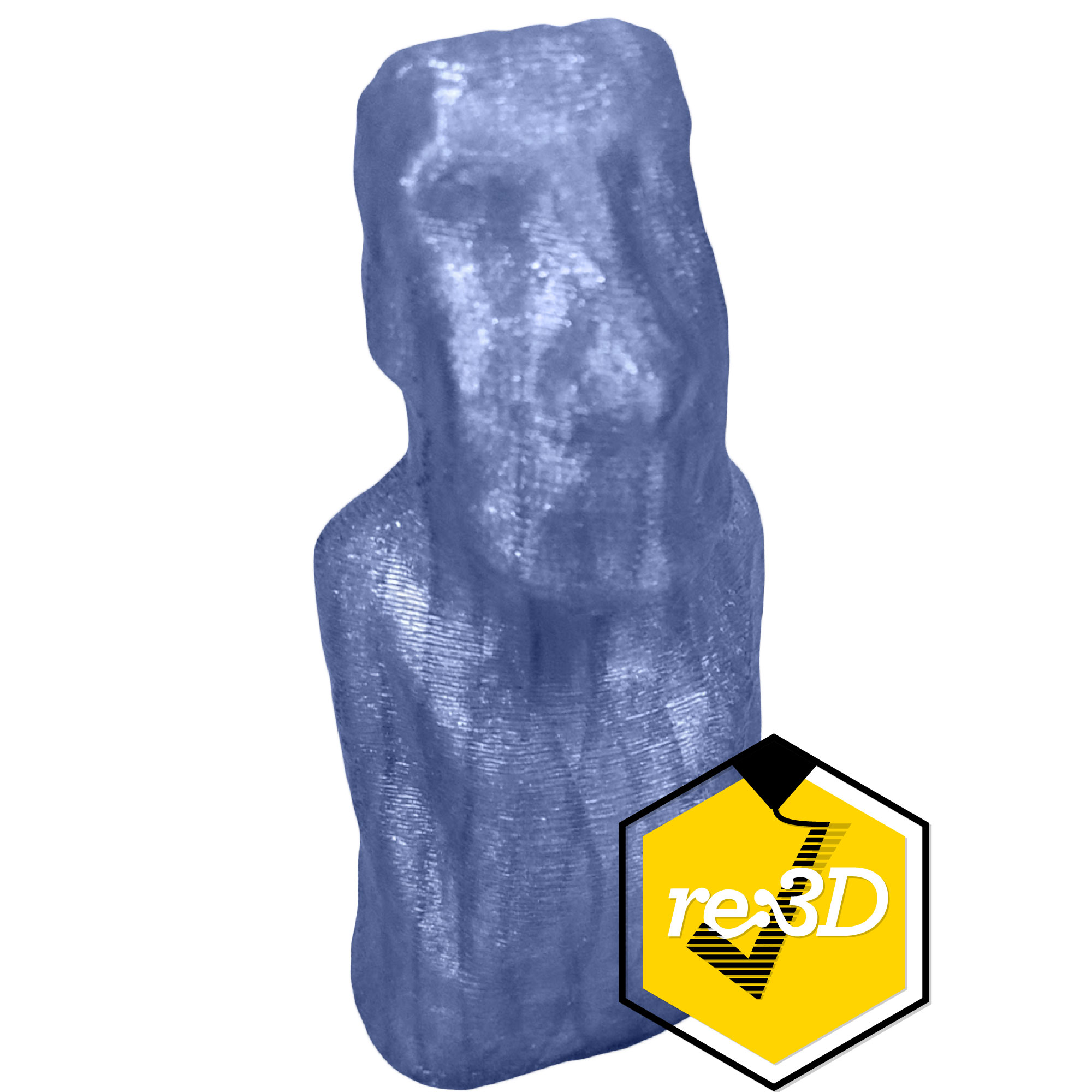

Design Services

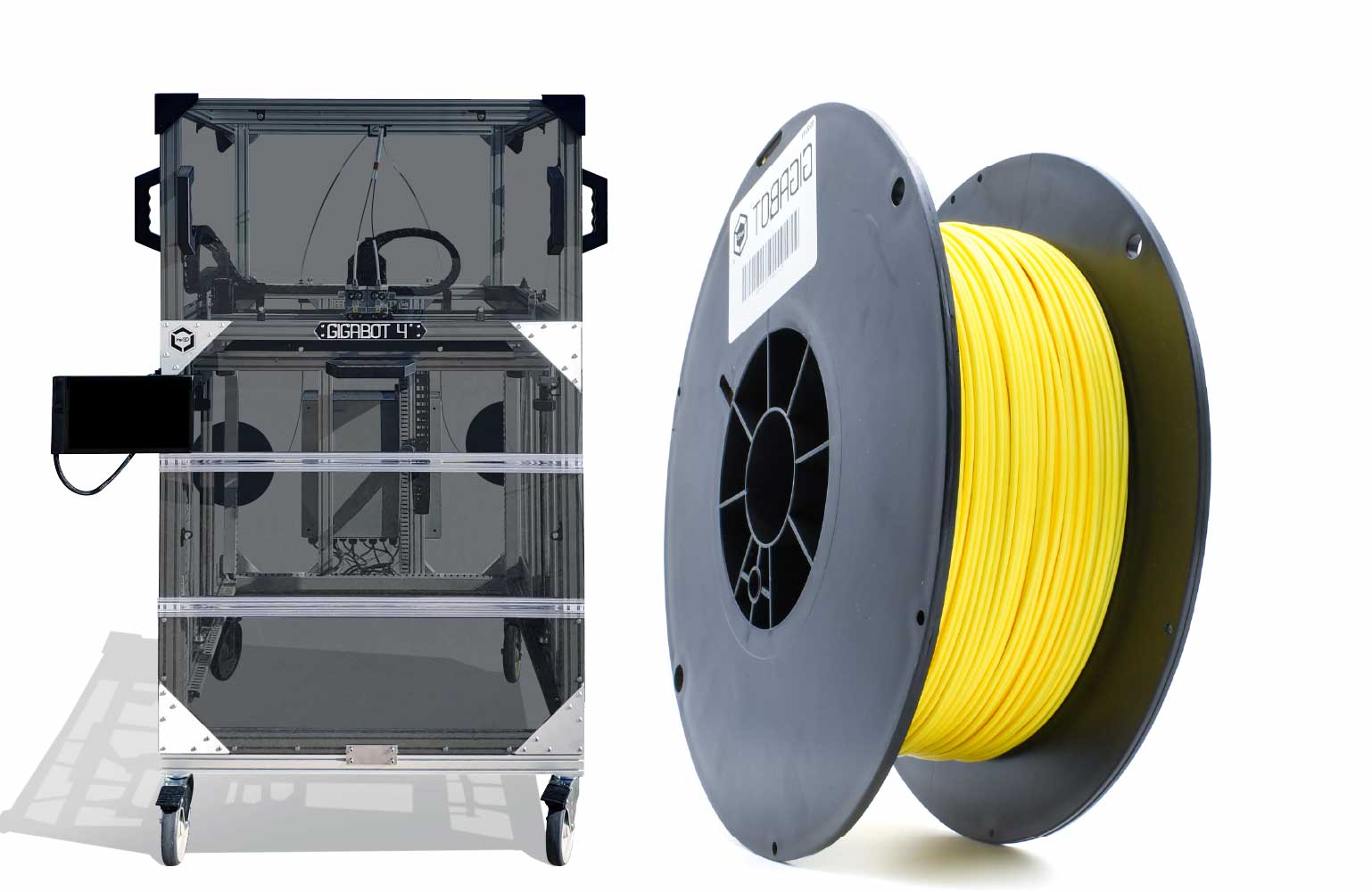

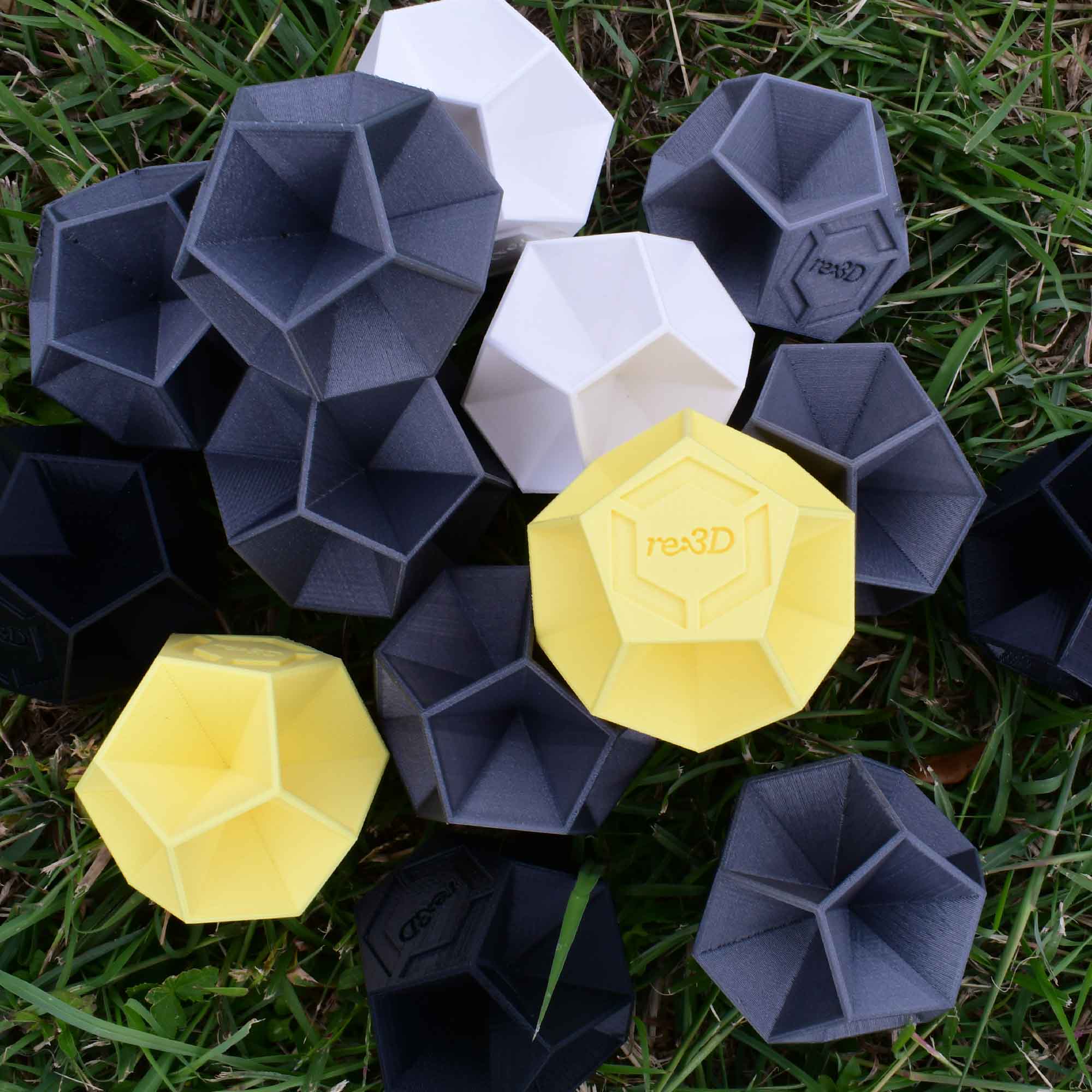

