If you find yourself staying at a hotel in the San Francisco Bay Area, there’s a good chance you may see a new face wandering the halls. His name is Relay, and he’s the friendly service robot who will be back…to deliver you that toothbrush you forgot at home.

Relay is the brainchild of Savioke (pronounced Savvy-Oak), a young robotics startup aiming to bring service robots to industries like hospitality, offices, and healthcare.

Currently in several different hotel chains around the Bay Area, Relay is freeing up his human coworkers to do the kinds of things robots can’t (yet), while he takes care of things like room deliveries (and cracking jokes or taking selfies, if you’re so inclined).

Room Service with a Smile

Adrian Canoso is Head of Product and Design at Savioke, and he’s been with them since the start, through the long road of testing and prototyping to get Relay to where he is today.

“We take for granted that we don’t bump into stuff – normally — when we walk around,” he explains. “From a robotics perspective, that’s a lot harder to do.”

With safety at the core of the product, Savioke had to ensure that Relay was able to maneuver through spaces with not only stationary objects, but also us unpredictable humans. A big part of this, Canoso explains, is rooted in peoples’ ability to understand Relay.

“When people look at robots and robots aren’t communicating in the right way, they might think it’s creepy, because they don’t know what it’s thinking,” he says.

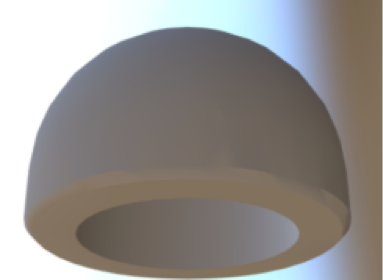

What this translates into is a lot of research and focus on design. From Relay’s touchscreen face which always tells you “who he is, what he does, and what he’s doing,” to the slight upward curve underneath his screen which forms his smile, every detail has been carefully thought-out.

“These little things came out of a ton of research that we had done in the past,” Canoso explains. “We’ve worked really hard to make sure we came up with a really simple way for Relay to communicate what he’s thinking. That helps people to empathize with [him].”

This empathy serves the dual purpose of helping people to become comfortable around the new robotic face, as well as aiding Relay in his tasks. His “pet-like form,” for example, helps Relay to easily enter elevators – people will hold the door for him, because, as Canoso puts it, “He looks kind of cute.”

And it’s true: from the friendly sounds he makes, to the happy dance he does when you give him a good rating after a delivery, Relay is a decidedly good-guy bot.

“That’s at the center of our product: making sure that people feel comfortable around our robots,” says Canoso.

The Prototyping Problem

As a young startup with an in-development product, Savioke needed the ability to prototype rapidly and often. As anyone who’s been in this position can attest to, options for young, often cash-strapped companies can be limited and far from ideal.

“We didn’t want to have to force ourselves into low-volume manufacturing,” Canoso says.

He explained that the options they faced for prototyping were between vacuum forming or high-end 3D printing services that were prohibitively expensive.

“From a workflow perspective, we needed speed, and if we had to go with another vendor – an external source – for making these parts, I think cost would’ve been just way too prohibitive,” he recounts. “We wanted to make sure that we were iterating in-house on almost a daily basis.”

With the form of their robot in near-constant evolution, they needed the ability to stay nimble from a design perspective.

“We wanted to make sure that we were doing one-offs…committing to tooling at the time just didn’t make sense at all from a financial or time-frame perspective,” he explains.

The Birth of Relay

Canoso’s past with 3D printing stretches back to grad school where he got his feet wet with a high-end, industrial 3D printer.

“It was pretty cool to use that to prototype projects that I was working on, but the problem is that it was really time-consuming, really expensive.” He recalled the beauty and also frustration of working with the high-quality, powder-based 3D printer. “You’d go to grab your model out of the printer and there’d be nothing there because there was some error in the mesh.”

At Willow Garage, the robotics research lab out of which Savioke was born, they had a similar 3D printing setup to Canoso’s university experience.

“We had a lot of resources at the time, so we could afford to get a really expensive printer, and we thought that was a good choice.” But Canoso explains that the process was time-consuming, parts took a lot of post-processing to get a good finish, and oftentimes they would warp.

