re:3D was first introduced to the US Department of State’s Young Leaders of the Americas Initiative (YLAI) in 2017. YLAI’s vision is to create a vibrant network of entrepreneurs across the Western Hemisphere. A key way this is achieved is through a Fellowship Placement with a business in the United States for four weeks. The Fellowship Placement is an opportunity for YLAI Fellows to experience the U.S. work culture and connect with key players in their industry. The YLAI Fellowship offers hands-on experience in exchange for using their skills and network to contribute to U.S. businesses and organizations. The Fellowship not only provides business insight and network for the Fellows but also provides their placement companies with cross-cultural understanding. Businesses form long-term relationships with their Fellows, extending the Fellowship well past the initial four-week placement.

Since 2017, re:3D has hosted three YLAI Fellows, the most recent being Juliana Martinelli from Brasília, Brazil in May of 2023. Samantha Snabes, re:3D’s Co-Founder and Catalyst and Juliana met over video to ensure that re:3D would be a good match for her fellowship. Juliana’s company, InovaHouse3D, 3D prints with cement and has a mission to print affordable houses in Brazil. Even though re:3D prints with plastic, we also have a social responsibility aspect to our work and admire InovaHouse3D’s goals!

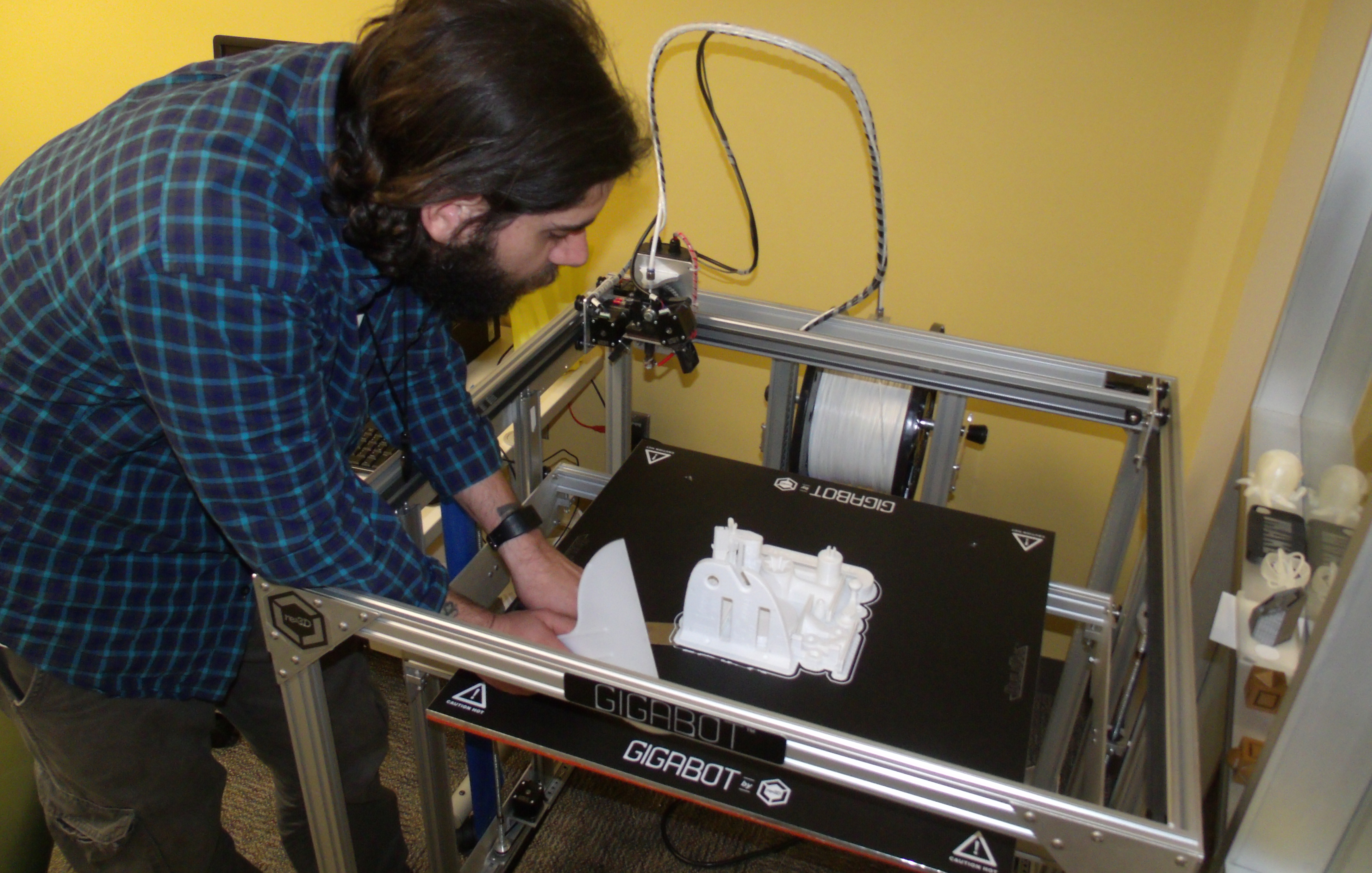

Juliana worked on three different projects during her Fellowship. The largest project she undertook was completing a customer outreach campaign to re:3D’s customers who spoke Spanish and Portuguese. Juliana individually contacted forty-four customers in Central and South America. She successfully heard back from twenty-five customers via email and set up in-depth phone calls with them. During these conversations, Juliana learned what each customer used their Gigabot for and the current state of their Gigabot. Juliana provided the customers with re:3D resources and connected them with other members of the re:3D team. re:3D values the relationships with our customers and the outreach Juliana did have a positive impact in connecting with customers we don’t normally get the chance to talk to. Additionally, this outreach campaign connected Juliana with more players in the Additive Manufacturing space in Latin America.