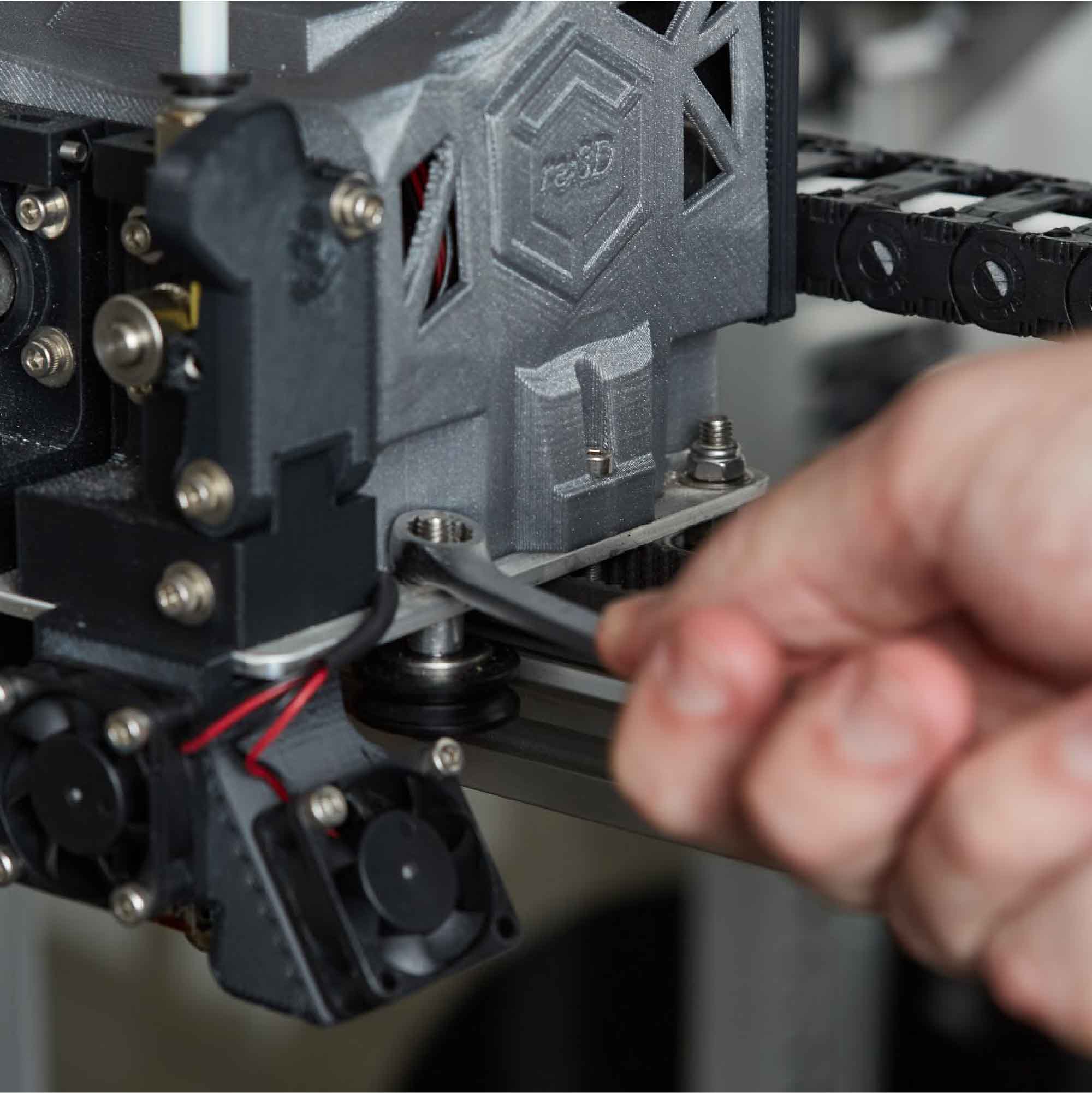

Whether it’s a custom 3D printed sign, a custom beer tap handle, machined metal, or even a custom 3D printer, re:3D designers have what it takes to turn your ideas into tangible objects.

