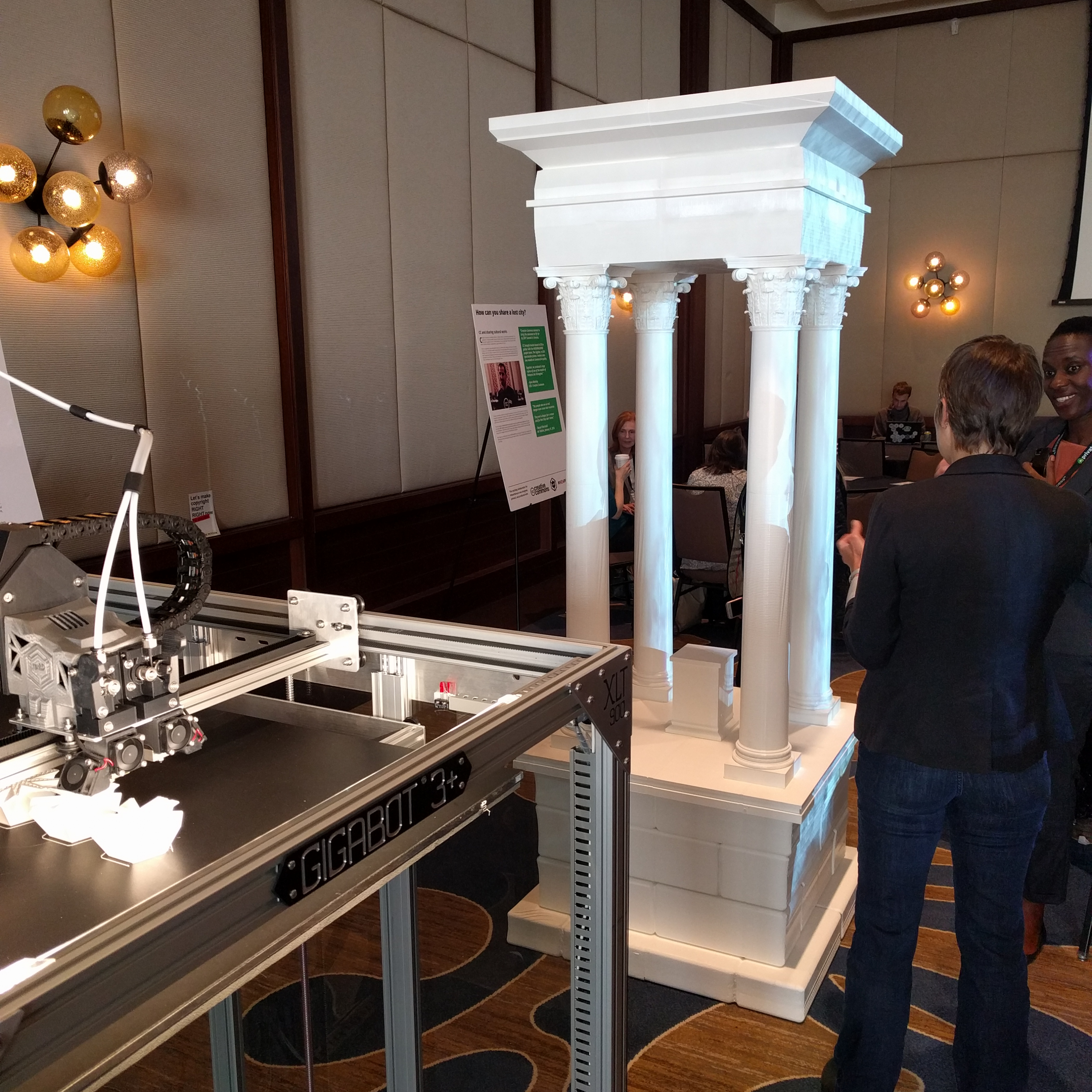

The piece that Creative Commons decided to bring to life for the Summit was the impressive Tetrapylon, one of four massive quad-column structures which mark the route of a road or central place in the city. These large structures were destroyed by ISIS in January of this year, as reported by The New York Times.

