2022 Update

Dear Gigabot Family,

re:3D still has about 200 face shields available for free anyone who needs them to keep your team safe. please fill out the form at https://houston.impacthub.net/getppe/

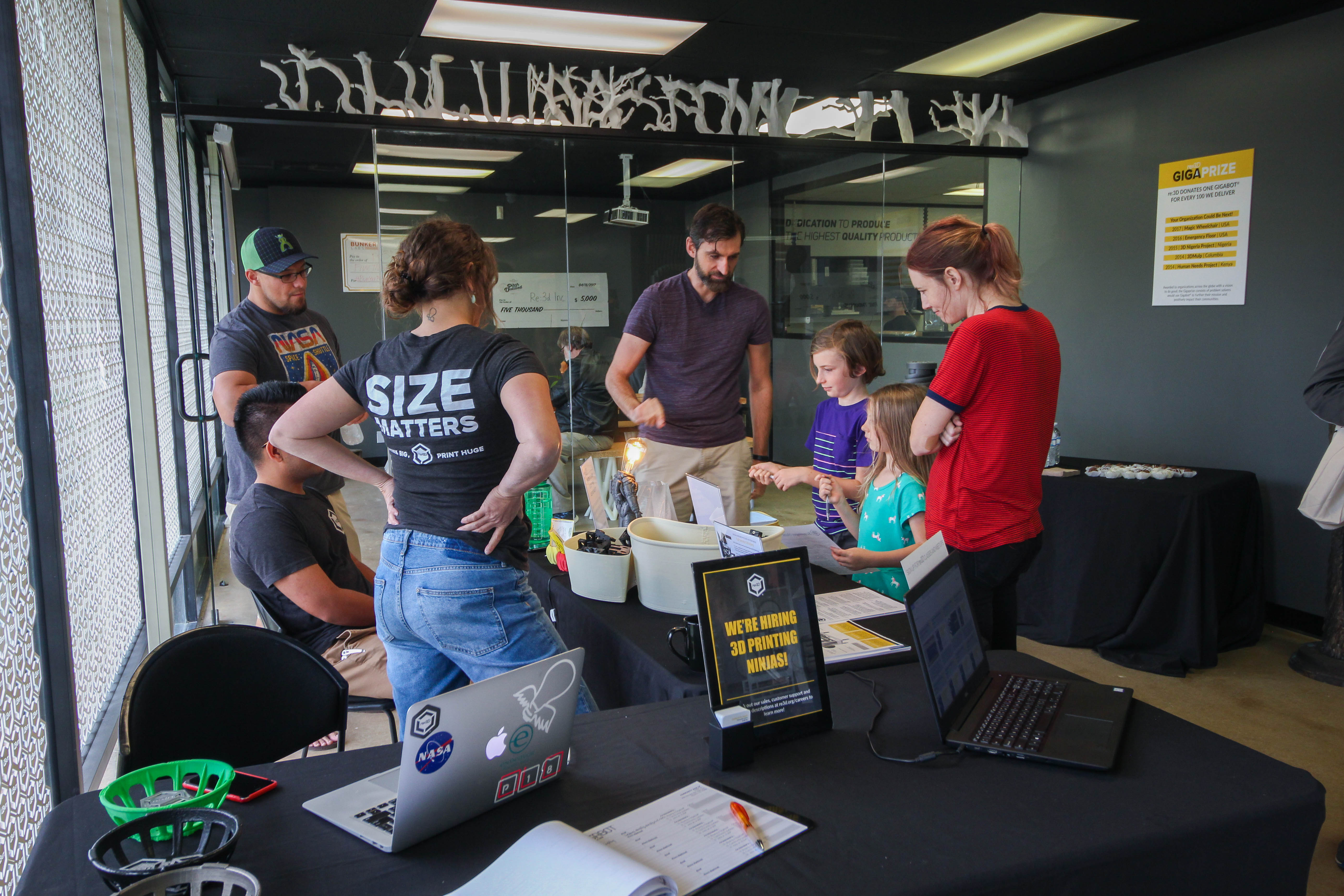

re:3D has returned to normal operations and are excited to be welcoming back groups of visitors to the Houston factory for tours and classes along with continuing our virtual tours. We are pushing forward on many of our R&D projects that began during the pandemic, and are building bigger with Gigalab, a shipping container sized manufacturing lab. We’re printing with even more trash plastic on Gigabot X and are hard at work on developing the next version of Gigabot, the Gigabot 4. Please reach out to us at either 512-730-0033 or info@re3d.org. We’re always happy to hear from you.

~ Team re:3D

2021 Update

To our Customers and Friends,

Since the latter half of 2020, re:3D has continued to support 3D printed PPE efforts in our local communities and beyond.

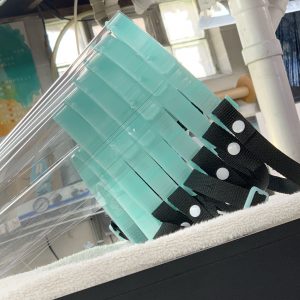

With a generous grant from Unreasonable Impact with Barclays, our program PPE for the People has expanded to provide PPE to those in need anywhere. Should you or a group you know have a need for face shields, ear savers, door pulls or splash guards, please fill out the request form at https://houston.impacthub.net/getppe/

We are heartened that vaccine distribution continues to ramp up and look forward to when we will be able to re-open our Houston Factory to in-person guests. Until then, we’ll keep making printers and PPE to protect those who can’t get it elsewhere, and you are always welcome to sign up for a virtual tour by visiting https://re3d.org/community/

Happy Printing!

~the re:3D Team

Update May 29, 2020

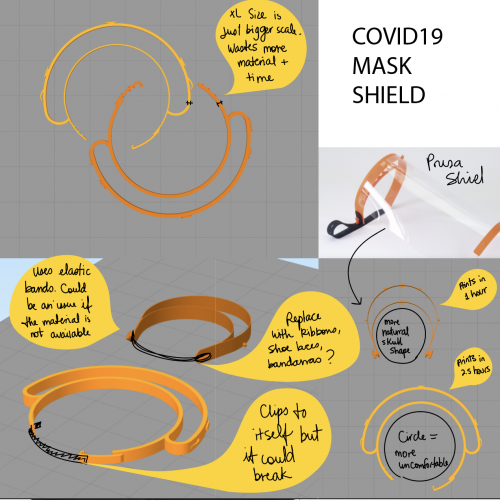

It’s been a month since our last update, and our COVID-19 response is still going strong! On May 12, we were honored to receive an honorable mention in the America Makes Fit to Face – Mask Design Challenge. Designer Mike Battaglia and Engineer Samantha Reeve submitted a mask in two sizes designed to be printed with NinjaTek Cheetah. We continue to collaborate with projects for supplying PPE and consulting on new solutions for face shields to ventilators because we understand that effective face protections is essential for keeping our employees and the general public happy and healthy.

Our Houston factory is still closed to the public, but our team remains committed to building your Gigabots and filling your supply orders and service needs.

Gigabot customers around the world are tirelessly supporting their communities and we are honored to share their stories. If you have been doing COVID-19 work, we’d love to hear from you!

AUSTIN UPDATE

Thanks to the efforts of so many groups in the city, the PPE needs for healthcare workers there have been met and we have wound down our collection boxes for 3D printed PPE.

HOUSTON UPDATE

As the city begins to open back up we have teamed up with Impact Hub Houston on PPE for the People, an effort to provide PPE to workers in minority and under-served communities who are at greater risk of critical illness from COVID-19. Please support this project by sharing, donating and letting local businesses know about the opportunity.

PUERTO RICO UPDATE

The PPE support work in Puerto Rico continues and the Gigabot collaboration at Engine-4 keeps churning out supplies for the island.

If you’d like to be connected to any local effort we would be happy to make introductions and provide resources. Please reach out to us at info@re3d.org.

Update: April 25, 2020

It’s hard to believe that two more weeks have past since our last post! We continue to aggregate and collect your PPE donations in Austin, Houston and PR. We also (just met the deadline for the America Makes Mask Fit Challenge). The final design will be posted to our NIH 3D print exchange tomorrow:)

We continue to be inspired by YOU, and welcome your pics and videos for future stories!

For those of you looking to help with PPE shortages near Austin, Houston and Puerto Rico, details can be found below:

AUSTIN

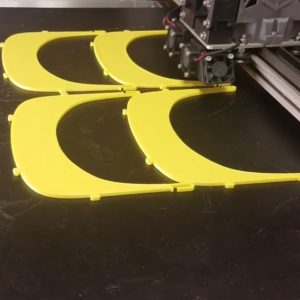

There is a huge maker community that has sprung to action to support the 3D printing of PPE here in Austin and the surrounding areas. One of the largest efforts is being run by Masks for Docs, who are actively soliciting donated face shield prints, assembling the shield, and distributing them to hospitals, health clinics, nursing homes, etc – all around the Austin area. To help with this effort, re:3D will be collecting donated 3D printed face shields in drop-boxes at two locations, Brew & Brew, Capital Factory and the Draught House Pub.

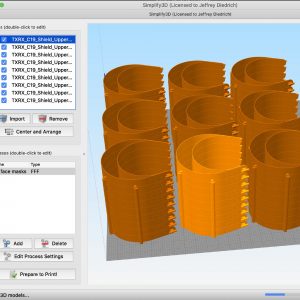

If you have a 3D printer at home or work & want to help out in the Austin area, you can access the Face Shield Design here. Recommended Print Settings: - PETG is preferred, but PLA is completely acceptable if you don’t have PETG or are not able to print with it.

- 3-4 solid top/bottom layers

- .3mm layer height

- 5 Perimeters (AKA Shells or walls)

- 0% Infill

Drop off boxes can be found at:Brew & Brew

500 San Marcos St #105, Austin, TX 78702

The Draught House

4112 Medical Pkwy, Austin, TX 78756

701 Brazos St, Austin, TX 78701

(located in the parking garage, next to the loading dock:)

HOUSTON

TXRX is winding down its collection of its 3d printed face shield as they have been able to move to injection molding; a move we fully support! We are keeping our drop box open for community PPE donations and will make sure they get donated to those in need. Currently we can accept: assembled face shields, ear savers and Montana Masks. As we get more requests we will post opportunities here.

The Clear Lake drop off box can be found at:re:3D Inc

1100 Hercules STE 220 Houston TX 77058

PUERTO RICO

The maker community, including a few Gigabots, have done a fantastic job collaborating in San Juan & beyond. We are currently collecting requests for those in need of PPE and sharing opportunties to connect with Engine-4 and Trede’s efforts in Bayamon, or other groups mobilizing. If you live in Mayaguez and would like create face shield to be assembled with sheets that have been donated to Engine-4, a drop off box has been established. A UPRM student has also initiated a Slack channel to share other needs. Email info@re3d.org for access.

San Juan face shield coordination:

Engine 4 Co-working Space: donation3dprinting@outlook.com

Mayaguez Drop-off:

UPRM Transit and Security, Tránsito y Vigilancia:

Enter UPRM Campus through main gate, and guard will direct you

Update: April 10, 2020

What a week! You all have done an amazing job helping our neighbors & the community at large!

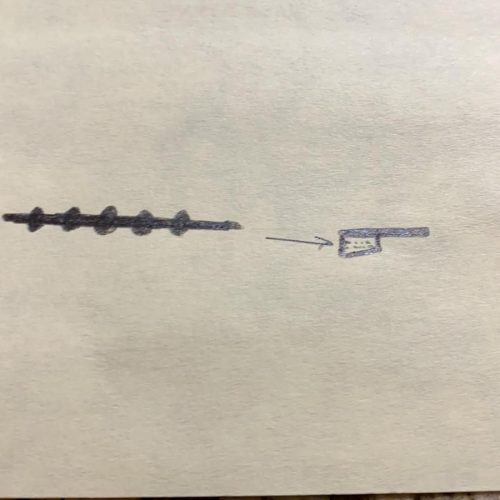

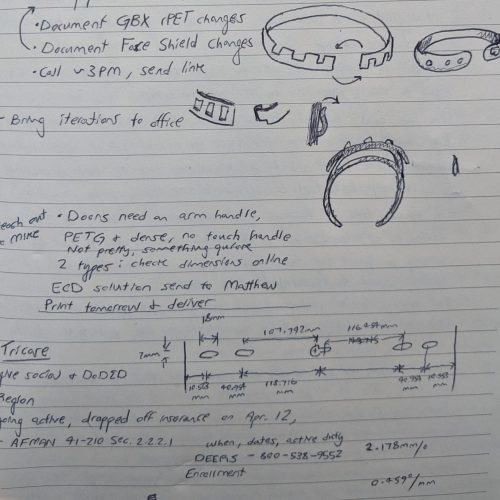

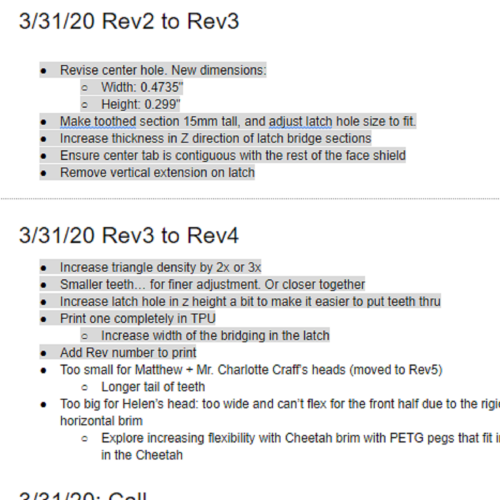

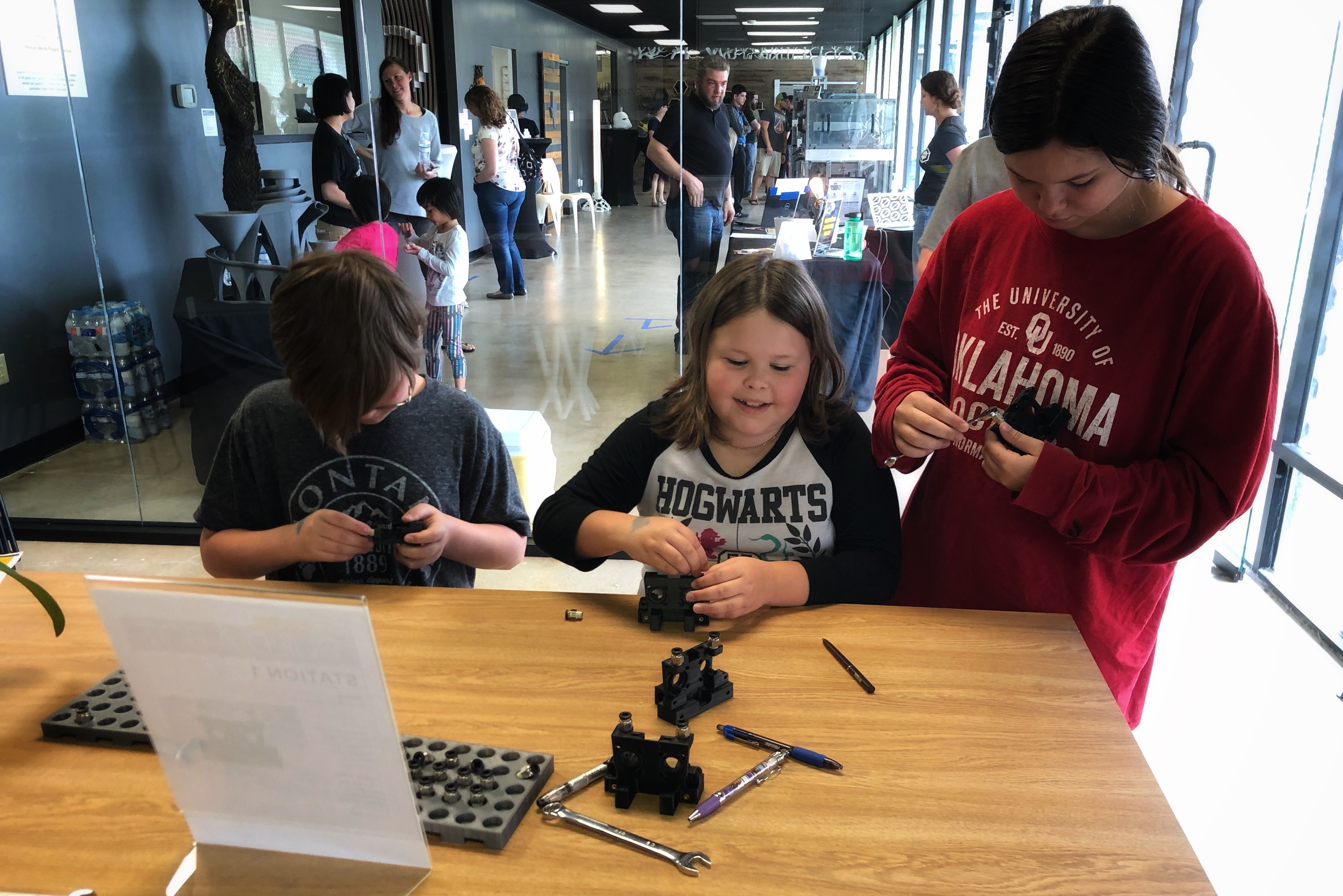

While we continue to iterate this face shield design for the Texas Children’s Hospital (you can view the design on the NIH 3D Print Exchange), as well as hands-free door pulls, we have been blown away by the many Gigabots around the world who are helping with the fight. We’ve started collecting some stories. If you would like to be added, please feel free to share your pictures, details and video with info@re3d.org!

Some of you have also asked how you can use Gigabot and/or other printers to support the local movements near our offices. For those of you looking to help with PPE shortages near Austin, Houston and Puerto Rico, details can be found below:

AUSTIN

There is a huge maker community that has sprung to action to support the 3D printing of PPE here in Austin and the surrounding areas. One of the largest efforts is being run by Masks for Docs (masksfordocs.com), who are actively soliciting donated face shield prints, assembling the shield, and distributing them to hospitals, health clinics, nursing homes, etc – all around the Austin area. To help with this effort, re:3D will be collecting donated 3D printed face shields in drop-boxes at two locations, Brew & Brew and the Draught House Pub.

If you have a 3D printer at home or work & want to help out in the Austin area, you can access the Face Shield Design here. Recommended Print Settings: - PETG is preferred, but PLA is completely acceptable if you don’t have PETG or are not able to print with it.

- 3-4 solid top/bottom layers

- .3mm layer height

- 5 Perimeters (AKA Shells or walls)

- 0% Infill

Drop off boxes can be found at:Brew & Brew

500 San Marcos St #105, Austin, TX 78702

The Draught House

4112 Medical Pkwy, Austin, TX 78756

HOUSTON

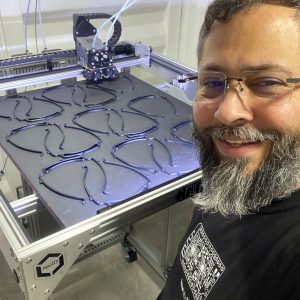

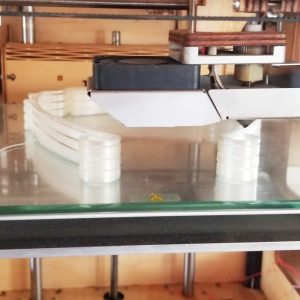

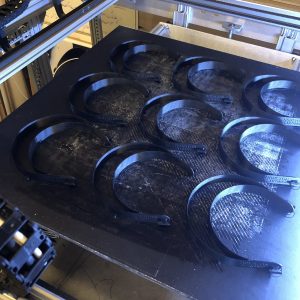

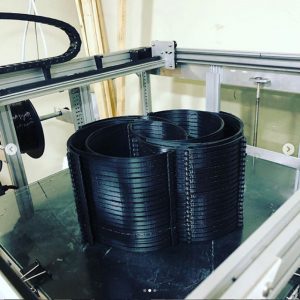

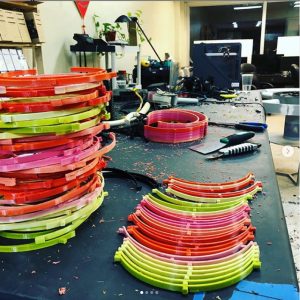

TXRX and the amazing maker-community continue to organize face shield collection around Houston. We are donating 3D printed face shields as well as hosting a community donation box for makers in the Clear Lake area who are printing the face shields at home. At our factory, the batches are consolidated and sent to TXRX for assembly and distribution to hospitals and first responders in the Houston area. We’ve received up to 300 donations in 6 hours- keep it up!

The Clear Lake drop off box can be found at:re:3D Inc

1100 Hercules STE 220 Houston TX 77058

PUERTO RICO

The maker community, including a few Gigabots, have done a fantastic job collaborating in San Juan & beyond. We are currently collecting requests for those in need of PPE and sharing opportunties to connect with Engine-4 and Trede’s efforts in Bayamon, or other groups mobilizing. If you live in Mayaguez and would like create face shield to be assembled with sheets that have been donated to Engine-4, a drop off box has been established. A UPRM student has also initiated a Slack channel to share other needs. Email info@re3d.org for access.

San Juan face shield coordination:

Engine 4 Co-working Space: donation3dprinting@outlook.com

Mayaguez Drop-off:

UPRM Transit and Security, Tránsito y Vigilancia:

Enter UPRM Campus through main gate, and guard will direct you

If you live outside of these areas and/or are seeking ways to contribute:

A Form to Volunteer is Available Here. We will be responding to inquiries this weekend and doing our best to facilitate introductions:)

Update: April 3, 2020

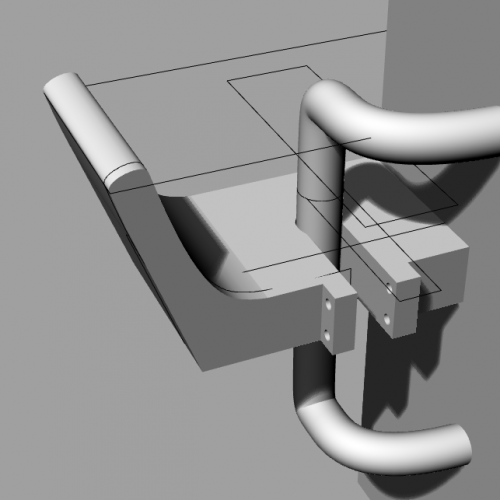

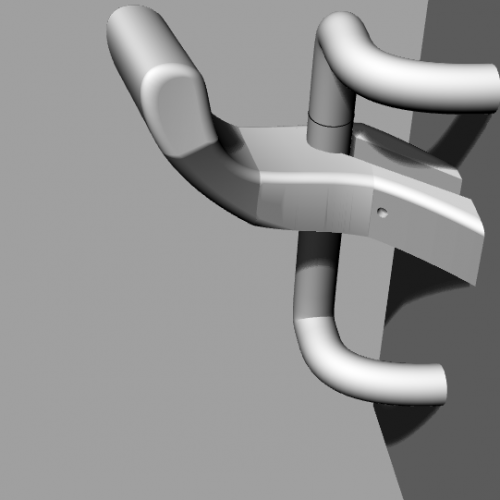

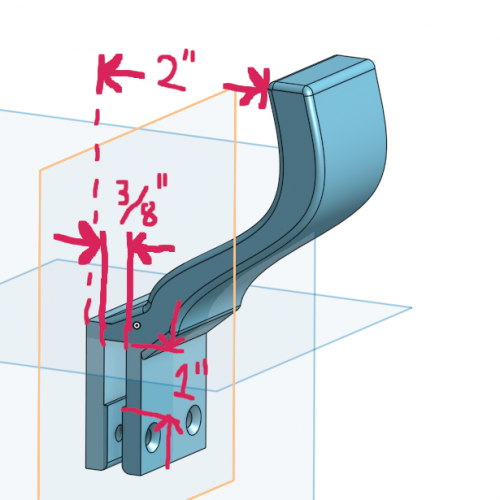

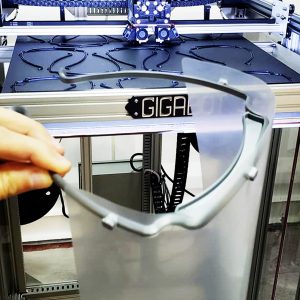

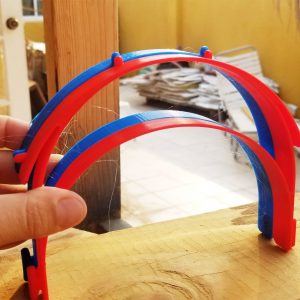

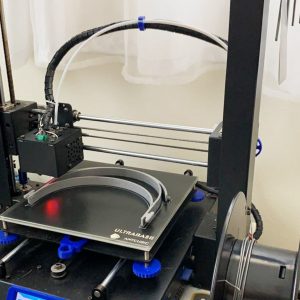

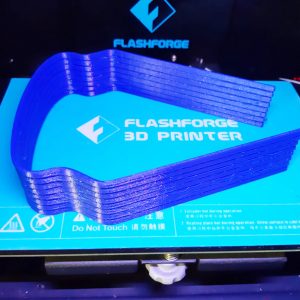

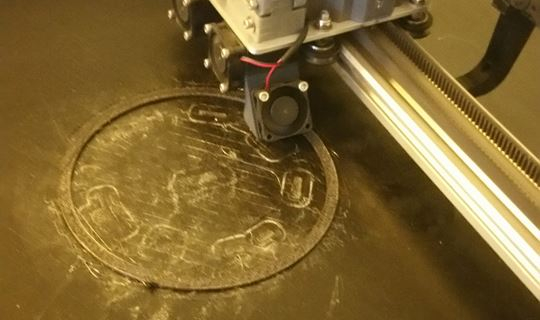

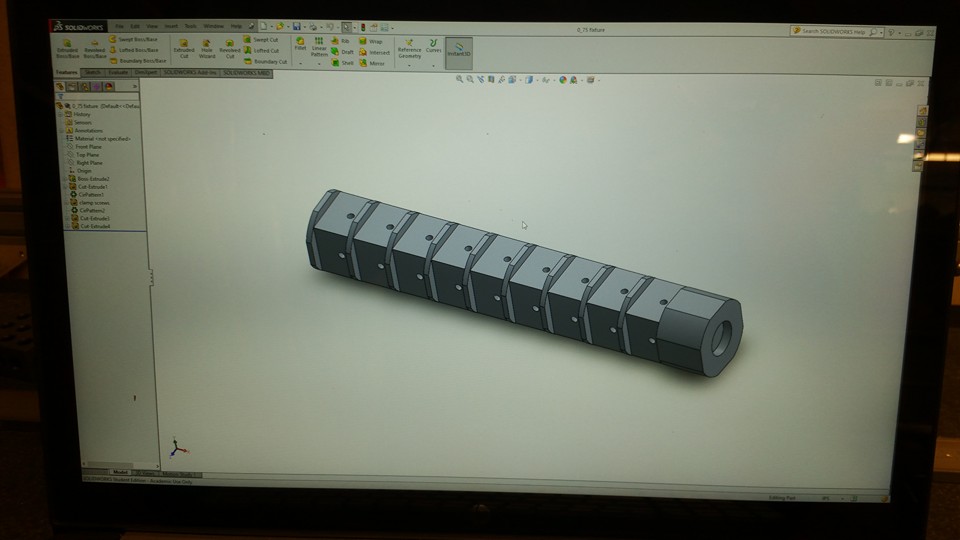

re:3D is working on a number of different projects related to 3D printing and COVID response. Our Houston factory is helping to support two efforts. The first is supporting the efforts of TXRX and the amazing maker-community organizing taking place around Houston. re:3D is donating 3D printed face shields as well as hosting a community donation box for makers in the Clear Lake area who are printing the face shields at home. At our factory, the batches are consolidated and sent to TXRX for assembly and distribution to hospitals and first responders in the Houston area. Second, the re:3D design team is prototyping a custom face shield design, in conjunction with doctors from Texas Children’s Hospital. The new design incorporates a pre-cut clear plastic face shield with a 3D printed holder/headband.

In Austin, re:3D is rallying the local maker community. While there are a number of people working on the 3D printed PPE issue in the Austin area, re:3D is hoping to help organize these efforts. The Austin team is designing hands-free door pulls and intubation boxes, and we will be releasing all of the 3D printable open-source designs that we have created, including face shields, door pulls and anything else we develop, free of charge. We are opening Austin community drop boxes at multiple locations where anyone who 3D prints can donate their COVID-19 parts. location information will be released as soon as it’s finalized.

In Puerto Rico, re:3D is supporting efforts led by Engine-4 on 3d printing face masks and ventilator splitters. Thanks to efforts by Parallel18, our Gigabot has been relocated to Engine-4 to print for this effort and we are hosting weekly calls for healthcare professionals, designers and makers to organize the community to support creating PPE unique to the needs on the island. We are connecting with every available Gigabot owner on the island to help them join the cause.

For anyone who wants to volunteer to help, please fill out this form.

Updated: March 25, 2020

To our Global Gigabot Family and Supporters,

We hope this message finds you and your loved ones safe and healthy. The 3D printing community is a talented, diverse and compassionate arm of the creative tech ecosystem. We are energized and inspired by the mass mobilization of 3D printing to tackle COVID-19 head-on by providing protective gear to medical personnel, medical equipment to aid victims and filling gaps in supply chains. Every day, you are proving that this technology changes the world for the better. Keep at it!

re:3D IS OPEN FOR BUSINESS!

We have been closely following COVID-19 developments in our areas and listening to the recommendations from local and federal authorities. The small yet mighty re:3D team has always been mobile and adaptable, and we are continuing our regular operations while keeping the health and safety of our team at the forefront of all considerations. Here’s how:

- Your Gigabots® are being built and shipped on their regular schedule.

- Your supply orders are being fulfilled with minimal delay.

- Your 3D printing, design and 3D scanning services are moving forward as planned.

- As an essential business, the Houston factory is open and fully operational. In-person visits are restricted to deliveries and pickups only to respect guidance on social distancing.

- Meetups, walk-in tours and in-person classes are suspended until further notice.

- Classes will move to online-only as format and demand allows.

$100 SERVICE CREDITS FOR EDUCATORSThe education landscape has dramatically changed in the last few weeks and as many educators gamely adapt to new methods of teaching, you have awed us with your adaptability, tenacity, and positivity. In recognition of your herculean efforts, now through April 10th we are offering to educators a $100 credit, with no minimum purchase required, for re:3D printing, designing and scanning services.

For all those schooling from home, we are extending a 20% off discount on all services (scanning, design, printing, materials testing) for any effort supporting distance learning.

Service quotes can be requested at re3d.org/services

HELPING THE EFFORT TO FIGHT COVID-19

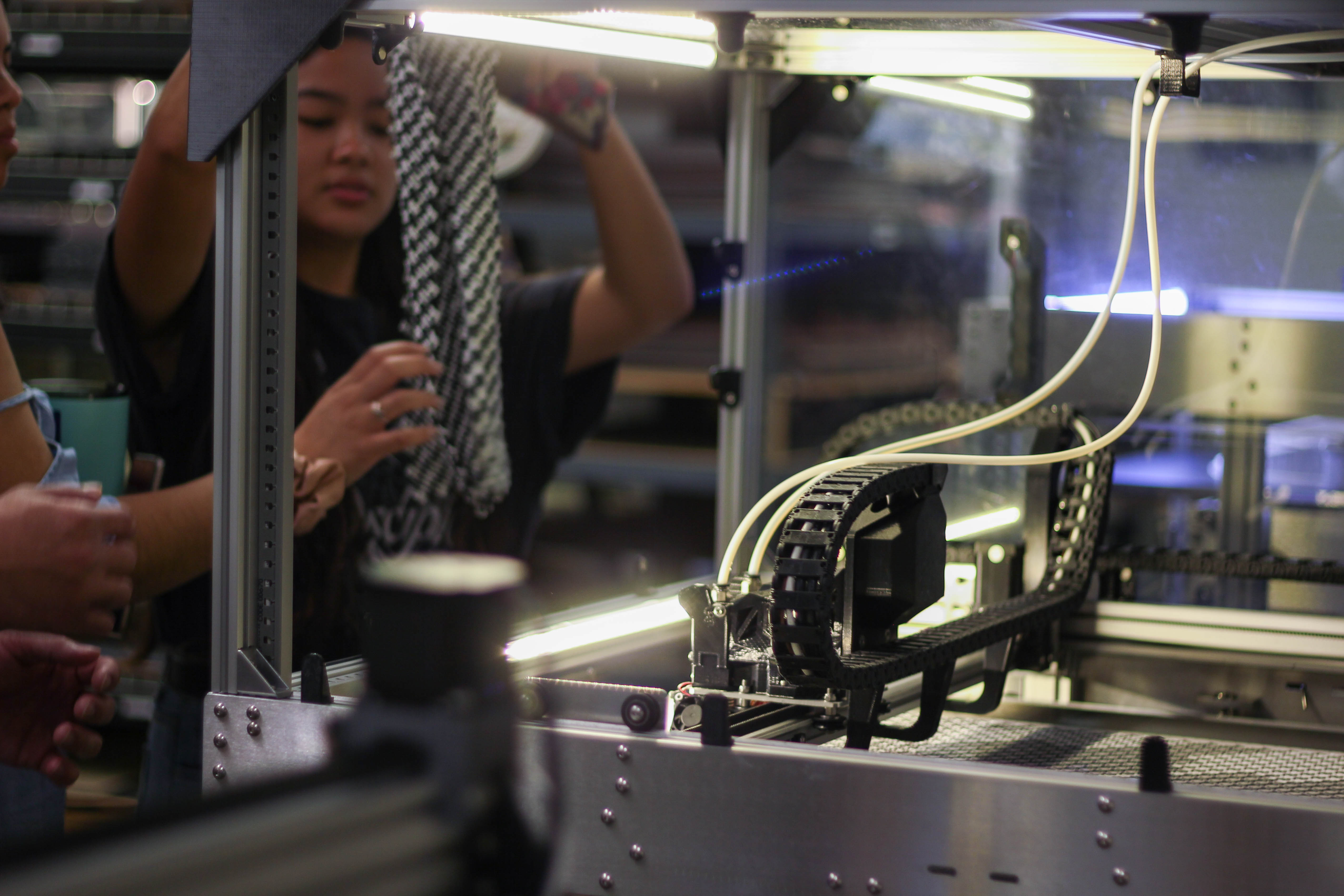

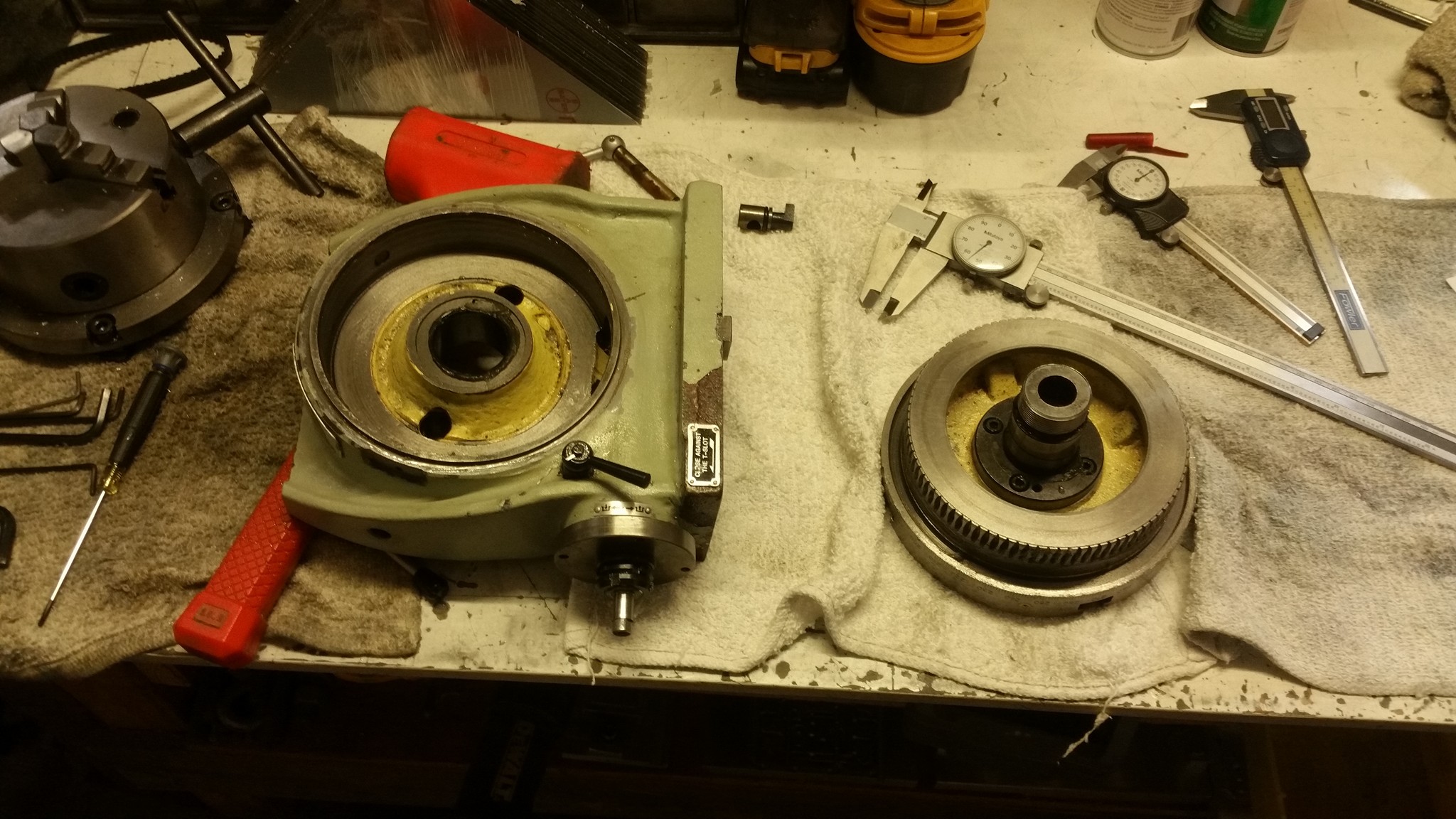

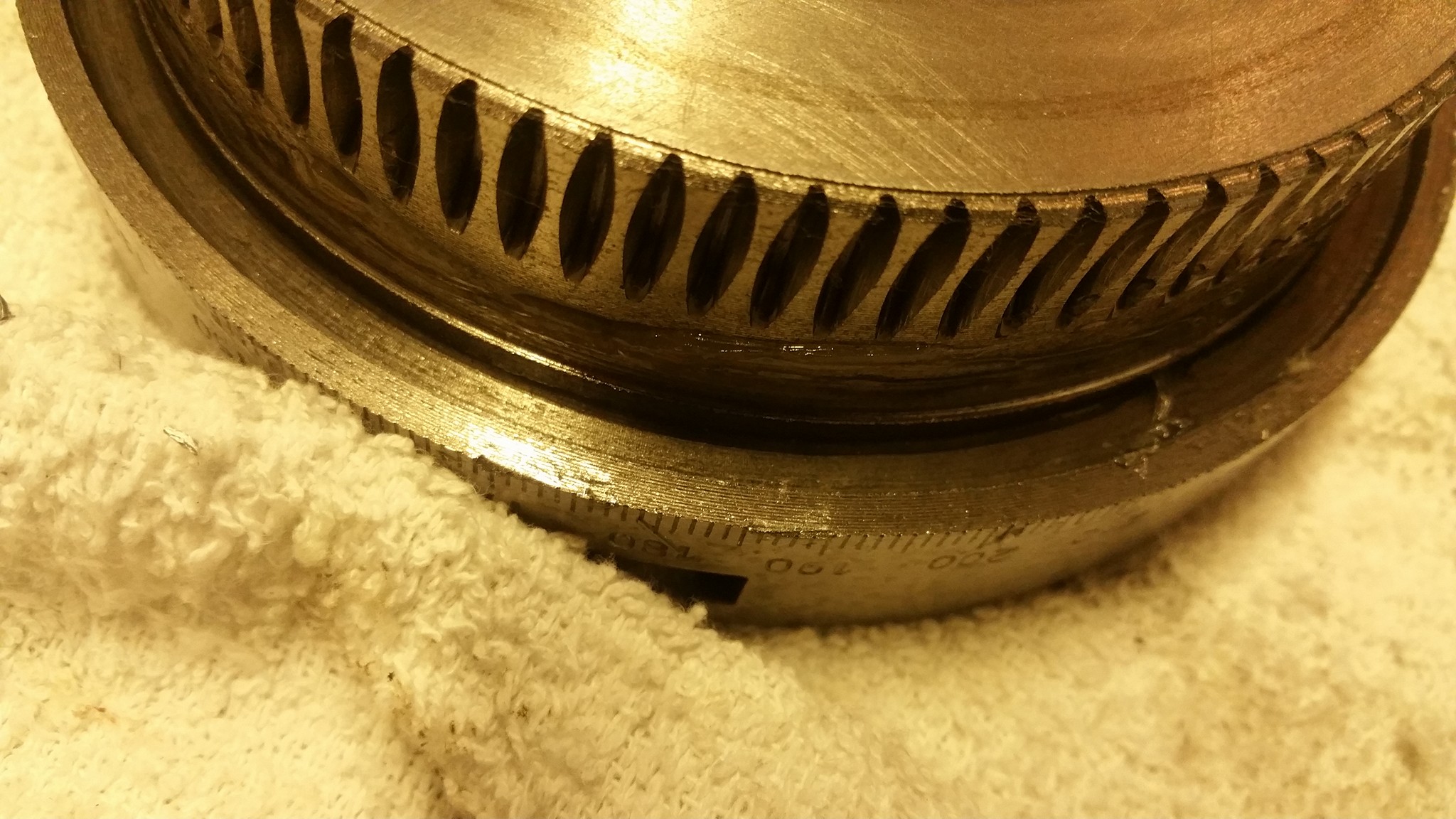

re:3D’s Houston factory is equipped with a printer farm of large-format industrial Gigabot® 3D FFF and FGF printers, a metrology-grade 3D scanner, a full machine shop that includes two CNCs, manual lathe, drill press and cutting tools. This equipment and our team of 25 engineers, designers and technicians is available to fabricate equipment for healthcare providers that has been reviewed for viability and safety by medical professionals. Please reach out to us at info@re3d.org to begin coordination. We are happy to prototype any life-savings device for free in order to expedite review by medical professionals.

For those looking for ways to put your 3D printing know-how to work in the effort to fight COVID-19, we are collecting contact information to share further developments and opportunities to 3D print for those in need.

A Form to Volunteer is Available Here

Additionally, a great list of other projects has been curated by our friends at the non-profit Women In 3D Printing.

Stay Healthy and Keep Printing!

~Gigabot & The re:3D Team