Below is the solution to the Monthly Puzzler Chief Hacker presented in our April Newsletter. Want to play? You can sign up to receive our monthly publication by submitting your email address in the sign up at the bottom of re:3D.org. Proposed answers are presented on our forum at: https://re3d.zendesk.com/hc/en-us/community/posts/206262336-April-Puzzler

The Question

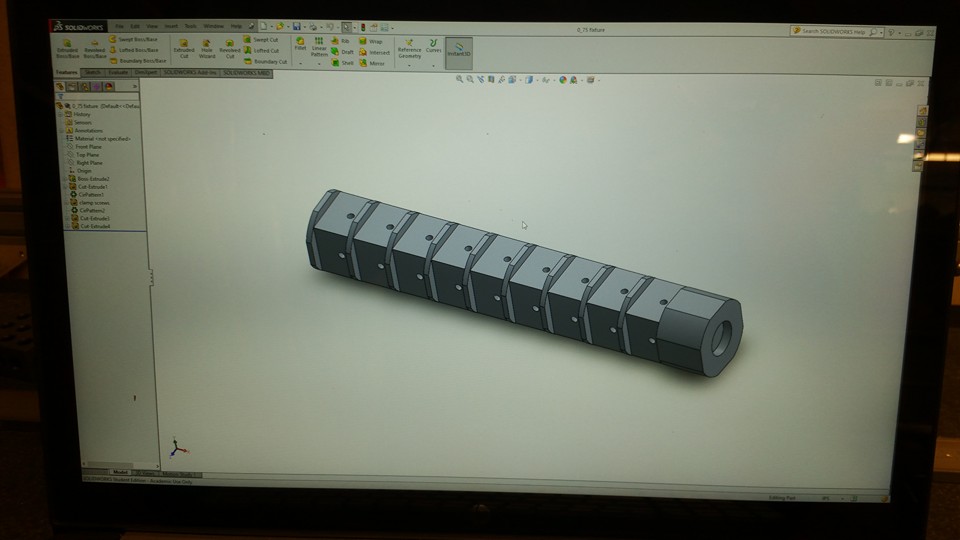