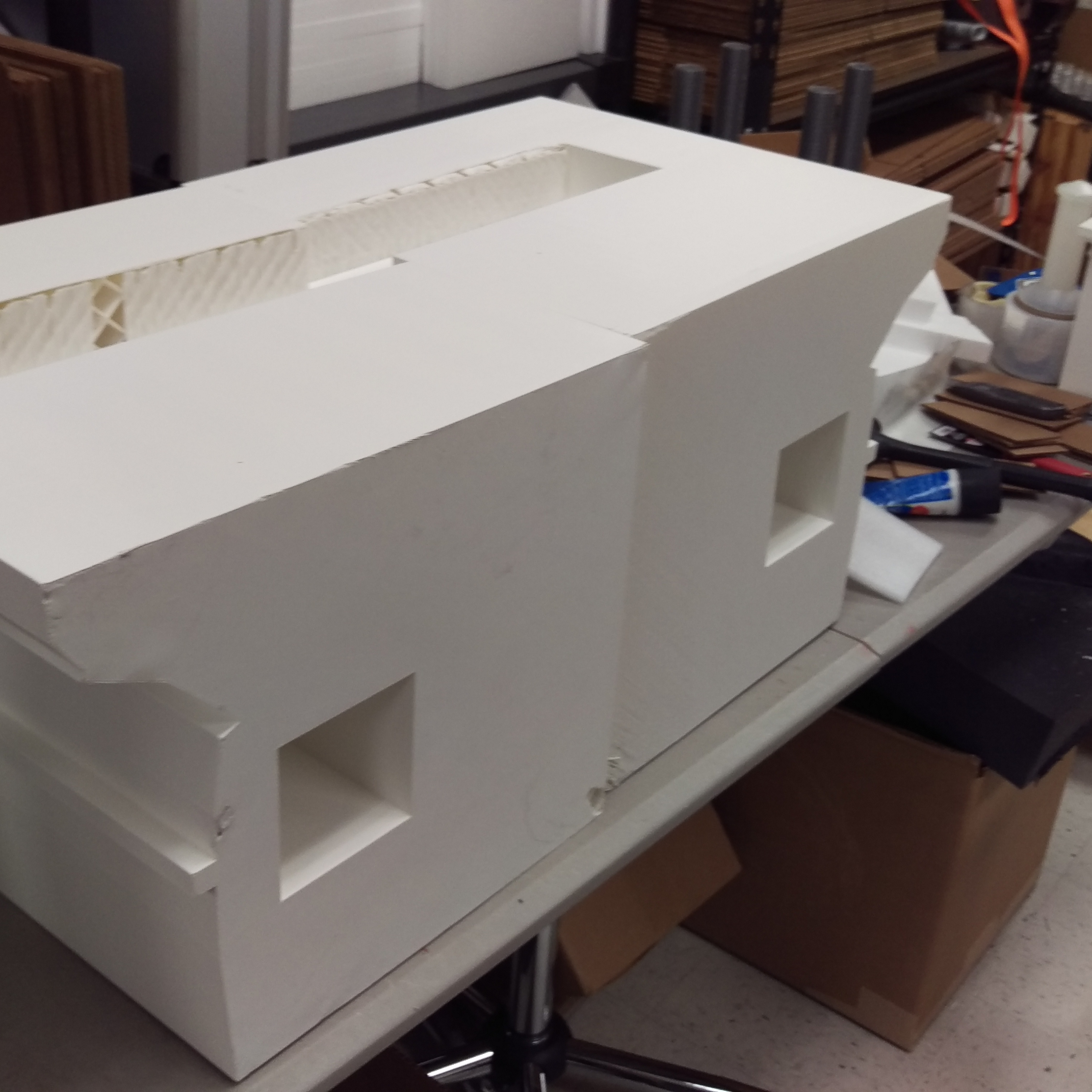

Creative Commons was looking for a machine capable of producing a version of one Tetrapylon which did testament to its immense real-life scale, which is how Gigabot entered the equation. We reconstructed a scaled-down Tetrapylon standing seven and a half feet tall and weighing in at over 200 pounds (90+ kg).