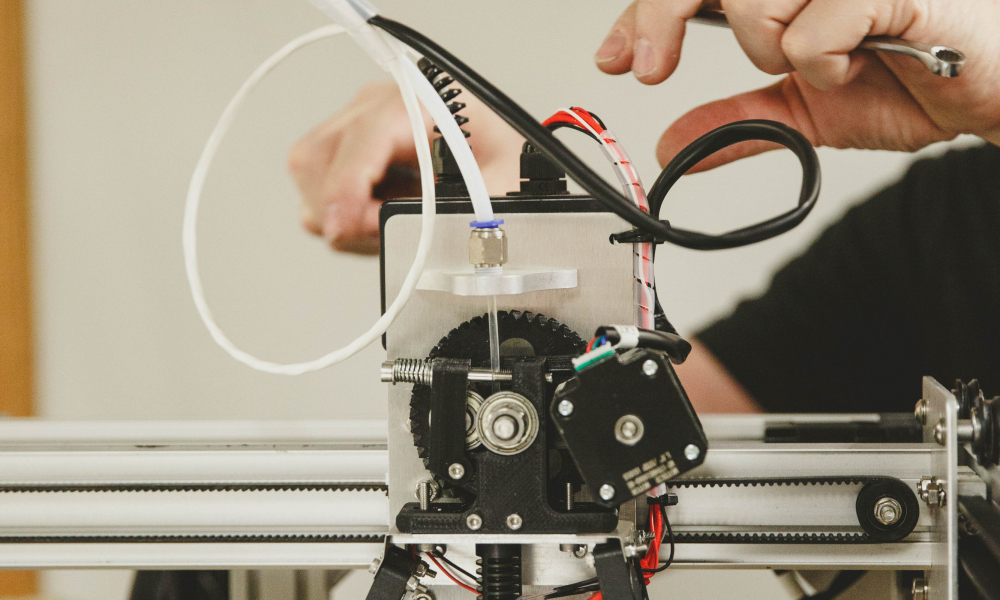

Because of Juliana’s background in Electrical Engineering, she was able to problem-solve grounding issues with Gigabot’s electrical box. This was incredibly helpful as re:3D was building up its engineering team. The final project Juliana worked on was a personal project. She wanted to pitch InoveHouse3D to a few American Investors to get their valuable feedback. Juliana was able to meet with two different Investors and strengthen her InovaHouse3D deck.

By the end of Juliana’s Fellowship, a strong connection had formed between her and the re:3D team. YLAI had let re:3D, and the other businesses hosting fellows, know that there would be an opportunity for an Outbound Exchange program. In this exchange, someone from re:3D would go to Brazil for two weeks and work with Juliana’s company. Jennifer Dennington, re:3D’s Account Manager, applied for the Outbound Exchange Program and was awarded the grant! Jennifer left for the exchange in early January 2024 to amplify the future of Additive Manufacturing in Brazil.

One of the main projects Juliana and Jennifer worked on was creating a storytelling blog post and video on re:3D’s customer Rhodes. Rhodes produces around 5 million components per year to assemble various models of office, school, and training chairs and public seats in airports, theaters, cinemas, and football stadiums. The blog article and video about how Rhodes uses its Gigabot will be published soon, so stay on the lookout for that.