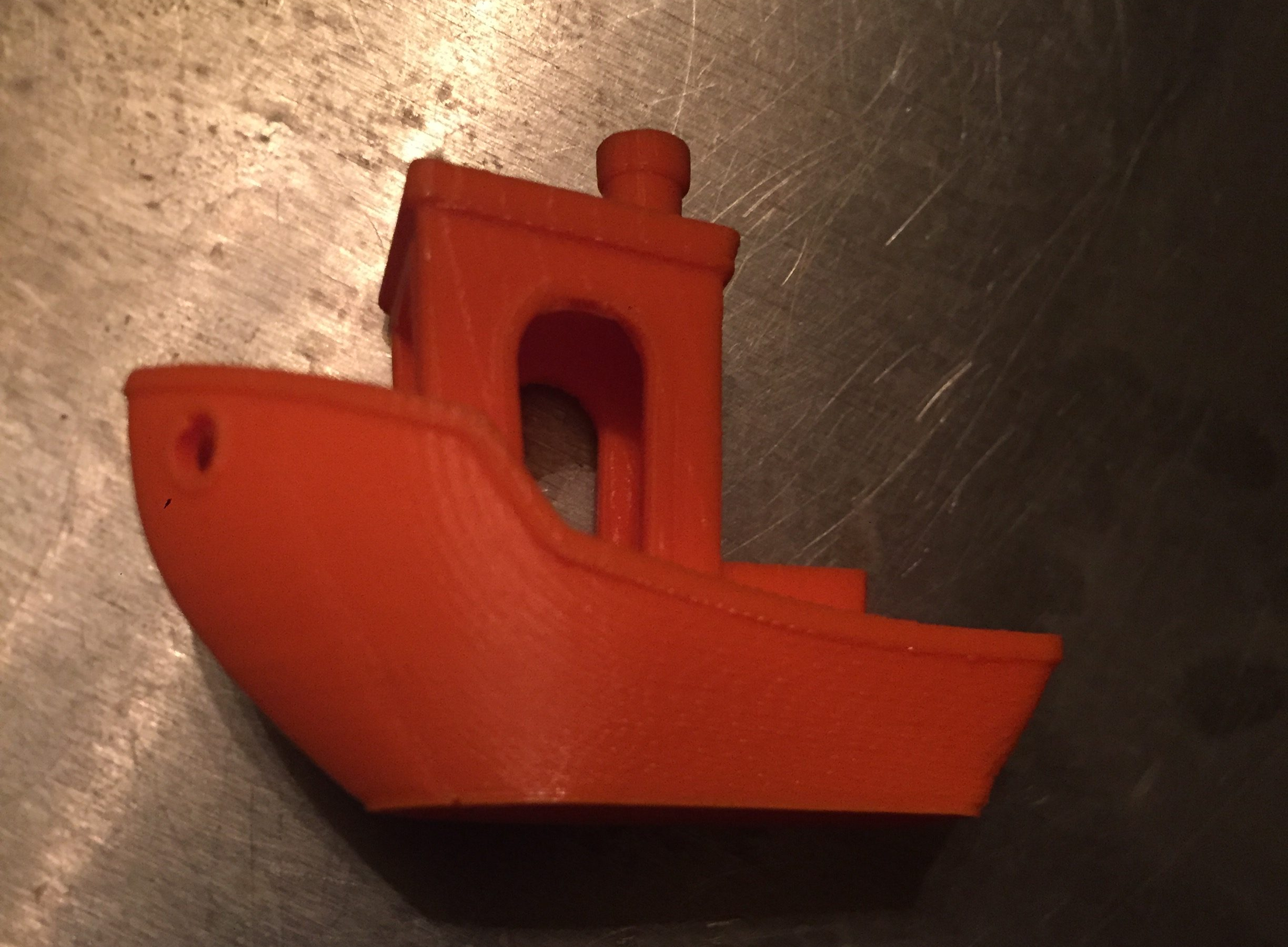

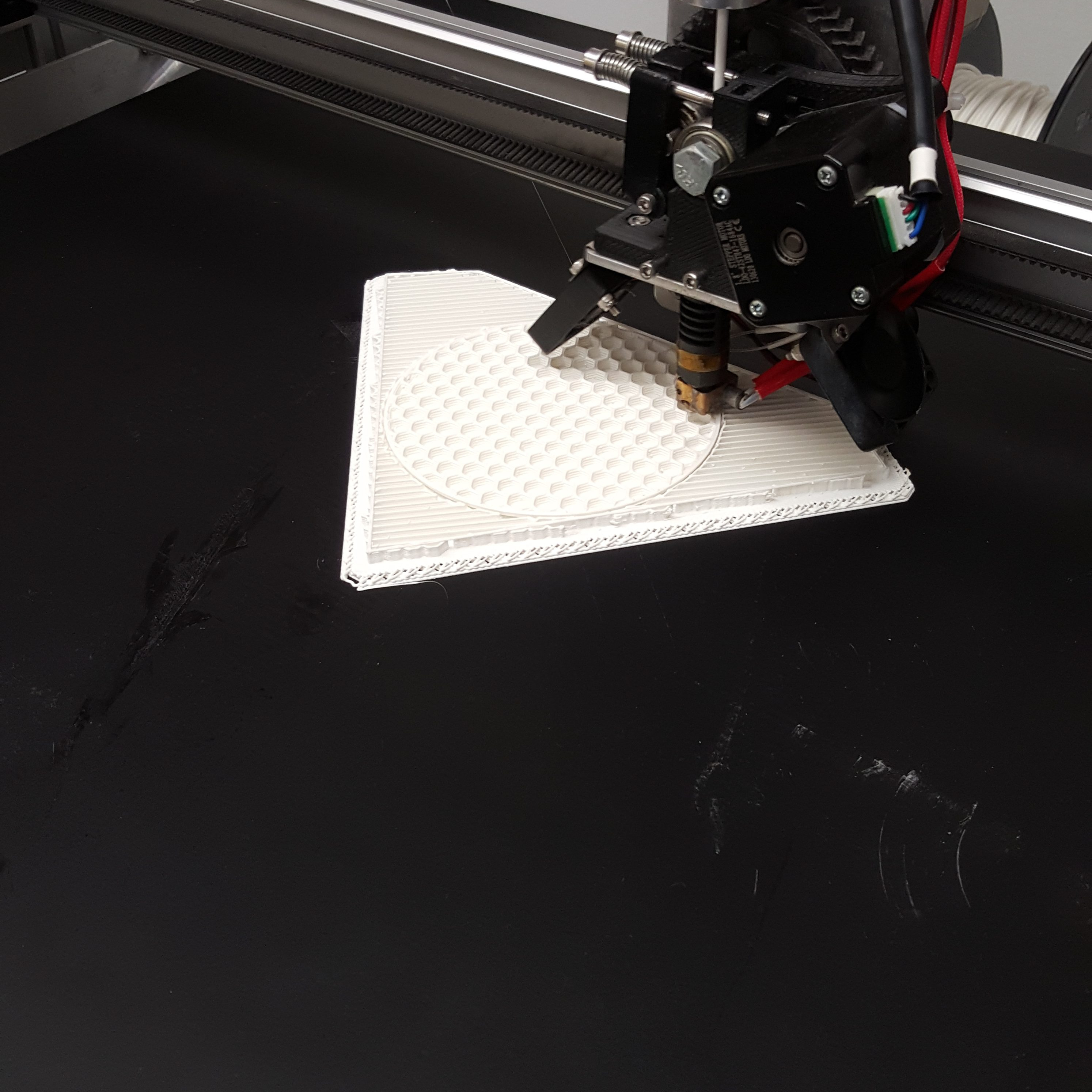

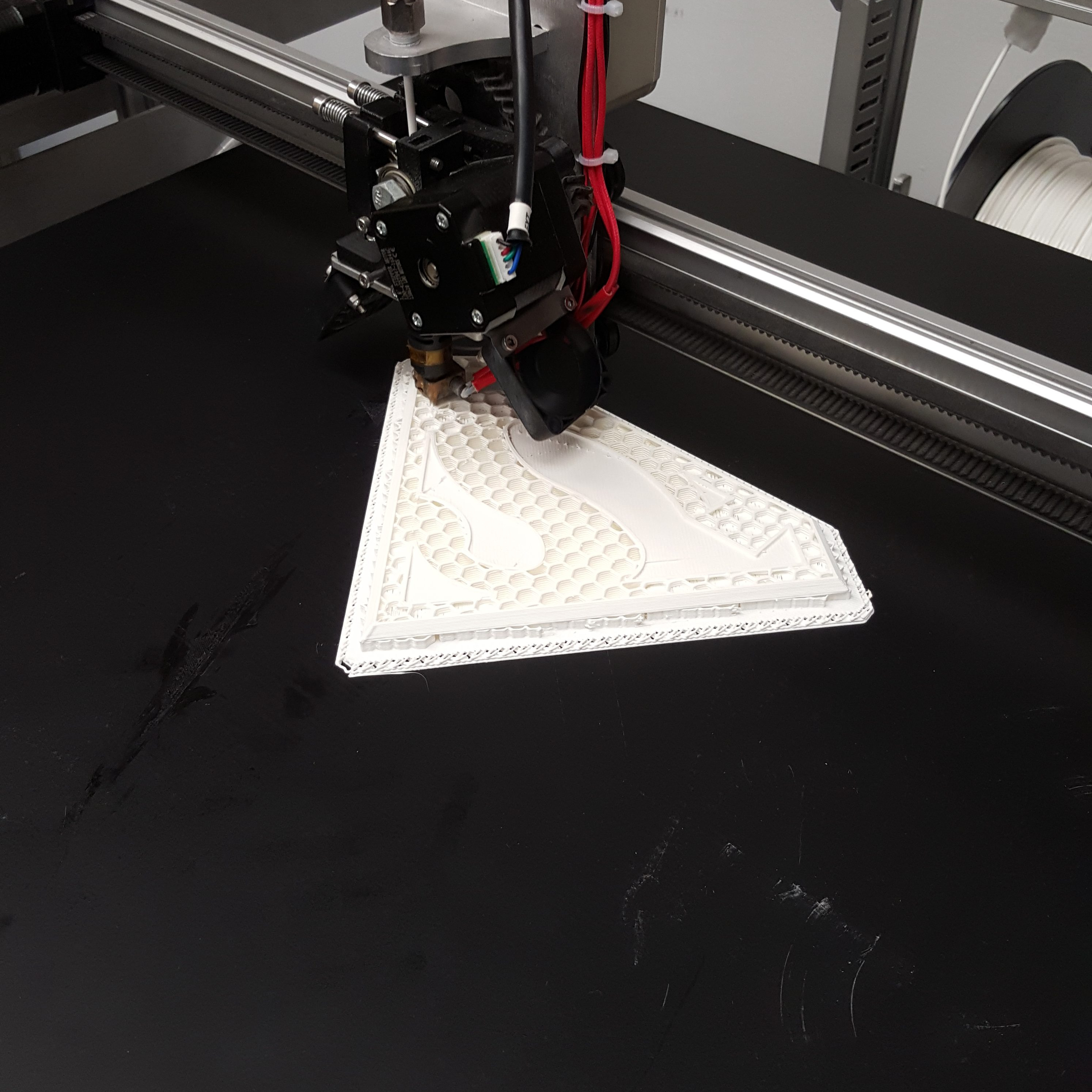

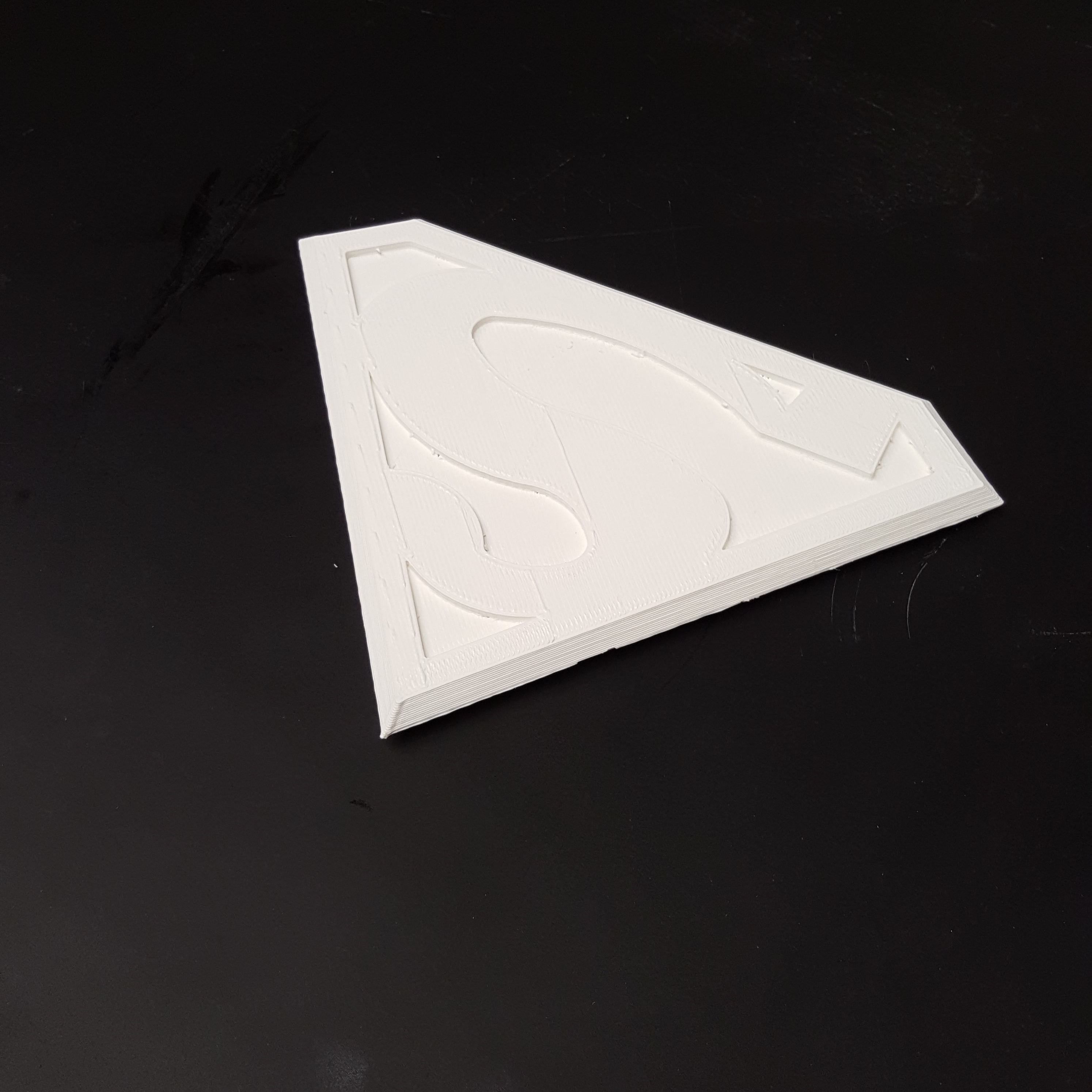

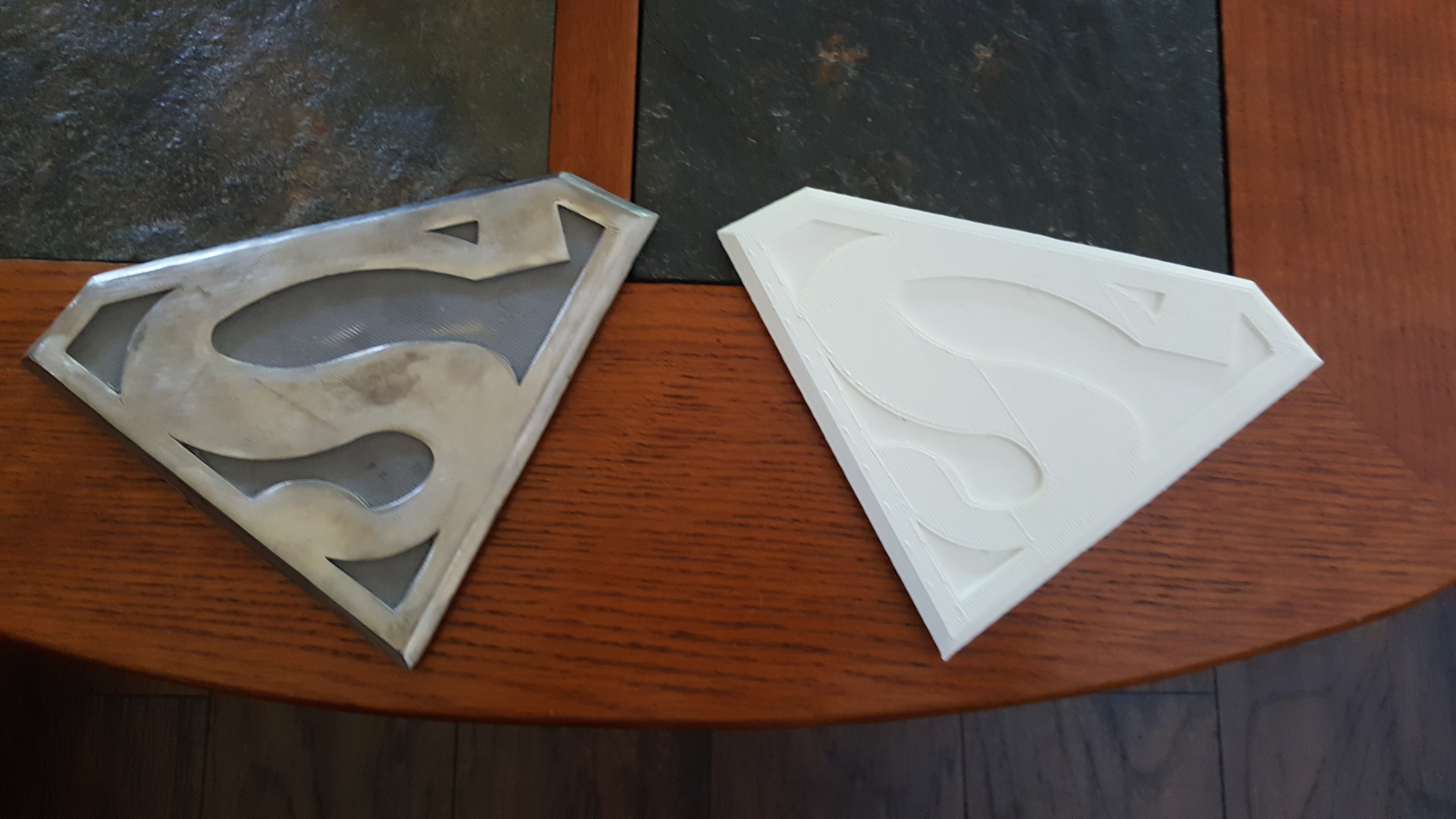

