The notes below reflect our new open-source filament testing protocol. After evaluating the printability of Coex PLA Prime/PLA 3D850 on Gigabot, I decided to experiment with a heat treatment process.

Manufacturer: Coex

Filament Name: PLA Prime

Color Tested: Natural

Date Received: 6/10/2016

Date Tested: 6/16/2016

Ease of use: Excellent

Appearance: Clearer than regular PLA

Size consistency: Great

Color consistency: Great

Odor: None

Manufacturer’s recommendations

- Speed: none given mm/s

- Temperature: has a higher MFI so should be able to print slightly cooler than regular PLA C

- Infill %: any

- Layer Height: tested at 0.3175mm

- Printer Used: GB # 004

- Print temperature used: 200 C (nozzle) /55C (bed)

- Speed used: 60 mm/s

- Layer Height:0.3175 mm

- Infill: 15%

- Odor: none

- Type(s) of print surface used: Print n Z

FINDINGS

Bed adhesion (1: terrible-5: fabulous!)

5

Stringing (1: lots -5: none!)

4

Shrinkage (1: lots-5: none!)

4: None!

Interlayer adhesion (1: terrible-5: fabulous!)

4: Perfect!

The technical datasheet for the pellets that the filament is derived from can be found here.

I suspect that most, if not all the temperature resistant PLA uses the 3D850 as its base. There is very little information out there for recommended heat treat methods.