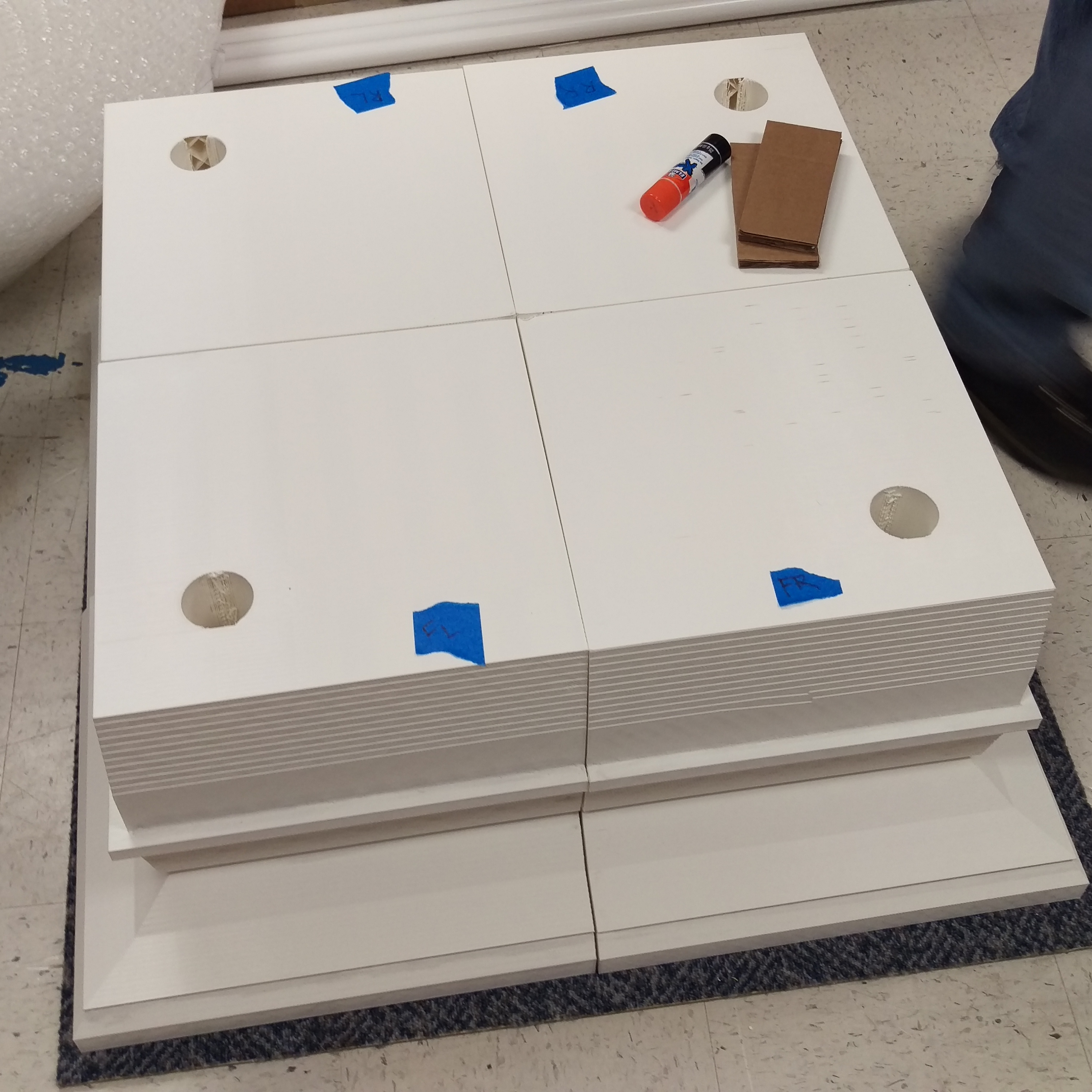

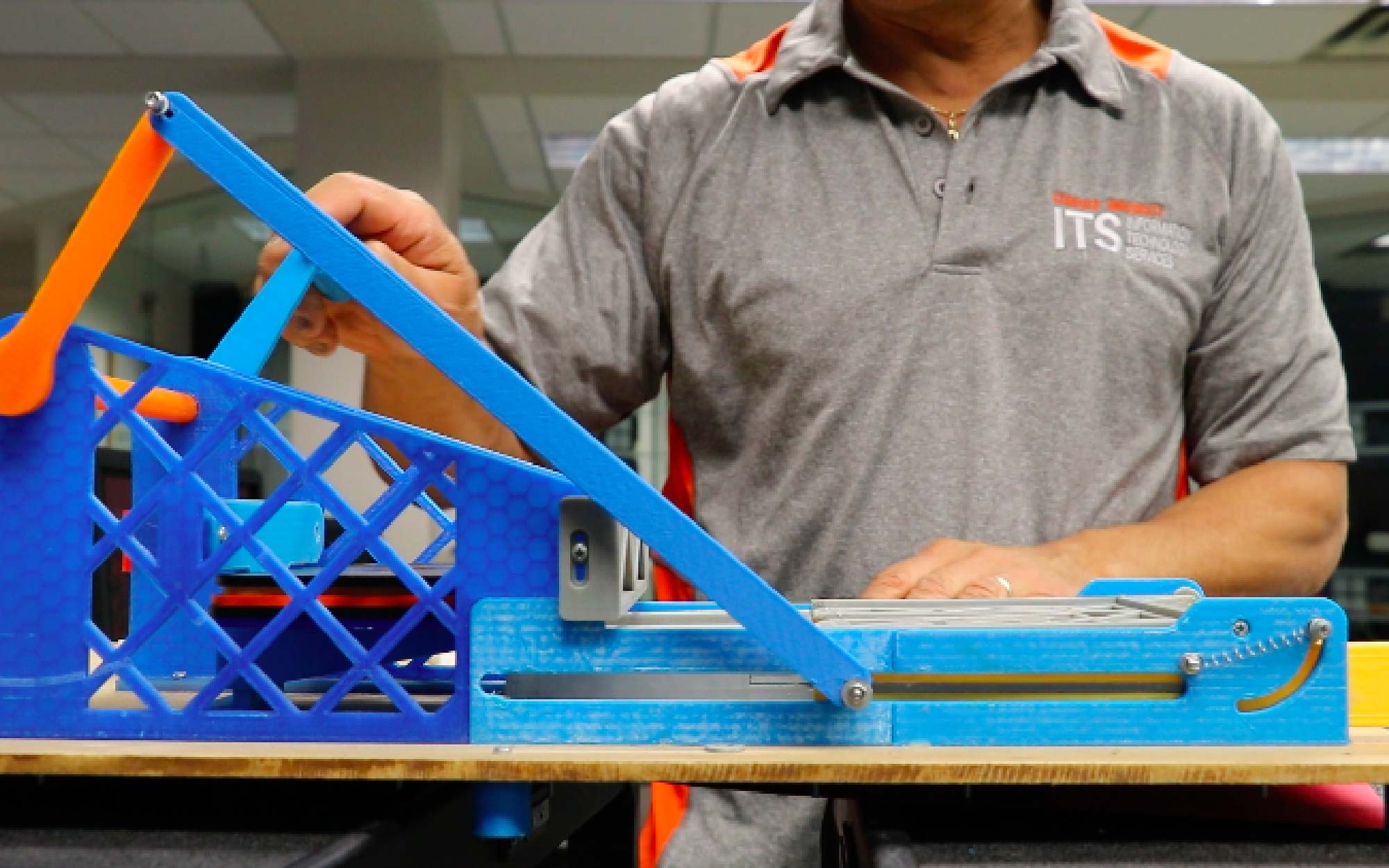

Using digital 3D models of the Tetrapylon provided by the #NEWPALMYRA team, Mike created printable files from the models. As he explained, “3D printing requires error-free ‘watertight’ models to create clean prints.” To accomplish this, he “ran the columns through several repair algorithms until they were good to go, redesigned the base to be better fit for 3D printing, and chopped up the model into smaller pieces that would fit [Gigabot’s] build volume.”

We broke the Tetrapylon into 25 separate pieces, clocking in around 800 hours of print time total. The biggest challenge for re:3D – as many of our bot owners can likely relate to – was working with this massive number of print hours. “The parts were so large that the print time estimates were through the roof,” said Jeric Bautista, Product Engineer at re:3D. Mike added, “This was the largest print that re:3D has taken on to date.”

