re:3D, Inc. honored by U.S. Chamber of Commerce as Community Support and Leadership Award Finalist

Finalists To Be Recognized During Annual Small Business Awards Program

HOUSTON, TX — The U.S. Chamber of Commerce announced re:3D Inc. from Houston, Texas as one of the finalists for its annual Dream Big Awards. The Awards, presented by Chase for Business with support from MetLife, celebrate the achievements of small businesses and honor their contributions to America’s economic growth.

“Over the last several months, small business owners have faced challenge after challenge. Yet, despite these challenges small business owners never stop innovating, pivoting, taking risks, working hard, and dreaming big,” said Tom Sullivan, U.S. Chamber of Commerce Vice President of Small Business Policy. “Small businesses are a critical and vibrant sector of the U.S. economy. The U.S. Chamber is proud to celebrate the very best in American small business through our Dream Big Awards.”

The Dream Big Awards program includes Business Achievement Awards to recognize excellence in eight categories and reflect the leading businesses in each of the following areas: community support and leadership, emerging, green/sustainable, minority-owned, veteran-owned, woman-owned, young entrepreneur, and small business of the year. This year’s finalists were selected from a record of over 700 applicants.

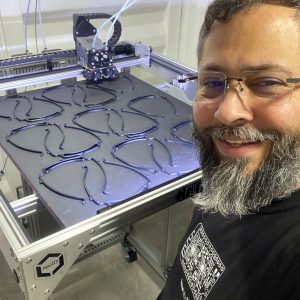

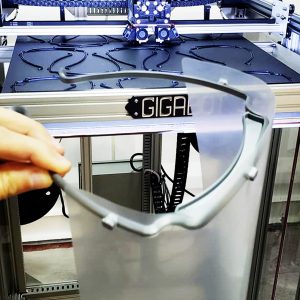

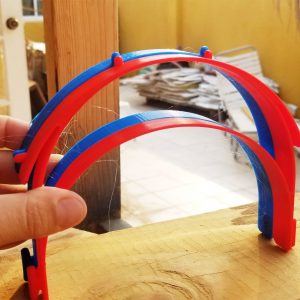

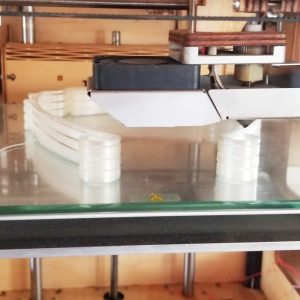

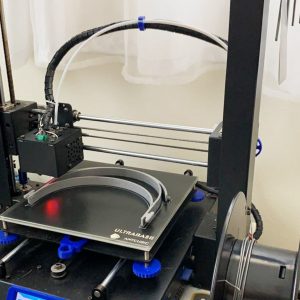

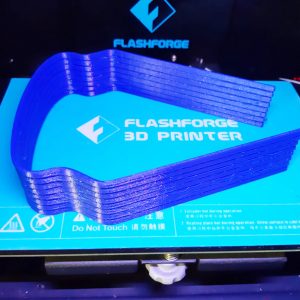

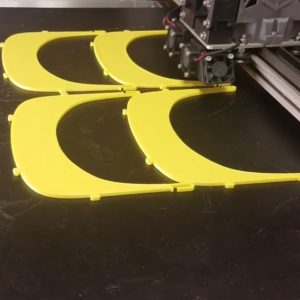

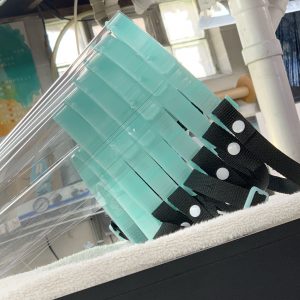

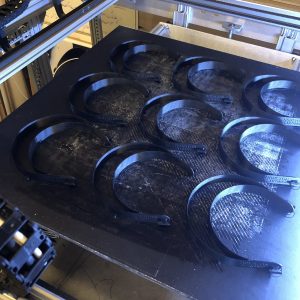

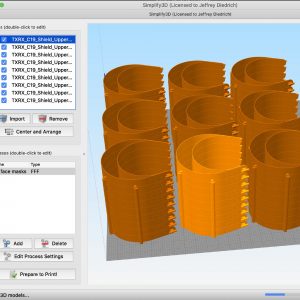

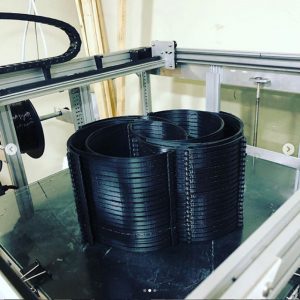

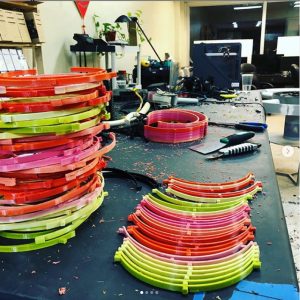

The Community Support and Leadership Award recognizes the success of one small business and honors its contributions to the growth and diversity of the American economy. This award recognizes a small business that has demonstrated an exemplary level of leadership and community engagement to assist the needs of its community, and to service the needs of its customers, employees, and neighbors during the coronavirus pandemic. re:3D has provided free prototyping of life saving devices, produced PPE for their community and supported their customer’s and partners similar efforts in response to the pandemic. The company manufactures large scale, affordable 3D printers that can 3D print from plastic waste as well as traditional feedstock and gives away one 3D printer for every one-hundred that they sell to someone making a difference in their community.

“The dire needs created by the pandemic have illustrated that local, small scale manufacturing, whether in your home or in small factories around the world, can be a means to serve your communities. We are grateful to the open source 3D printing community for banding together to create solutions for PPE shortages, and were honored to work alongside our fellow makers, customers and first responders to solve this challenge,” shared re:3D Community Ambassador, Charlotte Craff.

Award winners will be announced at the virtual Dream Big Awards program on Thursday, October 15 at 2:00pm ET.

About re:3D

re:3D consists of a group of explorers committed to decimating the cost & scale barriers to industrial 3D printing. Having pioneered the world’s first and most affordable, human-scale industrial 3D printer, re:3D likewise is creating large scale, affordable 3D printers printing from pellets, regrind, and flake plastic waste. Beyond creating 3D printers for customers in over 50 countries, re:3D offers 3D printing contract services, consulting, design and education services. For more information on re:3D, visit www.re3d.org.

Charlotte craff

Blog Post Author