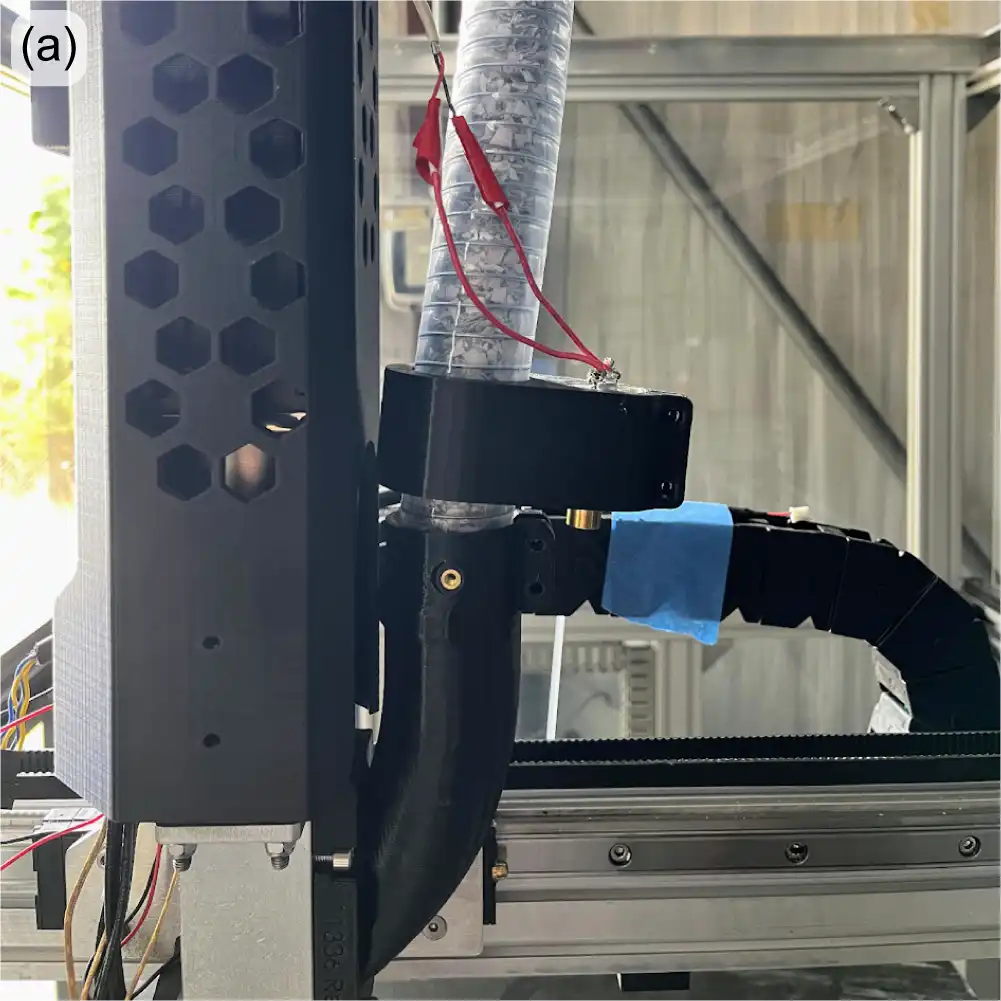

When we set up the Gigalab in Bayamón, Puerto Rico, alongside our neighbors and partners at Engine-4 Foundation, we weren’t just building a container lab. We were planting a seed, an idea that digital fabrication should be for everyone, and that creative tools should serve the people around us.

So we started small. One design, every Friday. Free. Useful. Sometimes funny. Sometimes experimental. Always open.

What started as a small weekly gesture quickly grew into something bigger, a rolling catalog of open-source designs, community responses, and whimsical one-offs that anyone can download, print, and build on. While we’ll be highlighting a few of our favorite moments here, there are plenty more where these came from. So if something catches your eye, or if you’re just curious, we invite you to dive into the rest of our #FreePrintFriday designs on Thingiverse and Cults3D.

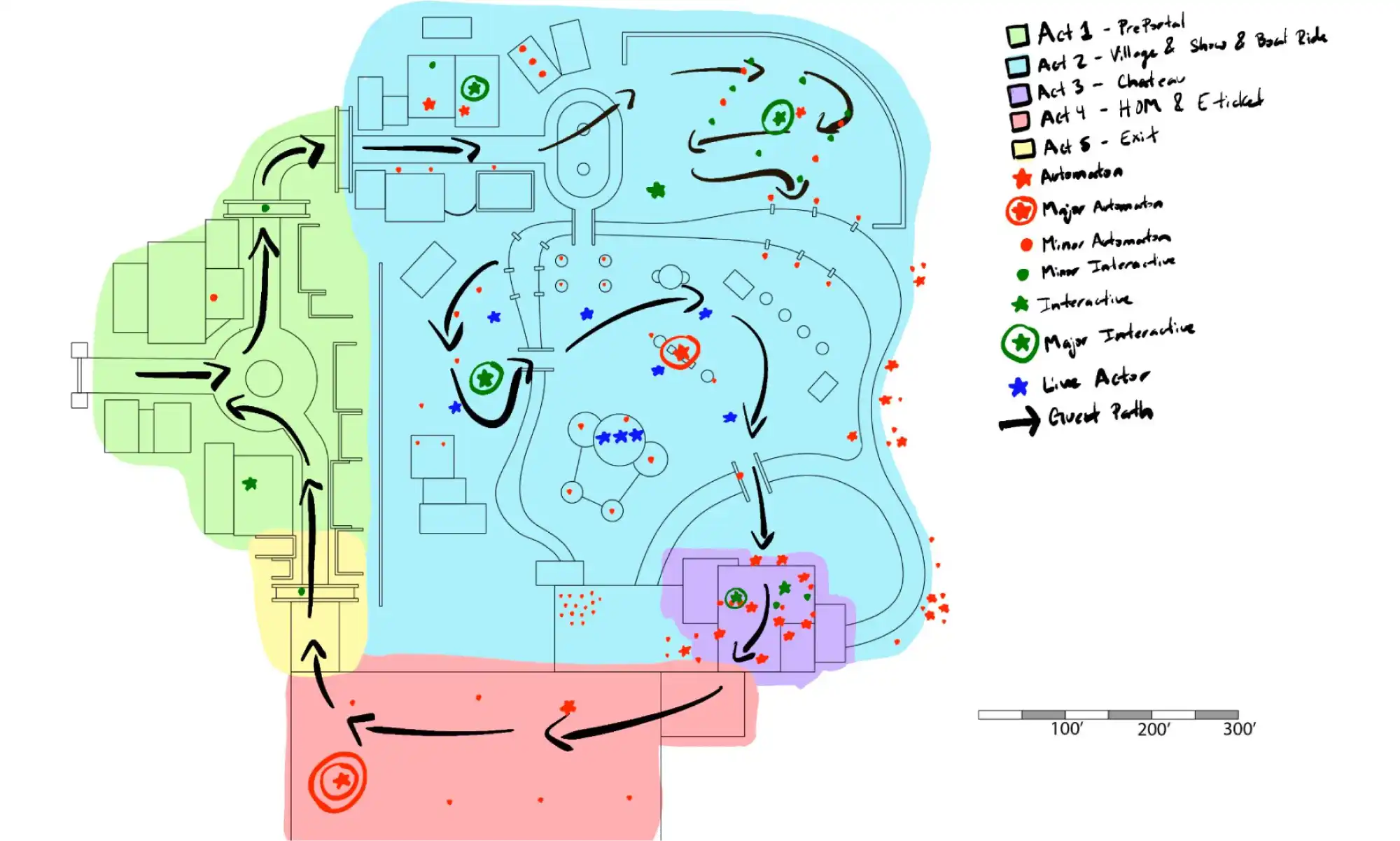

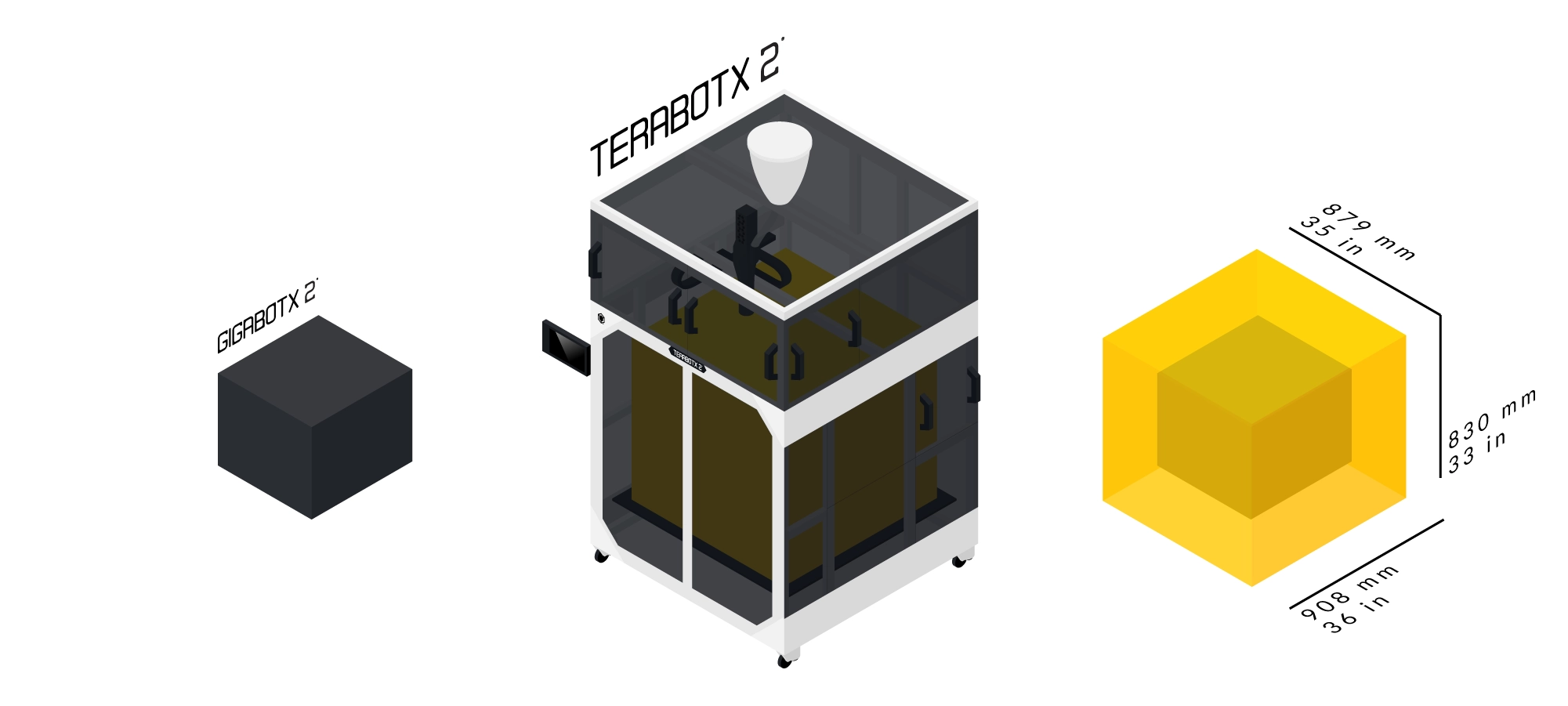

Big Bots, Big Ideas

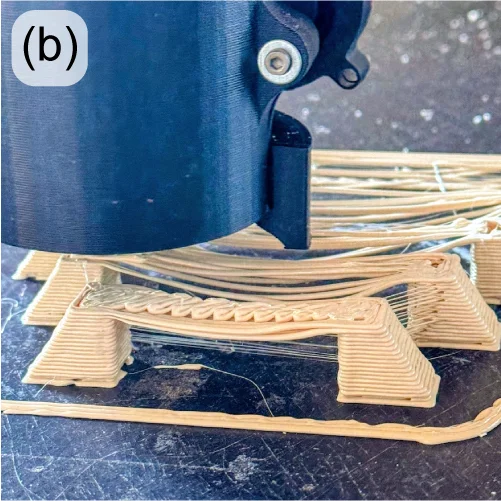

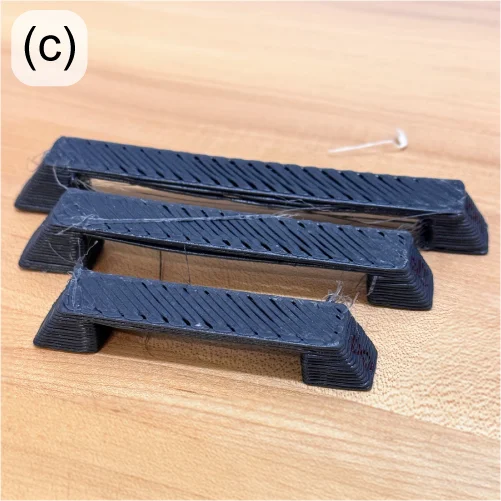

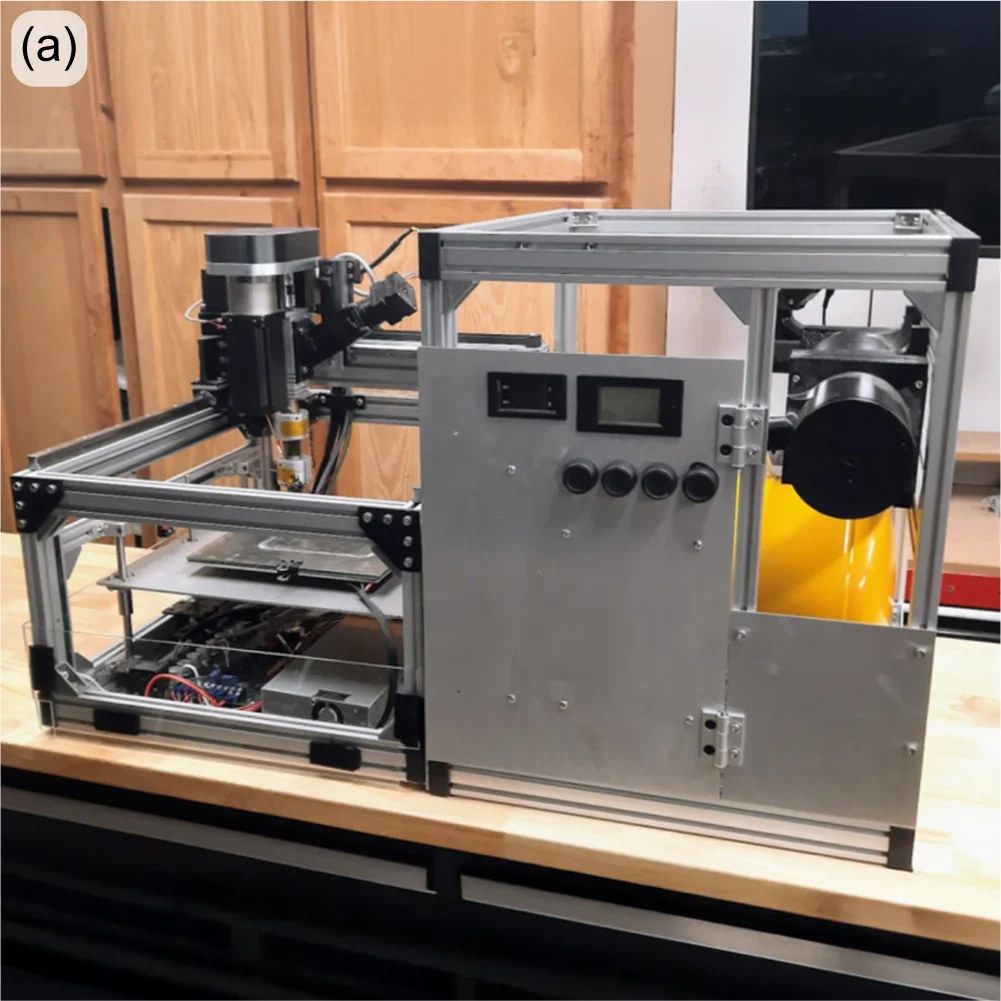

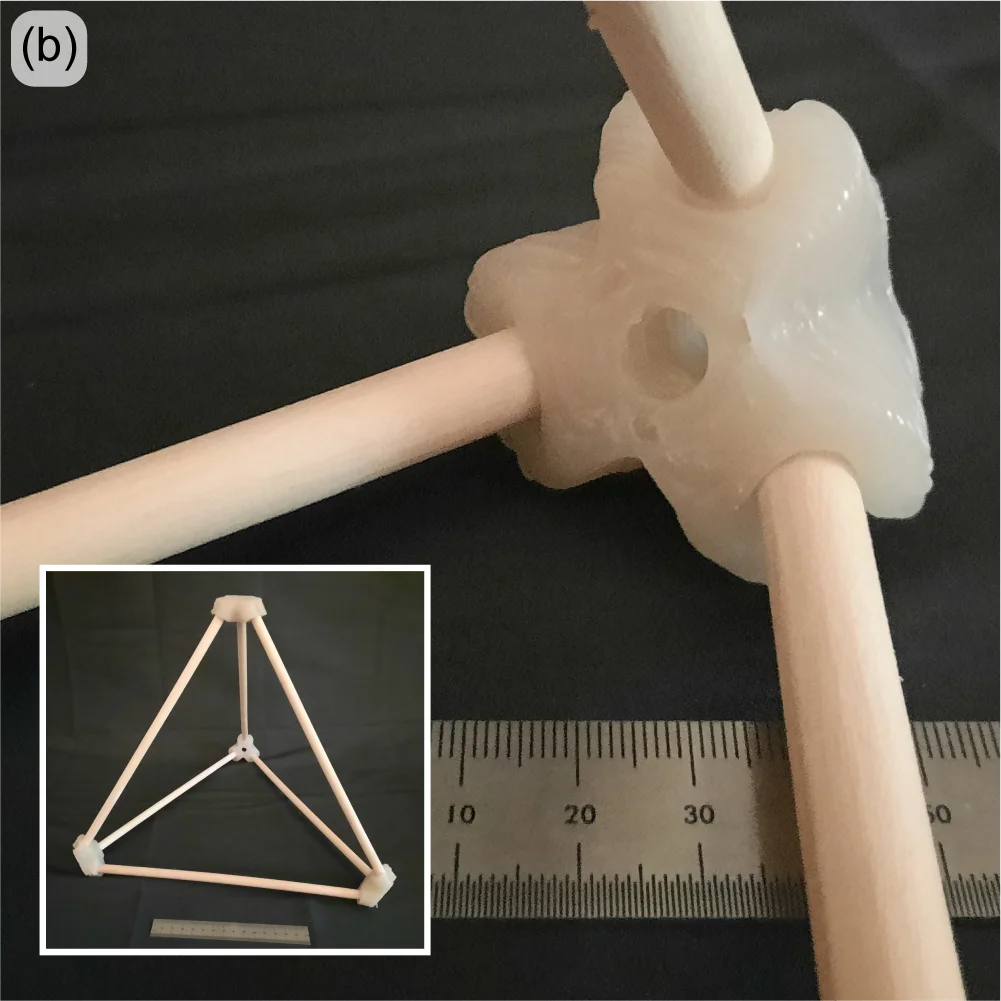

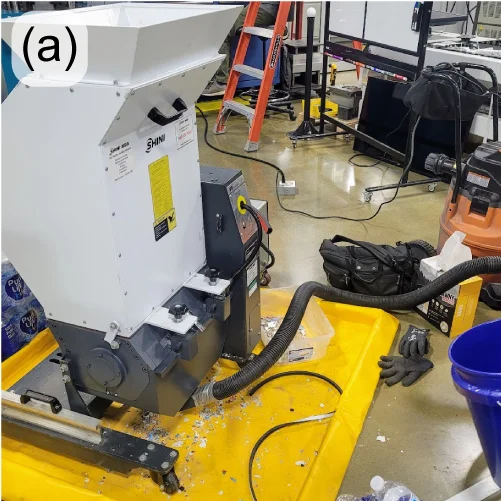

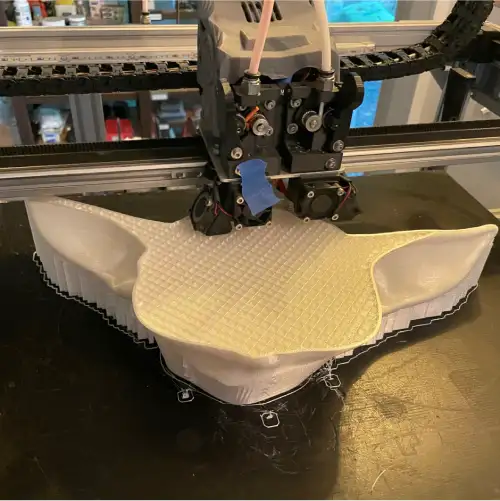

Our 3D printable kite experiment. Still very much a work in progress, but easily one of the most fun things we’ve ever designed. Building something that’s meant to flex, fly, and occasionally crash (gracefully) has pushed us to think differently about material use, weight, and structure—all while showcasing the beauty of recycled 3D printing.

Collaborations with Our Local Community

Working alongside our neighbors at Engine-4 Foundation has been core to Gigalab’s mission. Many of the ideas we’ve printed came directly from conversations at Engine-4 with Co-Founder, Luis Torres, whether it was a passing comment, a workshop brainstorm, or someone pointing at a problem and asking, “Can we 3D print a fix for that?”

Some standout collabs include:

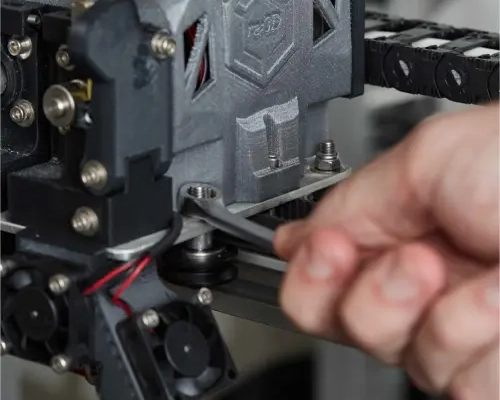

The drone care package hook, a collaboration with both Engine-4 Foundation and the Municipio of Bayamón, used in earthquake simulations to deliver supplies via agricultural drones.

More on the simulation from Puerto Rican local news:

Primera Hora | Telemundo

These kinds of projects remind us that when we design with our community, we design with purpose.

Culture, Celebrated in Layers

Some of my proudest open-source designs that connect with my Puertorrican identity:

Our photogrammetry model of the Monumento al Jíbaro Puertorriqueño, scanned, modeled, and shared to honor Puerto Rican heritage in a tangible way.

These designs always spark conversation, everything from an “aw” to an “I want one” to someone recognizing their own story in it, saying, “I used to drive past that monument every day. The view was breathtaking.”

Designed for People

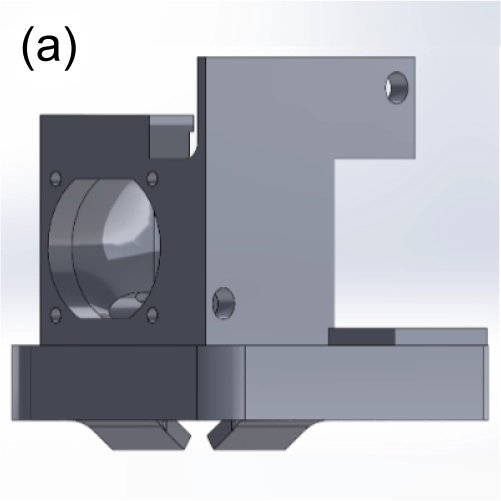

The most personal of our projects came through the Rotationplasty Prosthetic leg shell designs.

It started with a visit. Wilfredo Rodriguez and his daughter Emily came to Engine-4 with a bold question: could we design something that didn’t just cover for her unique rotationplasty prosthetic leg, but make it look and feel amazing? Something Emily could wear with confidence, something that felt like hers.

We scanned her leg using photogrammetry, modeled around it with Rhino and Fusion 360, and started prototyping with rPETG, Nylon, and TPU. Eventually, we found the right balance, lightweight, flexible, and durable enough for everyday life. The final shell was finished with automotive-grade paint for a smooth, protective finish.

But the story didn’t stop there.

Left is the back of Emily’s cover, middle is daniels cover and right is Emely and Anya

Emily’s friends Anya and Daniel, all the way in Boston, got scanned too. We designed and printed their custom shells right here at the Gigalab in Puerto Rico, and sent them north, each one uniquely shaped and styled for them.

This wasn’t just about aesthetics. It was about saying, with a smile, “I want that leg”

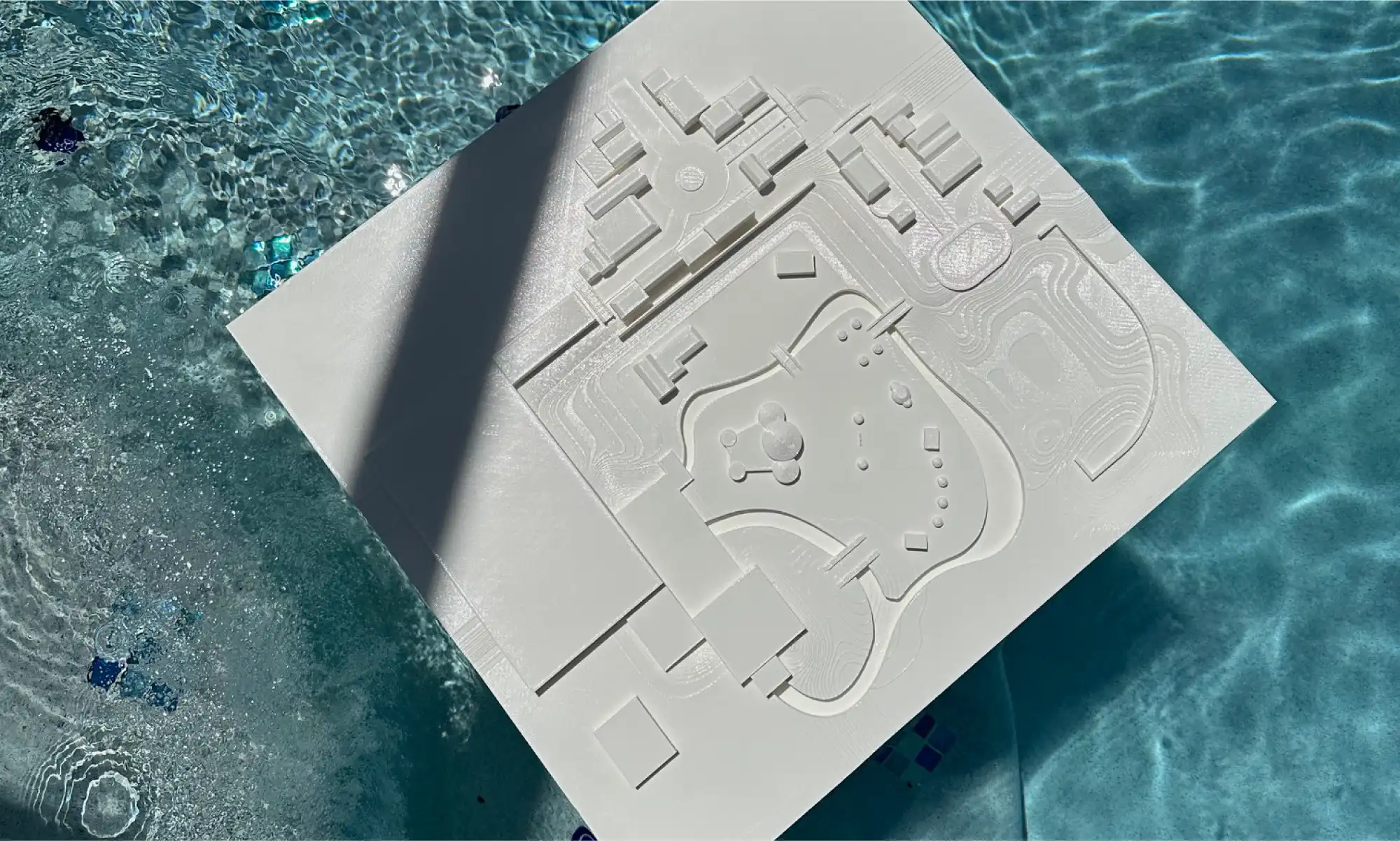

Creative Chaos at Haystack

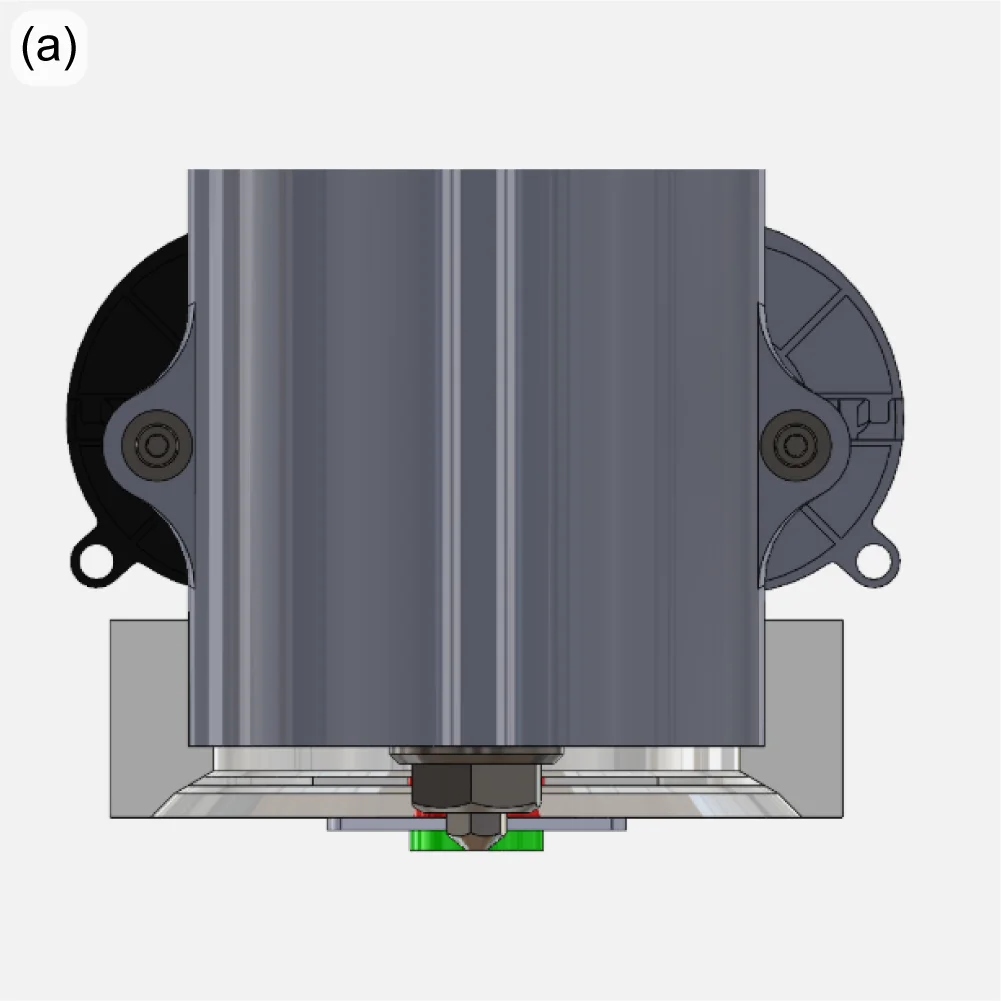

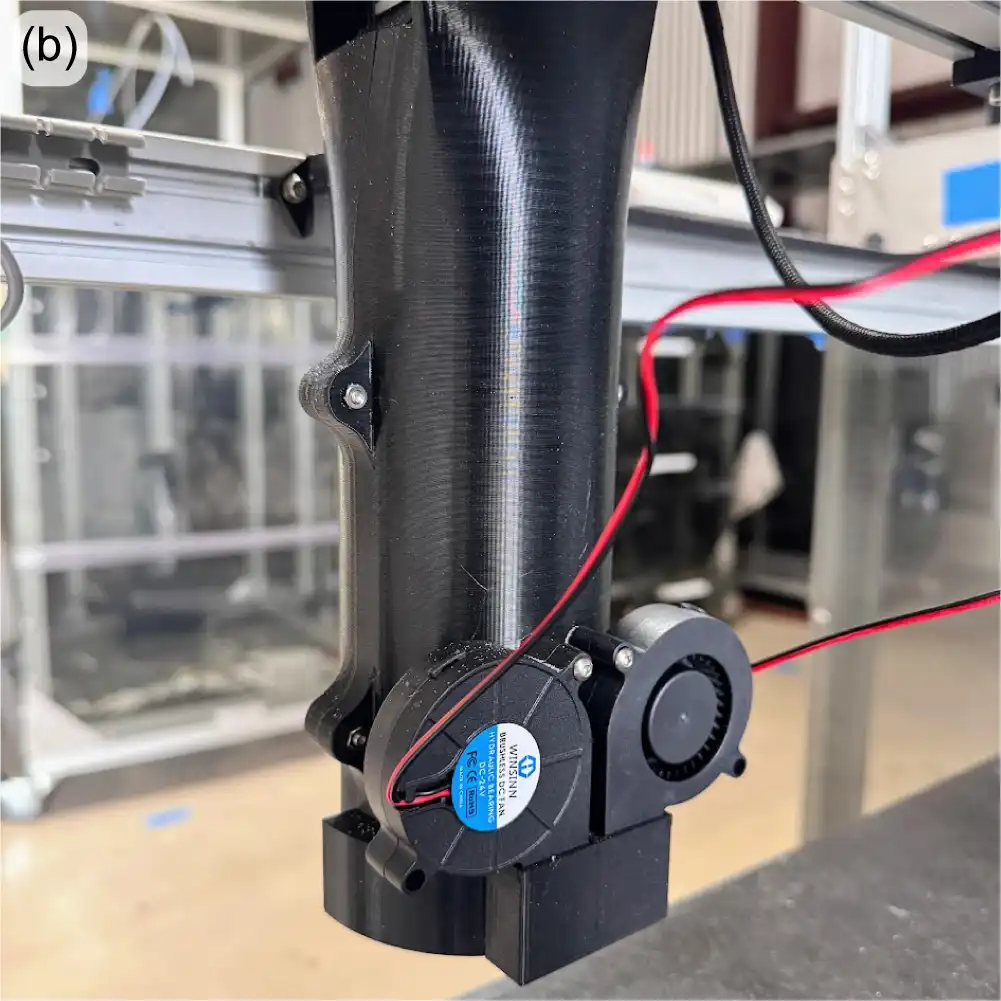

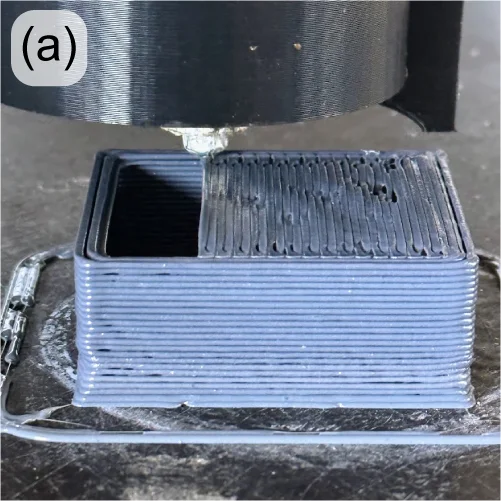

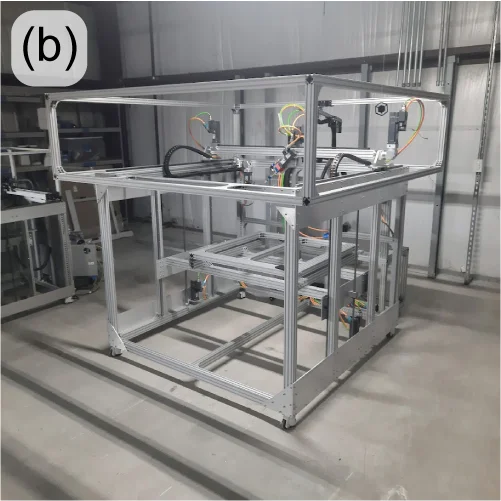

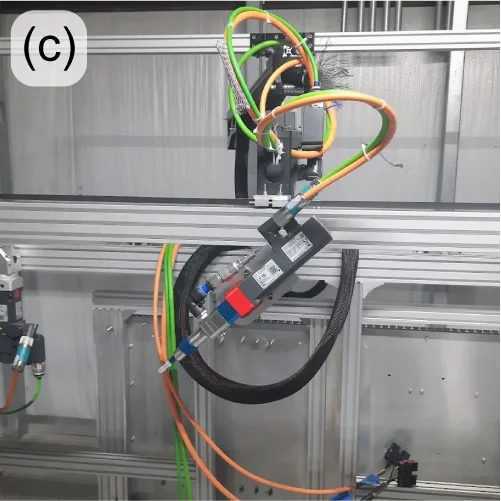

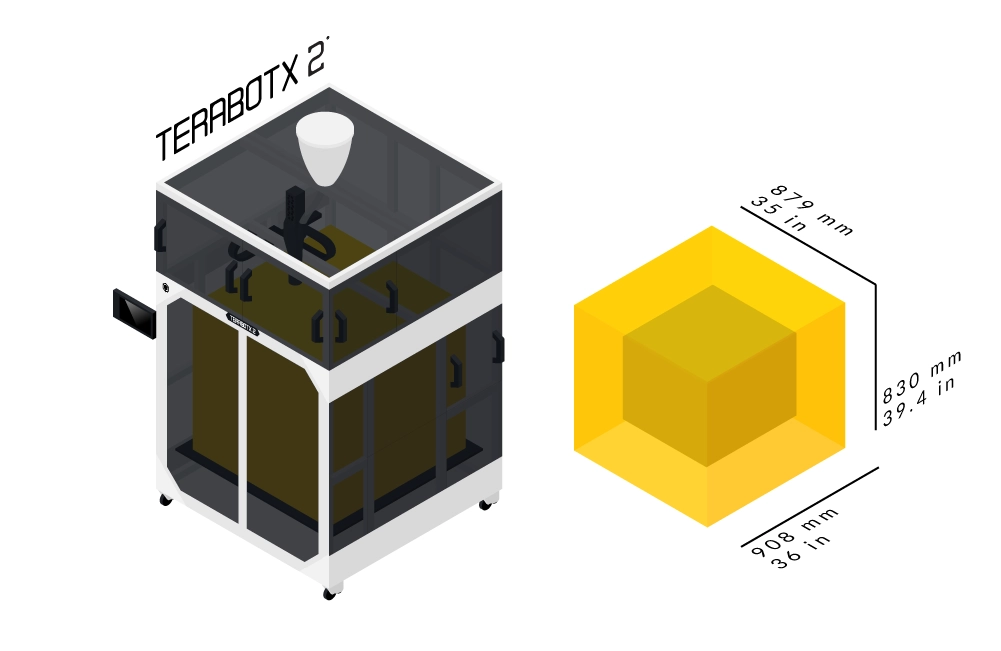

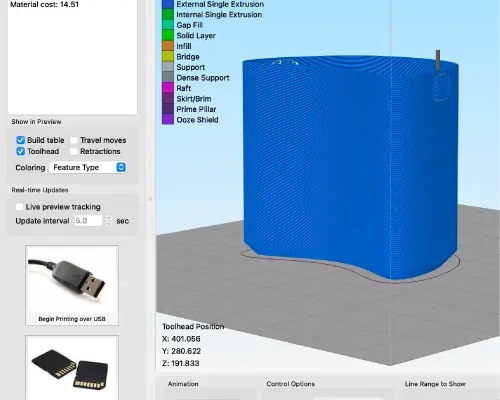

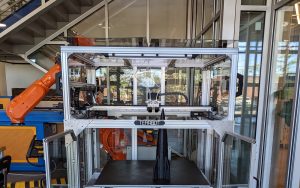

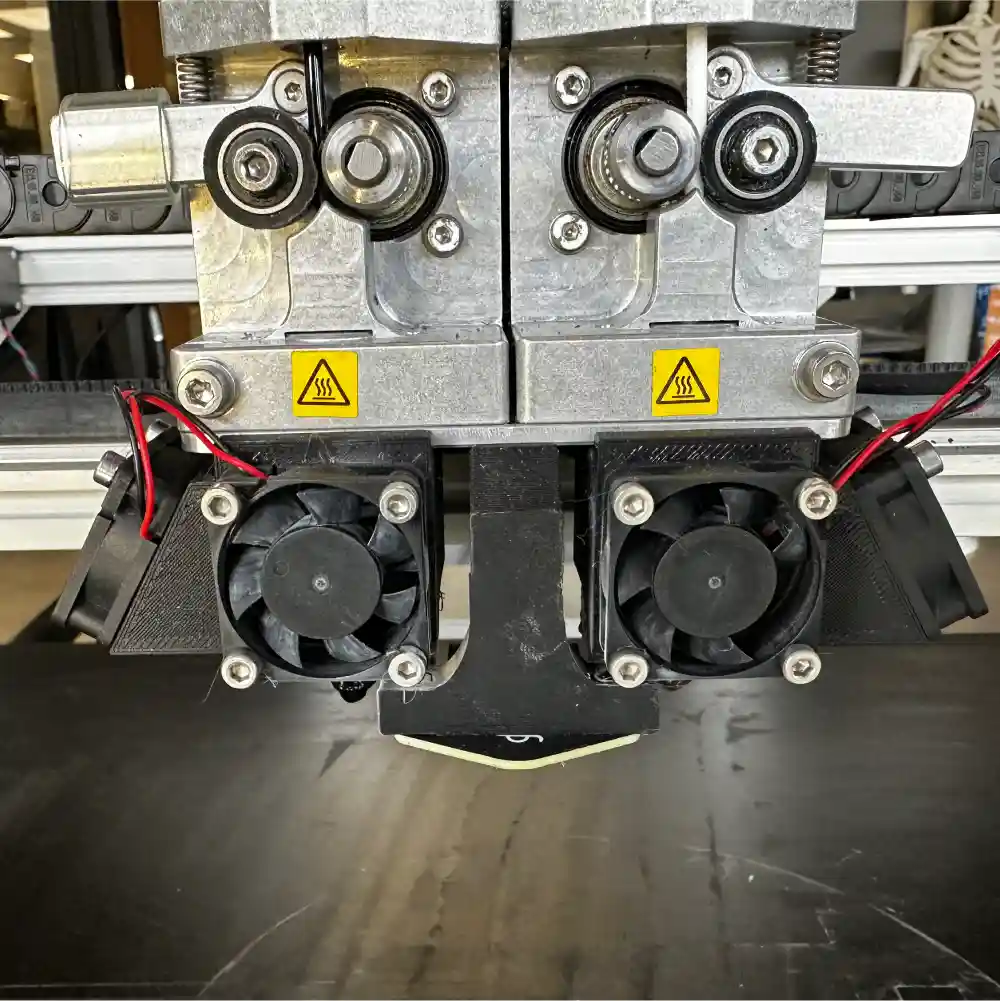

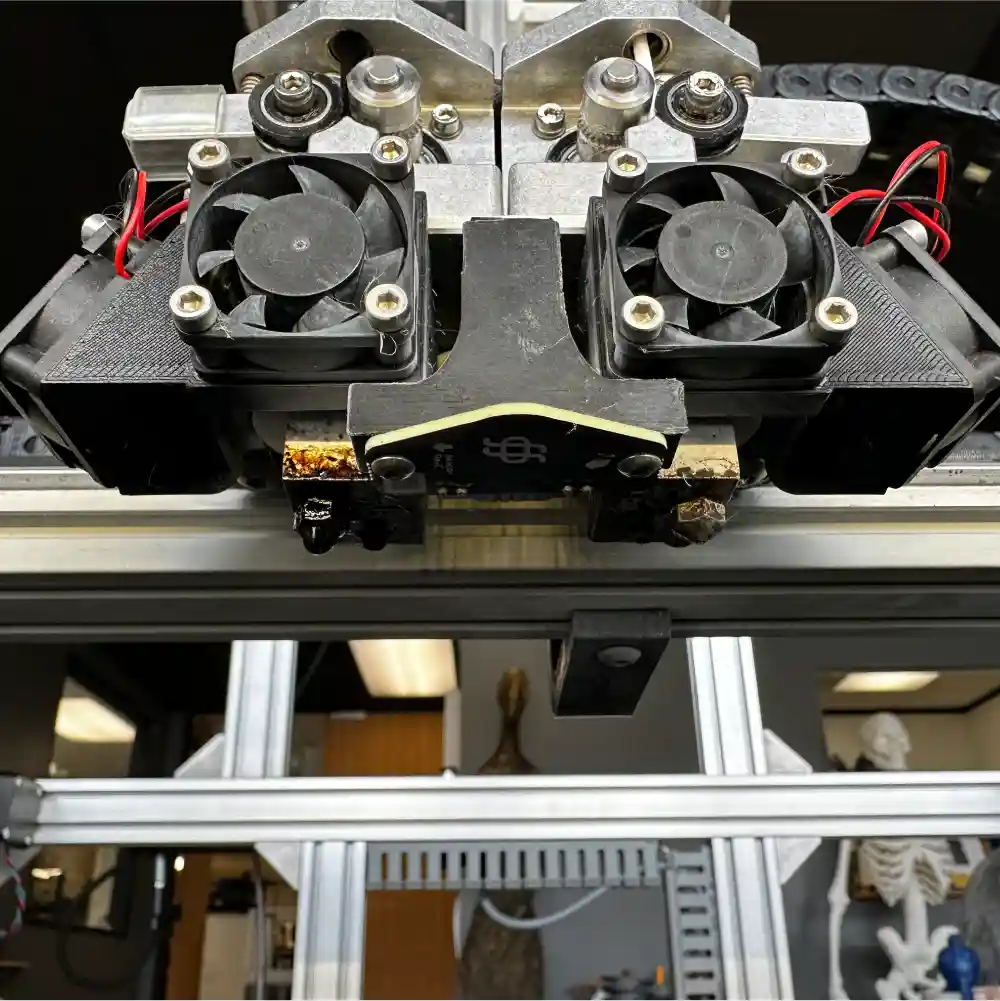

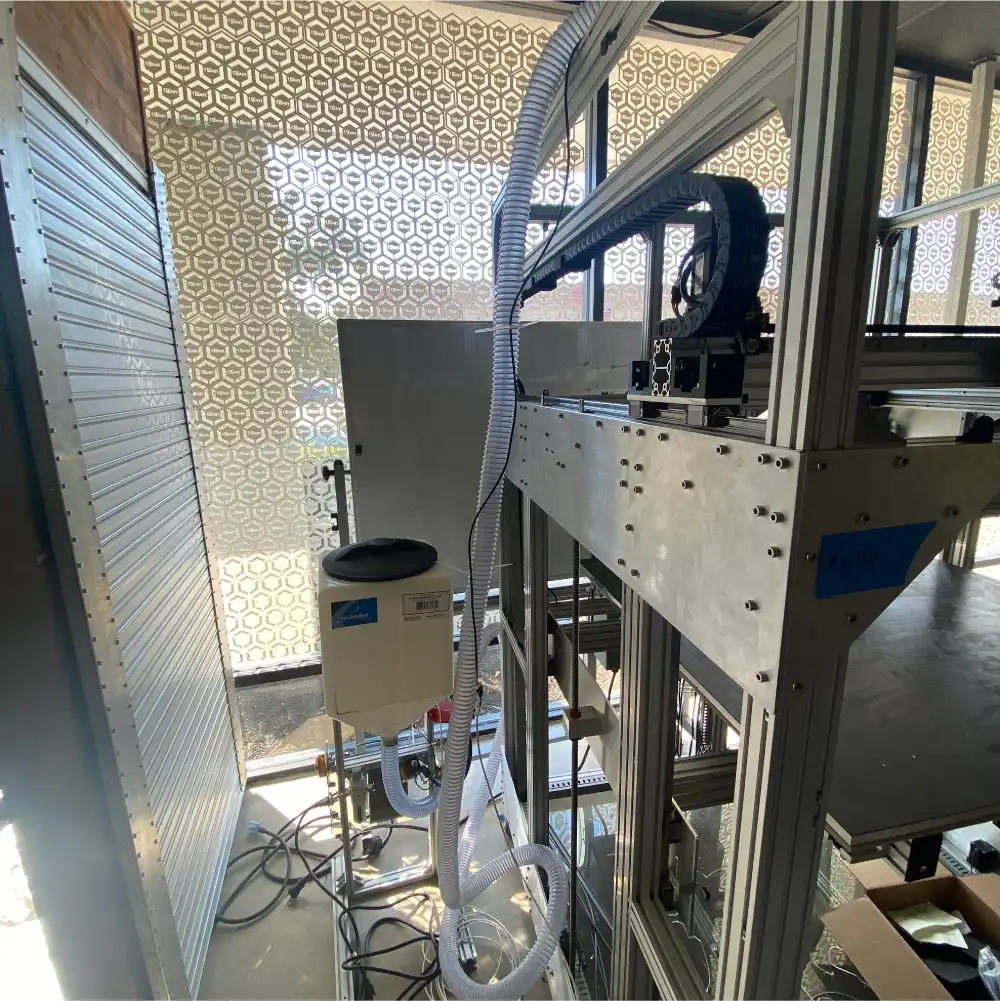

Located on the rugged coast of Deer Isle, Maine, Haystack Mountain School of Craft is a legendary space where artists, designers, and thinkers come together to push creative boundaries. We were lucky enough to be invited to spend a week there with the GigabotX 2 XLT for Haystack Labs, joining a wild mix of tinkerers and craftspeople for a creative tech residency.

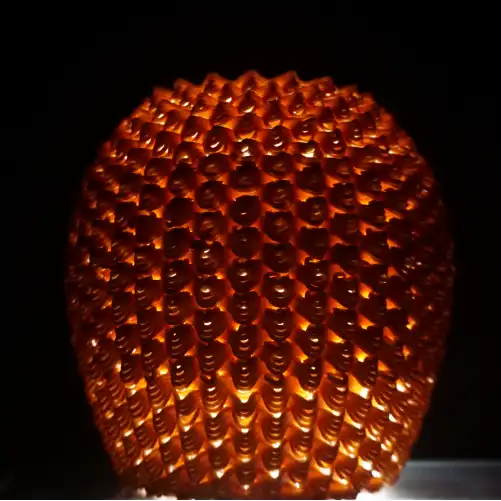

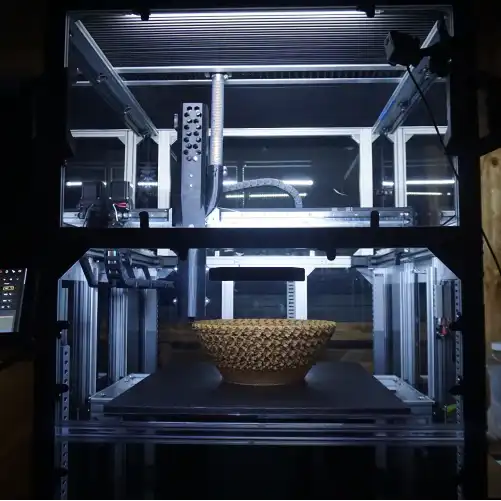

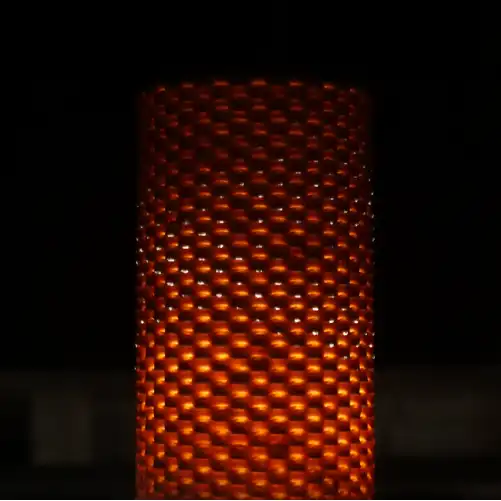

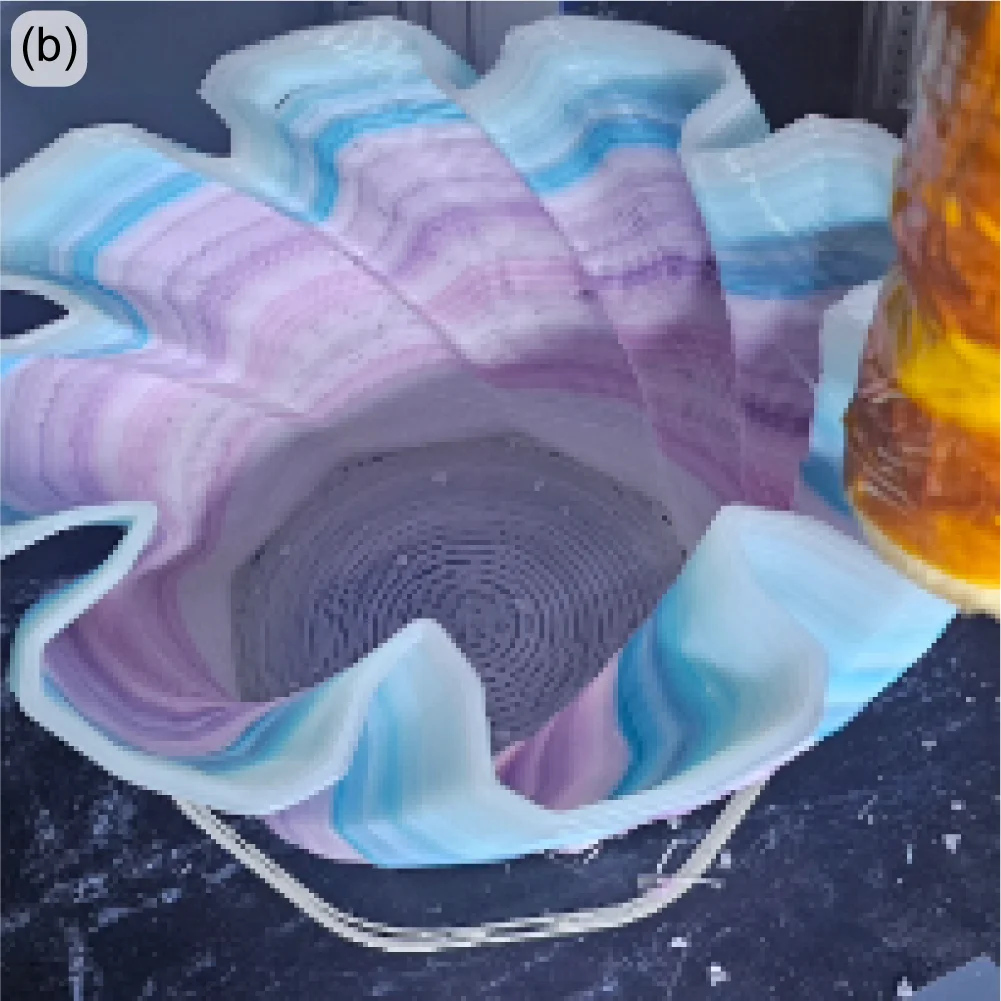

Designed by Shelby Doyle and printed on GBX2 XLT

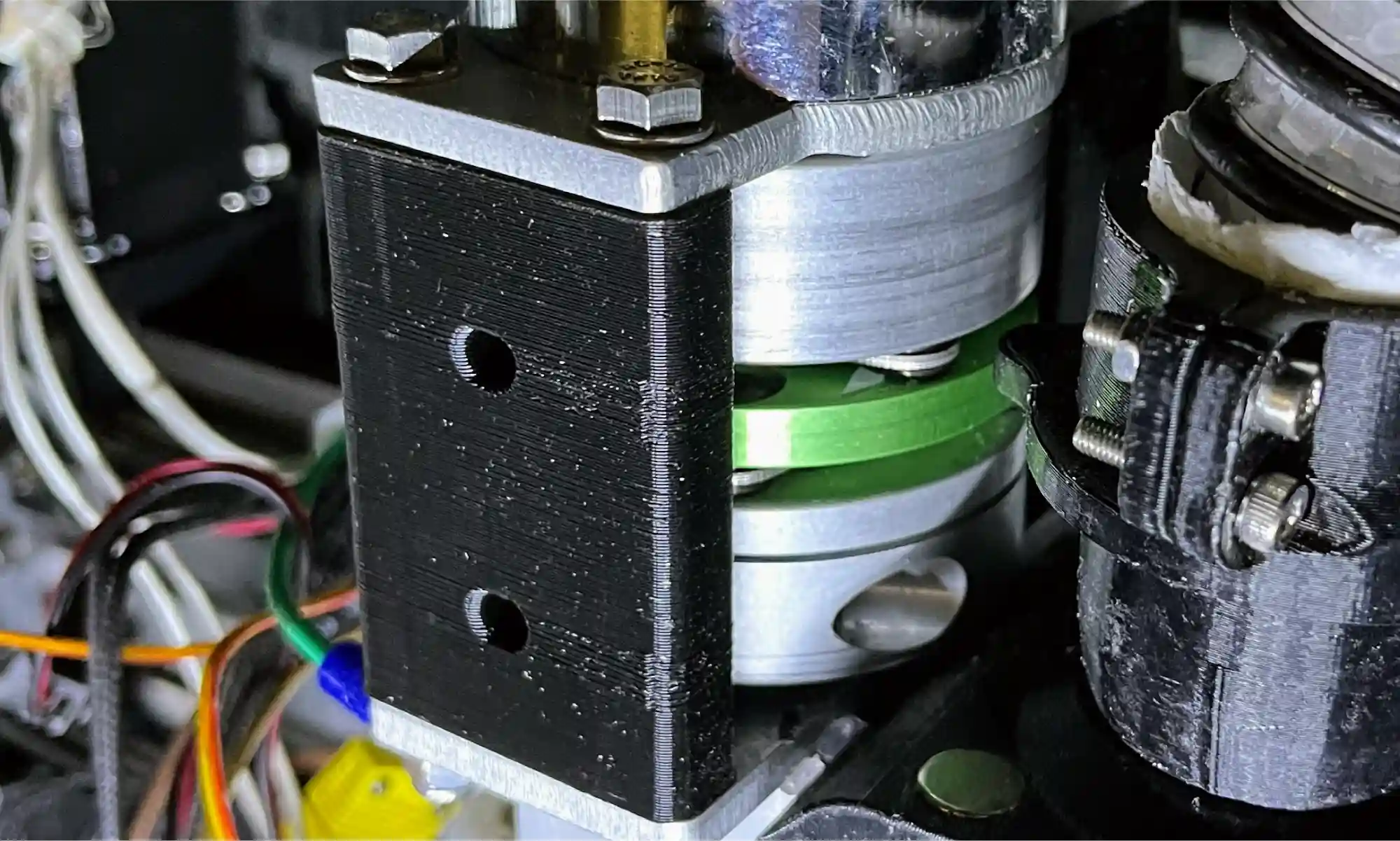

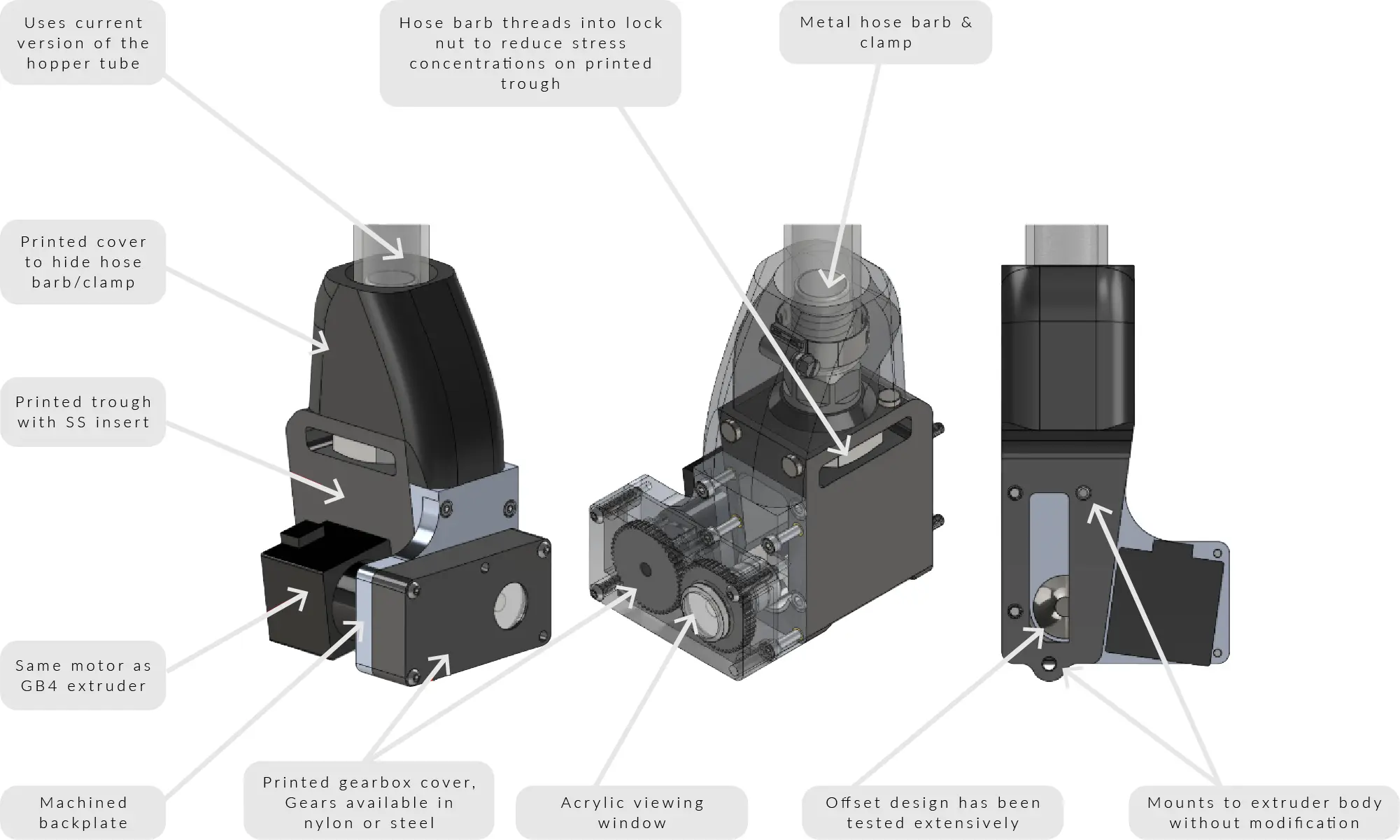

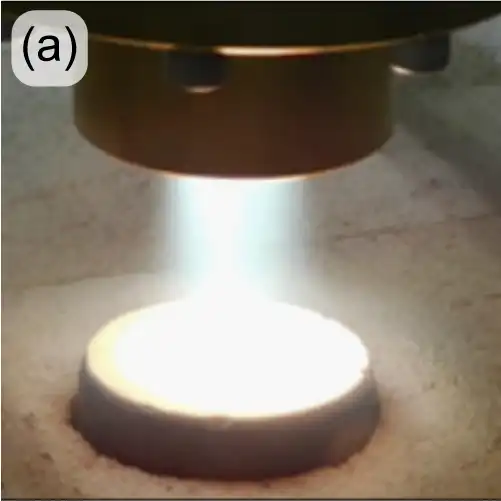

At Haystack, we experimented with University of Maine’s wood pulp PLA feedstock, tested out sculptural forms, tricky overhangs, and parametric designs that challenged our printers and our imaginations. We had the pleasure of learning with Shelby Doyle, AIA, an Associate Professor of Architecture at Iowa State University and co-founder of the ISU Computation & Construction Lab. Her expertise in digital fabrication and design-build education brought valuable insights to our explorations, pushing the boundaries of what we could achieve with recycled materials and large-format 3D printing.

But one of our favorite prints? A five-mug coffee caddy we designed because we were too lazy to take our mugs back to the kitchen one by one. Turns out the kitchen staff liked it too as it’s a recurring problem!

Functional Tools, Fun Fixes

A lot of our most downloaded open-source designs are little things that solve specific, everyday problems stuff that just makes life smoother:

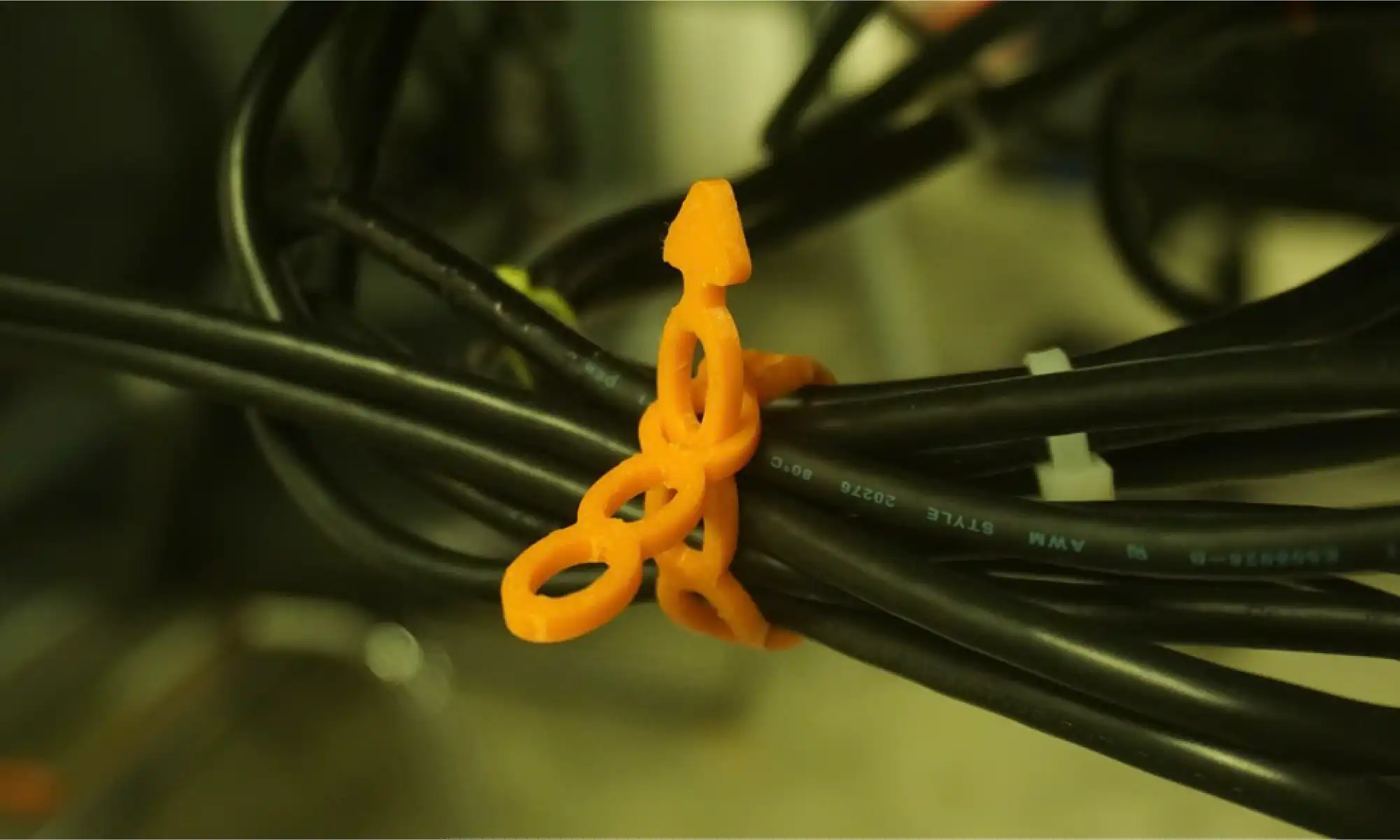

Inspired by SSgt Hart during our Gigalab demo at Cannon Air Force Base, she needed a better way to manage cables, had a great idea, sketch it out for us and we helped turn that need into a print anyone can use!

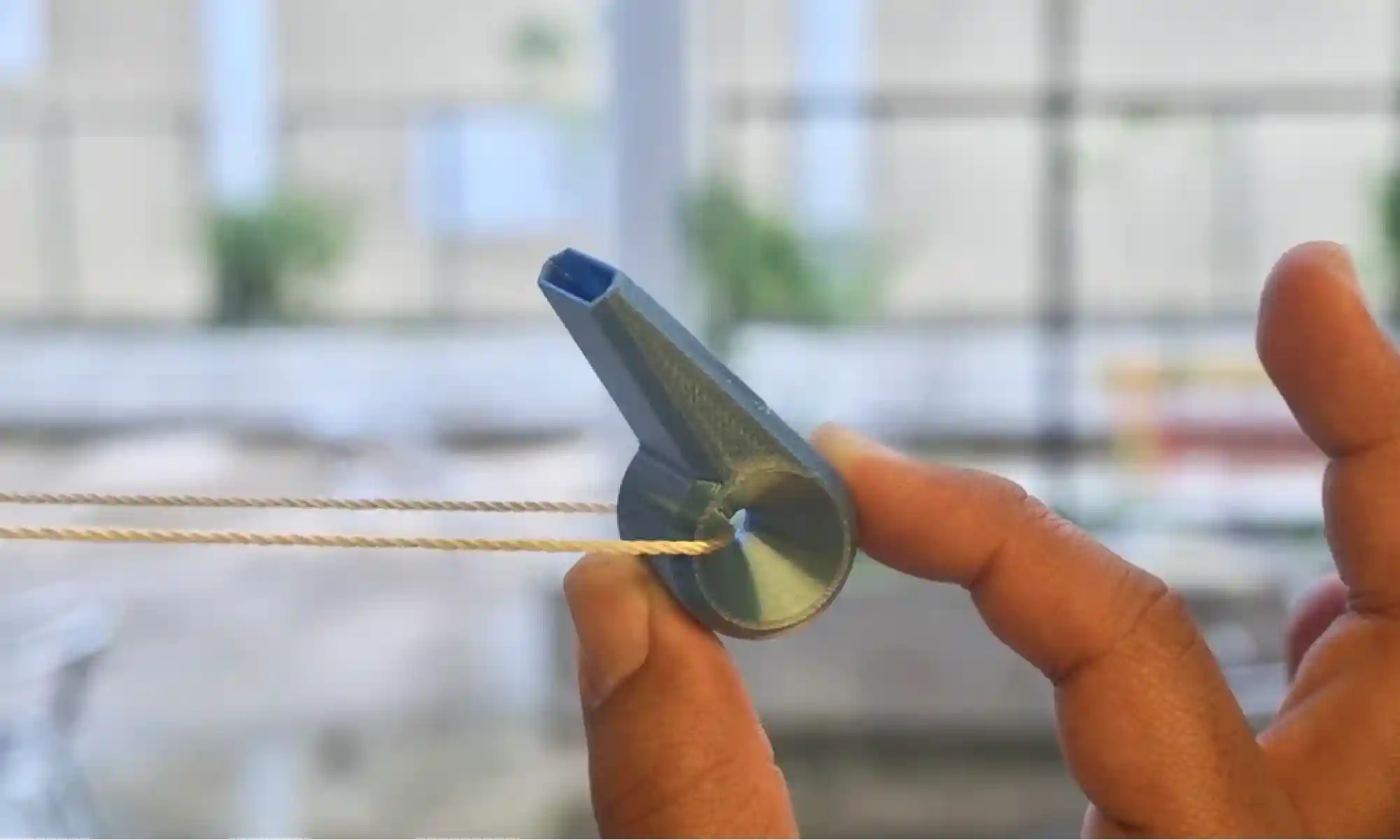

These weren’t built for retail. They were built for daily use, most came to life in under an hour, sparked by someone asking, “Hey, can you print something for this?” or even just a playful thought like, “What if we 3D print a whistle?”

A Year of Creative Response

Over the past year, we’ve shared over 50 open-source designs. Some are silly. Some are super niche. Some are actually really useful. Most are a little of all three.

What they all have in common is this: they came from the community, and they’re going back to the community. Free. Open. Ready to print.

Whether it’s a bookmark, a birdhouse, or a prosthetic leg cover, every design came from a simple idea: listen, learn, make, and share.

We believe 3D printing isn’t just a trend. It’s a tool for local problem solving, education, expression, and play. That’s why we do #FreePrintFriday .

So what’s next?

We’ve still got a backlog of unreleased prints. Expect more cultural remixes, more functional tools, more weird stuff. Maybe even more community collabs!

Got an idea? Shere it with us by filling out our #FreePrintFriday form, we’d love to hear it!

Here’s to another year of printing what matters (and what’s fun). See you Friday and happy printing!

– Michael C. Pujols Vázquez and re:3D team

Michael C. Pujols Vázquez

Blog Post Author