Confidential

Disclosures governed by Nondisclosure Agreement

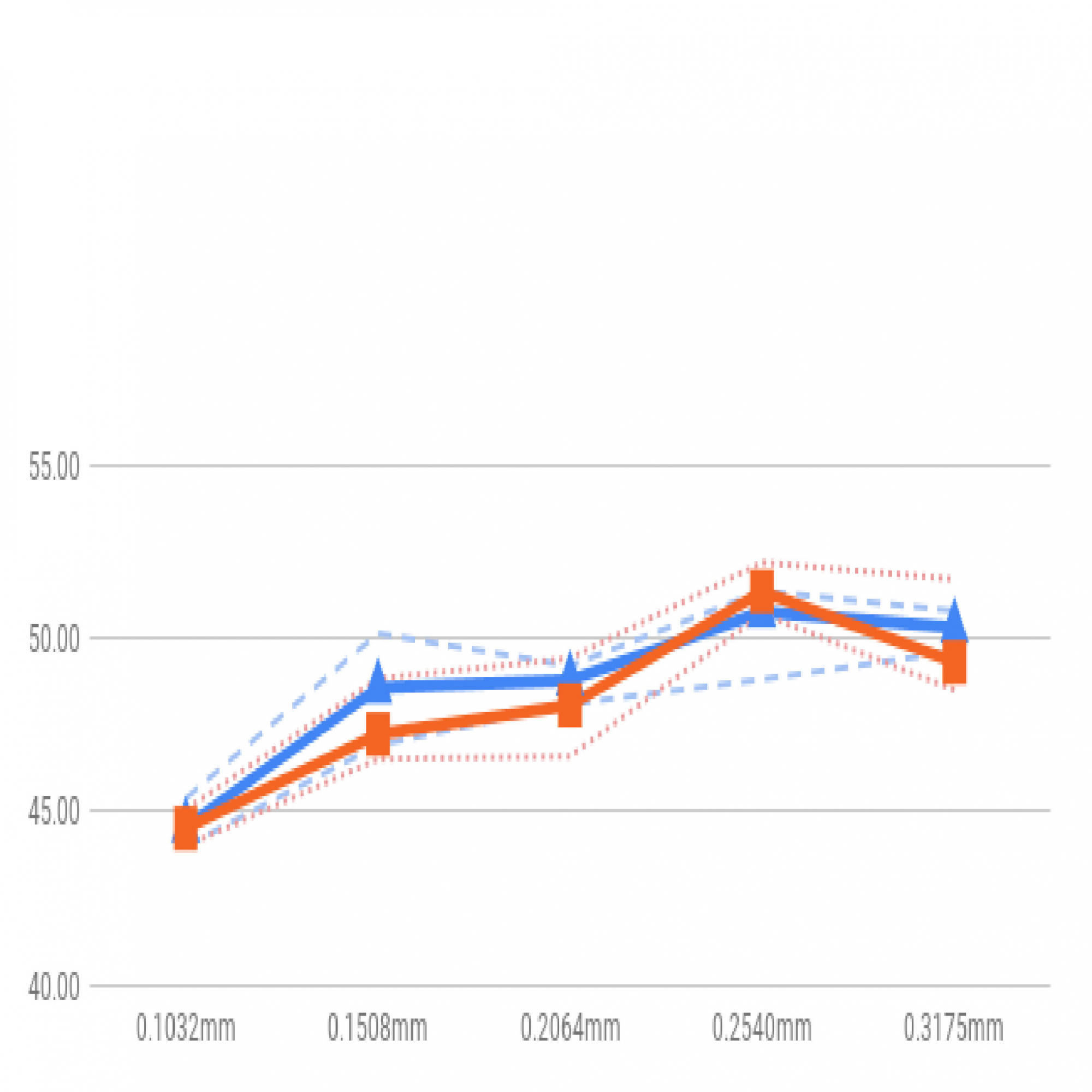

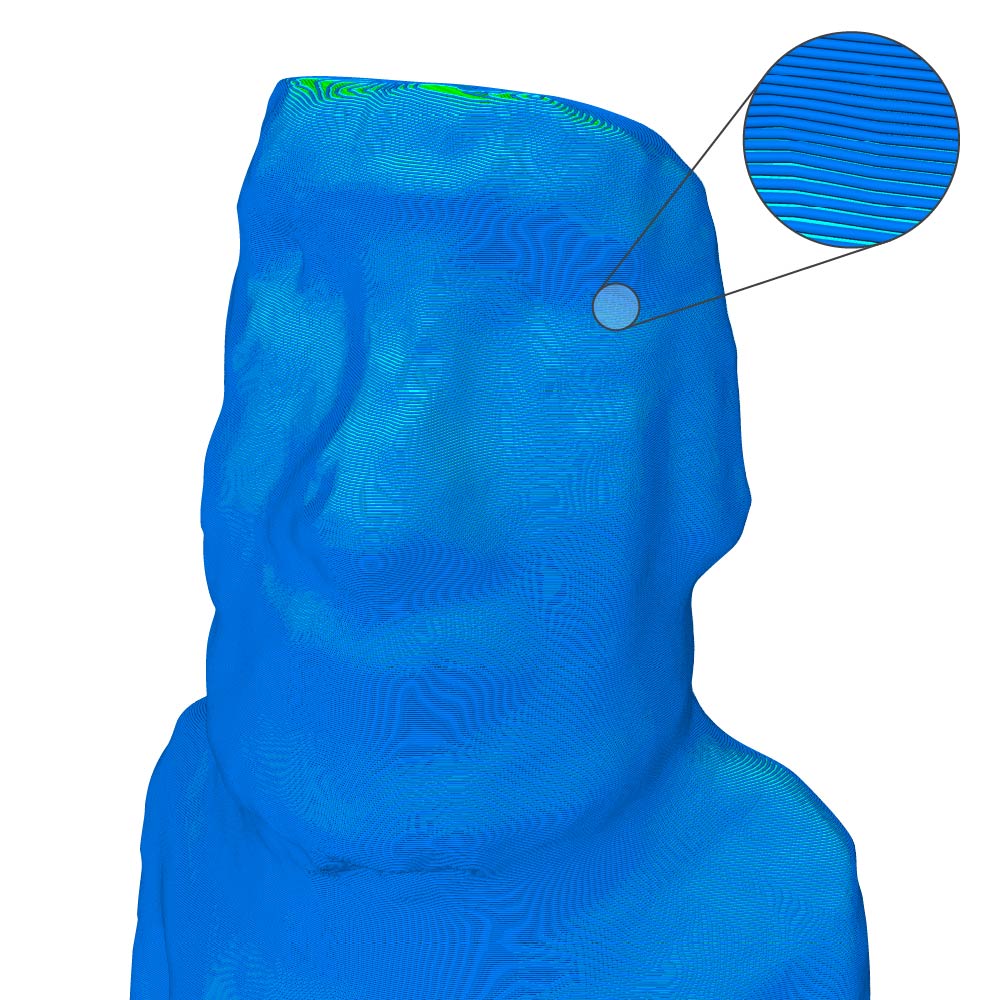

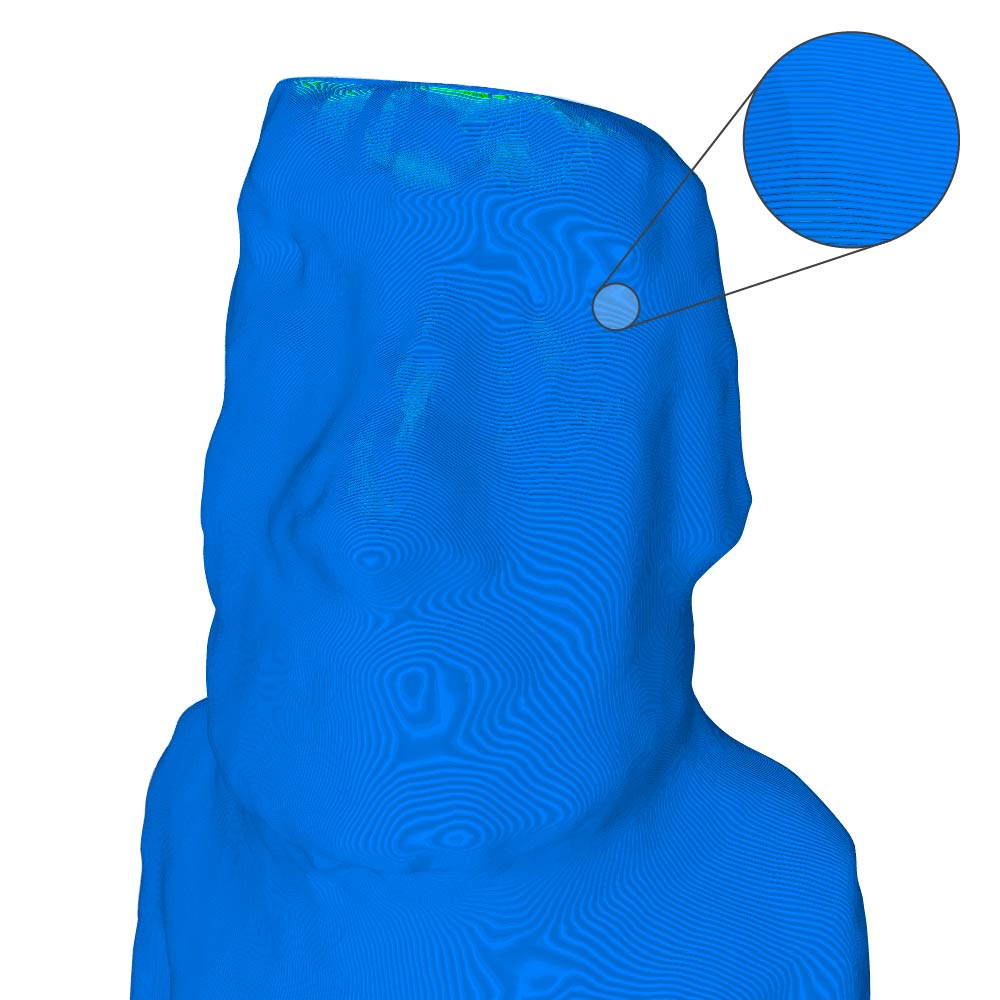

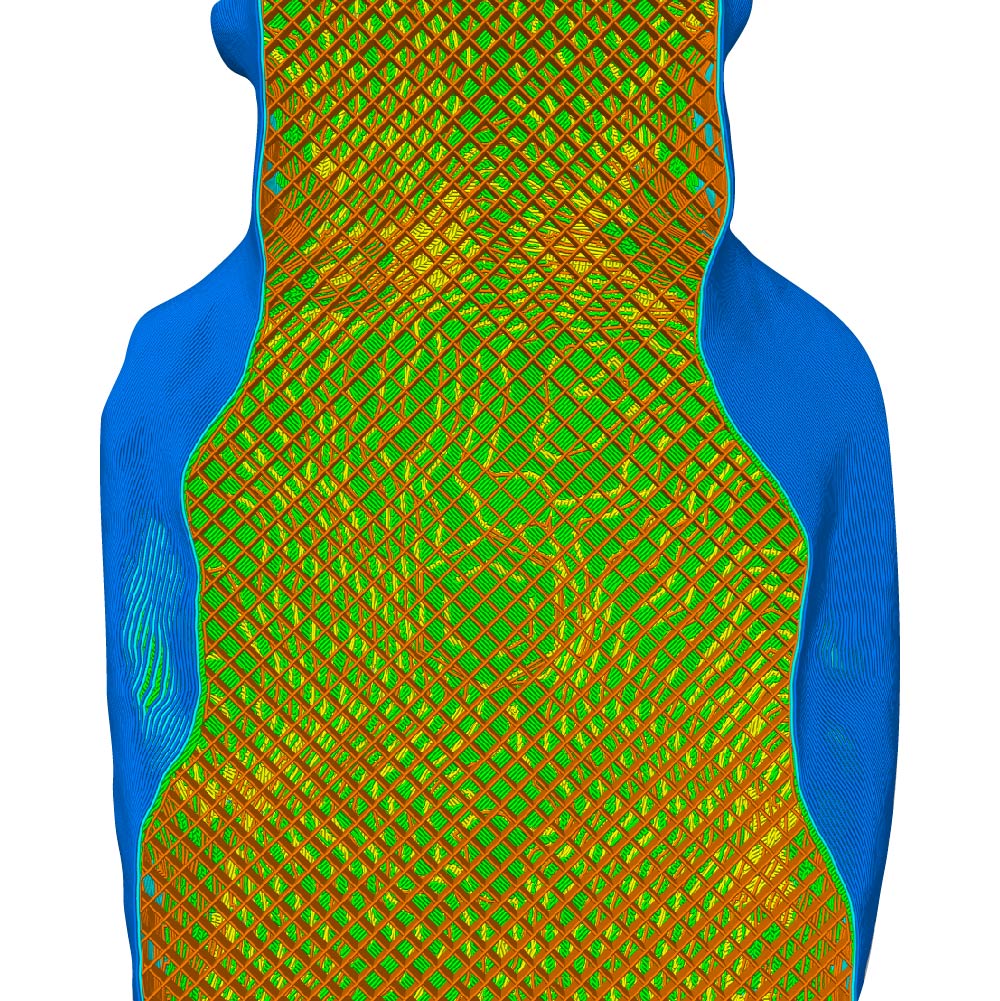

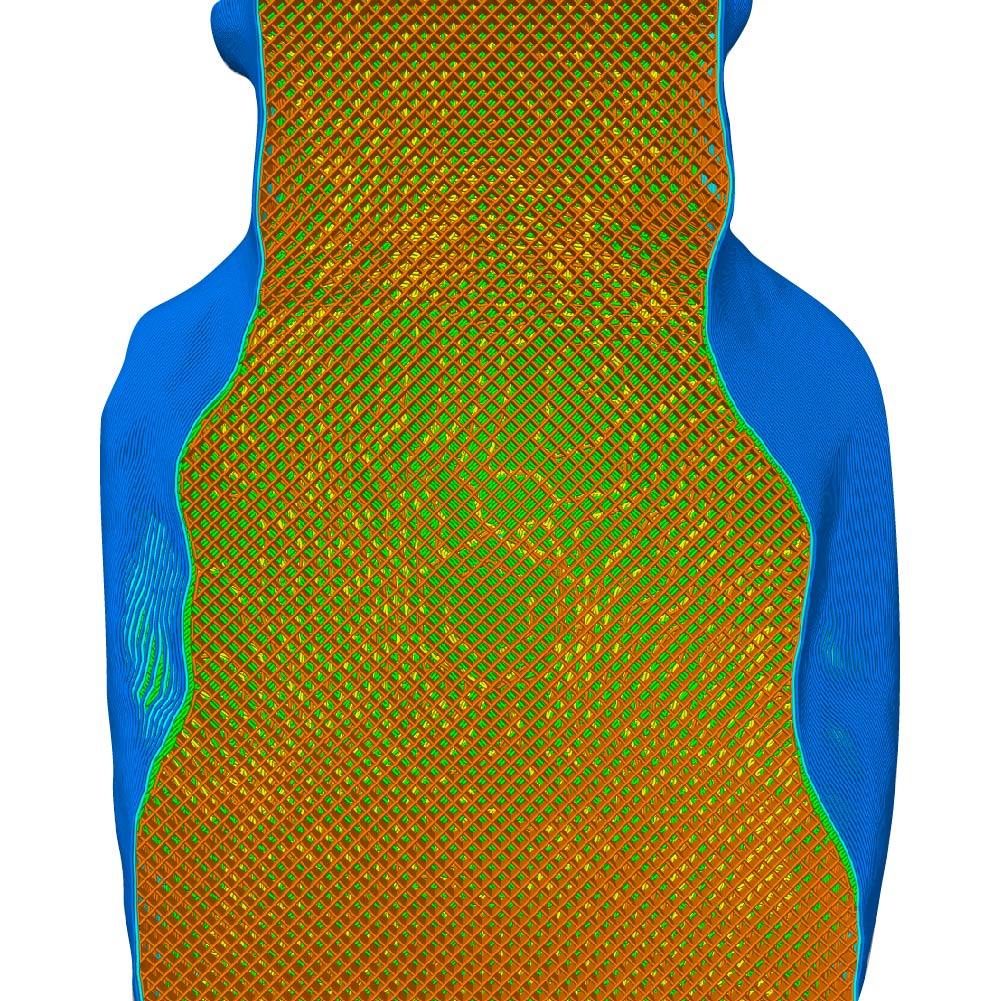

Efficient

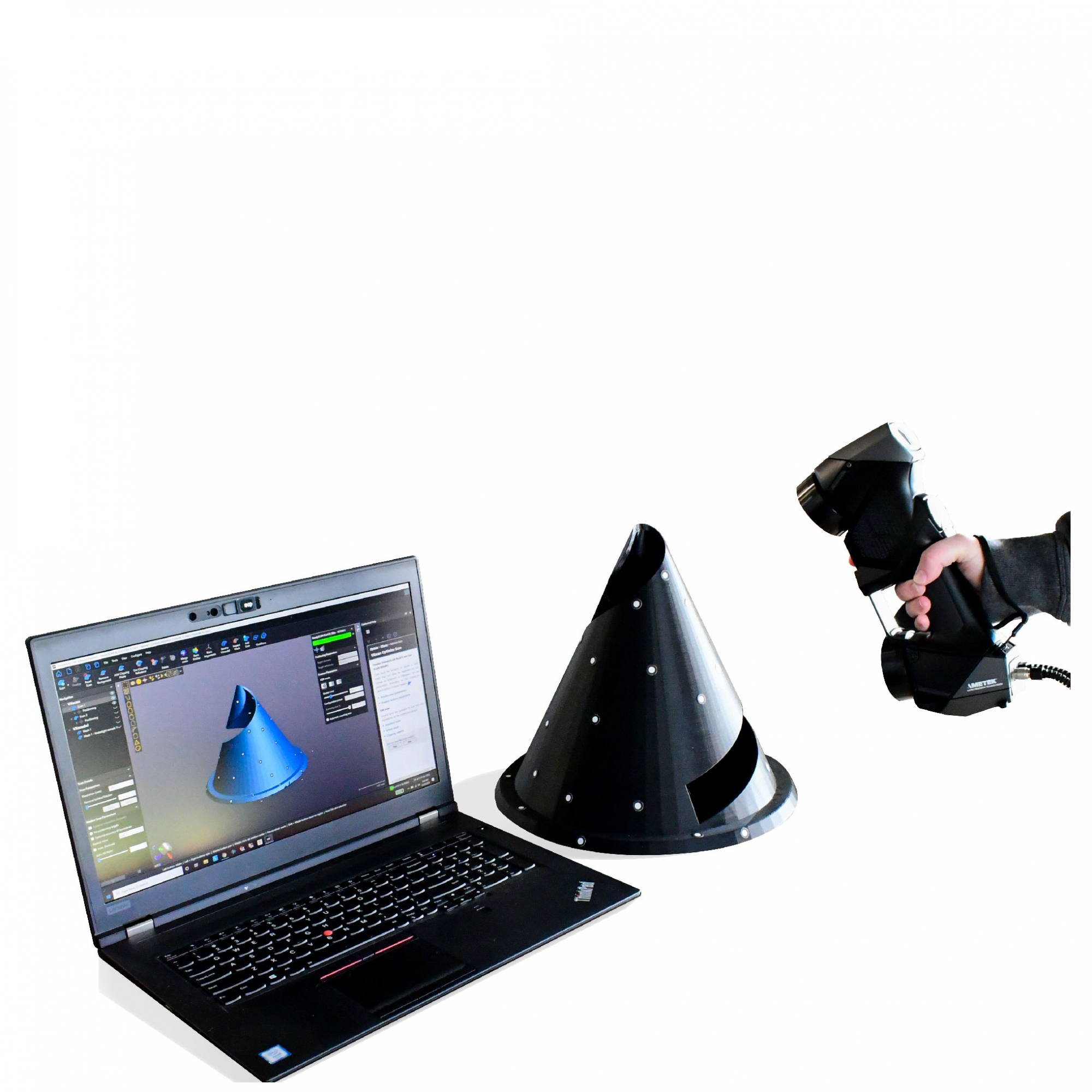

Iterative design using 3D printing and CNC machining cuts the cost and timeline for your product

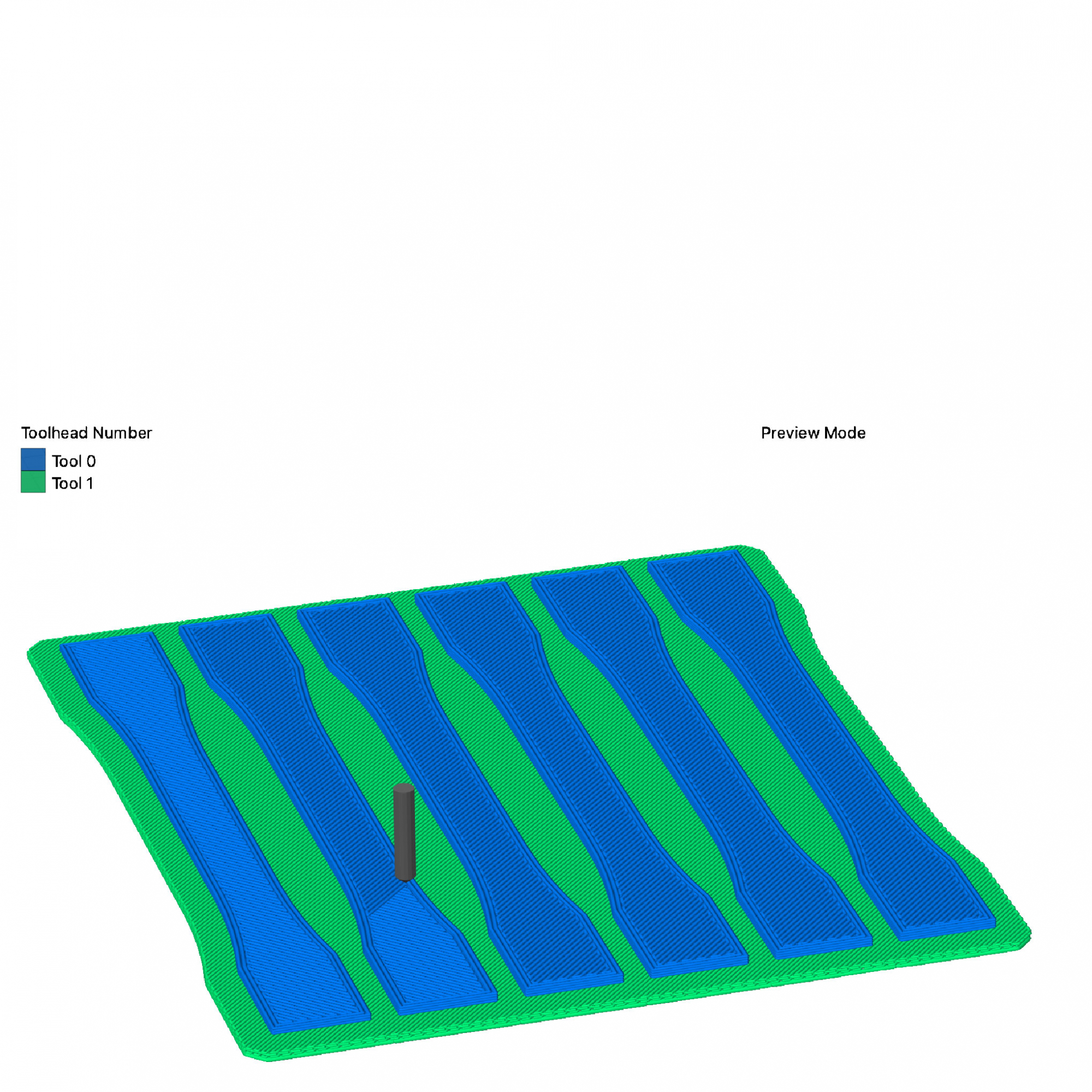

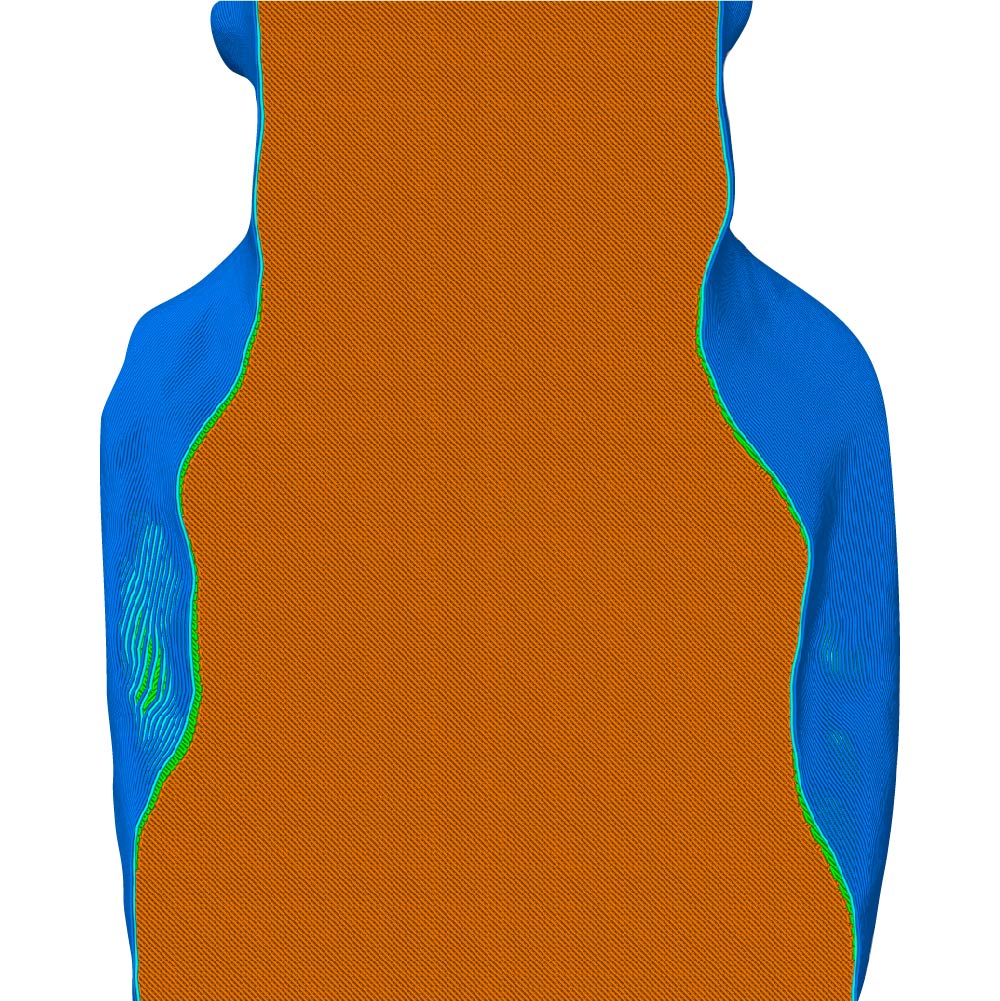

Transparent

Accurate timelines, renders and 3D models can be provided to our clients along the way