The Big Idea

Like most start-ups intent on exploring the intersection of tech and sheer awesomeness, the vision to 3D print a surfboard was cast over beer, at a co-working space (Capital Factory), subsequent to a lack of sleep. Disregard the fact the nobody physically present at our Q2 re:treat had actually surfed, we were still proudly penny-pinching, and had few Gigabots available for extended personal print marathons. Instead, Marketing Co-Leads Katy and I corroborated with our Gigabot Ambassadors Rebecca, Morgan and Todd to develop a list of “use cases” to demonstrate functional 3D printing to be executed by a cadre of summer interns. Buoyancy made the shortlist, and a surfboard was an obvious case study.

Our leadership team cultivated job descriptions, which Katy hosted under a tab she designed at re3d.org/careers. The response to our unpaid internship postings were higher than anticipated, and ultimately we selected Akshay as our 2015 Design Intern focused on 3D Printing a surfboard. Despite still being in High School, his confidence, professionalism and experience modeling through his high school FIRST Robotics team convinced me he was up for the challenge. He also had a glowing recommendation from his coach Norman.

The Design

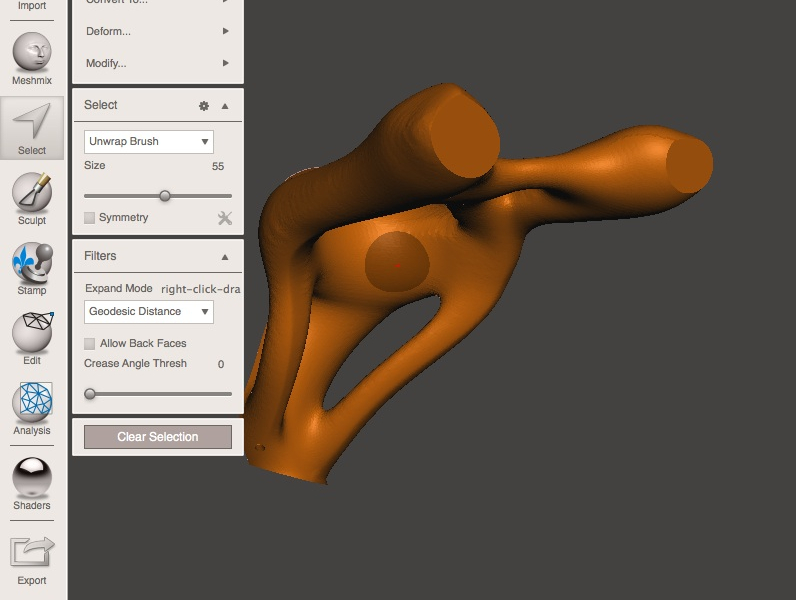

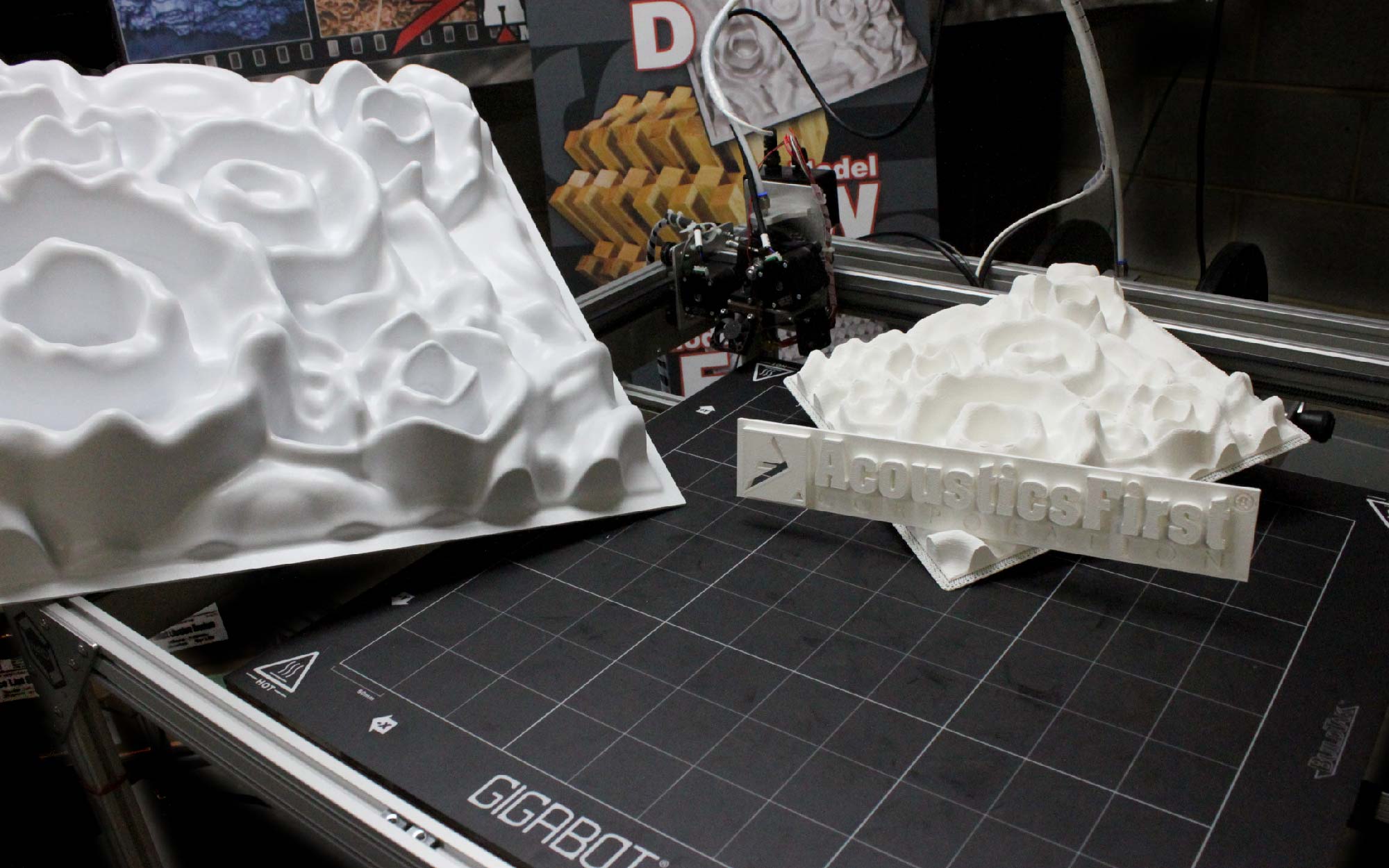

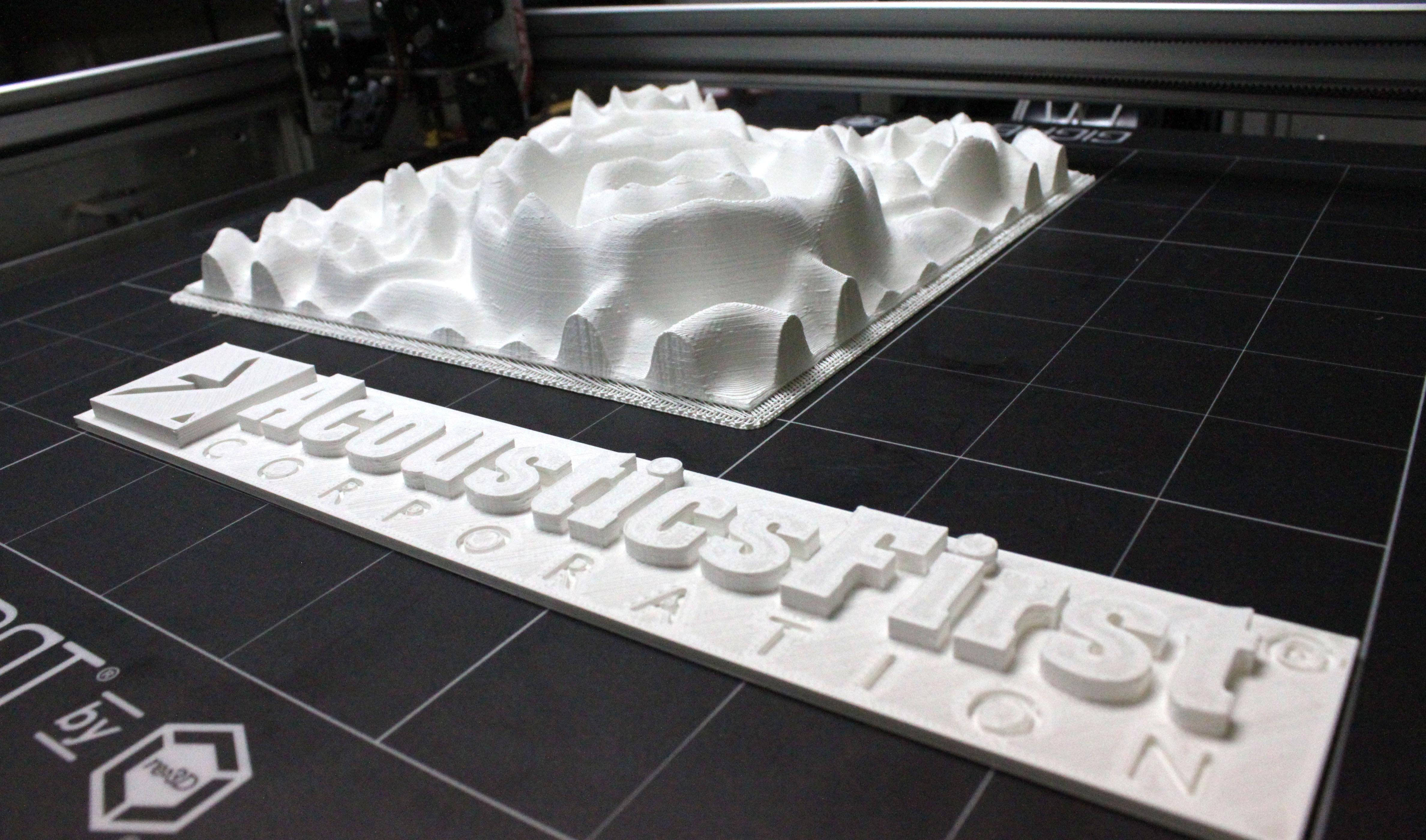

Within just a couple weeks of on-boarding and conducting research on surfboard 3D printing, Akshay presented his concept. He had identified others who had been successful including a Father & Son, as well as professional 3D printed surfboard companies. Those