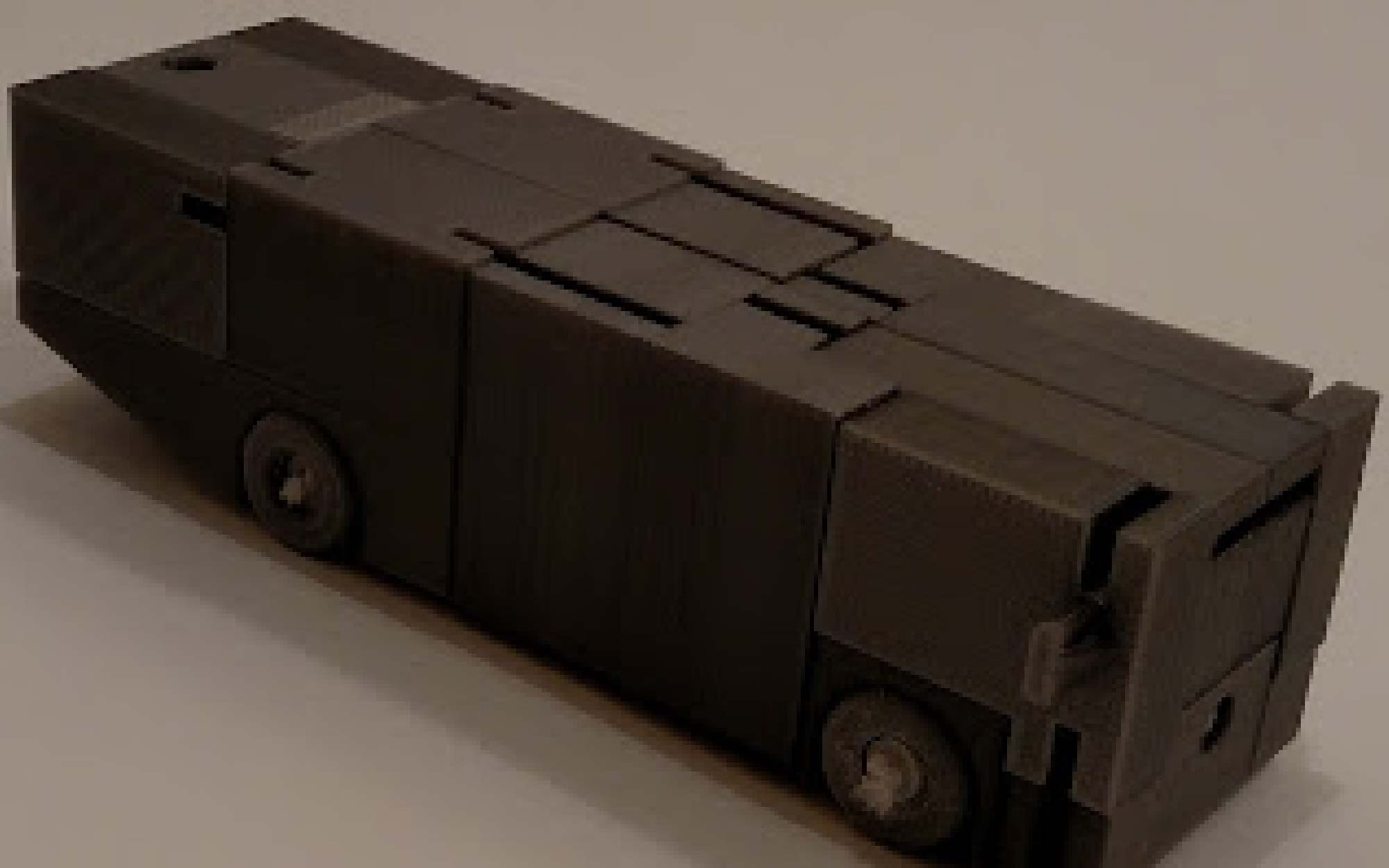

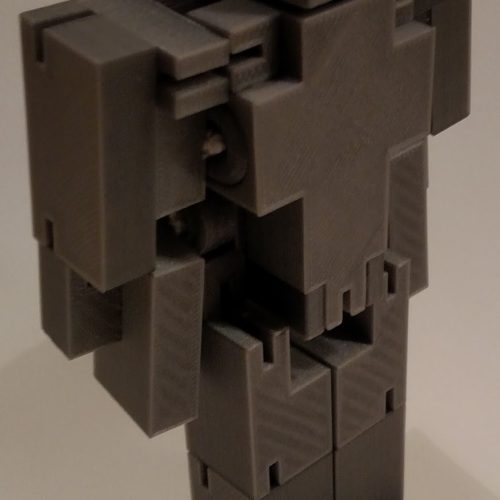

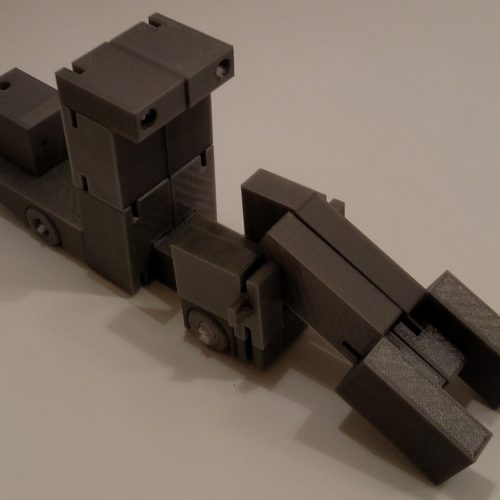