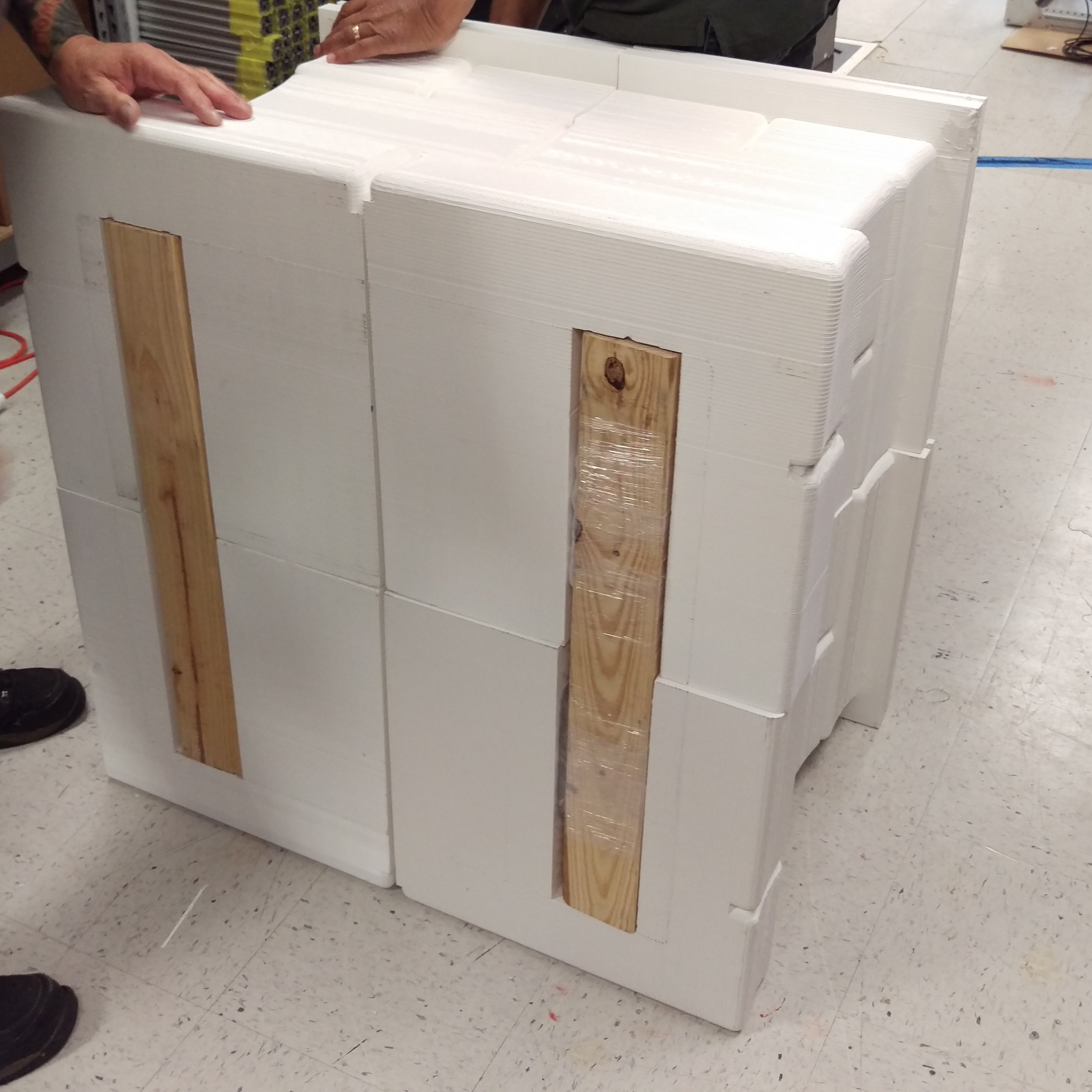

As for the sheer size of the print, Mike remarked that, “The fact that we had to design in safety measures because of the weight of the object was new to me. If one of those columns were pushed out, whoever was standing next to it could have had a very bad day.” For safety purposes, Mike designed channels into the print to run rods down each column, locked into place with 4×4 wooden blocks.

Coupled with the challenge of the overall size of the object was the detail variation within the print. While some parts of the structure are large and uniform – like the columns – other parts are so fine to the point that dual extrusion printing was required. The print resolution throughout the Tetrapylon ranges between ultra-detailed 200 microns and very large layers of 600 microns.

Jeric explained, “The completion of this project hinged on our R&D efforts to enable high-flow printing on Gigabot that drastically reduced printing times, as well as reliable dual extrusion printing to create highly detailed parts.”