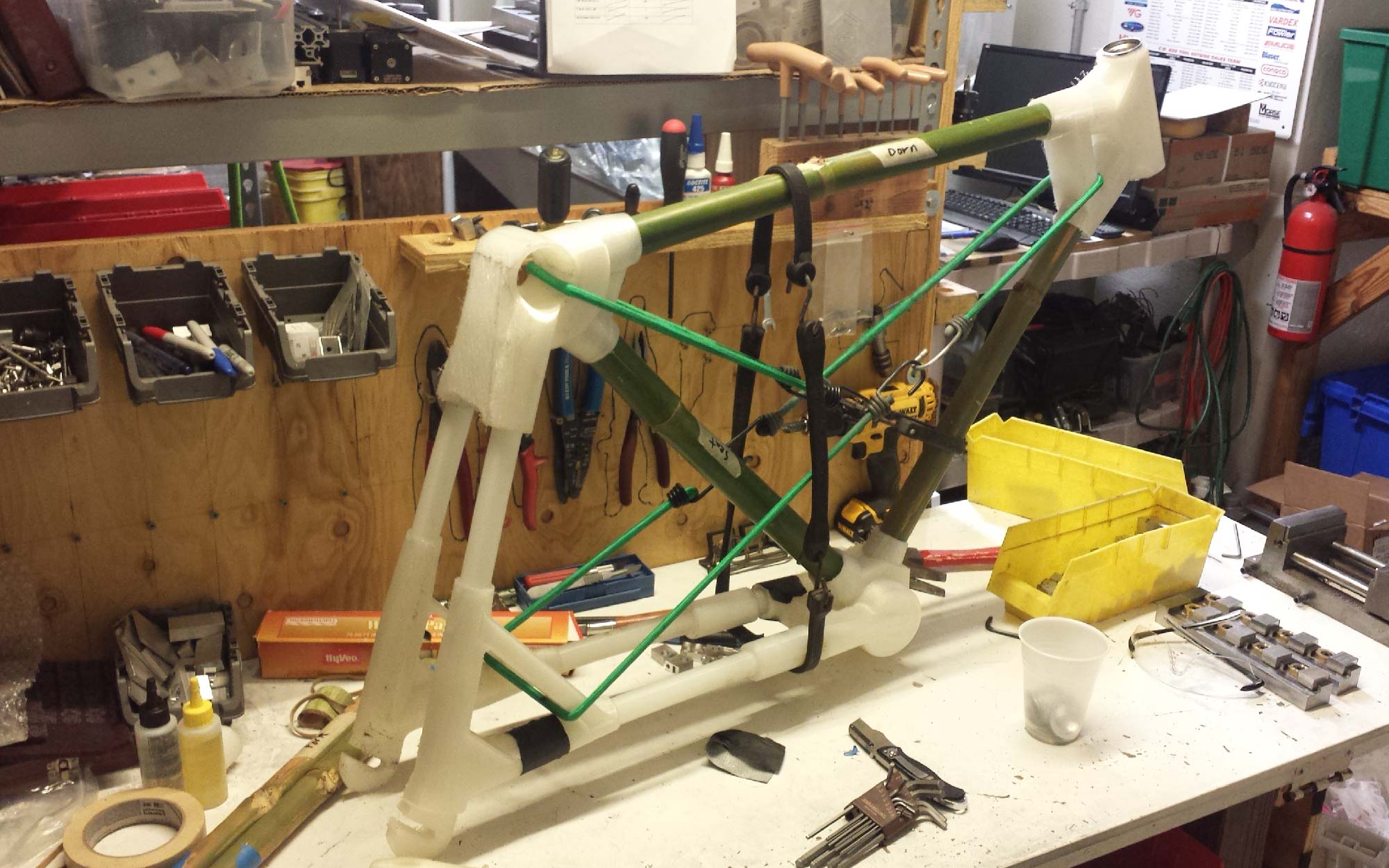

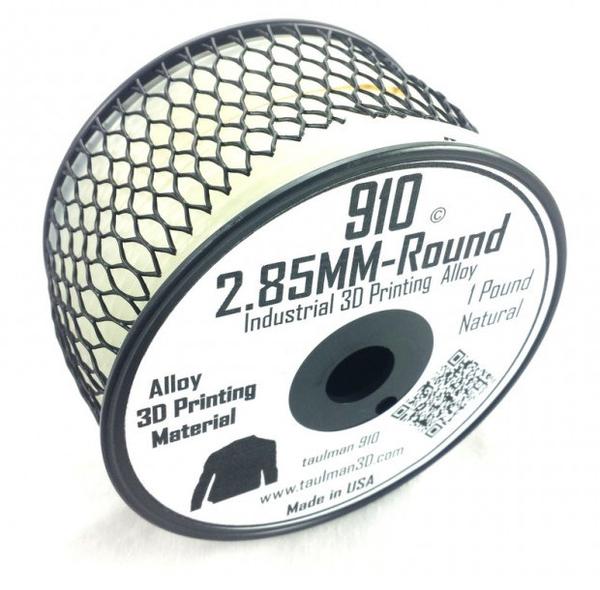

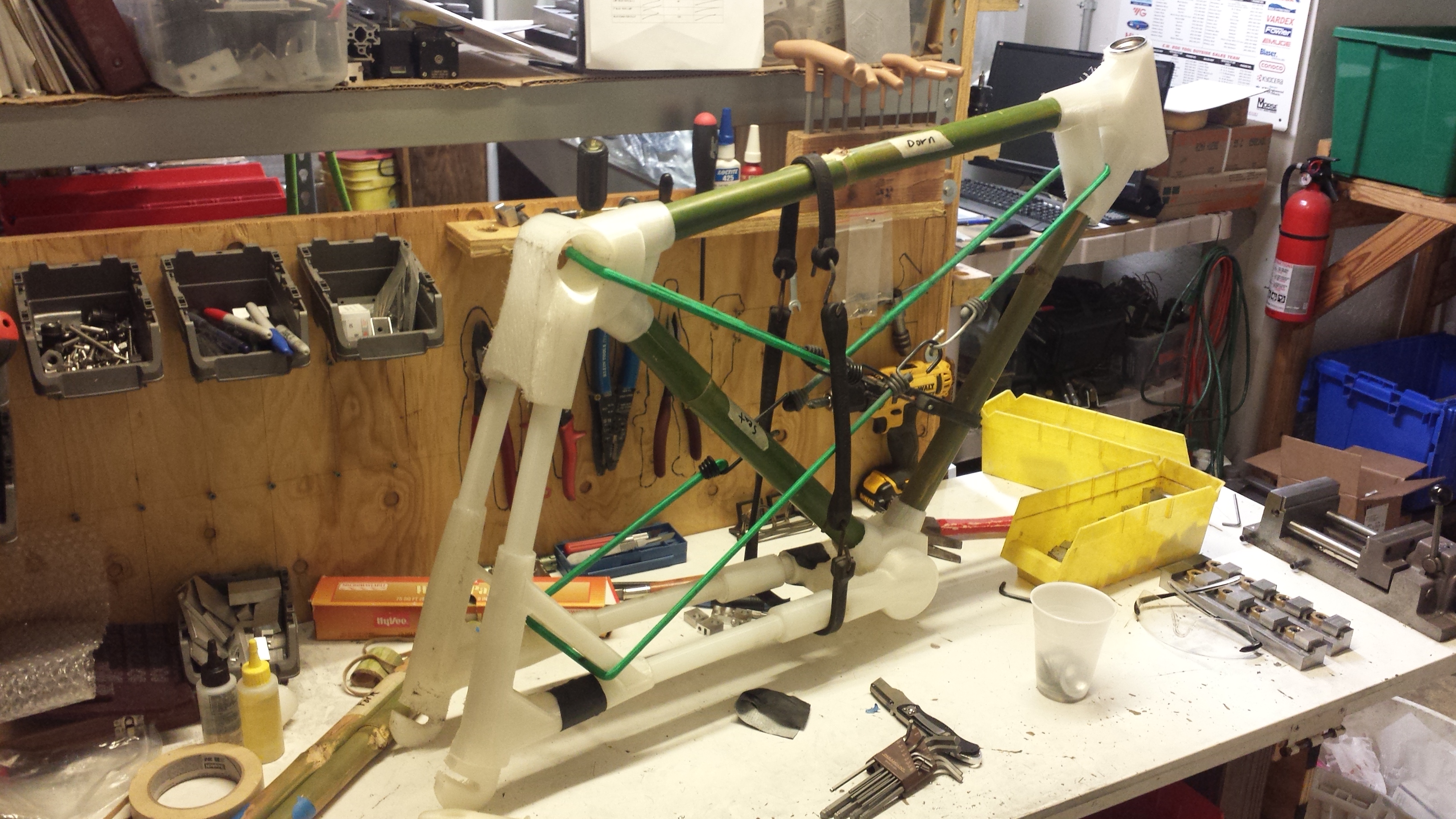

“It turns out,” he says, “that as an industrial designer that’s doing a lot of prototyping, FDM is actually a really great process.” From the material options, to limited post-processing and minimal warping, they found it to be ideal for robot prototyping.