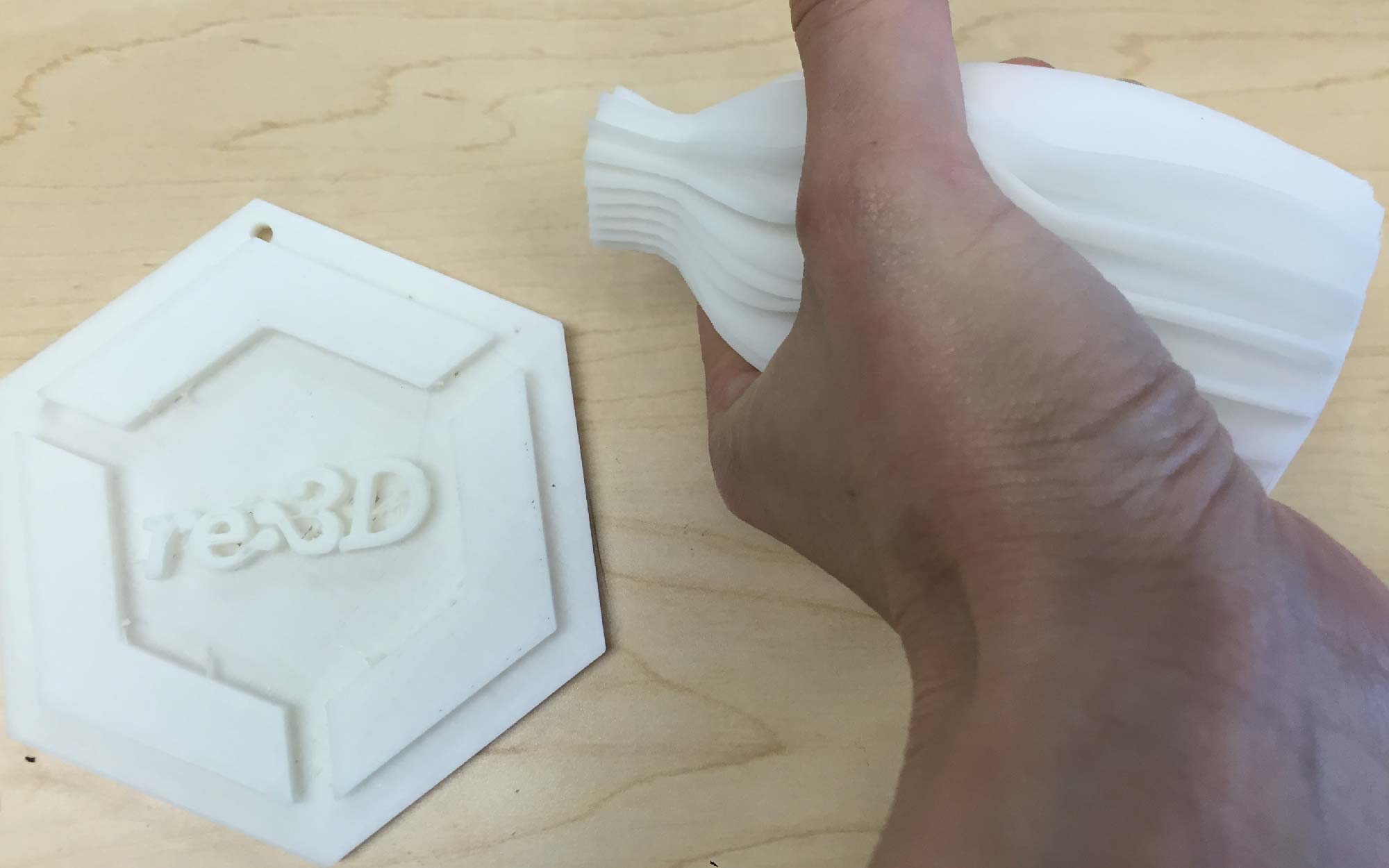

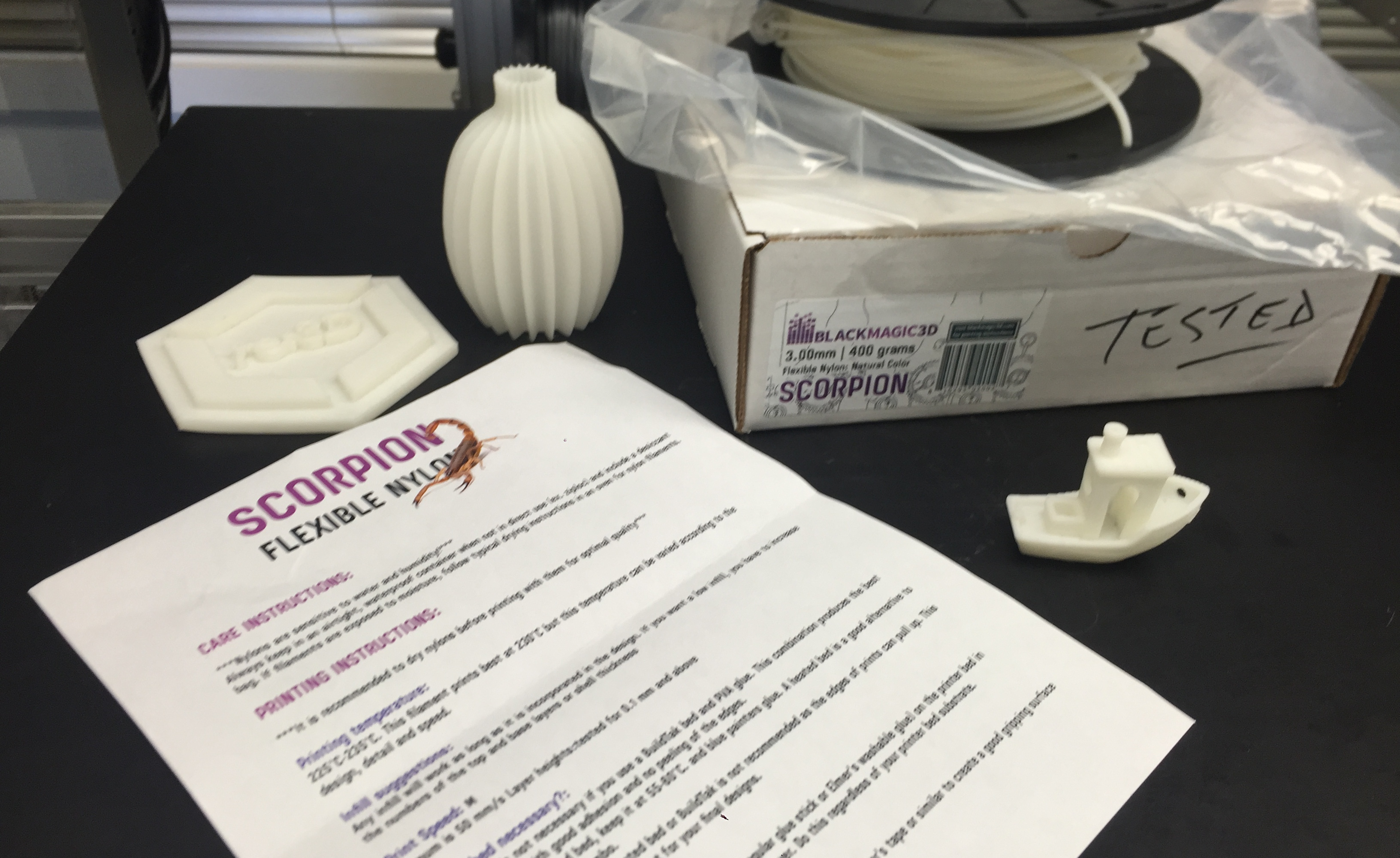

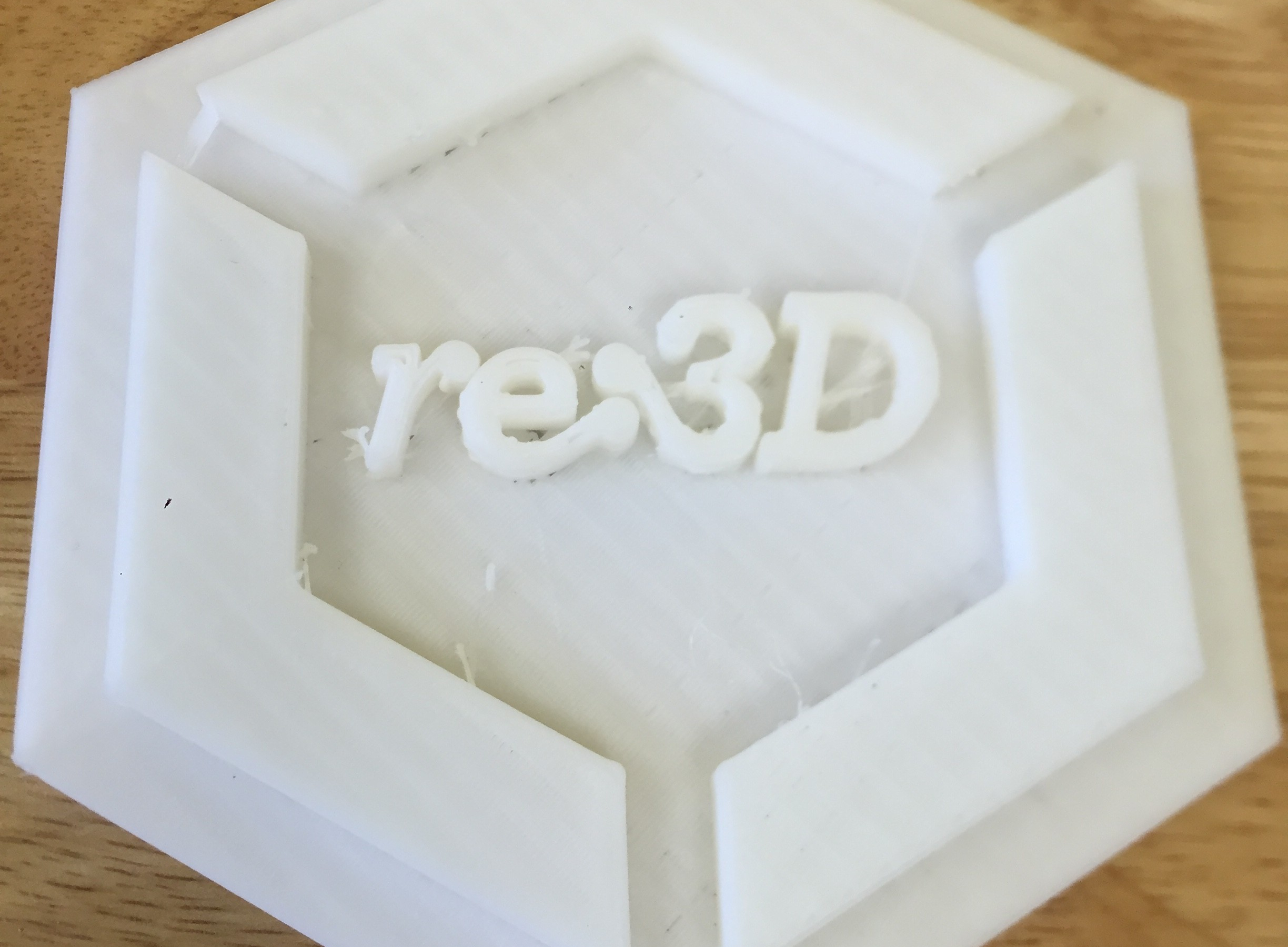

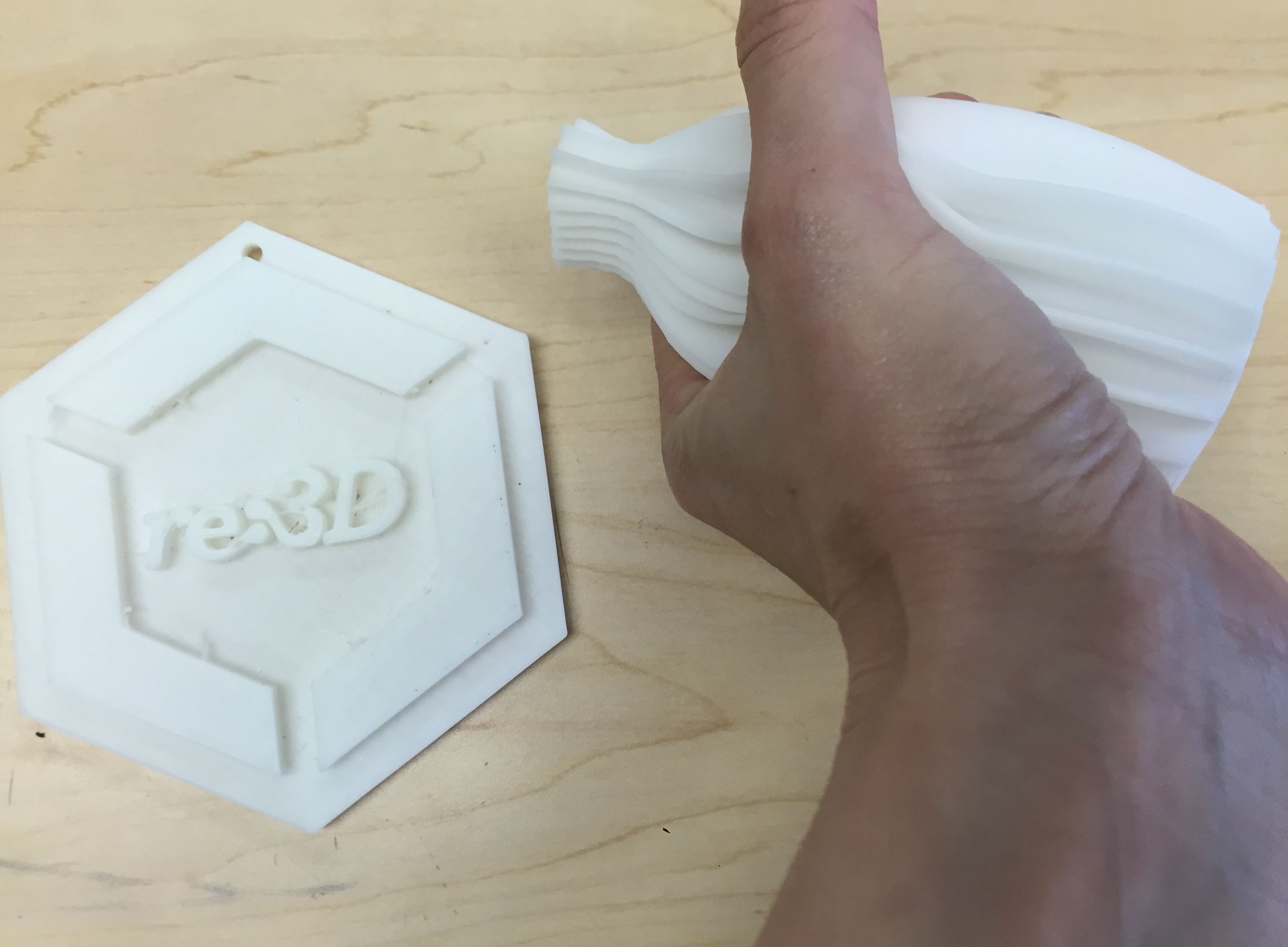

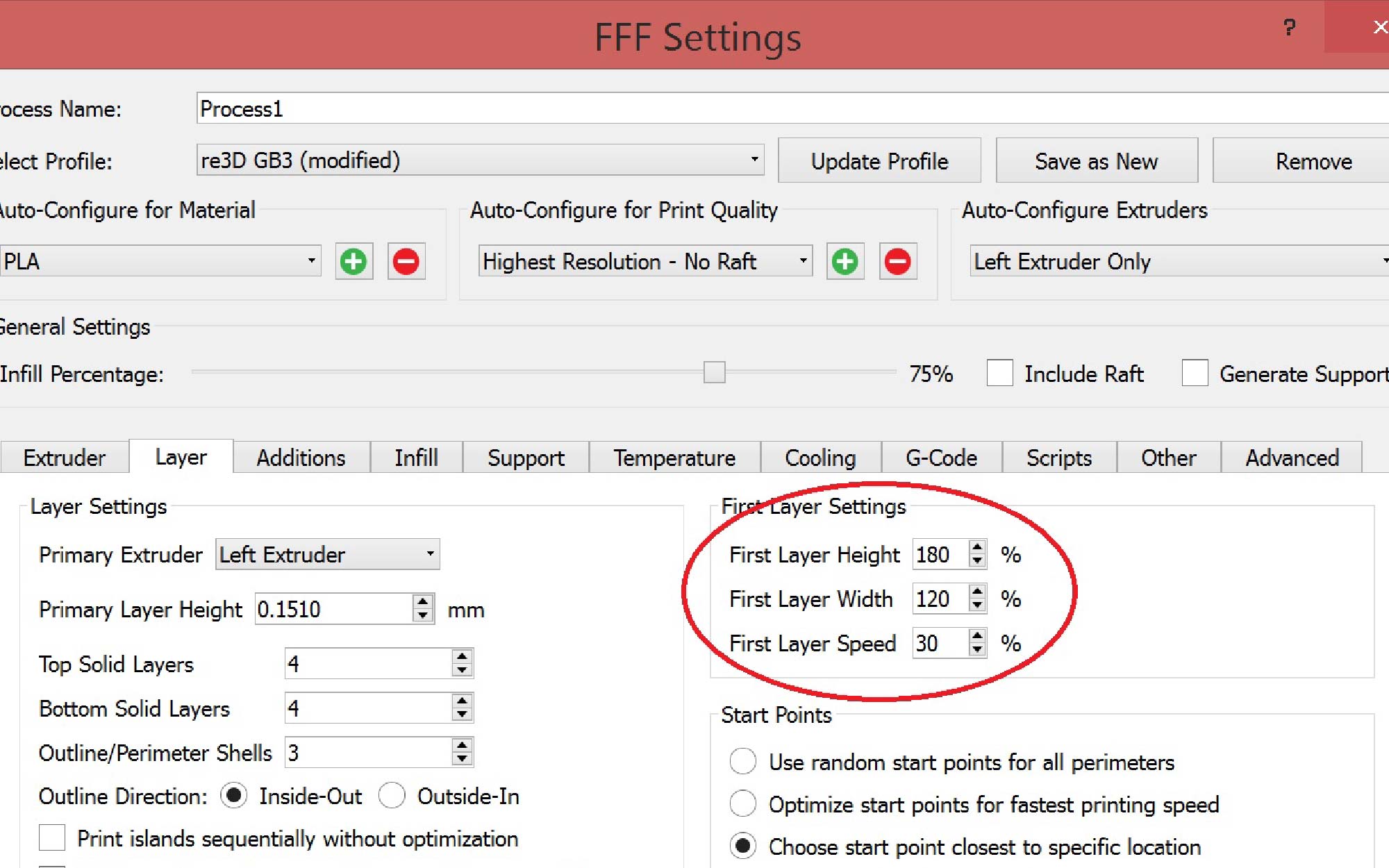