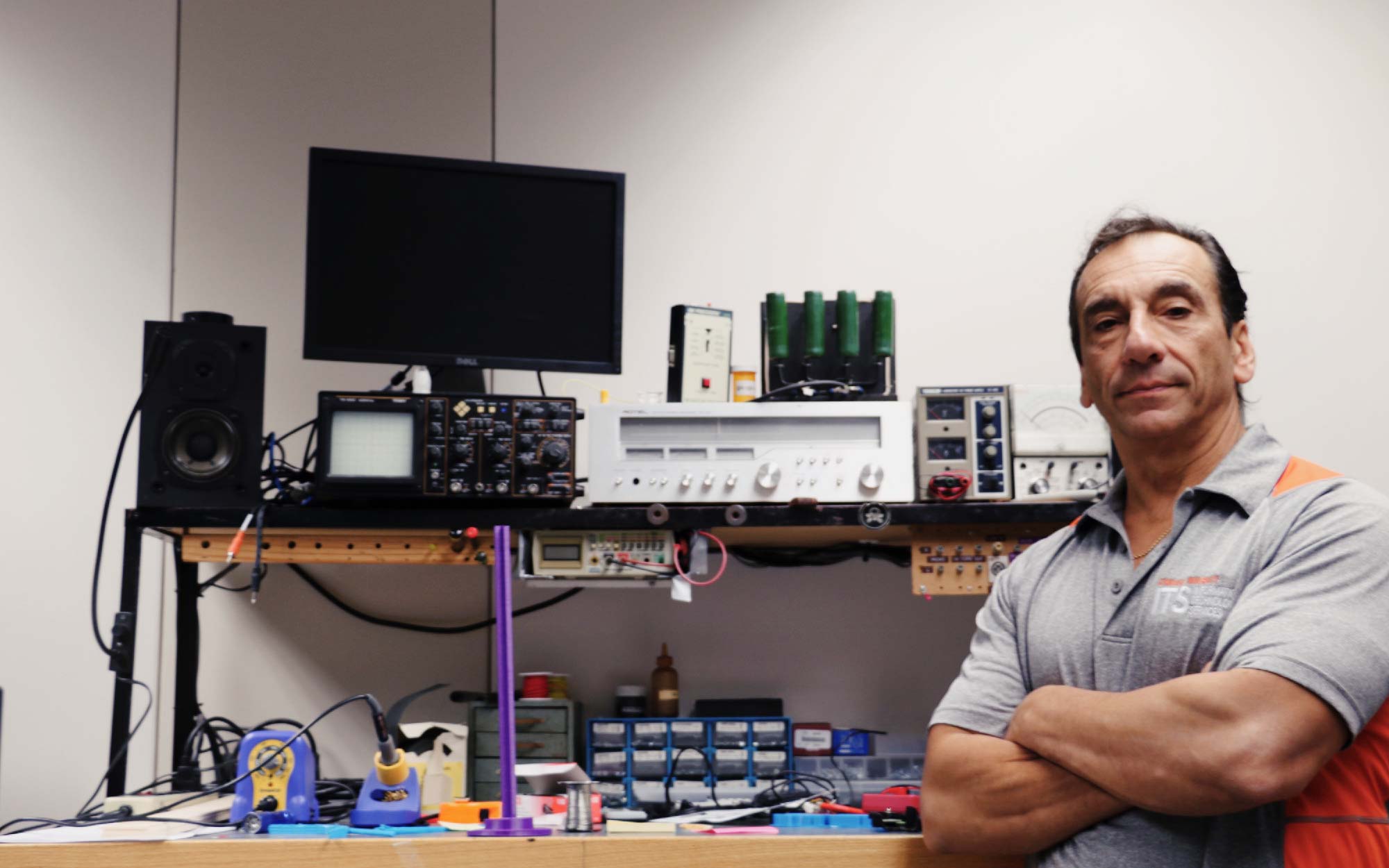

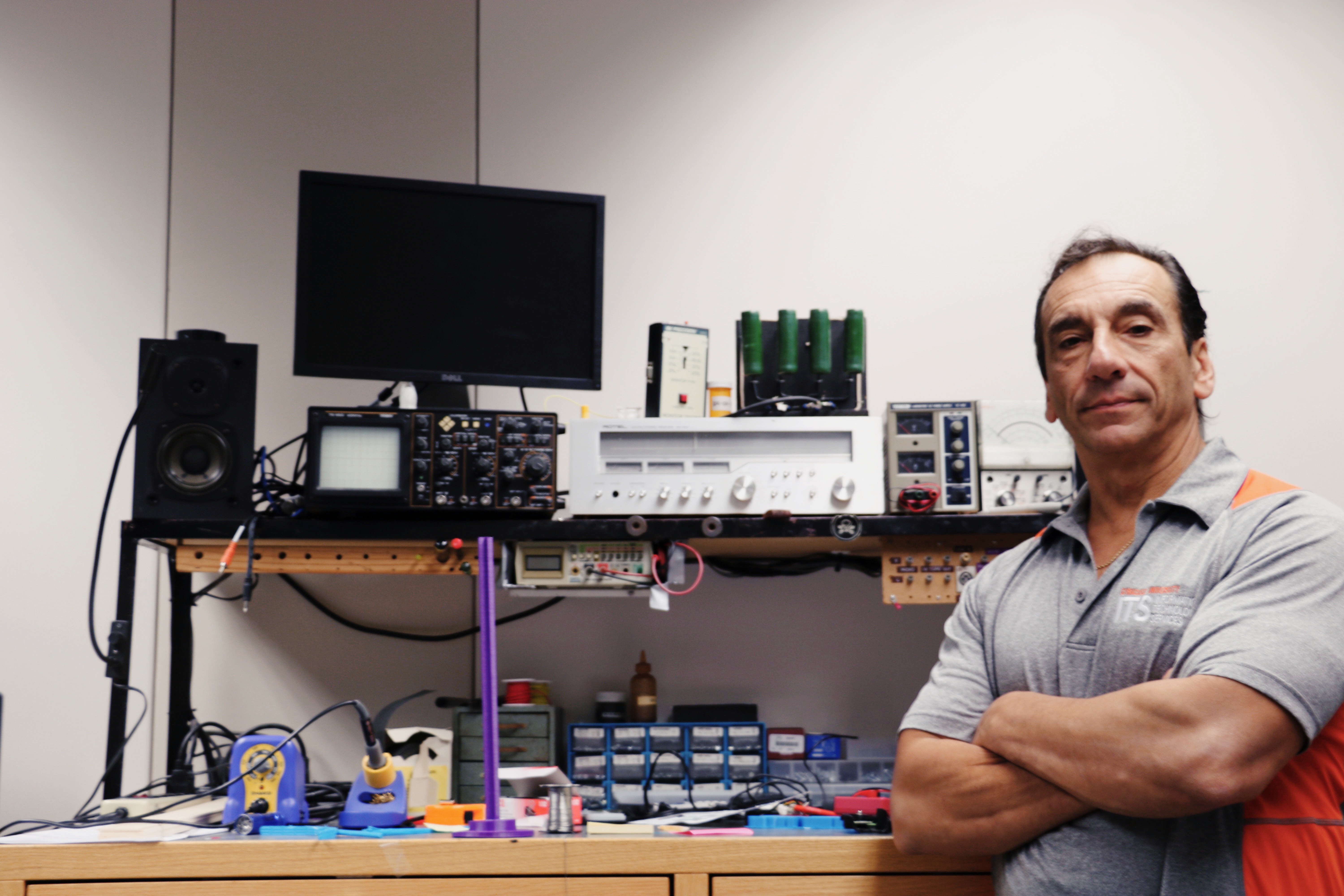

Steve Johnson, lead Machinist and Programmer at re:3D, was in charge of creating a new hot end for the job. He explained his task of manufacturing one with a “longer heating area that would allow us to extrude faster because of the size of the print and the short time frame we had to complete it in.” He designed and machined four hot ends to be used for the project.

The tackling and subsequent success of this challenge reverberated throughout our engineering team.

Gigabot owners will be happy to hear Jeric’s take on things. “I want to go bigger and faster,” he said. “Going back to R&D – we were able to multiply our material output 5-10x for this project, but of course we won’t stop there.” He added, “I’d like to see how our ‘big printing’ R&D initiatives will put us in an even better place to tackle projects at larger scales.”

Crossing these technical challenges was one aspect of what made this project so rewarding. “Not only did we jump over multiple technical hurdles to get the printing done, but it was awesome to see everything literally come together before our eyes,” Jeric said. “And that was just on the 3D printing side, which was the last piece of an already long-running initiative.”