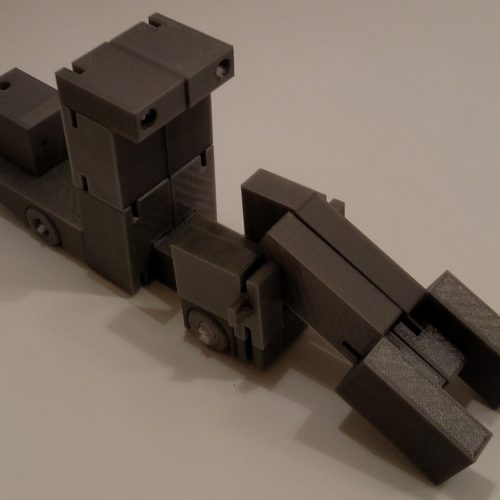

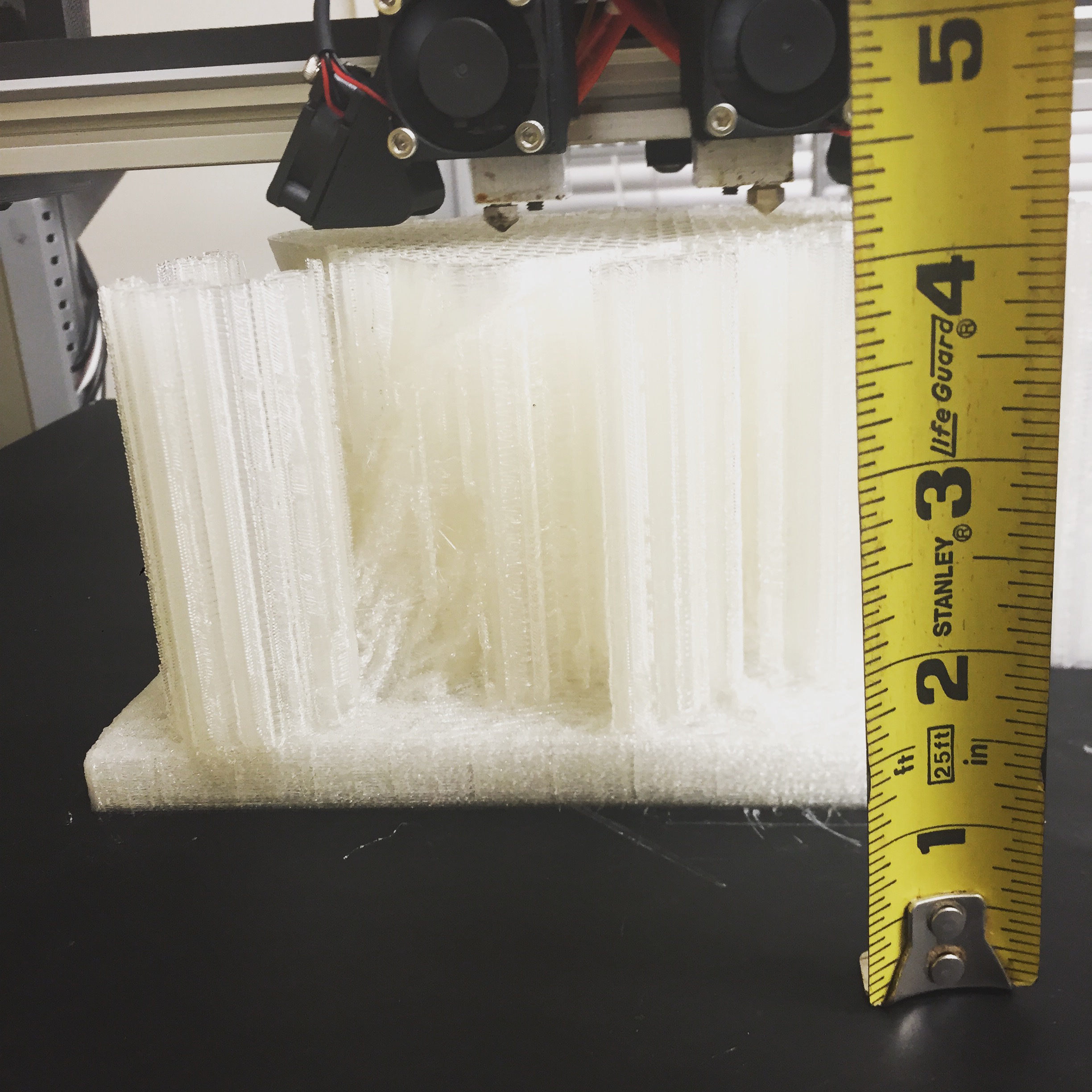

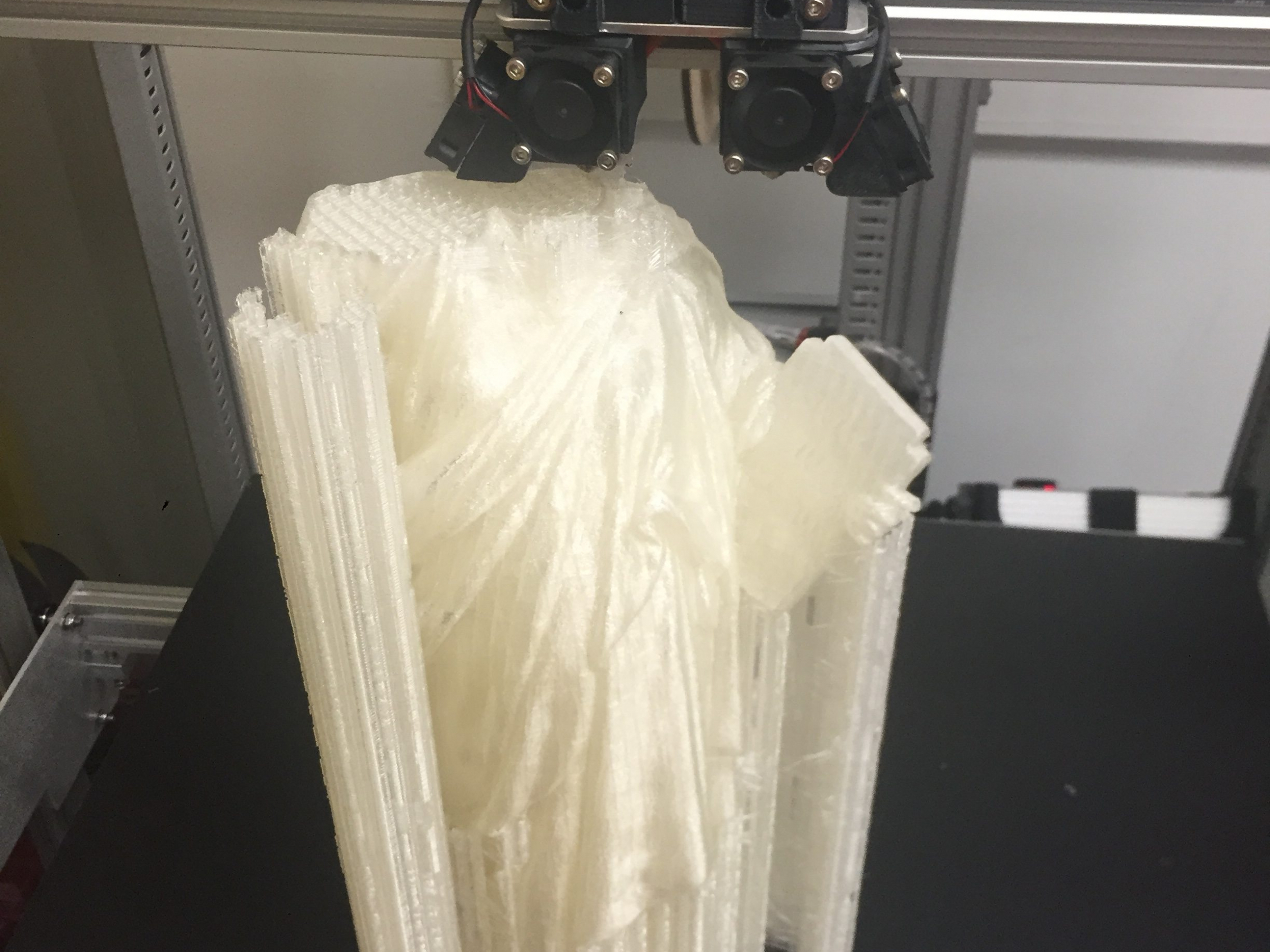

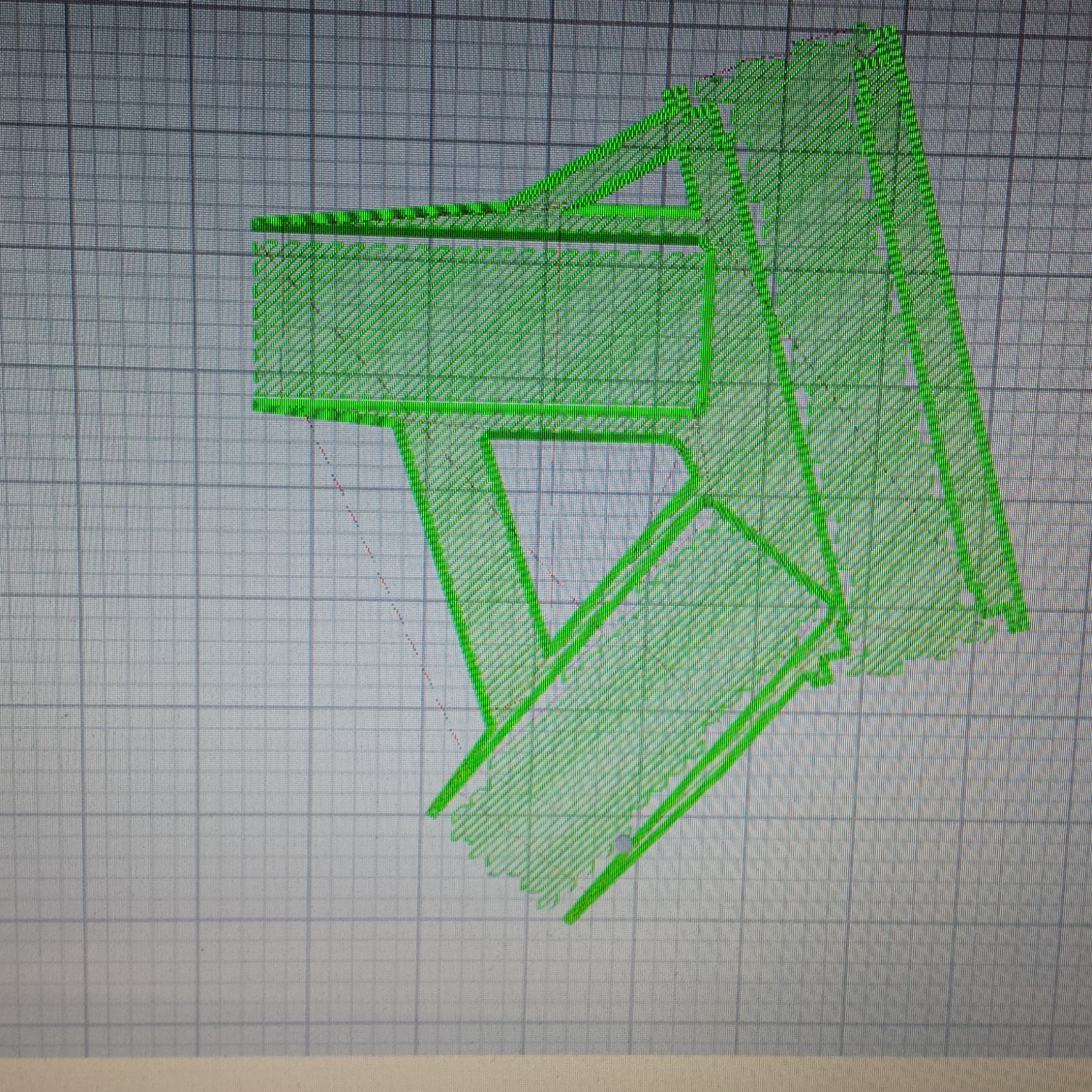

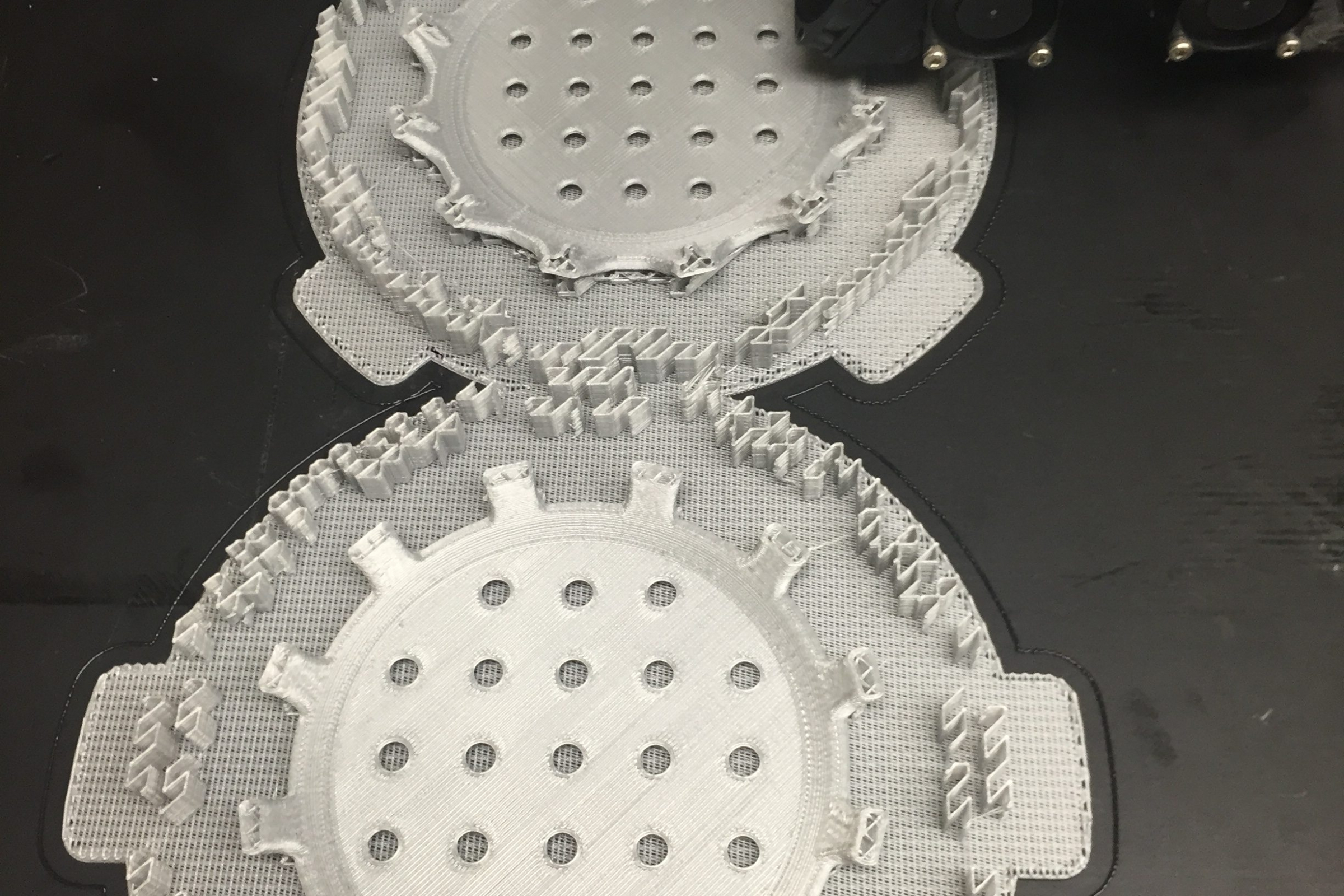

At Savioke, they began the prototyping stage with foamcore, ultimately graduating to CAD and 3D printing when they began to nail down the design of the robot. When they outgrew the build volume of the desktop printers they were using, they began searching for something that could accommodate the two-foot-plus-tall shell of their robot.

“That’s when we saw the Gigabot show up on Kickstarter,” Canoso recounts, “and we were like, ‘Oh my God, that’s really what we need.’”