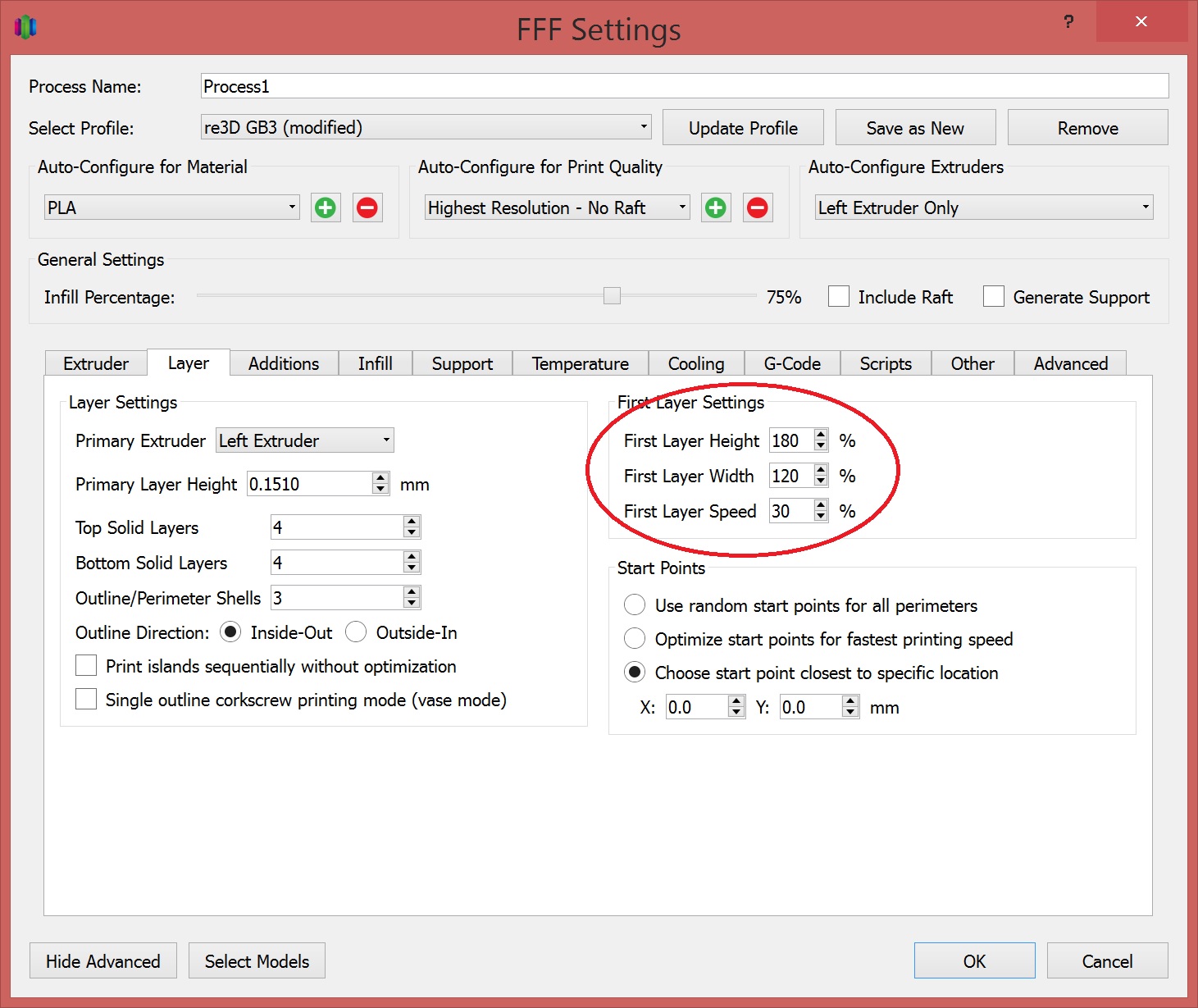

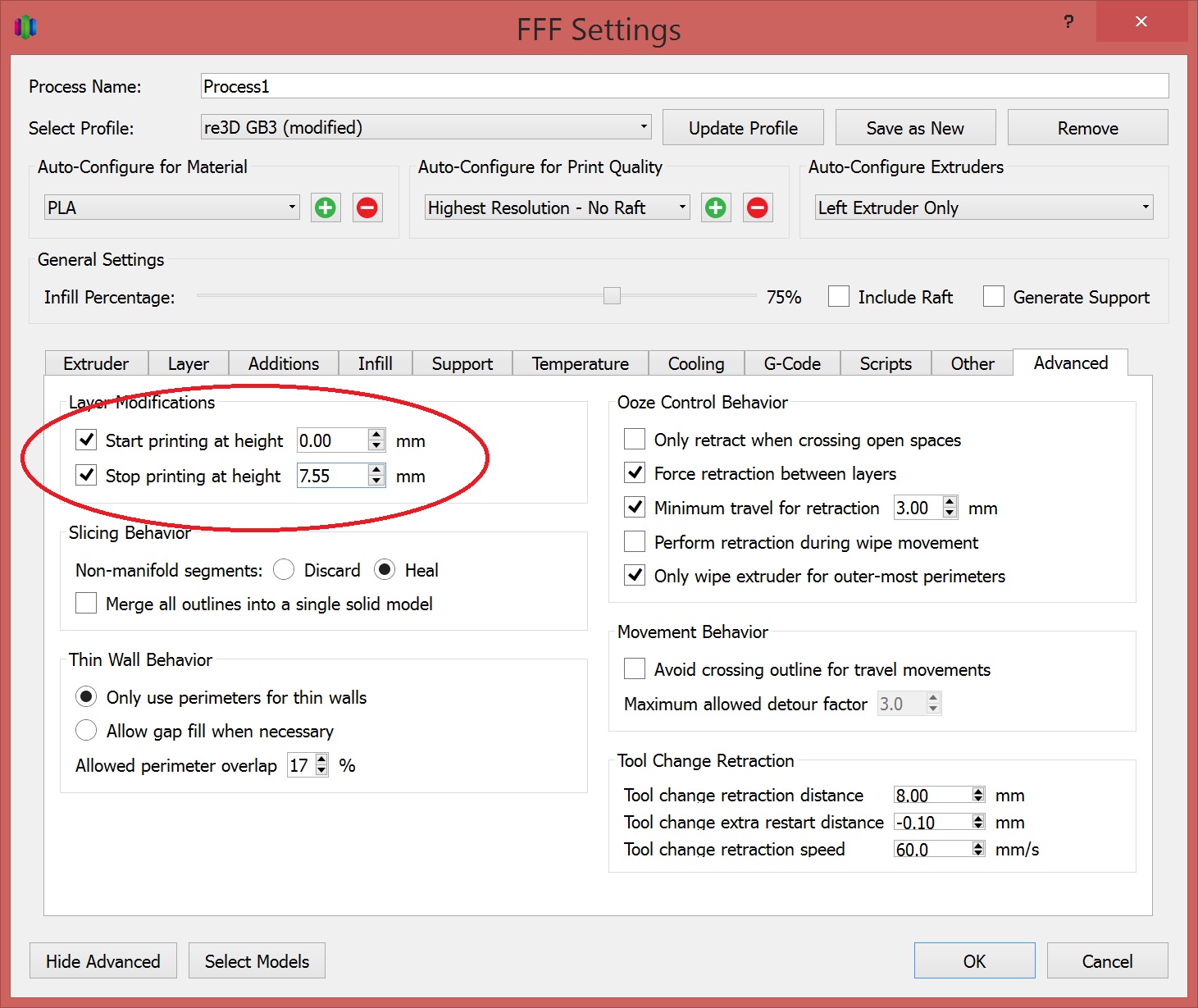

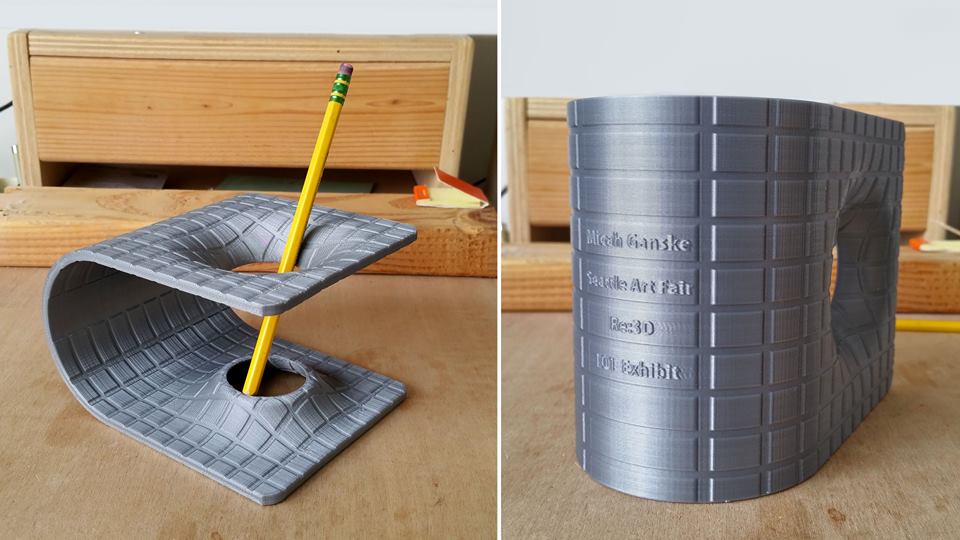

The April puzzler is another print quality mystery. Take a look at the below pictures of an oversized auger screw originally designed for an automated pet feeder. On one side of the auger there is a blemish in the print yet from another view the print shows an excellent surface finish. What is causing the poor print quality on one spot only?

The Solution

The winning answer was presented by whosawhatsis who stated both reasons for the problem.

- Uneven cooling

- Steep overhang with no support

Great job to everyone and keep an eye out for an improved 360 degree cooling feature for the GB3 hot end to give even better printing capabilities!

Happy Printing!

Matthew Fiedler

Blog Post Author