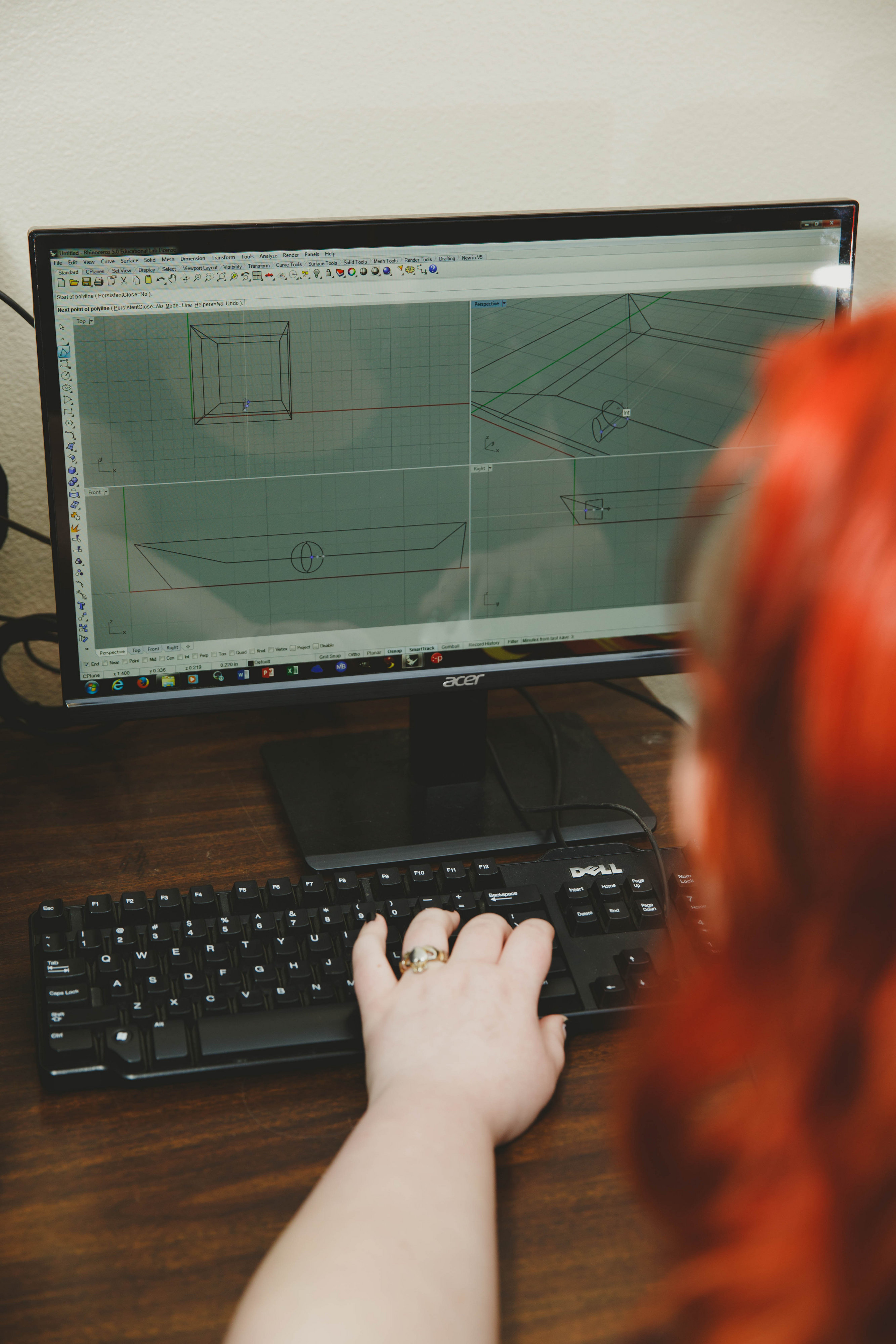

Another project Jennifer and Juliana collaborated on was creating Additive Manufacturing lessons for Brazil. Jennifer’s background is in Special Education, she has a passion for making education fun and accessible to all people. Juliana teaches lessons to schoolchildren at the Planetário de Brasília (Brasília’s Planetarium) and has connections with public schools in Brasília. Before coming to Brazil, Jennifer knew she would share re:3D’s Introduction to Autodesk’s TinkerCAD lesson where Juliana would teach students how to make 3D models on their computers. However, after speaking with Juliana, Jennifer learned that many students do not have access to technology at school. Jennifer shifted gears and decided the first lesson she needed to create was an Introduction to 3D Printing lesson for students with limited to no knowledge of 3D printing and limited access to technology.