that have gone before had done an amazing job curating surfboard designs that truly exhibit the benefits of 3D printing, whether it be enabling custom designs or geometries not easily produced in traditional manufacturing. However, due to the small volume of many affordable printers, we noticed multiple parts were required to later be stitched together like a jigsaw puzzle or they depended on expensive SLS printers to produce a monocoque body.

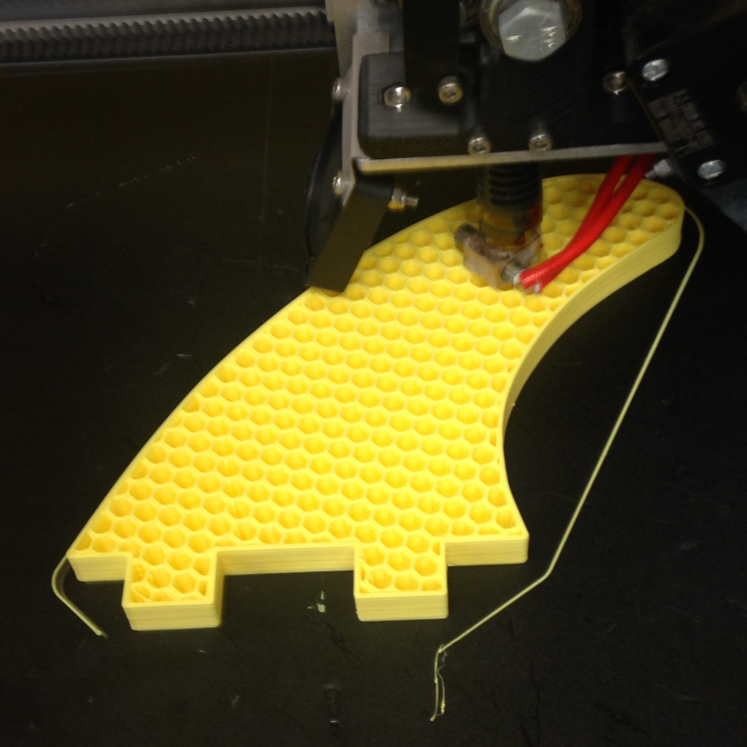

Knowing that we had the benefit of leveraging one of the largest affordable industrial printers at our disposal, we set out with Akshay to investigate if we could make a FFF (Fused Filament Fabrication) design in the fewest pieces possible. We also wanted to challenge notions of material strength. Akshay’ s research unveiled that our desktop 3D printing peers used ABS, a plastic despised by many for its stinky smell during printing, but stronger than it’s as readily accessible counterpart PLA. Being bootstrapped, we work from a small office, so we decided to use PLA to print our board to see if the sweet smelling, accessible filament could support the weight of a human in the ocean repeatedly, thus challenging the assumptions of PLA’s limited value in functional, life-sized 3D prints. You see, we didn’t choose PLA because we thought it SHOULD be the material of choice, rather we wondered if it COULD be used in a functional application.

And if it worked (even limitedly), we wondered…..what other applications would you and other members of the open-source community cultivate that could expand on our buoyancy experiment?

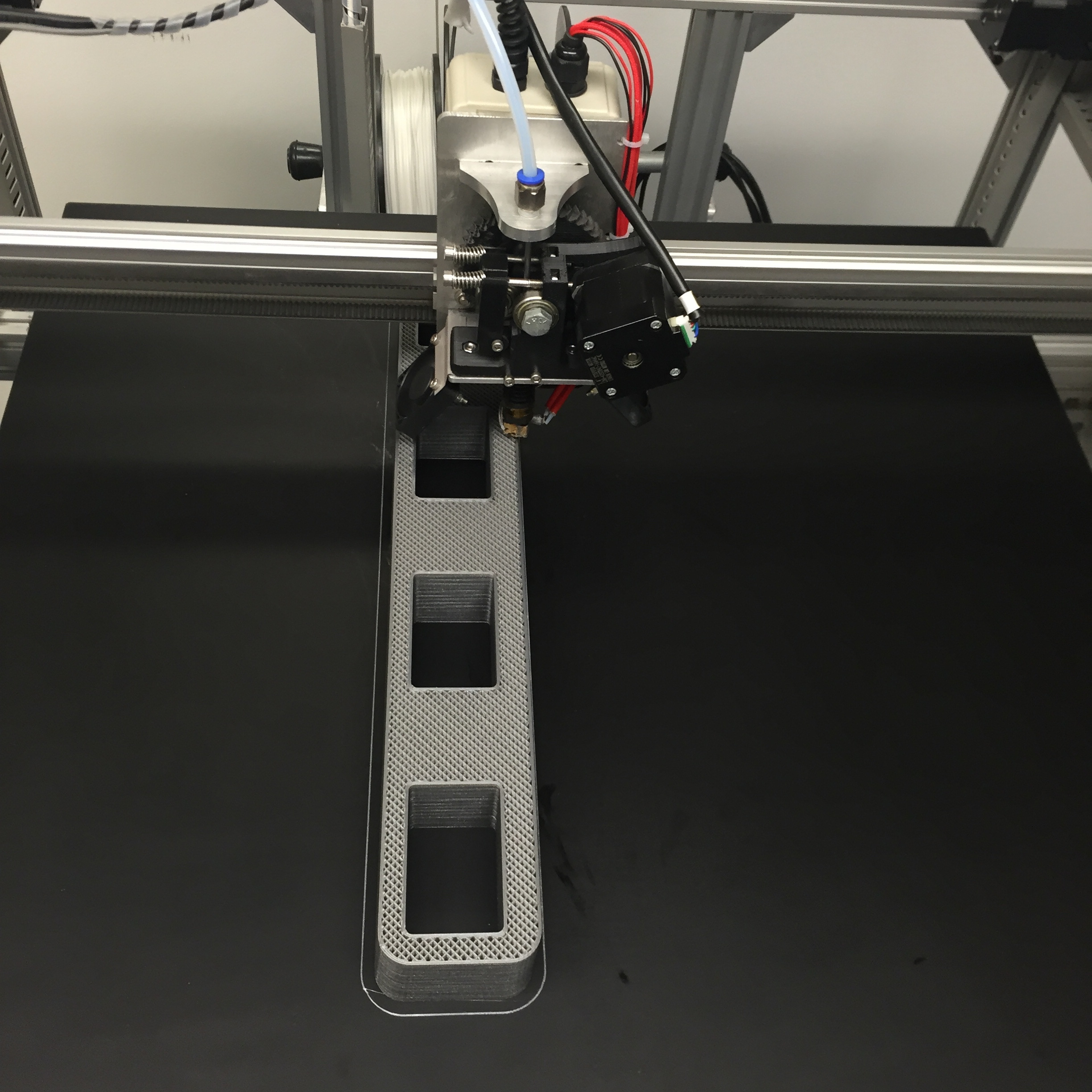

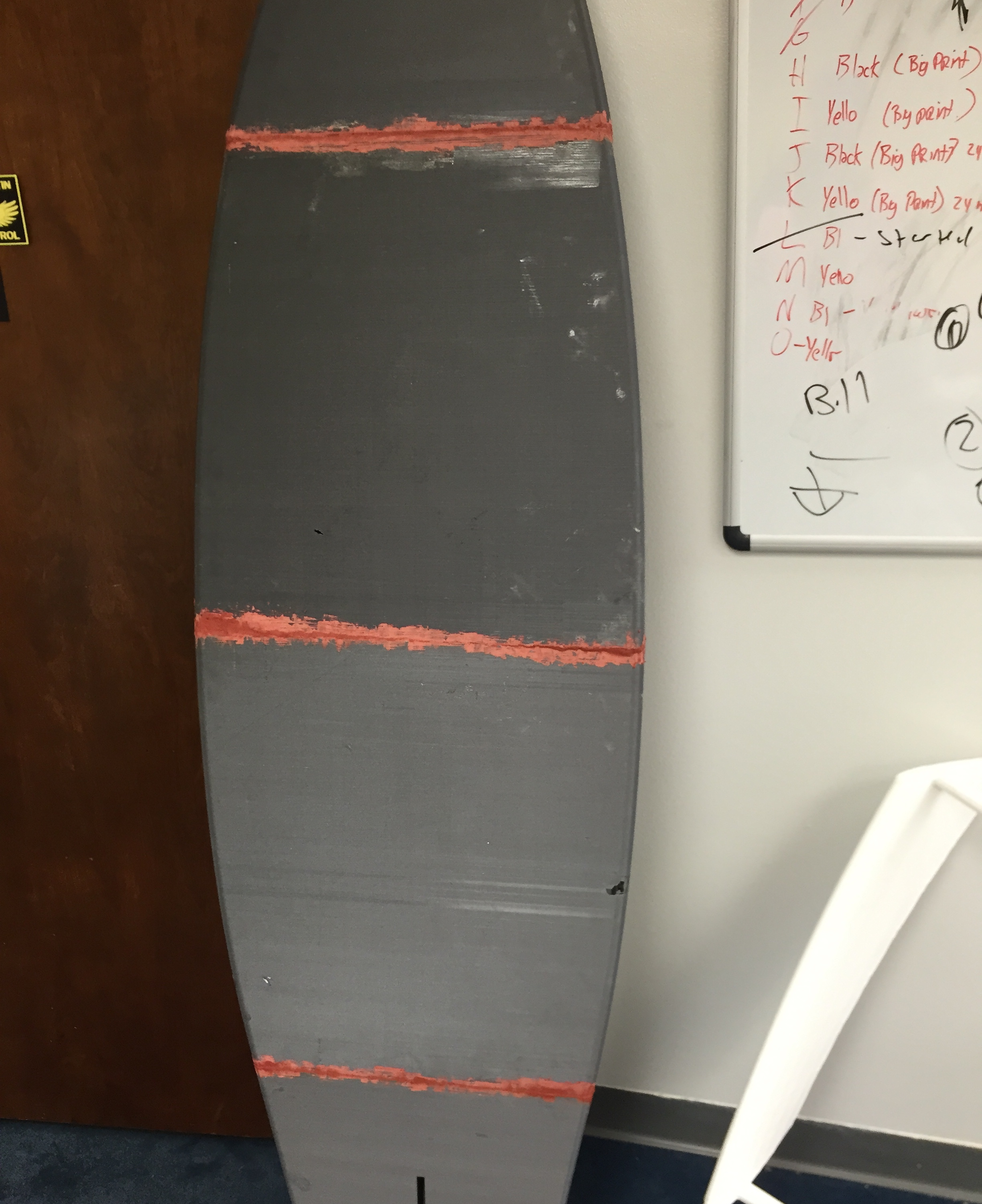

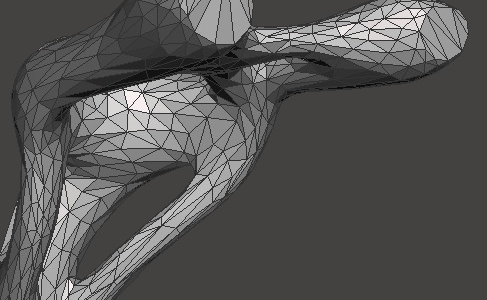

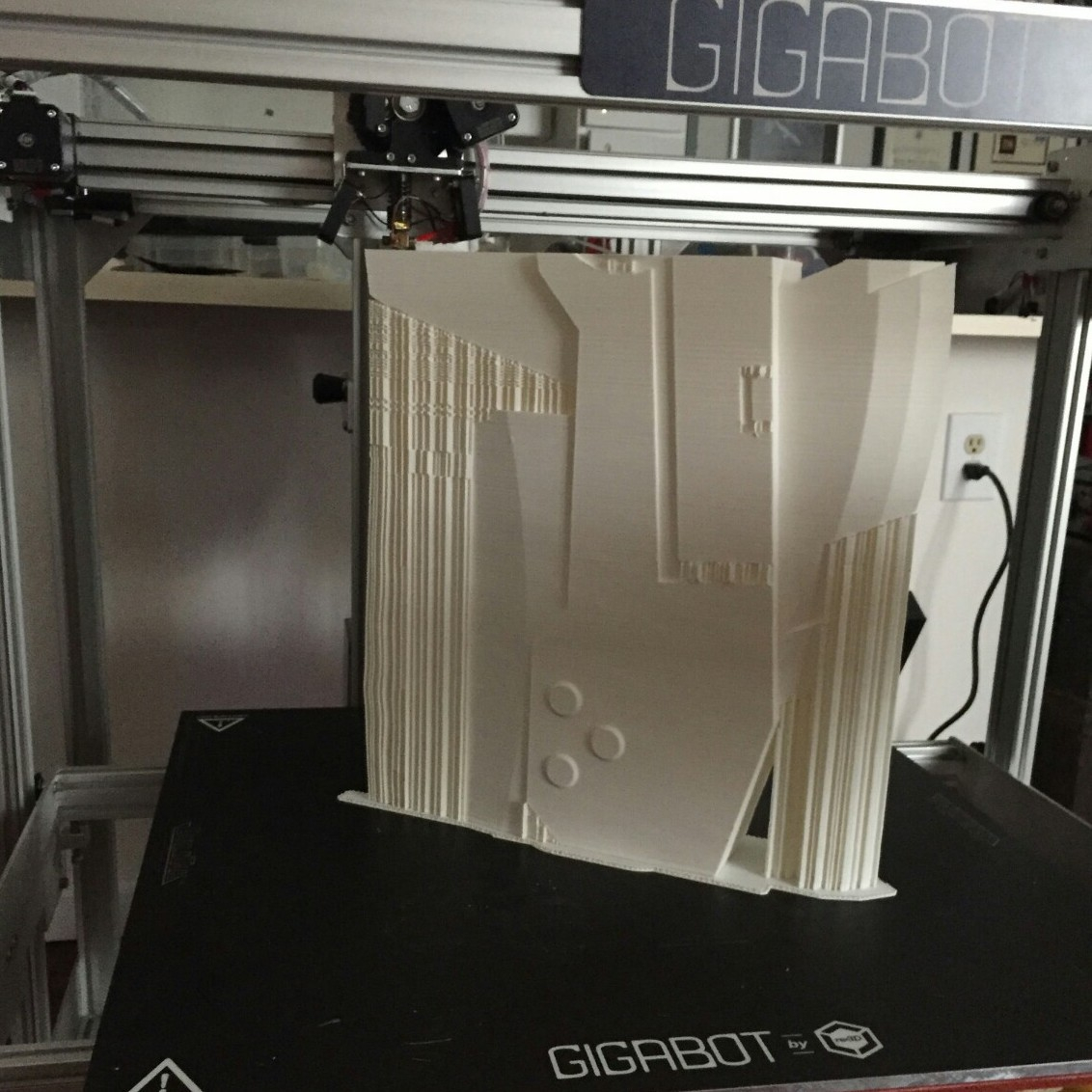

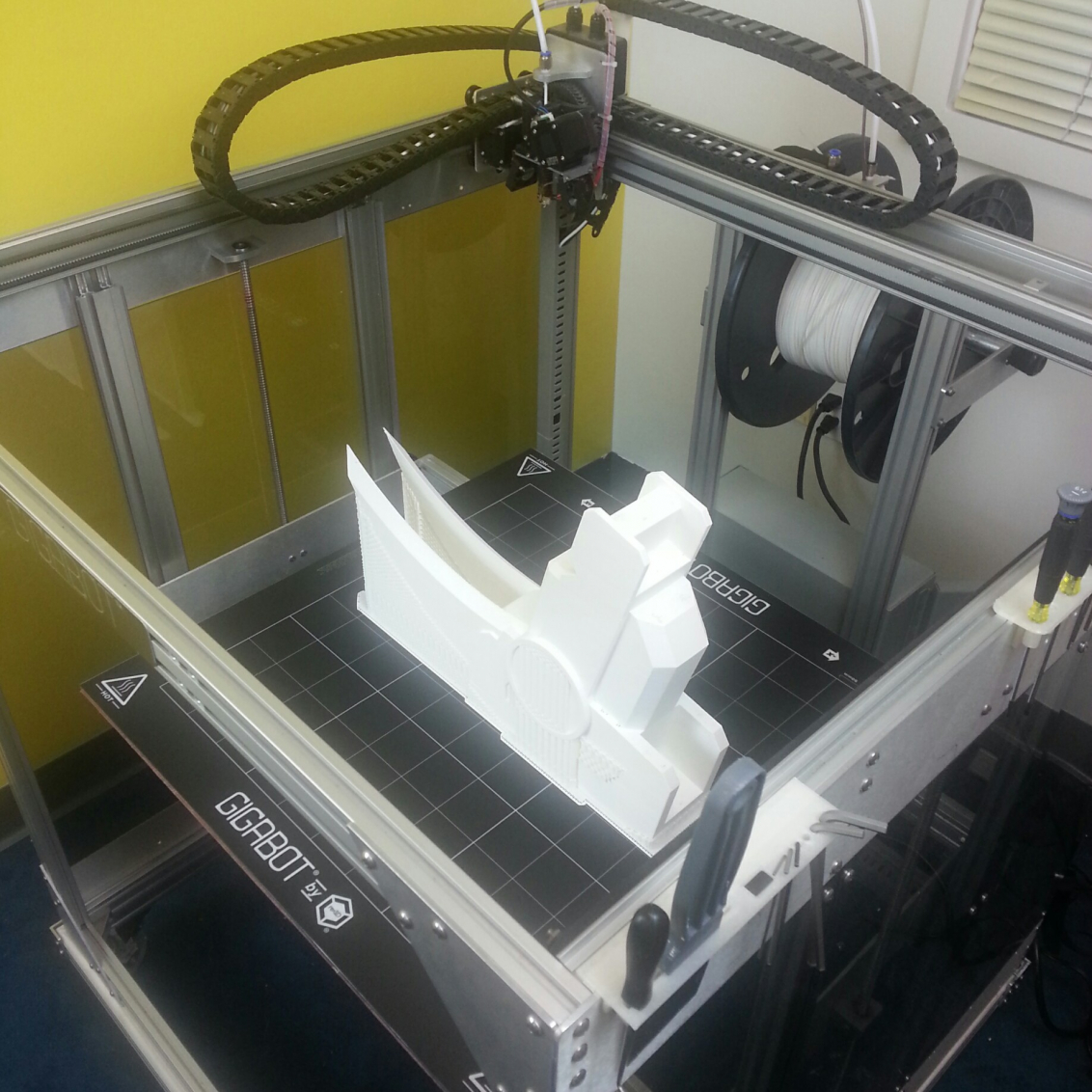

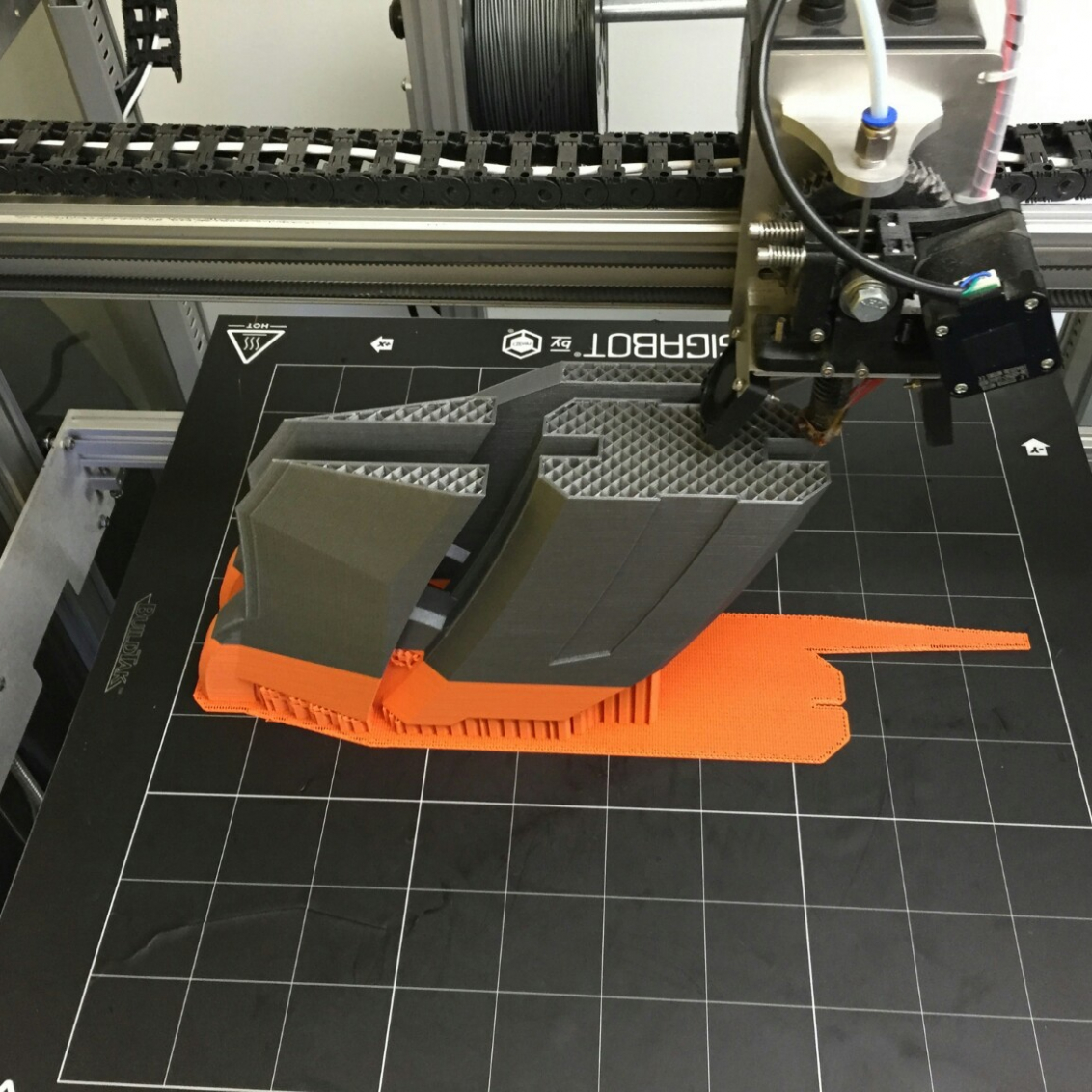

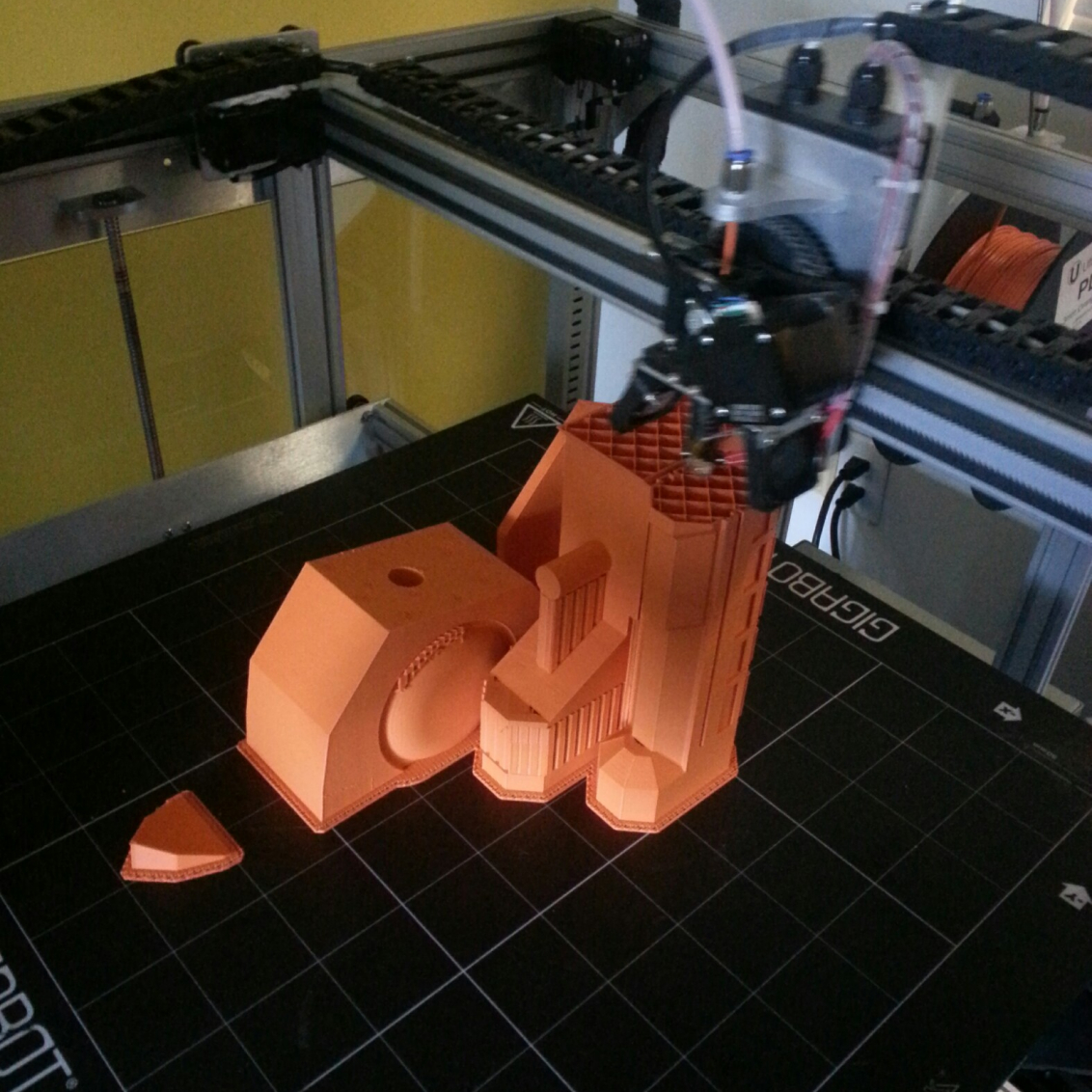

To develop the initial concept, Akshay paired up with our Summer Stand-up Paddleboard Design Intern Evan, who was also exploring the possibility of supporting a load on water. During Katy’s Thursday Design meetings they evaluated each other’s models in Solidworks, discussed stress points, and analyzed the best way to join components. They also ran a series of experiments to deduce not only if PLA floated, but also if it could be water tight. While they initially pursued similar concepts involving a series of rods conjoining dense pieces, they later opted for separate methods. The stand-up paddleboard included a series of hollow segments, filled with Great Stuff, bound with Gorilla Glue, and fiber wrapped. The surfboard, Akshay decided, would be four, 6% honeycomb-filled segments held together by a series of 50% infill 3D printed bricks. Like Evan, his instrument of choice for sealant included copious amounts of Gorilla Glue.

This was our first foray into a “formalized” summer intern program and the weeks flew by. We learned a ton about setting deadlines, procurement delays, accounting for R&D or marketing inventory in our budgeting & bookkeeping, and how to better mitigate bottlenecks in Gigabot availability for multiple, multi-day crazy prints.

As June turned to July, the scaled-models and sketches transformed to full-scale experiments. Katy’s design meetings became increasingly important as the group collected feedback from the team and data from real-world tests which influenced model adjustments.

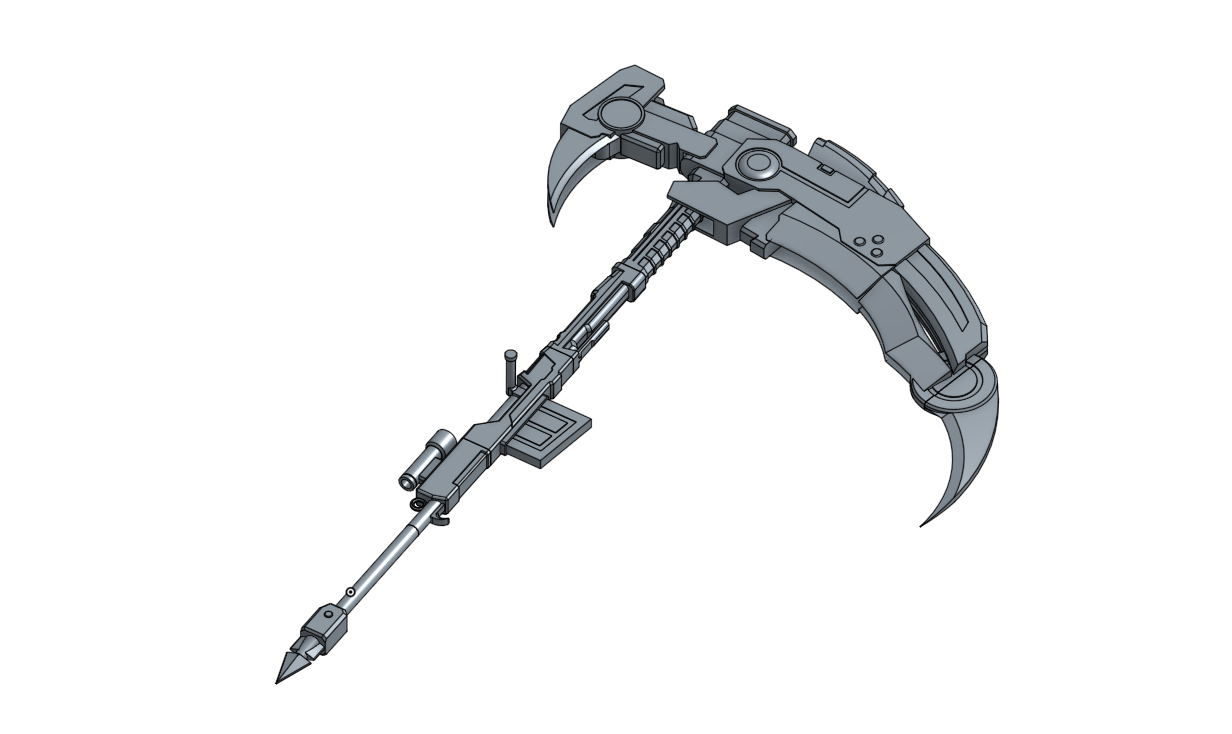

Fin Design

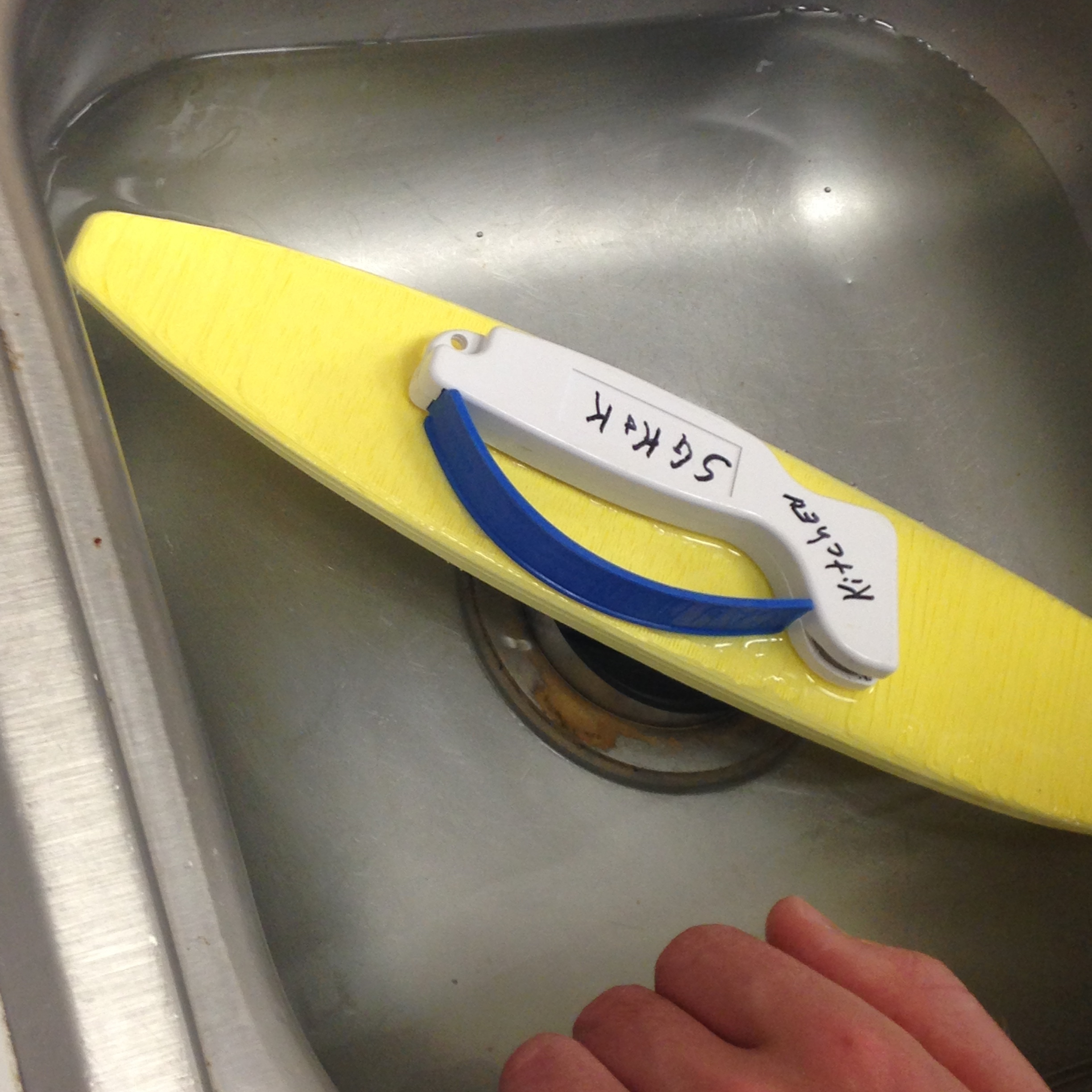

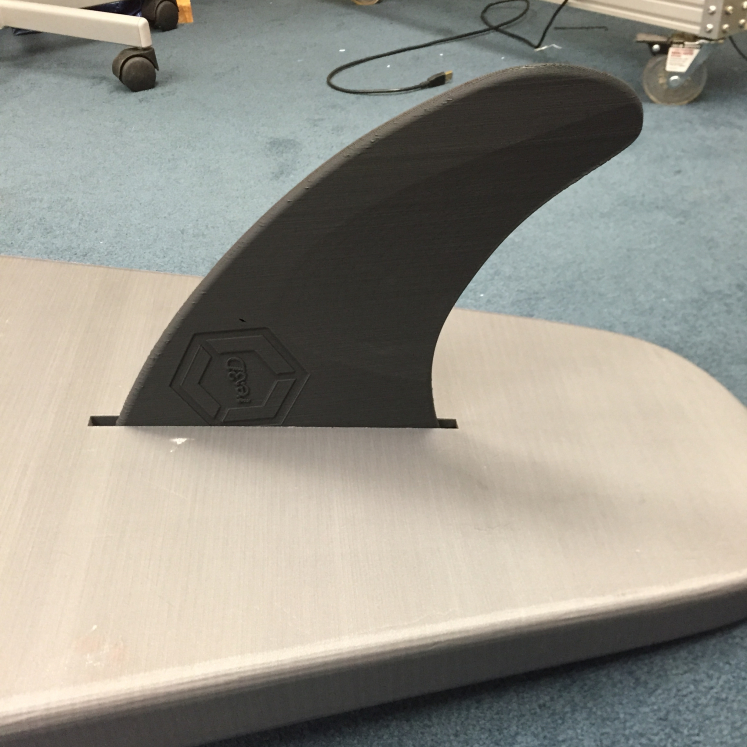

Throughout the summer, the surfboard fin underwent as significant an evolution as our scaling team using input from experts, the open source community, and our own failures. Askhay’s first design included two tabs to be glued into the frame, which floated and appeared to have the infill & form required to be successful based on our initial tests. However, after delving into the minutia of surfboard design, Akshay discovered that most fins are supported via a T-slot in the surfboard body. For this reason, he later designed a fin to be inserted into a groove. Unfortunately, we later learned we needed screws holes on either side to mount into the T- nuts. Mike responded to the challenge and mocked the final design, which included the re:3D logo as well as fixtures for the screws to mount into Akshay’s conceived T-nut slot. Mike also suggested that the fin be printed in black to complement Akshay’s silver board.

Final Construction

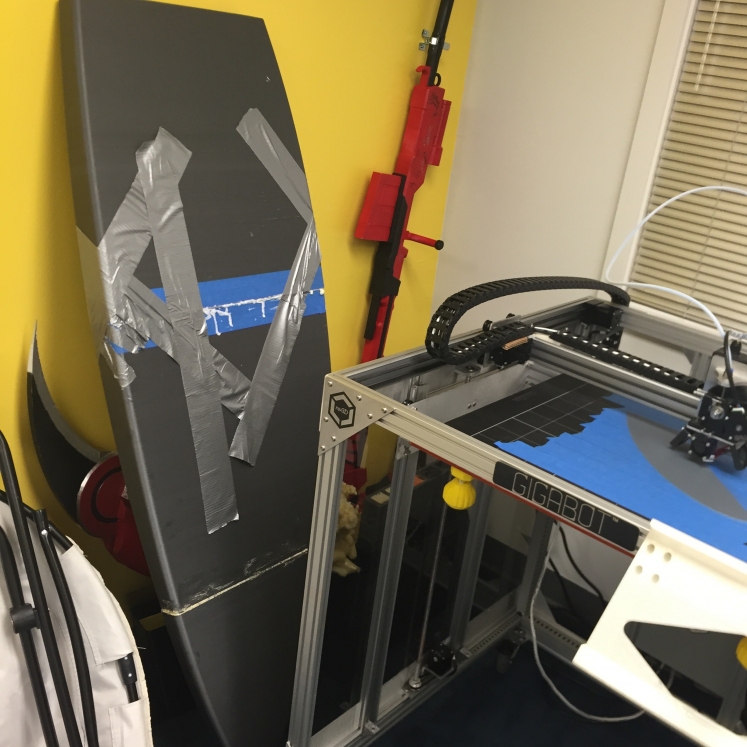

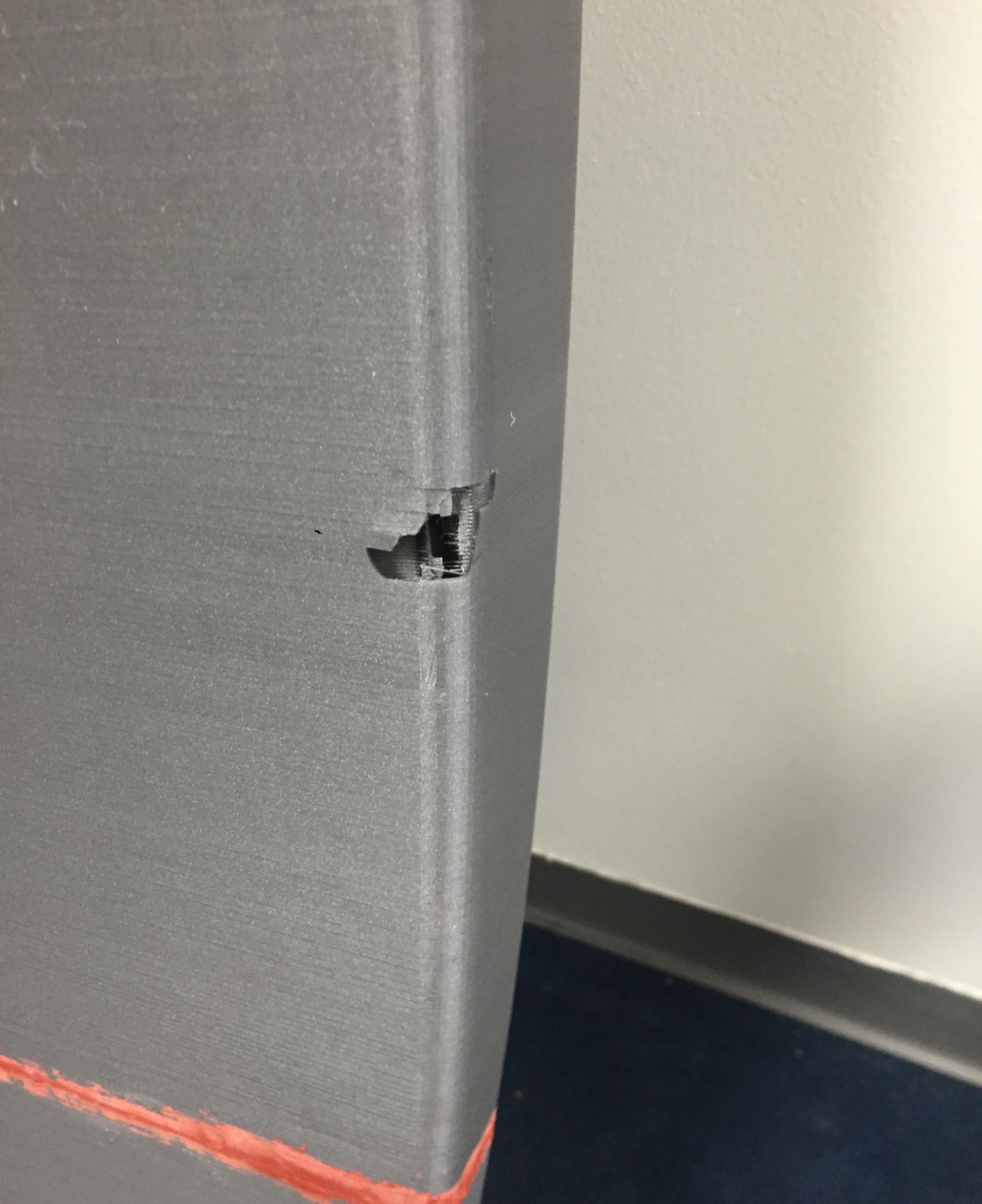

By the time the 1.5 long week print was ready for the final piece, July had morphed into August and Akshay had to return to high school. A couple of weeks into September we attempted to resume the project and he modeled the 4th piece using feedback I relayed remotely. Despite my best efforts, the measurements provided were a little off and the 4th piece wouldn’t align. Both Jeric and Mike supported a redesign and during a long weekend, Mike ultimately generated the final component to Akshay’s vision as well as some much needed “deckholes” our research revealed was required for a surfboard leash, which we purchased from SUP ATX as we figured the extra length on stand-up paddleboard leashes offered might be needed later. With the body complete, we encountered a new set of challenges. During a commute between our Houston and Austin offices, our almost finished 3d printed surfboard took a tumble on our high-strength 3D printed bicycle designed by Patrick, leaving a rather impressive hole. Determined to make it work, I filled the crevice with silicon prior to using Bondo to level the uneven Gorilla Glue texture.

Jeric did a stellar job capturing a time-lapse of the final piece!

The Test

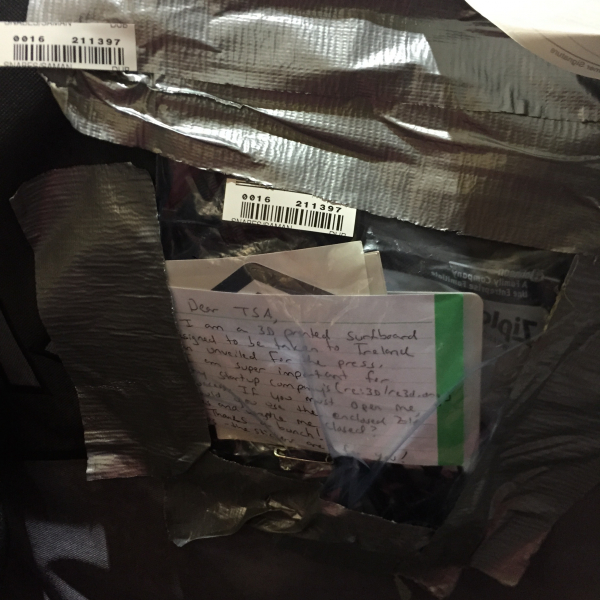

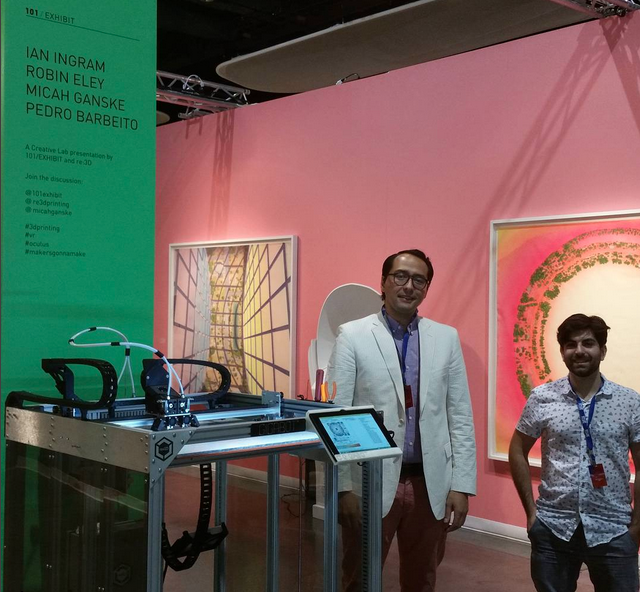

While touring an untested BETA experiment 7000 miles might sound crazy, for our team it made perfect sense. We had won 2nd place at Websummit last year for pitching our vision to 3D print from trash and 1st at their US event, Collision which granted us free passes for our team to return to Ireland. It therefore seemed natural to transport a untested ambitious print across the sea in front of thousands of media & startups in the name of challenging assumptions around 3D printing. Upon reflection on the flight to Ireland, it became evident that our success to date and win at Collision, was truly a testament to community support. For this reason, we decided it would be an honor to recruit as many stickers as possible from Web Summit attendees willing to affix their brand to our untested experiment. We humbly collected 150+ logos, including StickerMule, a popular vendor.

Shaun the Sheep

If you followed us or Web Summit/Surf Summit on social media in the past month, you might be a little confused by the multiple references to sheep, Shaun, Gigabot, Irish shepherdesses, and surfing sheep.

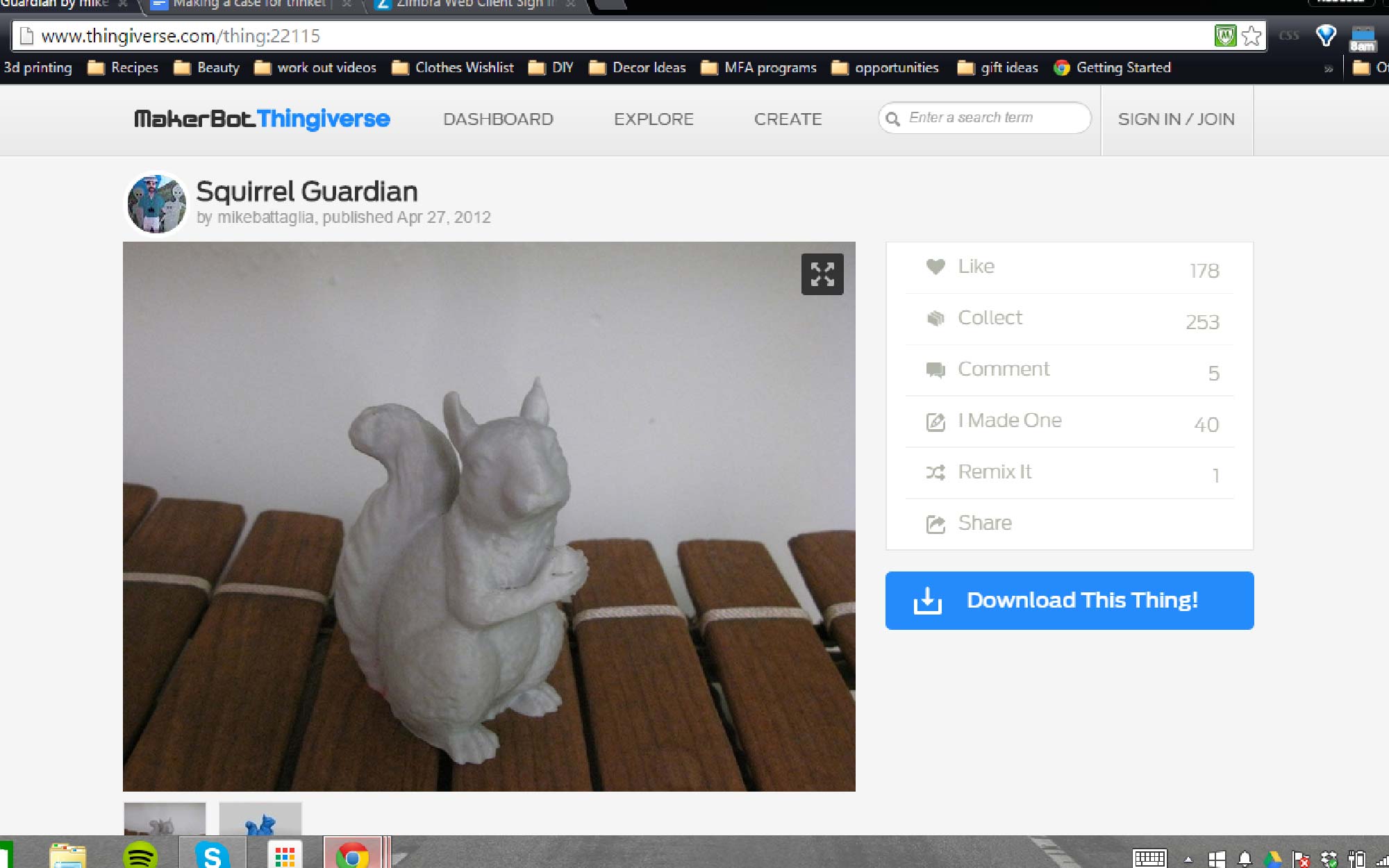

The idea to 3D Print Shaun the Sheep was conceived by a female Sheppard & blanket maker named Suzanna of Zwartbles Ireland. Suzanna maintains an active community via social media (@ZwartblesIE) and during our flight over suggested #Gigabot could #3dprint a #sheep in #ireland. The initial Tweet inspired a lively conversation and I found myself Googling open-source sheep stls while flying past Iceland. When Katy & I landed, Matthew suggested this Wooly Sheep by pmoews to test out on Gigabot, which had been created using a 123D Catch, now ReCap Pro, scan of a garden ornament. Three days of continuous sheep printing and ewe puns soon began. Katy christened the first small-scale sheep as Dolly before making a larger 14 hour sheep. The downside of running large prints is that Gigabot has to work throughout the night. The 3rd shift security team had the pleasure of watching our biggest sheep complete and informed us one morning that they had named him Shaun. It wasn’t until later the next day that we learned Shaun referred to a popular show titled Shaun the Sheep. Shaun quickly garnered a small fan club, and we decided to take him to Sligo, Ireland for Surf Summit as the prize for the 1st surfer to successfully catch a wave on the surfboard.

Surf Summit: The Moment of Truth

As soon as Web Summit concluded, we crated Gigabot for the return to Texas, them scrambled to pack our bags, the surfboard, and sheep for the bus ride to Sligo, the host of Surf Summit. Surf Summit is an incredible post-summit event to cultivate friendships while experiencing the Irish countryside. As the video reveals, it was a breathtaking experience- our only regret being Matthew couldn’t attend in leu of a customer he committed to visiting in the UK. As complete surf novices, Surf Summit provided the perfect proving group for the surfboard test as several surf pros were in attendance to share their experience & wet suits!

Prior to surfing, we attended the kickoff festivities and allowed Shaun to circulate with the attendees before (he hoped) he would be gifted to a deserving surfer.

Session 1

The next morning we loaded the board, attached the fin, crossed our fingers for good luck and took off to Streedagh Beach. Upon arrival, we were greeted by a team of instructors from Surf World Bundoran, who helped us wax the board and taught birthday girl Katy & I to surf for our first time. The experience was unforgettable.

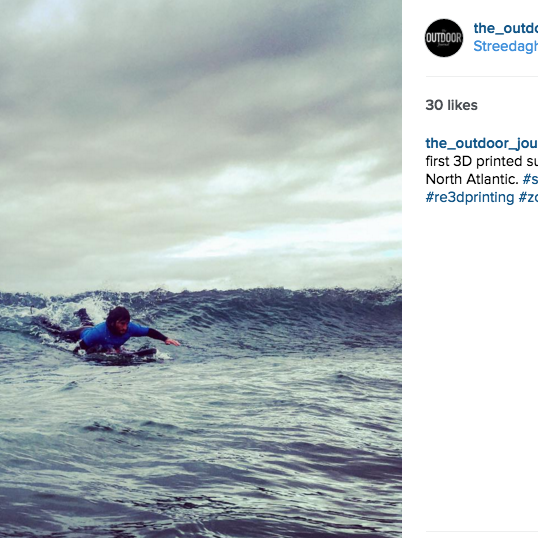

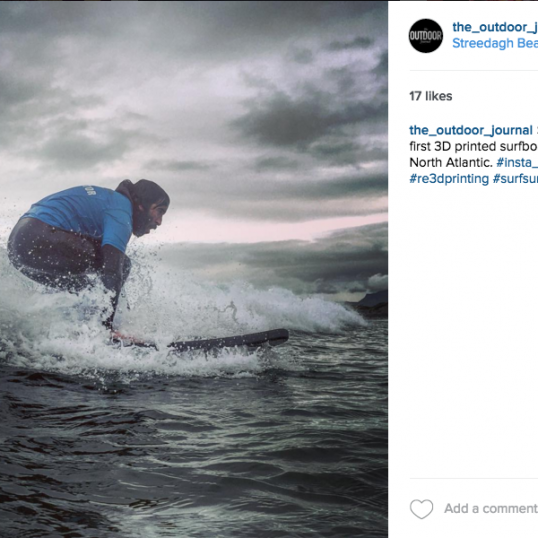

As our lesson concluded, SurfWorld Instructor Tony volunteered to take our stickered print out on the water. We grabbed our cameras and huddled with our new start-up friends from The Outdoor Journal to capture a mini photo shoot before take-off. The tension was palpable and we all lingered a moment discussing the project, for fear that the board was soon break or worse, sink, taking with it the evidence of so many peers who had supported the endeavor.

Tony proceeded with caution, first testing the buoyancy in shallow waters near the beach, then gradually paddling out further. After a few minutes, he headed out to see if he could catch a break. It wasn’t long before a series of rolling waves emerged and, as luck would have it, he was able to ride one in!

After Tony broke the seal, two other brave instructors also offered to take the surfboard out, despite loosing a fin!

Session 2

Wanting to optimize our wave catching, we headed back to the hotel, then caught a cab to Strandhill beach to join another surf instruction course after lunch. There we met the crew at iSurfIreland who agreed to try her out and broke personal records in distance traveled (which complicated picture taking)! Four surfers tested the board, and gave us valuable improvement ideas.

Feedback

In total 7 instructors braved the board. The advice we received was pretty consistent:

- The current board is too thick

- In the future it should be thinner and consideration should be given to reducing weight

- The curve is not ideal

- The board should bow more at the top

- We could have better leveraged the benefit of 3D printing

- The current design mirrors current manufacturing aesthetics and could have been sexier

- Surfers appreciate custom features (holds for cameras, grips, personalized lettering)

- The absence of a durable fin made it hard to maneuver

- I should have printed the fin flat so it couldn’t delaminate, and/or used honeycomb for more density

- A three or multiple fin design would be ideal

- Ours had only a single fin

- Stickers made the board more slick, albeit cool!

- Everyone seems optimistic that 3D printed has great potential in watersports, especially wakeboards and body boards

One Month Later

Currently the surfboard resides in our Austin office. What began as an idea, transformed into a internship, that took us 7000mi and introduced us to new friends around the world. As we reflect on the people we met through Akshay, sheep printing, sticker collecting, and trial by water we are struck by the creativity & vision that the community shared. We hope this is the first of many use cases that will expand our perspective on what is possible through affordable, life – size 3D printing. We welcome your ideas on where we go from here!

Happy Printing,

Samantha snabes

Blog Post Author