they have already had. We’re honored to be able to extend our support through the Unreasonable Impact COVID-19 Response Initiative, which provided grants that will help these entrepreneurs to accelerate their work in response to the ongoing pandemic.”

Daniel Epstein, Founder and CEO of Unreasonable Group, added, “Unreasonable Impact was co-created with Barclays with a shared intention to support and scale up entrepreneurial solutions to the world’s most pressing challenges. The global impact of COVID-19 is unlike any challenge any of us has seen in our lifetimes. Setting up the second COVID-Response to support and amplify even more Unreasonable ventures leveraging business to combat challenges related to the pandemic, is a natural extension of our mission. We are humbled to be supporting the exceptional work of re:3D.”

For more information and to be invited to attend the Exclusive Summit, visit https://bit.ly/3hJsIks

Full list of ventures selected:

- 75F: Utilizing the Internet of Things and the latest in cloud computing to create systems that predict, monitor and manage the needs of buildings

- Aerofarms: Responsibly and sustainably feeding humanity by growing flavorful, safe, and healthy food in the world’s largest indoor vertical farm.

- Air Protein: Using microbes to convert elements of air into a sustainable protein product

- Cell-Ed: Delivering essential skills training in three-minute lessons on any mobile phone — learners simply call, text, or click to access a world of learning

- Green Fuels: The world’s leading supplier of biodiesel processors, producing over 400 million liters of sustainable fuel every year in over 50 countries

- LEAF: Bringing safe and hygienic fresh fruits and vegetables to the marketplace by empowering all shareholders in the agricultural value chain.

- Livox: The first intelligent alternative communication software for people living with disabilities, helping 20,000 people more easily interact with others

- Purpose Works: Enabling sustainability, agility and operational efficiency in global supply chains.

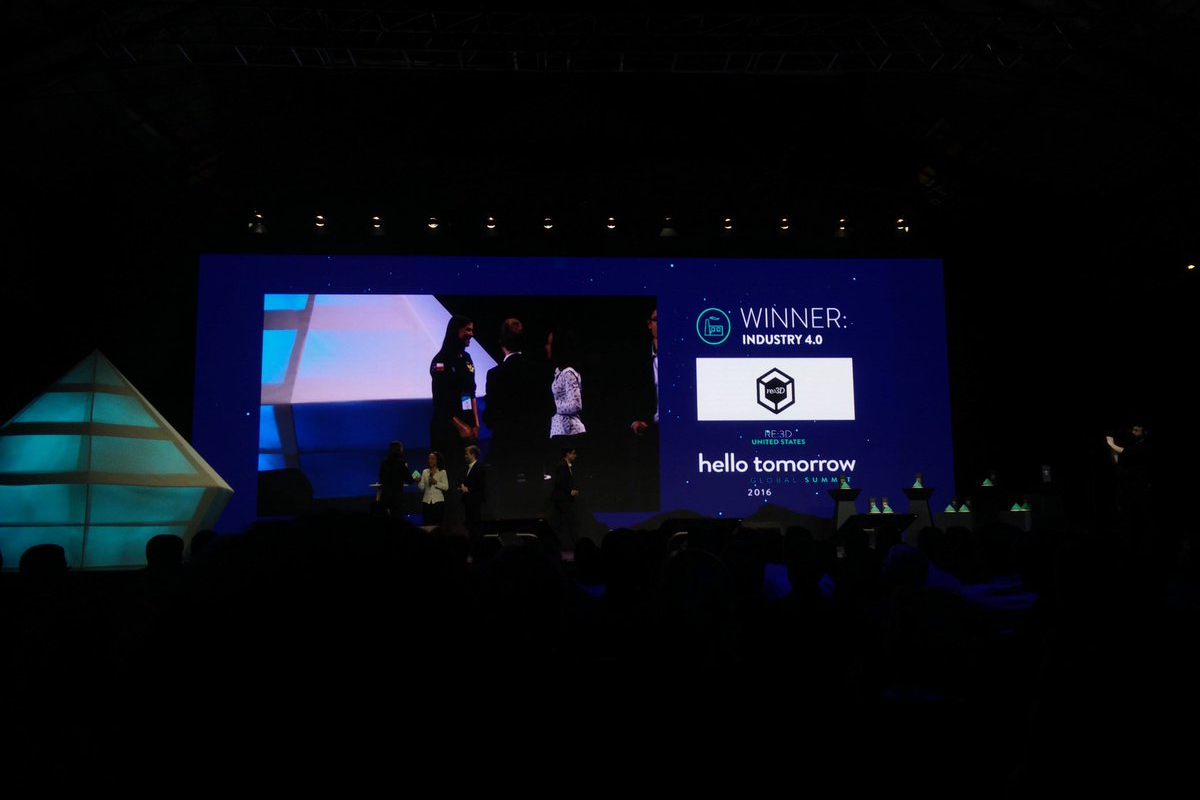

- re:3D, Inc.: 3D-printing objects 30 times larger than competing desktop models, at a more affordable cost.