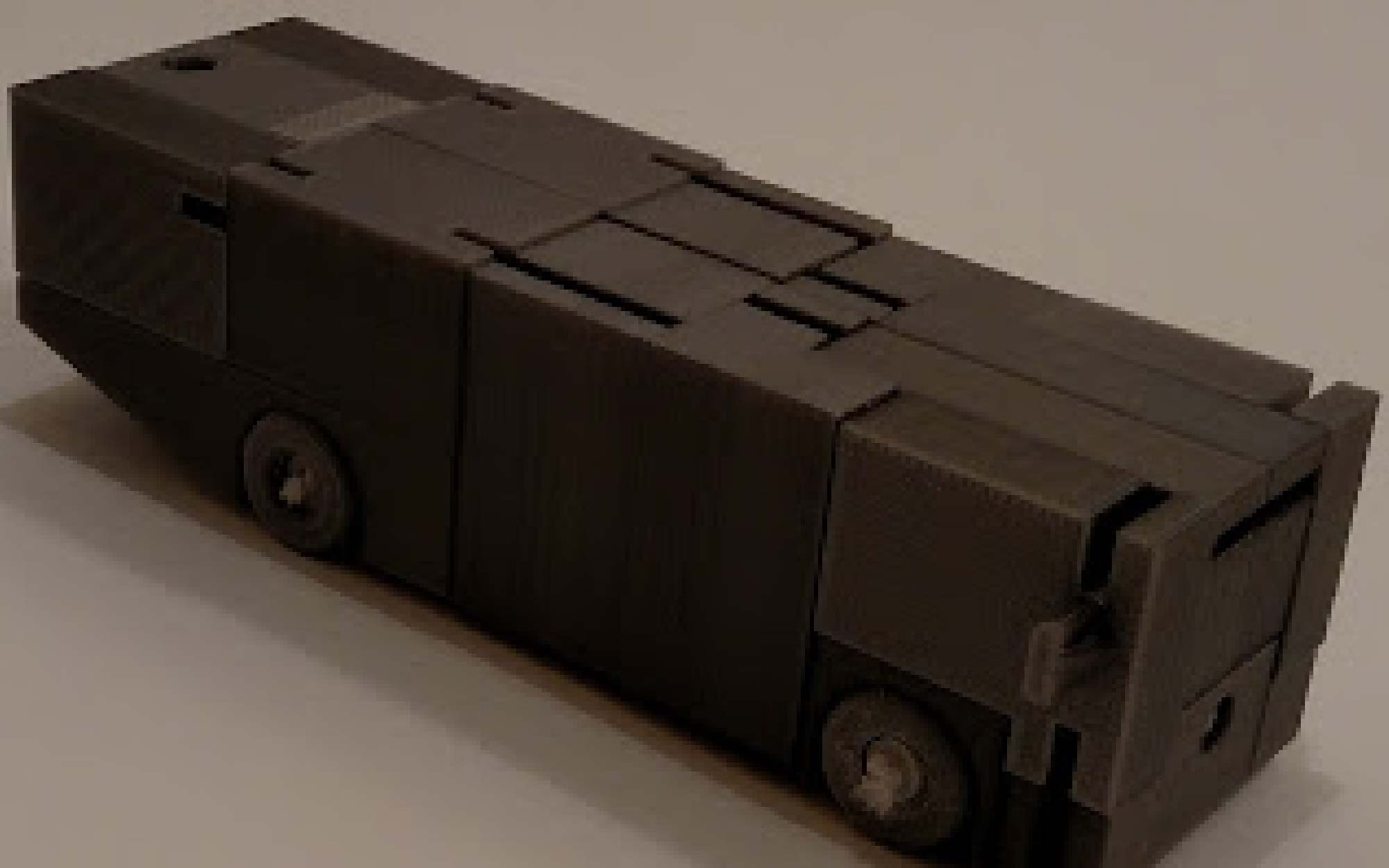

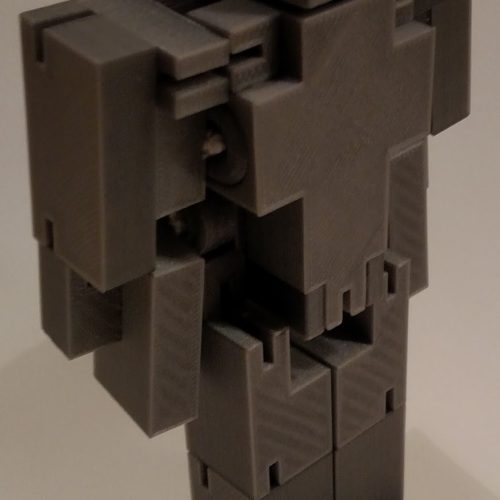

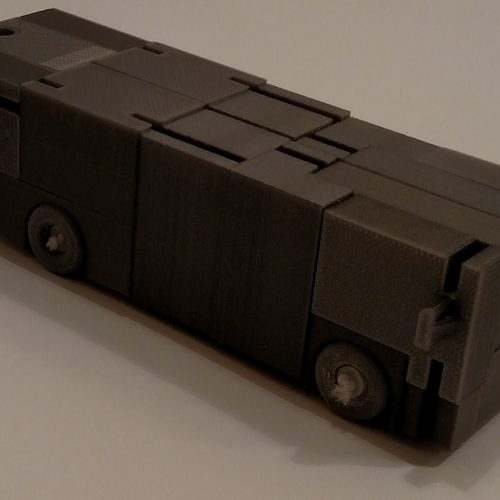

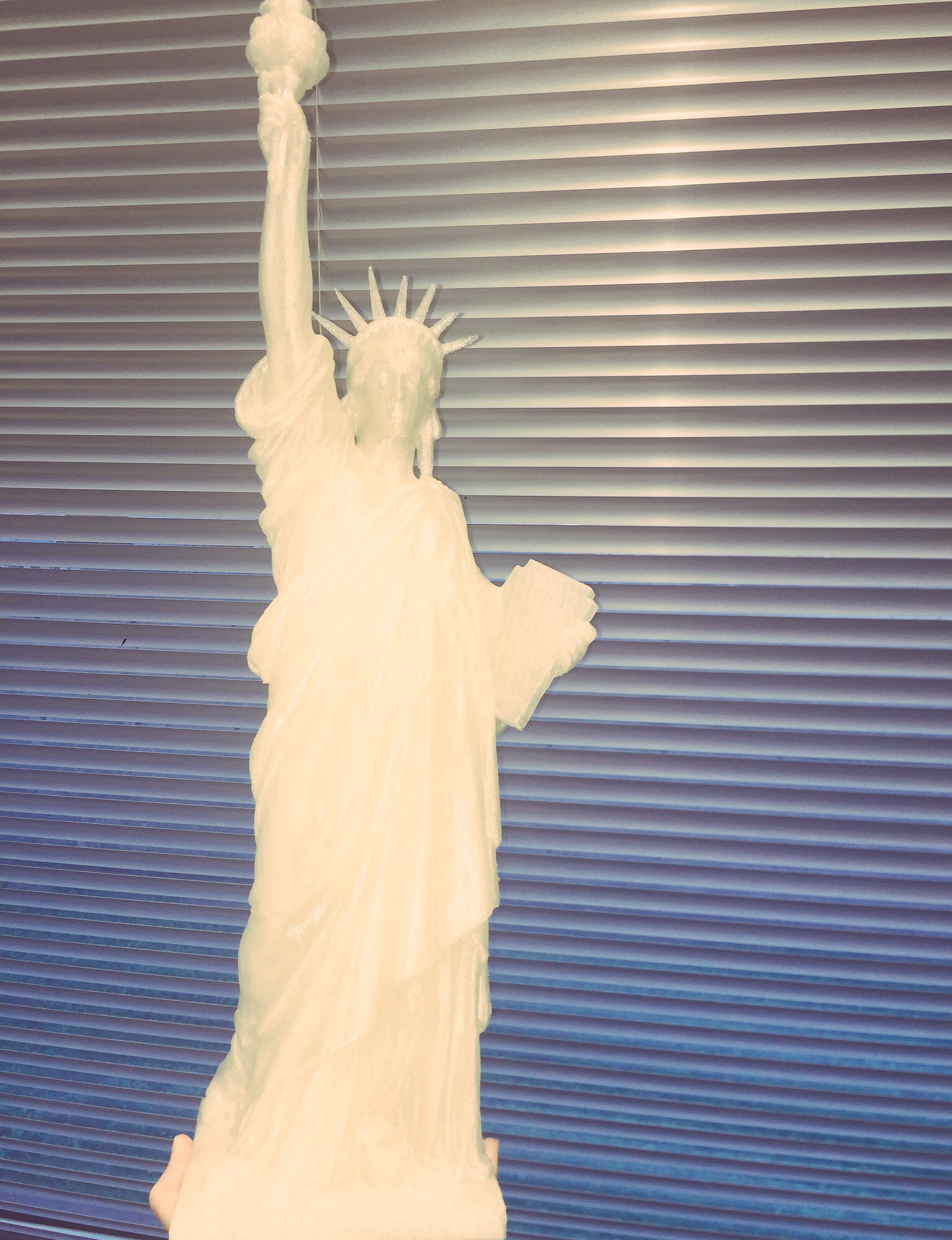

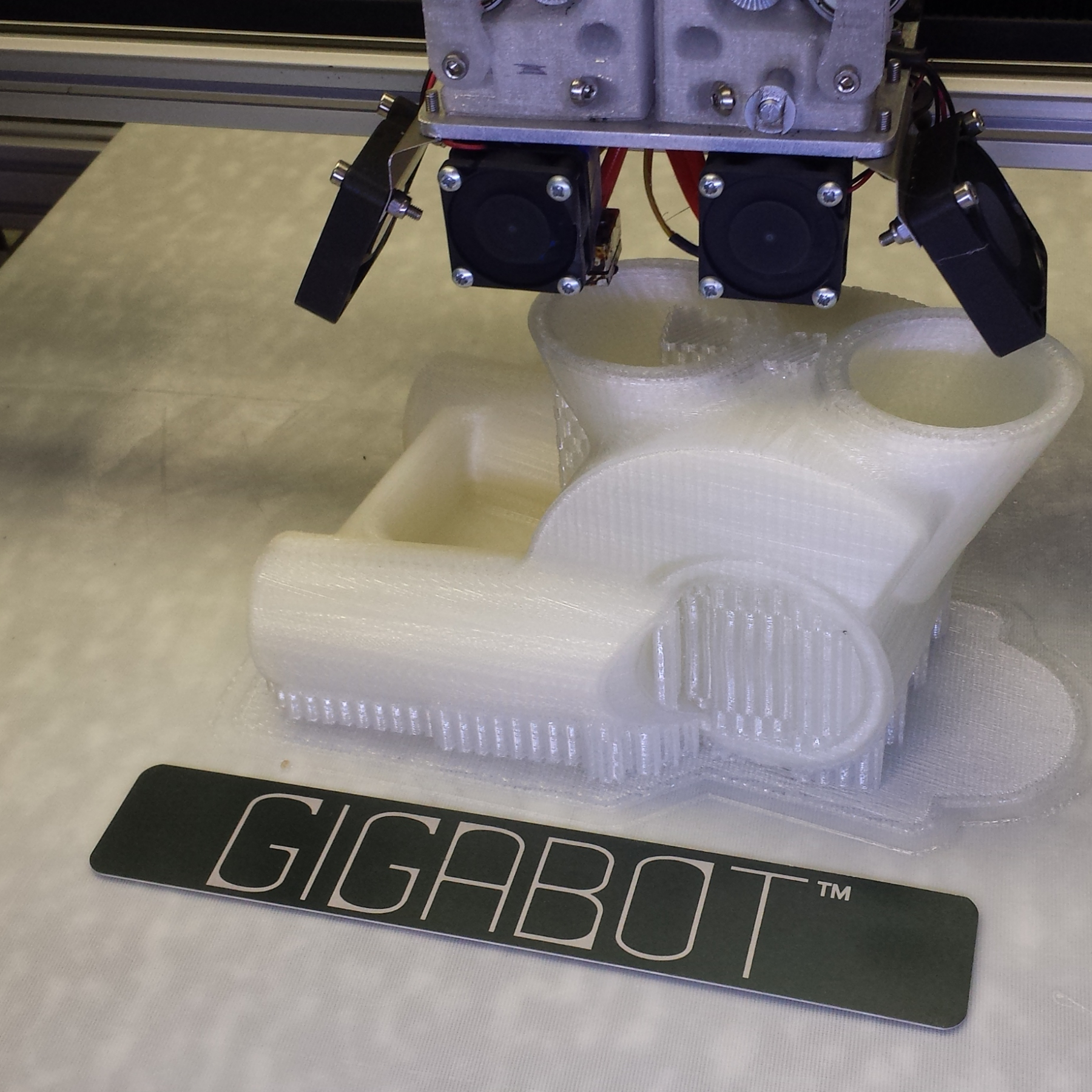

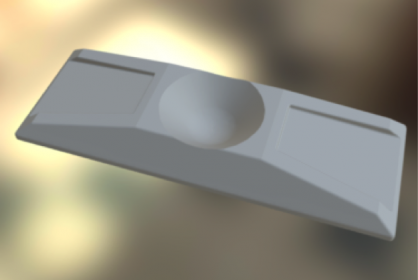

For the first batch of prototypes for hotel pilots, Savioke used Gigabot to print the full outer torso panels of the robots, achieving a final-manufactured look through some in-house post-processing. “The impression we consistently got is that we used a more elaborate process,” Canoso commented.

They also use Gigabot to print the entire bottom portion of the robot: a top and bottom piece which encase the mechanical base. “Those pieces were printed in one shot, which was awesome,” Canoso remarks. “[Gigabot] allowed us to just iterate as fast as we needed to.”

To date, Savioke has completed over 15,000 fully-autonomous deliveries, and is expanding to more hotels in the coming months.

You can follow Savioke at @savioke, and Adrian at @Adrian_Canoso

Morgan Hamel

Blog Post Author