Syracuse University got their first Gigabot in 2014 for their new Makerspace, poised to fill the position of “large-scale 3D printer.”

Since then, they’ve found uses for their Gigabot’s build platform size across the board, from “mass-manufacturing”-type jobs filling the bed with many smaller pieces for groups of students, to large-scale prints that have pushed the multi-day mark, like the infamous “backside print” for a visiting UK-based artist.

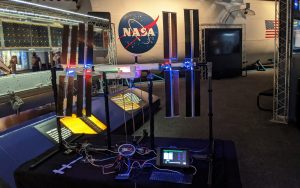

Their Gigabot has filled a valuable spot among 30-some-odd other 3D printers — all desktop-sized — as their largest 3D printer, allowing them to keep up with the Makerspace’s heavy demand for prints, big and small.

And there’s more exciting news afoot at Syracuse since our visit last fall: more Gigabots.

Their “workhorse” of the Makerspace now has company. In December, Syracuse got a second, new-generation Gigabot to add to the Makerspace’s lineup, and within the last couple of weeks, they placed an order for a third bot for a different department on campus.

3D printing is changing the way a lot of industries do business — for education it means enabling students to create things that they may not be able to make otherwise. As John put it, “You can have that idea in the morning and have it in your hand by the afternoon. That’s something that didn’t exist.”

Morgan Hamel

Blog Post Author