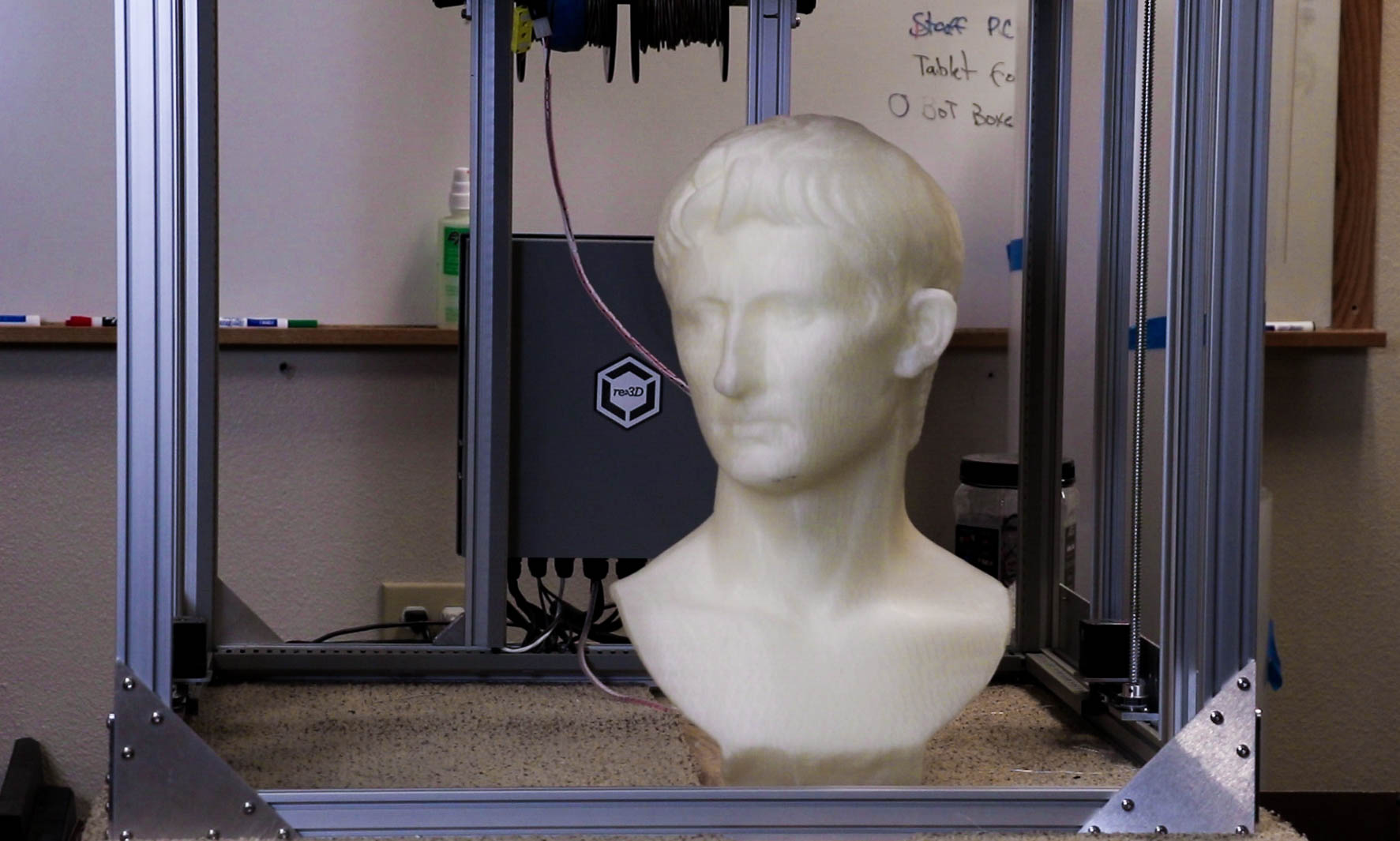

Jennifer modeled this lesson after the 5E Model of Instruction where students engage, explore, explain, elaborate, and evaluate 3D printing. She only included resources that Juliana had readily available to be used in the lesson. For example, because of Juliana’s partnership with the University of Brasília’s LAB, Juliana could bring 3D printed examples to show the students on top of having the Google Slides presentation. Click here to view and download the Introduction to 3D Printing Google Slides and here to view and download the full lesson plan.