- Richcore: Eliminating contamination risks and creating safer medicines with animal origin free (AOF) proteins.

- Sure Chill: Disrupting the entire cooling industry with new technology that doesn’t require a constant power source, enabling refrigeration of food products, life-saving vaccines, and more.

- WizeNoze: Facilitating access to an easier-to-understand internet for children, teenagers, people with a low level of literacy, immigrants, and the elderly.

- Árvore Educação: Improving students’ literacy skills and understanding of local and world events through a digital reading platform

About Unreasonable Impact, created with Barclays

Unreasonable Impact is an innovative multi-year multi-geographic partnership between Barclays and Unreasonable Group to launch the world’s first global network focused on scaling up entrepreneurial solutions that will help employ thousands worldwide in the emerging green economy. To date, the more than 100 ventures that comprise the global cohort operate in more than 180 countries, have raised over $2.1bn USD in funding, have generated over $2bn USD in revenue, and have created more than 30,000 net new jobs since joining Unreasonable Impact. For more information, please visit www.unreasonableimpact.com

About Barclays

Barclays is a British universal bank. The company is diversified by business, by different types of customers and clients, and by geography. Barclays’ businesses include consumer banking and payments operations around the world, as well as a top-tier, full service, global corporate and investment bank, all of which are supported by their service company which provides technology, operations and functional services across the Group.

For further information about Barclays, please visit www.home.barclays.

About Unreasonable Group

Bringing together a global network of entrepreneurs, investors, creatives and business leaders, Unreasonable acts as a catalytic platform for entrepreneurs tackling some of the world’s most pressing challenges facing us today. From designing highly curated immersive programs, facilitating access to a global network of mentors to operating a private equity fund and providing advanced storytelling and media activities, Unreasonable operates at the highest intersection of business and impact. It is uniquely positioned to support growth stage entrepreneurs solving key global environment and social challenges to scale up through the deployment of knowledge, networks and capital.

For more information about Unreasonable, please visit www.unreasonablegroup.com

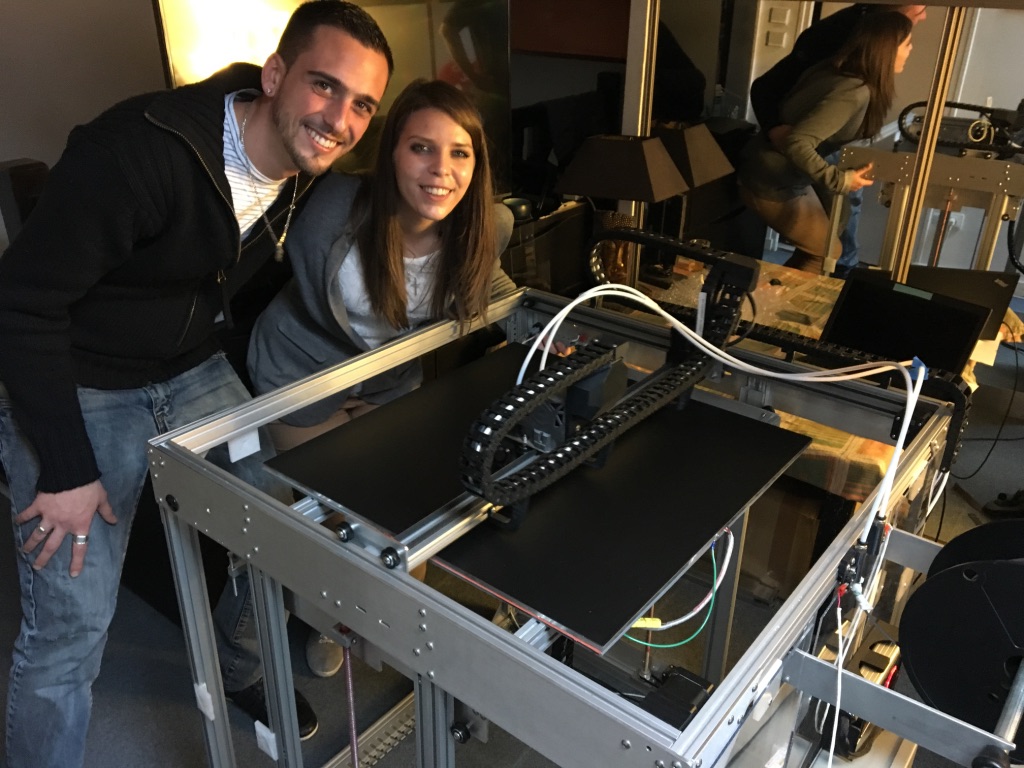

About re:3D

re:3D consists of a group of explorers committed to decimating the cost & scale barriers to industrial 3D printing. Having pioneered the world’s first and most affordable, human-scale industrial 3D printer, re:3D likewise is creating large scale, affordable 3D printers printing from pellets, regrind, and flake plastic waste. Beyond creating 3D printers for customers in over 50 countries, re:3D offers 3D printing contract services, consulting, design and education services. For more information on re:3D, visit www.re3d.org.

Media Contact: