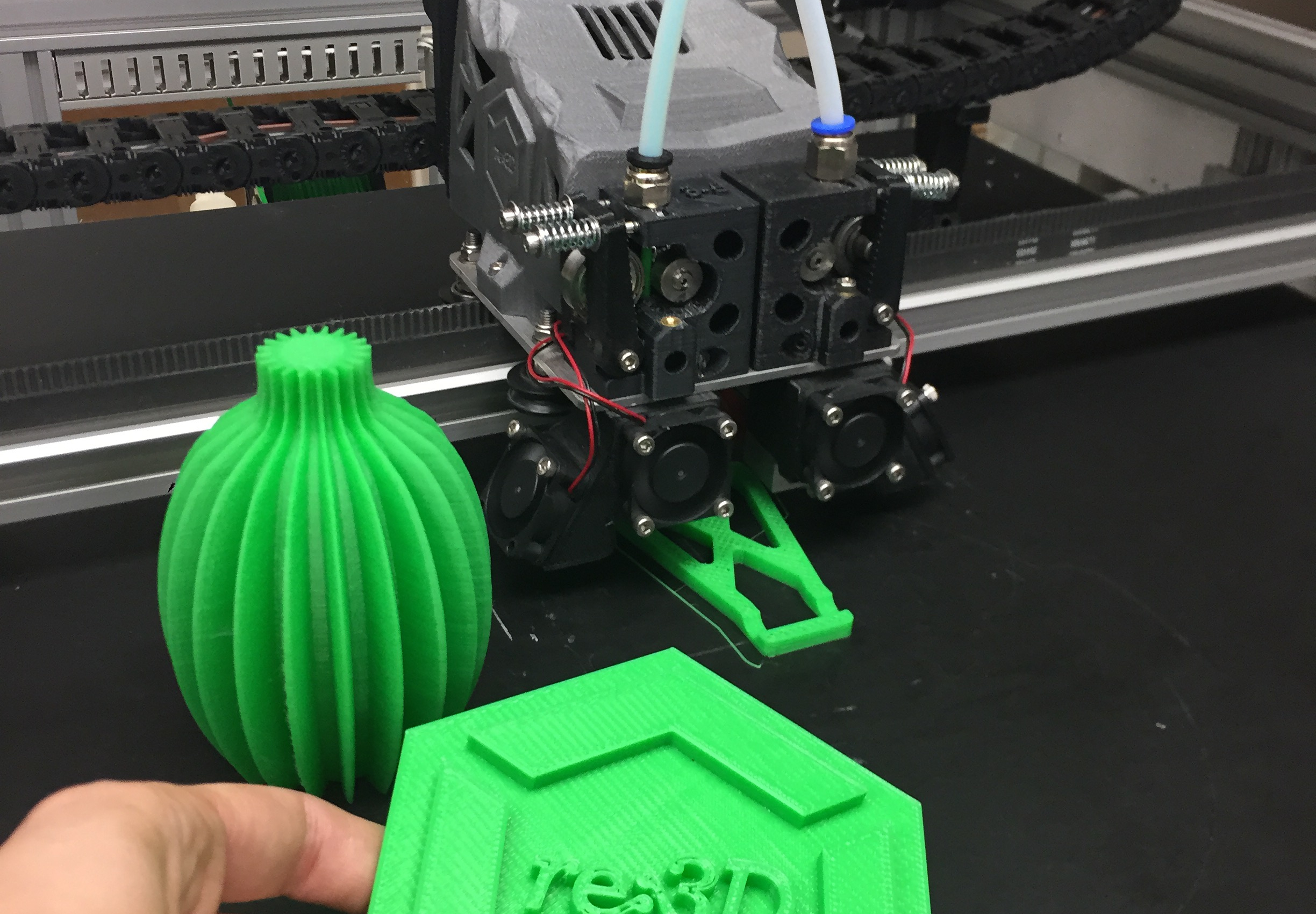

With some new filament in the office, I took the opportunity on a recent visit to Houston to do some materials testing, also known as breaking things, which happens to be my specialty.

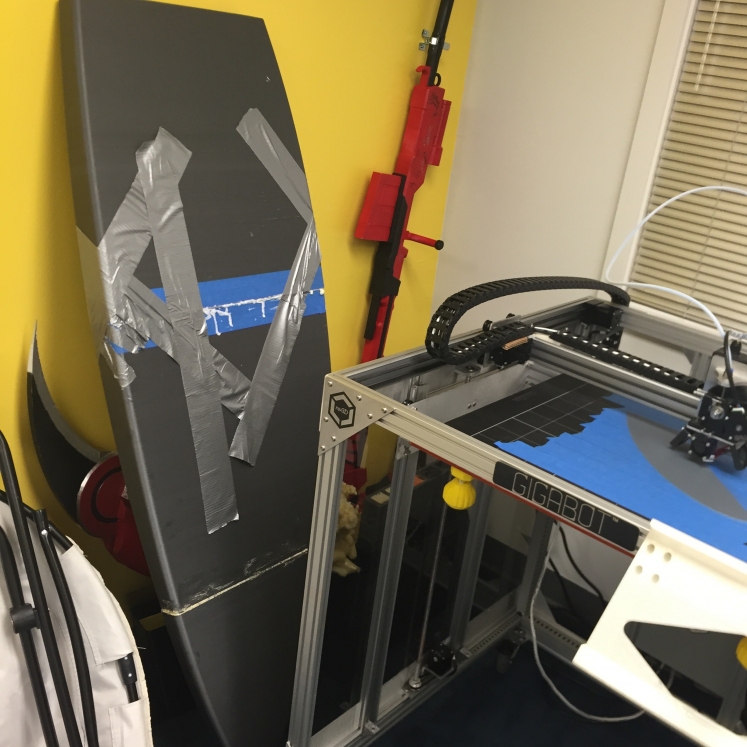

My main goal was to test out a new filament called PLA++ by Breathe-3DP and compare it to the regular PLA we use. As they describe it, the second “+” is for functionality – where normal PLA snaps, their PLA++ stays strong. I wanted to see that for myself.

To spice things up a bit, I threw some n-vent into the mix, which ended up adding a nice third dimension to the spectrum of strength we saw.

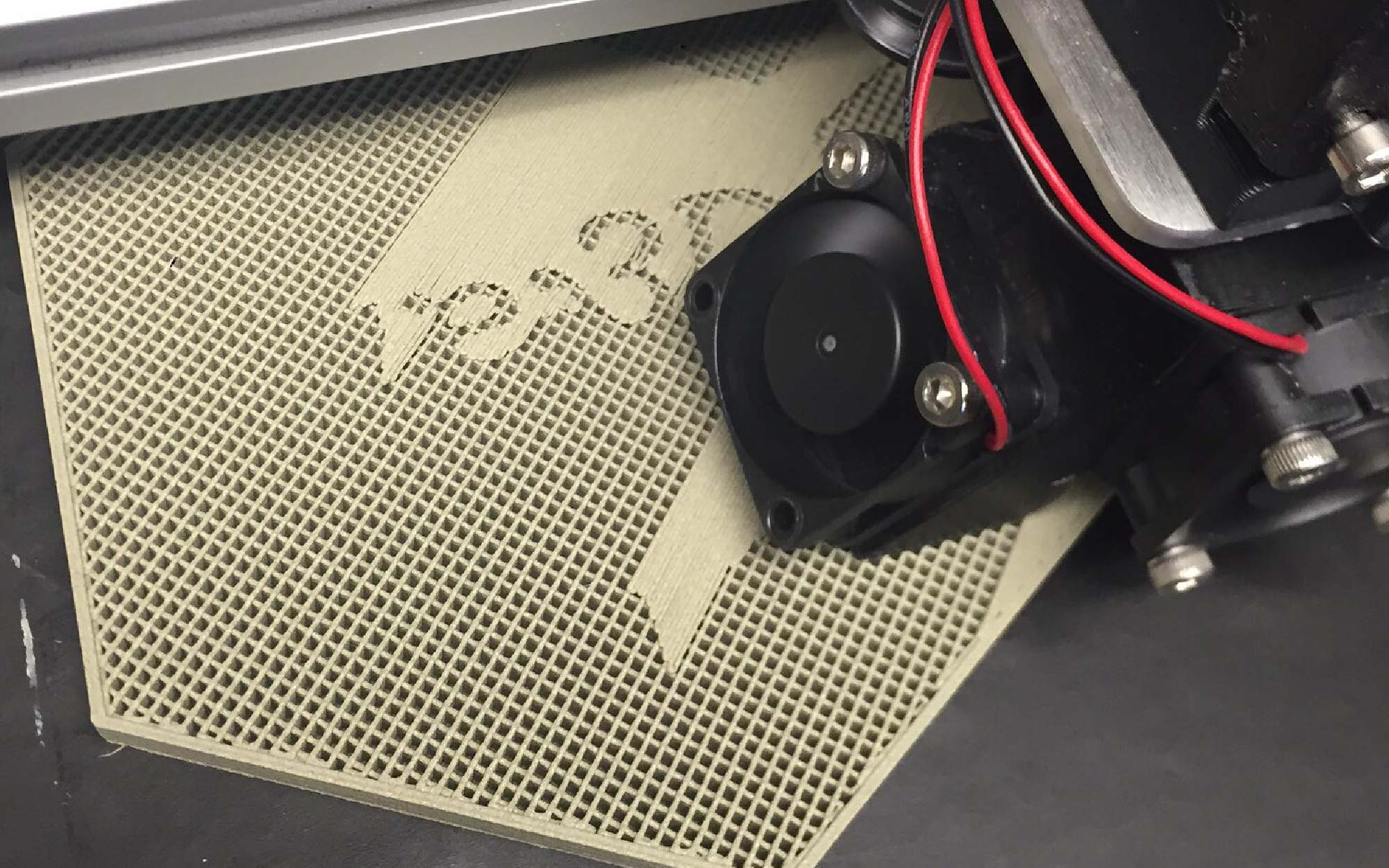

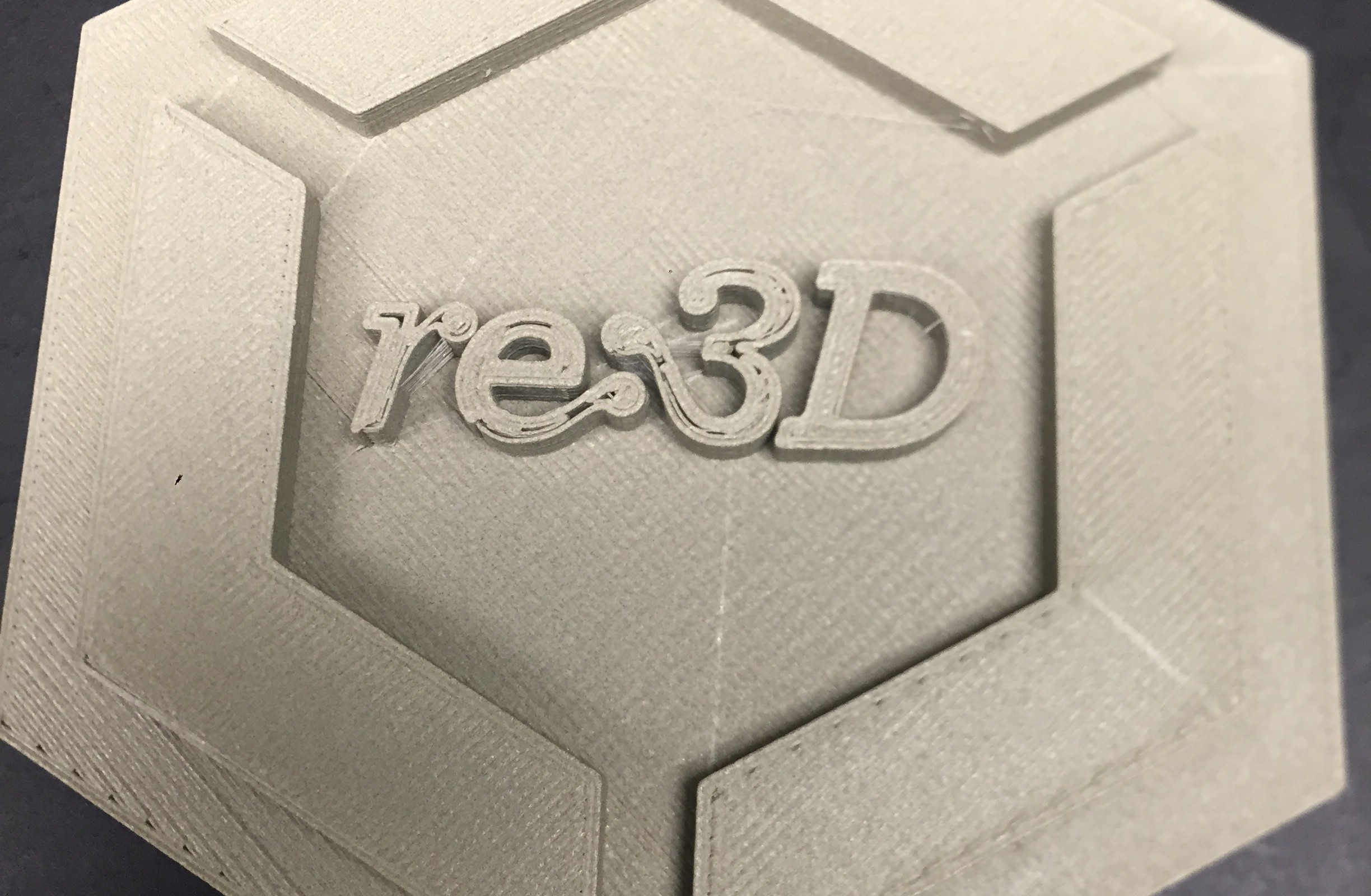

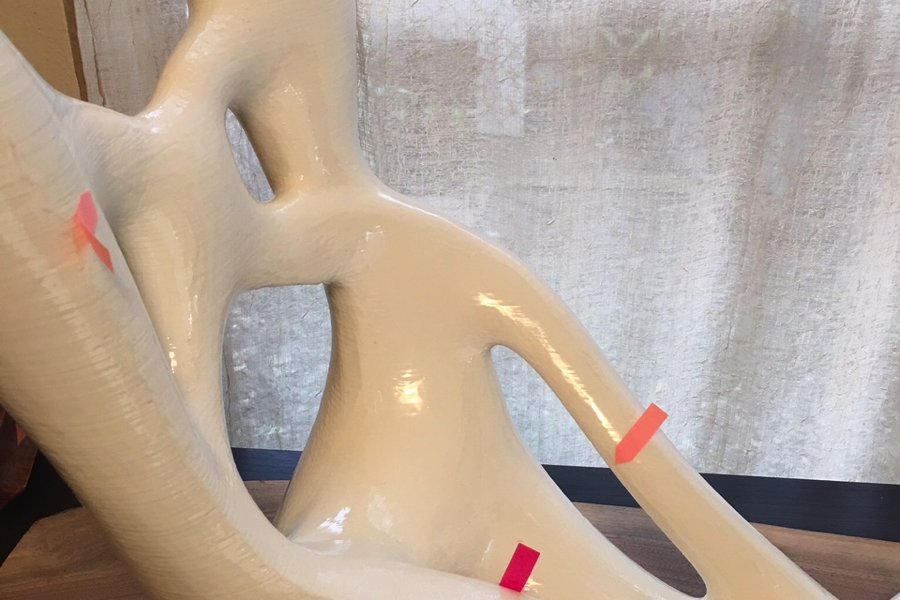

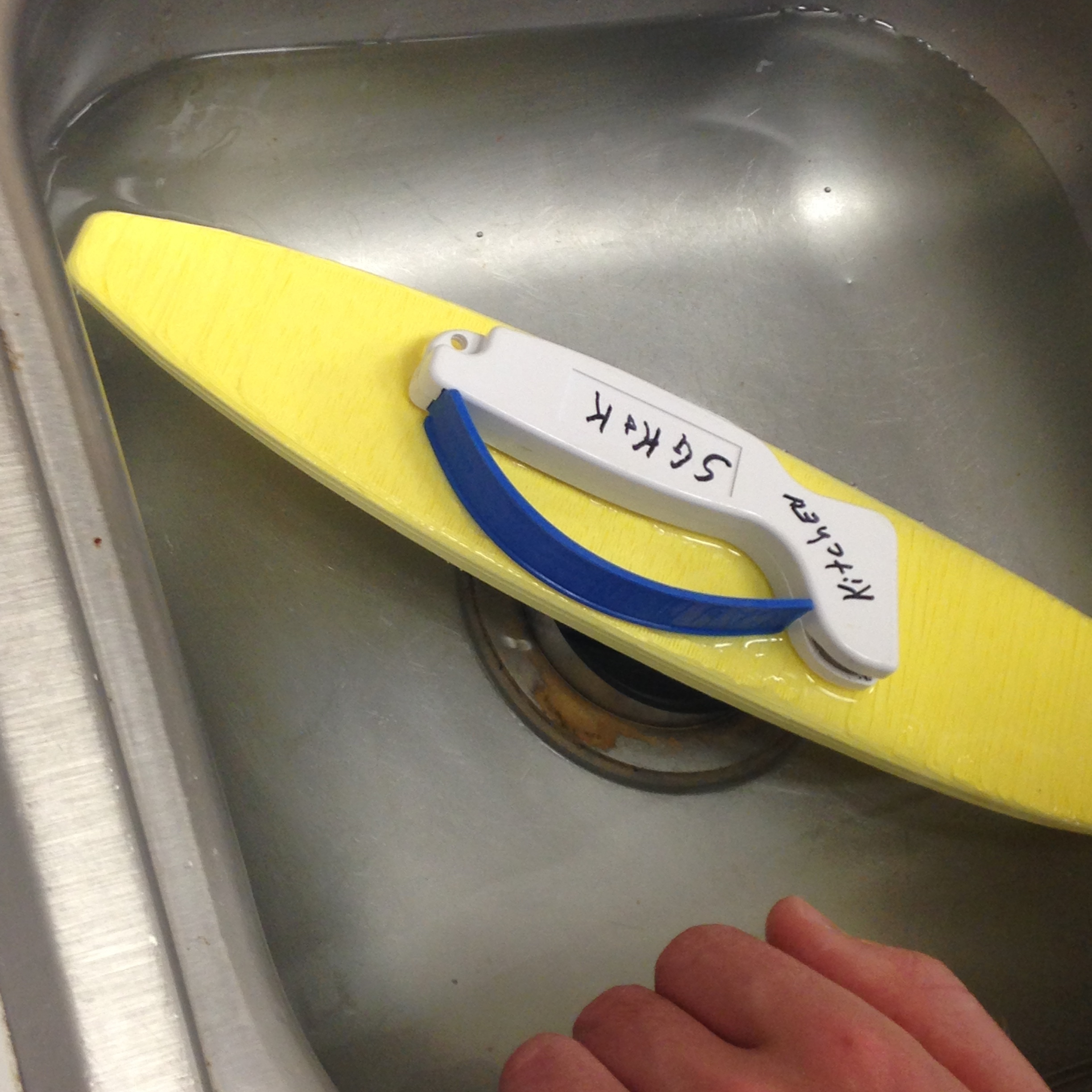

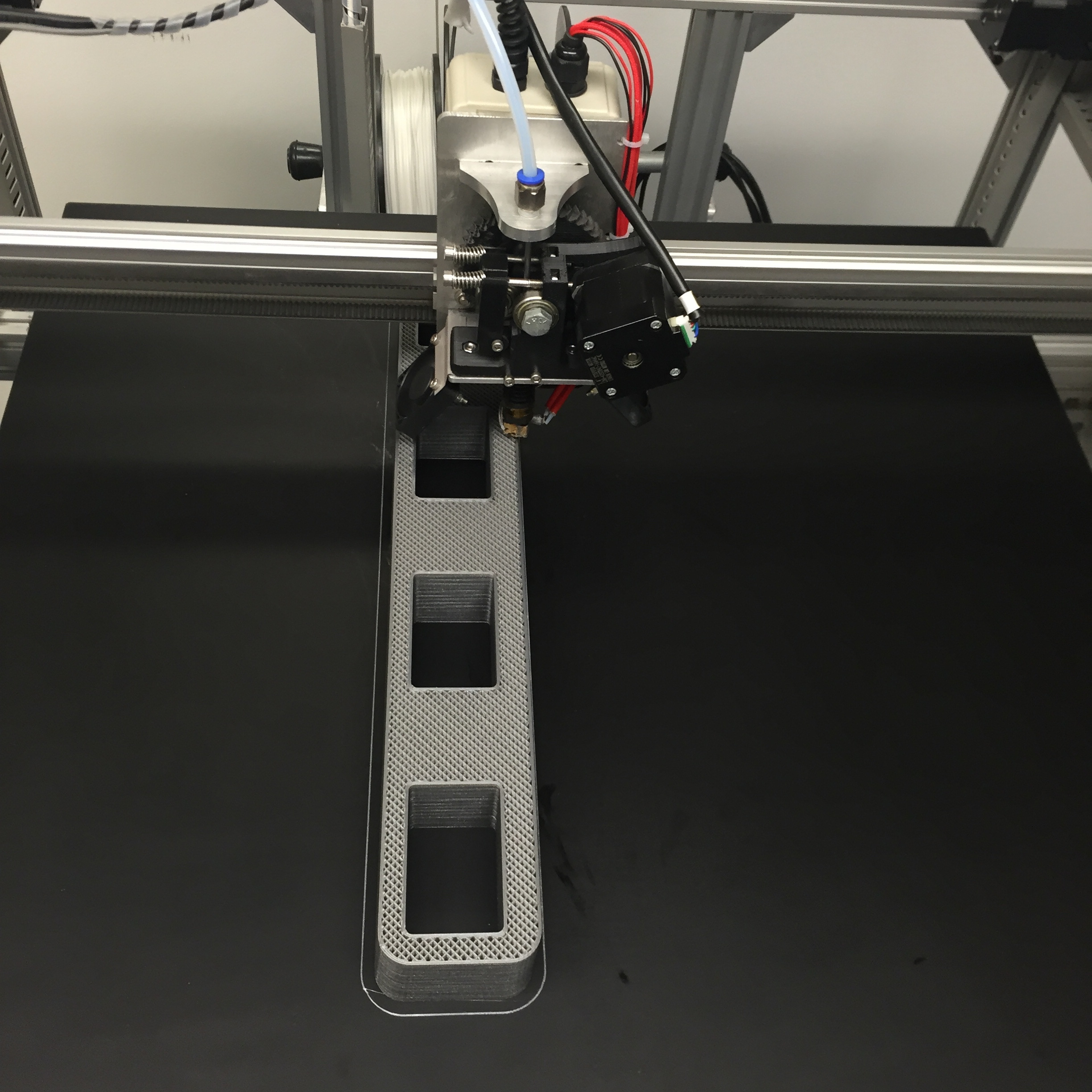

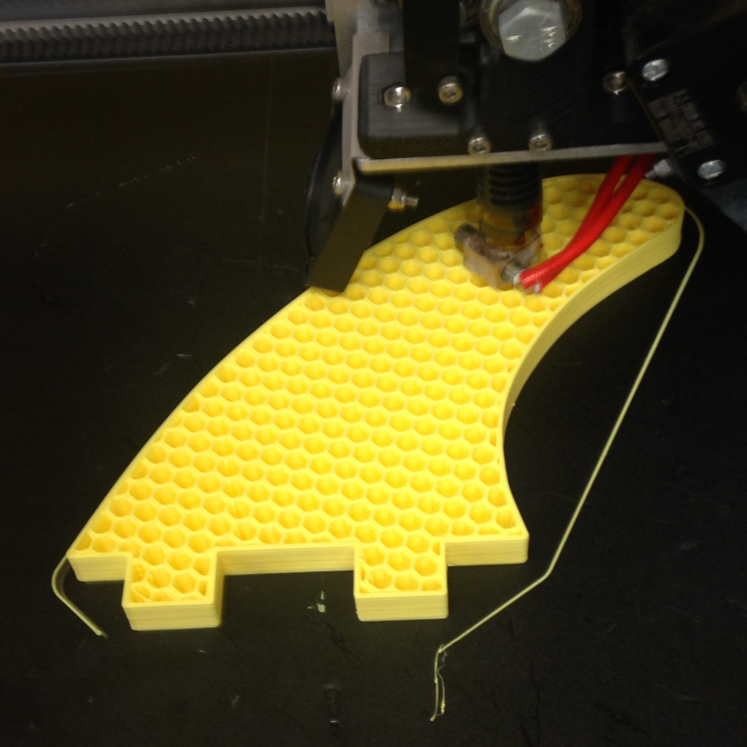

I printed out a handful of the ASTM Tensile Test Specimen, dubbed the “dogbone” in the office, and got to breaking things. The PLA++ was first on the chopping block.

You can see in the video that I’m able to get the dogbone flexed into a nice St. Louis Gateway Arch shape – it had a good amount of give to it. I could feel the material bend under my fingers; in the video you see the edges in the center start to turn a slight white color as the print flexes. Only once I move my thumbs to the outside of each end and force the two together does the center finally give.

Even once it does finally break, only the top of the print has actually split – the bottom is still attached. It takes me ripping the two apart to separate the two halves. You can see in the video how much the print has curved due to my bending it, and it retains that bend even after it is broken.

The flexible nature of the PLA++ becomes more apparent when compared to the standard PLA test. PLA, our choice filament around the office, is known for its ease of printing, but also its brittleness.

I’m able to flex the PLA dogbone a fair amount – further than I expected, but not as far as the PLA++ – but its reaction to this flexion is explosive and violent. You can see pieces rocket off once the print reaches its breaking point, loud enough to make one of our engineers in the room jump and whip around to see what new trouble I was getting myself into.

Last up was the wild card, Taulman’s n-vent. What seemed promising to me was its ease of printing yet also its toughness and resistance to high temperatures.

The n-vent wouldn’t quit. I bent it one way, then the other way, then back the first way, flexing it beyond where the PLA++ made it. When it finally gives up the fight, it’s a slow, unceremonious break. With the outer edge finally split, I’m able to flex the two ends until they touch, and even then the dogbone wouldn’t break in two.

You may notice a hand model swap at different points throughout the video – our lead engineer jumped in for a piece of the action – and the n-vent put up just as much of a fight for him. He bent the two halves back and forth several times before forcefully ripping them apart.

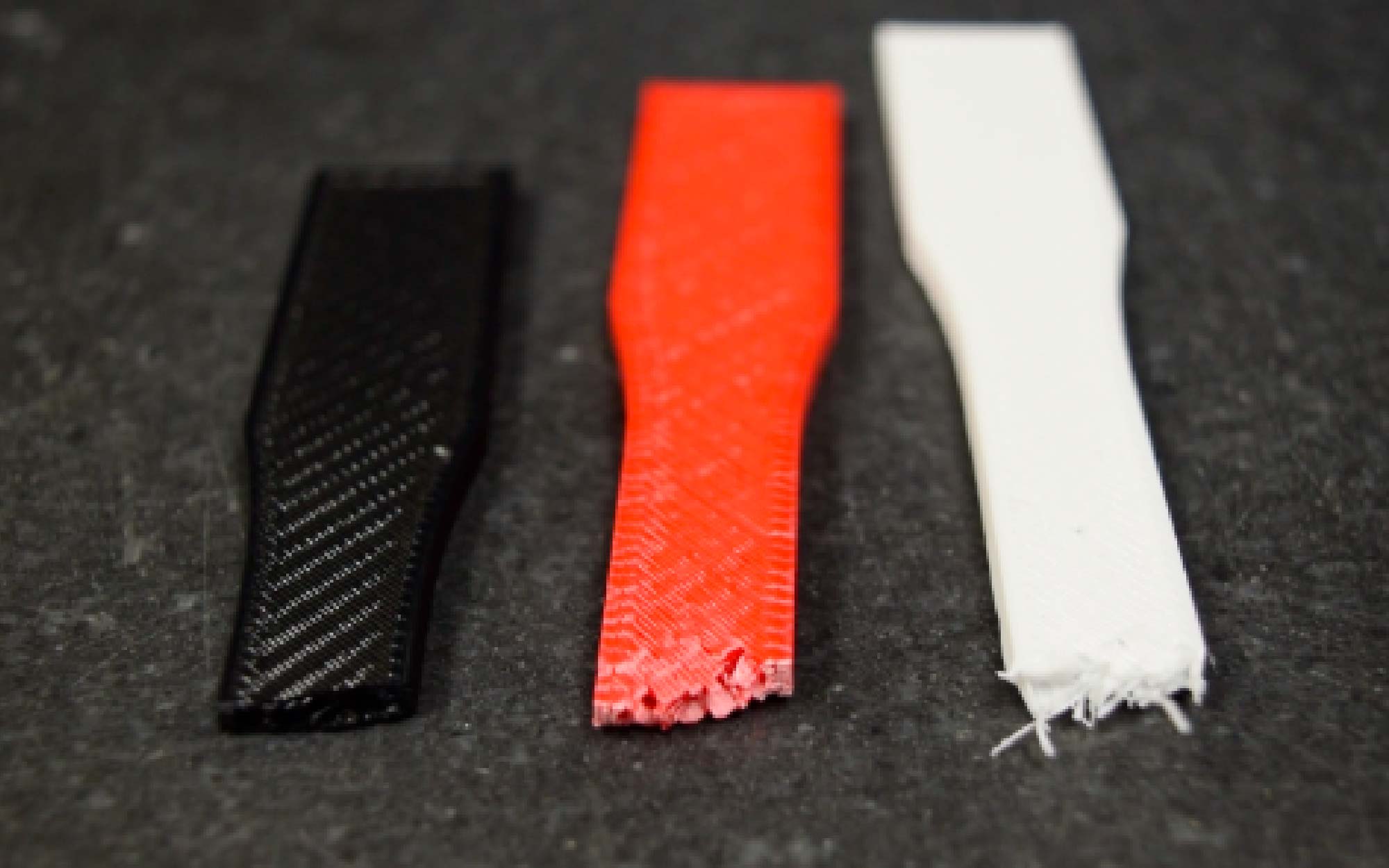

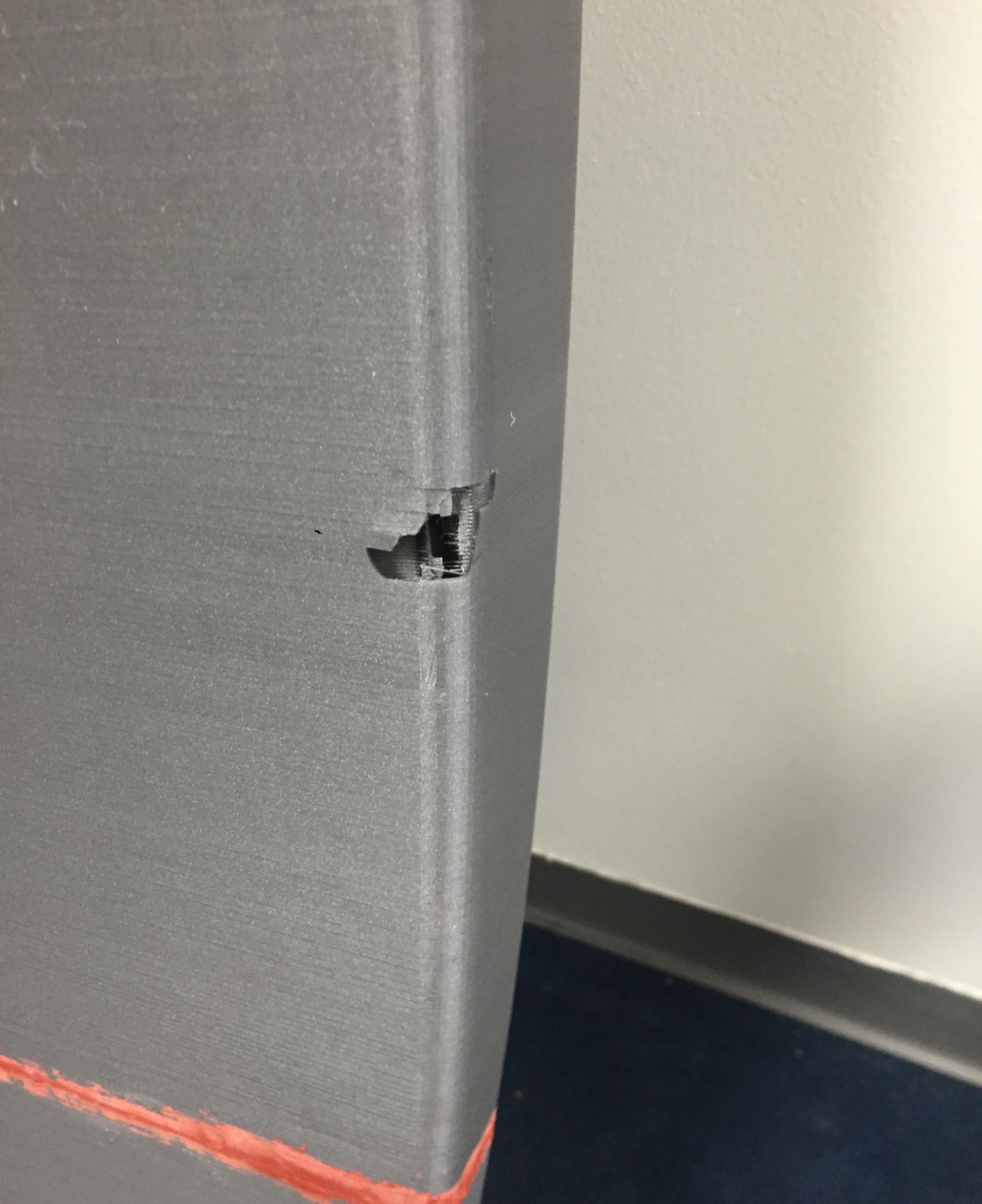

In the close-ups at the end of the video you can see the stringy infill of the n-vent print, the internal structure which kept the two ends hanging onto each other so well. In contrast, the standard black PLA shows a clean break – unsurprisingly – after the gunshot-like force by which it broke. The PLA++ shows an edge somewhere between the two – not stringy like the n-vent, but with a rougher edge than the standard PLA, due to the slower, bendy break it experienced.

In the end, the n-vent won out in overall toughness, with the PLA++ a close runner-up; though the PLA++ has a leg up in the “ease of printing” category. The standard PLA continues to be a favorite around the office and strong recommendation from our engineers to our users due to the fact that it prints so well and easily. For design and prototyping it does the trick – it’s only once you venture into working prototypes that require some strength or temperature resistance that you may run into issues with it.

In conclusion, each filament has different strengths that lend it well to different applications – it’s all about choosing the right one for your particular project.