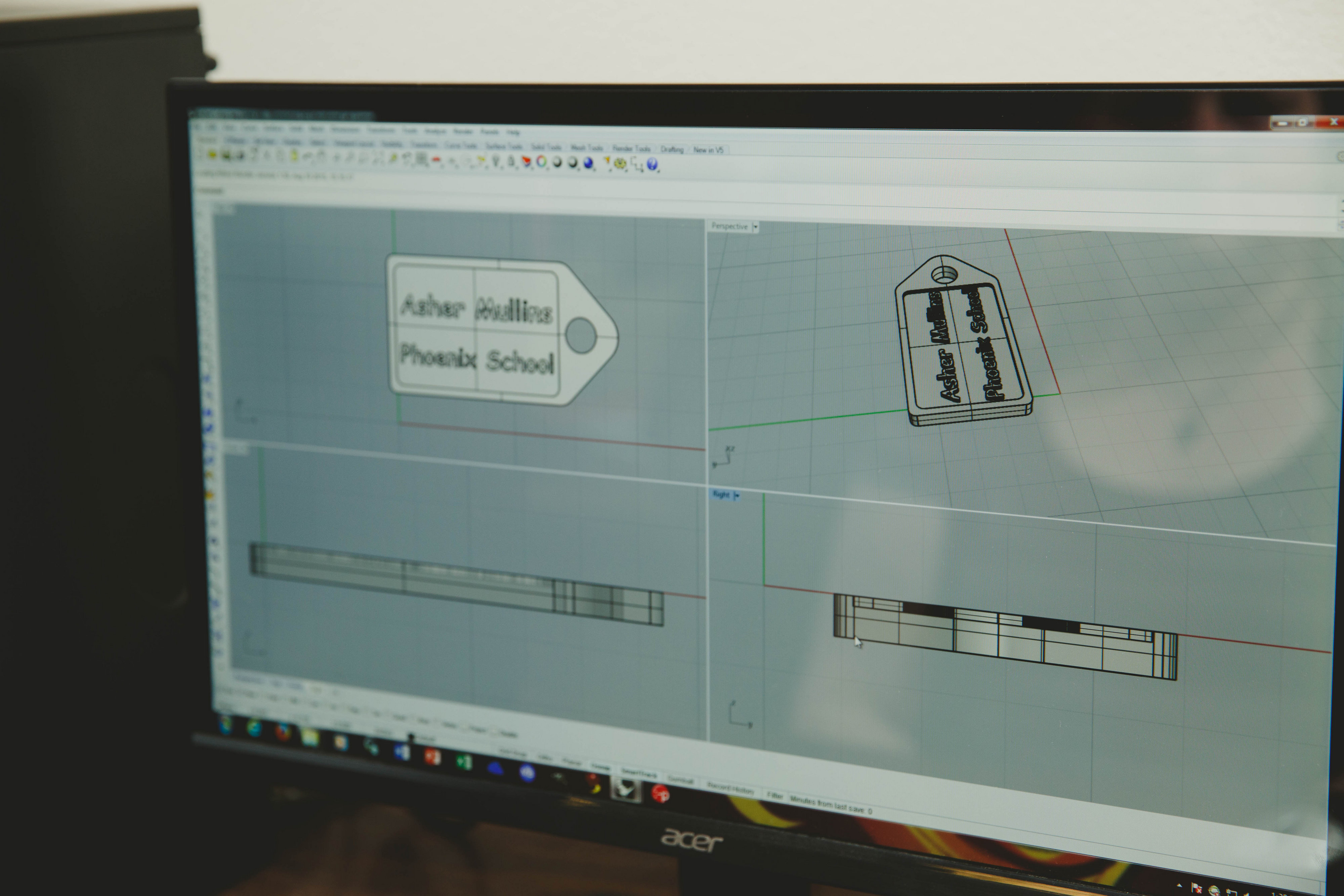

After Jennifer finished the Introduction to 3D Printing lesson, she went back to the Introduction to TinkerCAD lesson because it is a personal favorite of re:3Ds. TinkerCAD is a fantastic resource for teachers because you don’t have to have a 3D printer to do incredible and engaging lessons with your students. Teachers will have students they do not expect to interact with this lesson get really into it and become incredible 3D designers. Not only can students make 3D designs with TinkerCAD, but also they can create circuit boards and learn how to write code, all for free! TinkerCAD puts out challenges each month for students to compete in and educators post lessons they have created on TinkerCAD as well. Click here to view and download the Introduction to TinkerCAD Google Slides and here to view and download the full lesson plan and other additional resources. These lessons can be replicated and customized to fit different cultural contexts, educational settings, and learner demographics, thereby extending the reach and impact of 3D printing education. Jennifer hopes her lessons contribute to building a future workforce equipped with valuable science, technology, engineering, art, and math (STEAM) knowledge and competencies, thus promoting innovation and economic development in the long run.

Juliana took Jennifer on a tour of Programando o Futuro, an electronic waste (e-waste) recycling center with a broader mission of providing free technology education to the community. Their hands-on courses in robotics, 3D printing, computer repair, and marketing aim to equip people with tech skills, boasting a 55% job placement rate. With a commitment to inclusivity and sustainability, Programando o Futuro engages in extensive plastic recycling, collaborating with companies like HP to transform shredded plastic into new products or filament for their 3D printing lab. Programando o Futuro has repaired and donated over 3,000 computers and aims to recycle 1,100 tons of material this year. They want to partner with Juliana and the University of Brasília to get a spectrometer, which will help them rapidly and accurately identify the types of plastic that are donated. Additionally, Juliana wishes to use her partnership with Programando o Futuro to apply for re:3D’s Gigaprize program or apply for a grant to purchase a GigabotX 2 for their organizations.

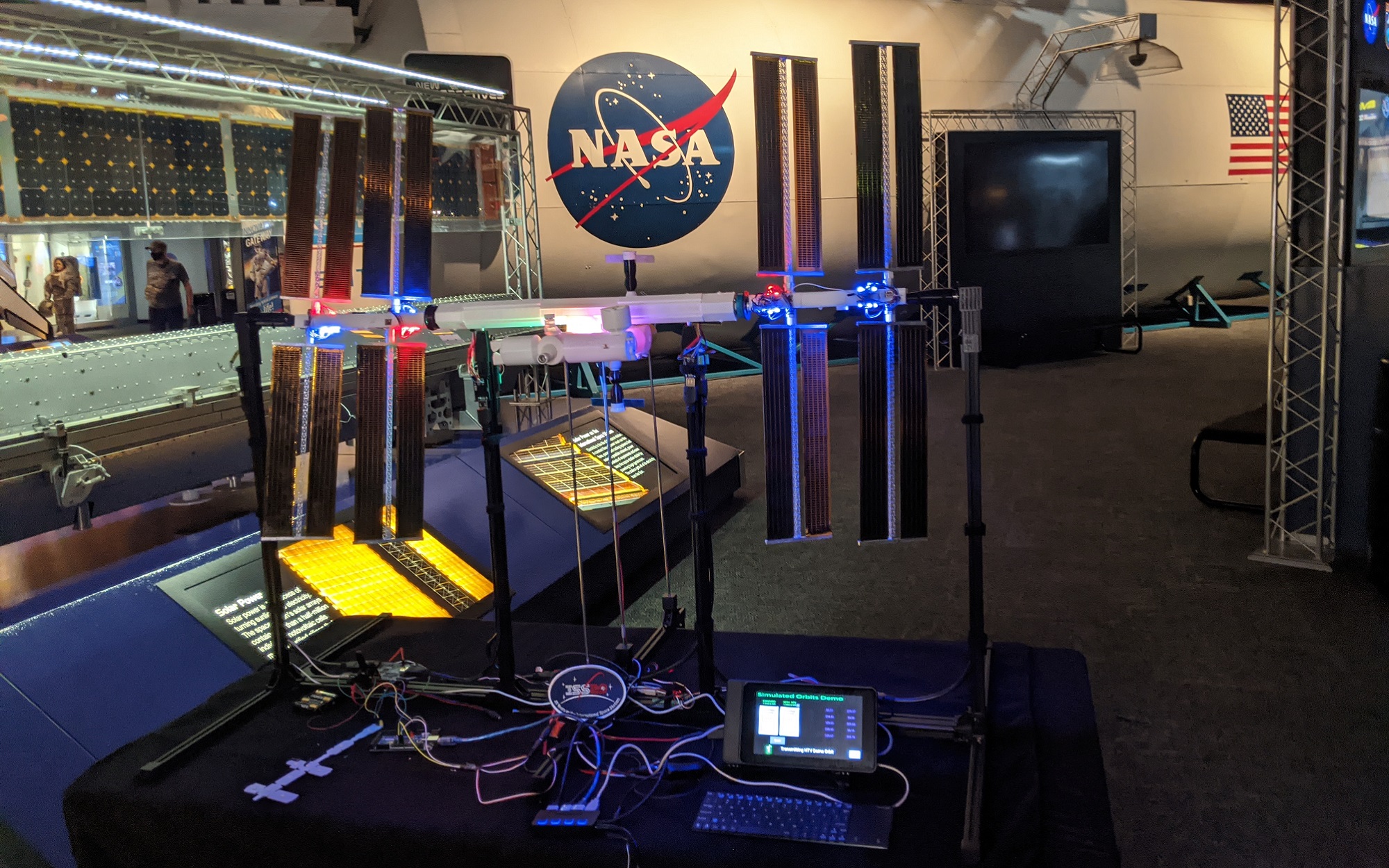

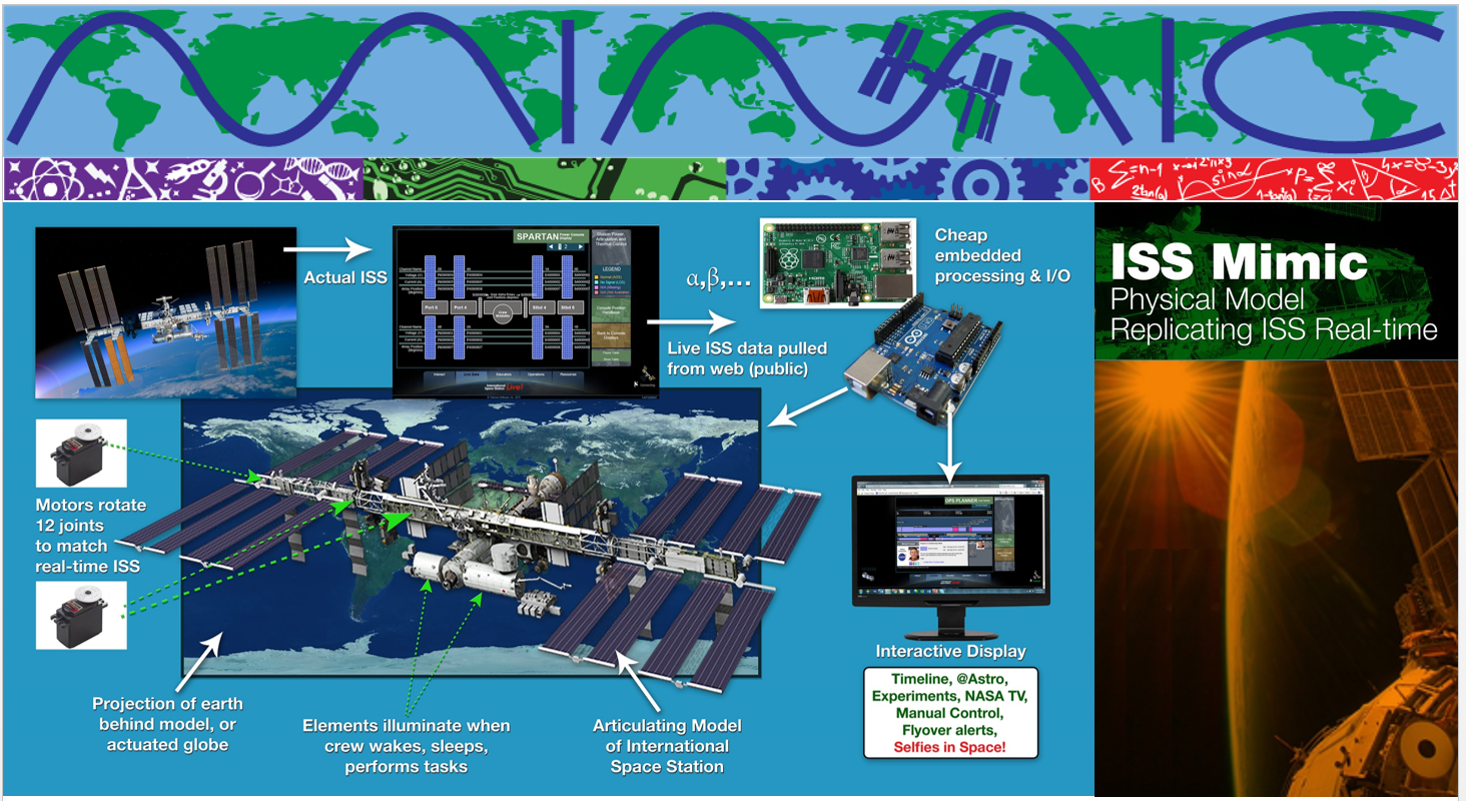

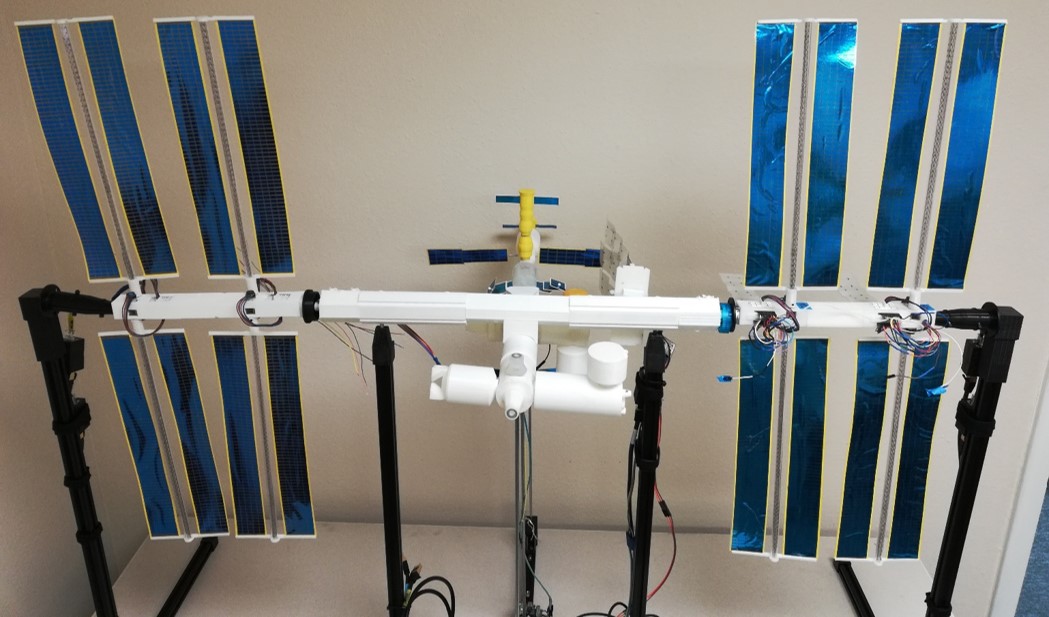

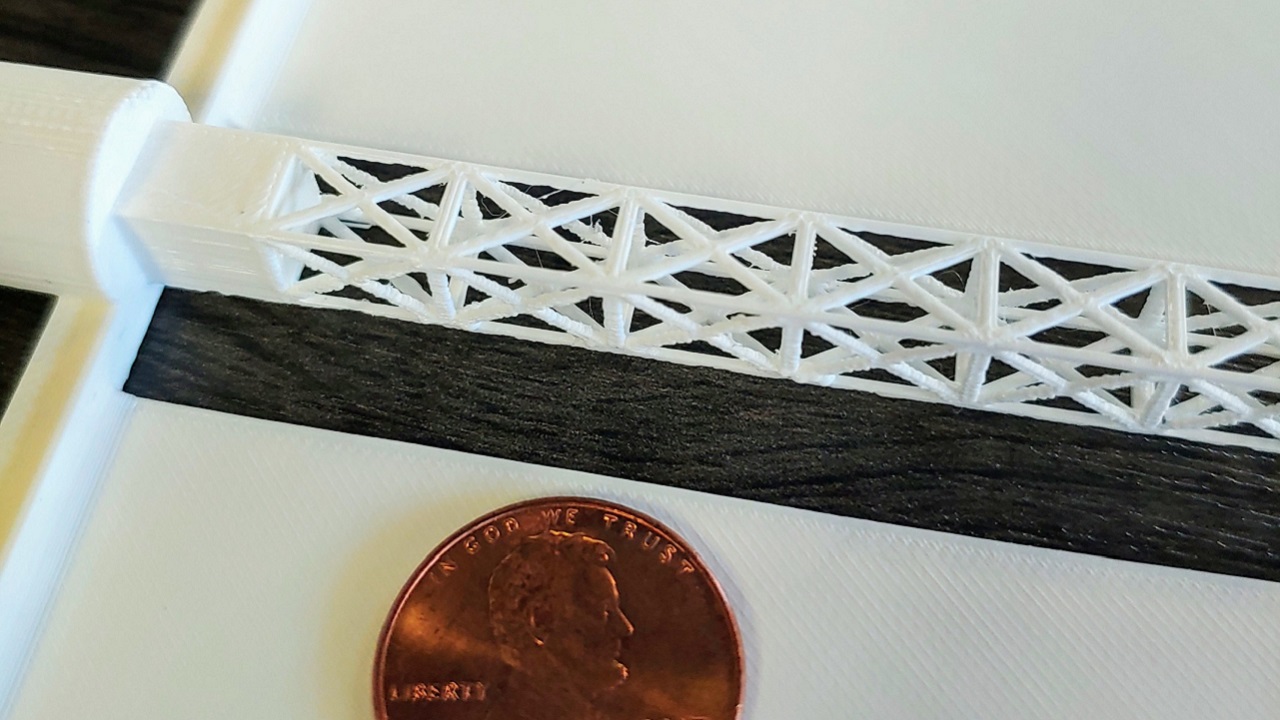

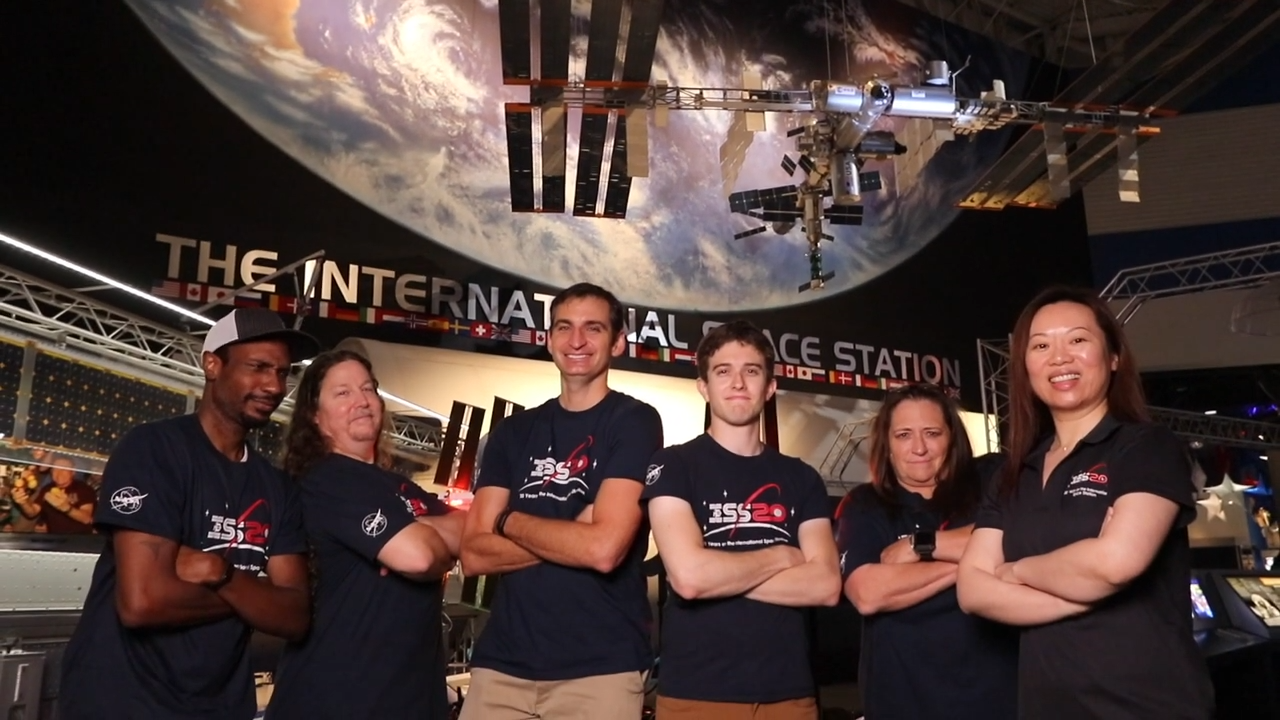

A bonus meeting happened with Bryan Murphy, Associate Chief Engineer for the International Space Station (ISS), at Boeing to bring ISS Mini-Mimics to Brazil. The ISS MIMIC is a 1:100 scale articulating model of the International Space Station (ISS) that runs off of live data streaming from the real ISS. re:3D has had the joy of helping the ISS Mimic team by 3D printing solar arrays and participating in the 11 Freeman Library Community Builds of the ISS Mimic. If you would like to learn more about the ISS Mimic, check out this article written by re:3D. Jennifer and Juliana’s meeting with Bryan was successful because they secured three ISS Mini-Mimics for educational institutions in Brasília. The goal is that after Juliana completes the ISS Mini-Mimic with students, she will then apply for grants to fund an ISS Mimic community build at the Planetarium! She is also hoping to get support from Brazil’s only astronaut, Marcos Pontes, who is currently a Senator for São Paulo, in this endeavor. Bringing the ISS Mimic to Brazil has the potential to foster a lasting interest in space exploration and STEAM fields to all who encounter it.

A final fortuitous event happened at the end of Jennifer’s time in Brazil when she was able to meet with the 2024 Class of Brazilian YLAI Fellows. Jennifer was in Brasília at the same time as their orientation for YLAI. Juliana and Jennifer went and spoke about their YLAI experience with the Fellows for an hour and a half. The Fellows Jennifer met were awe-inspiring entrepreneurs. They have built up their business and are incredibly hard workers. When they come to the US they are paired with businesses and are partnered with anyone from the CEO of the company to an Account Manager. YLAI is not only about the Fellows coming in and learning from an American company but also about them sharing their knowledge and passion with the company they are paired with. If you are interested in hosting a YLAI Fellow, please email info@re3d.org, and Jennifer will put you in touch with the proper contacts. re:3D hopes to continue partnering with YLAI for as long as we are around.

Jennifer Dennington

Blog Post Author