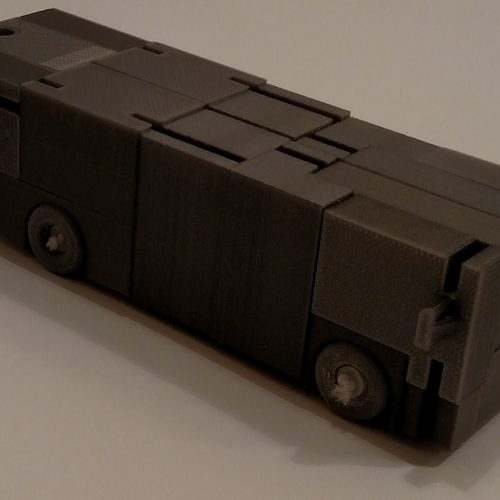

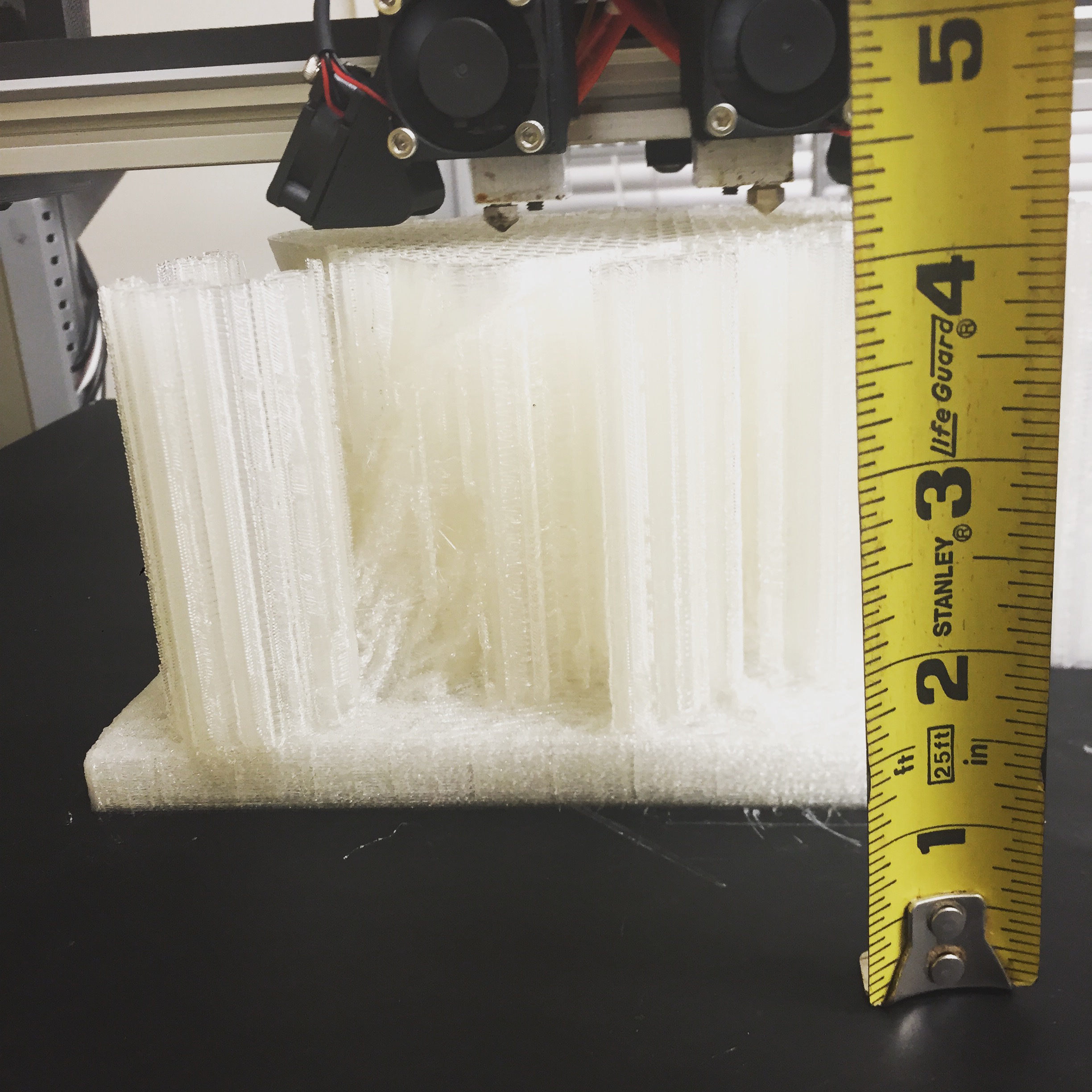

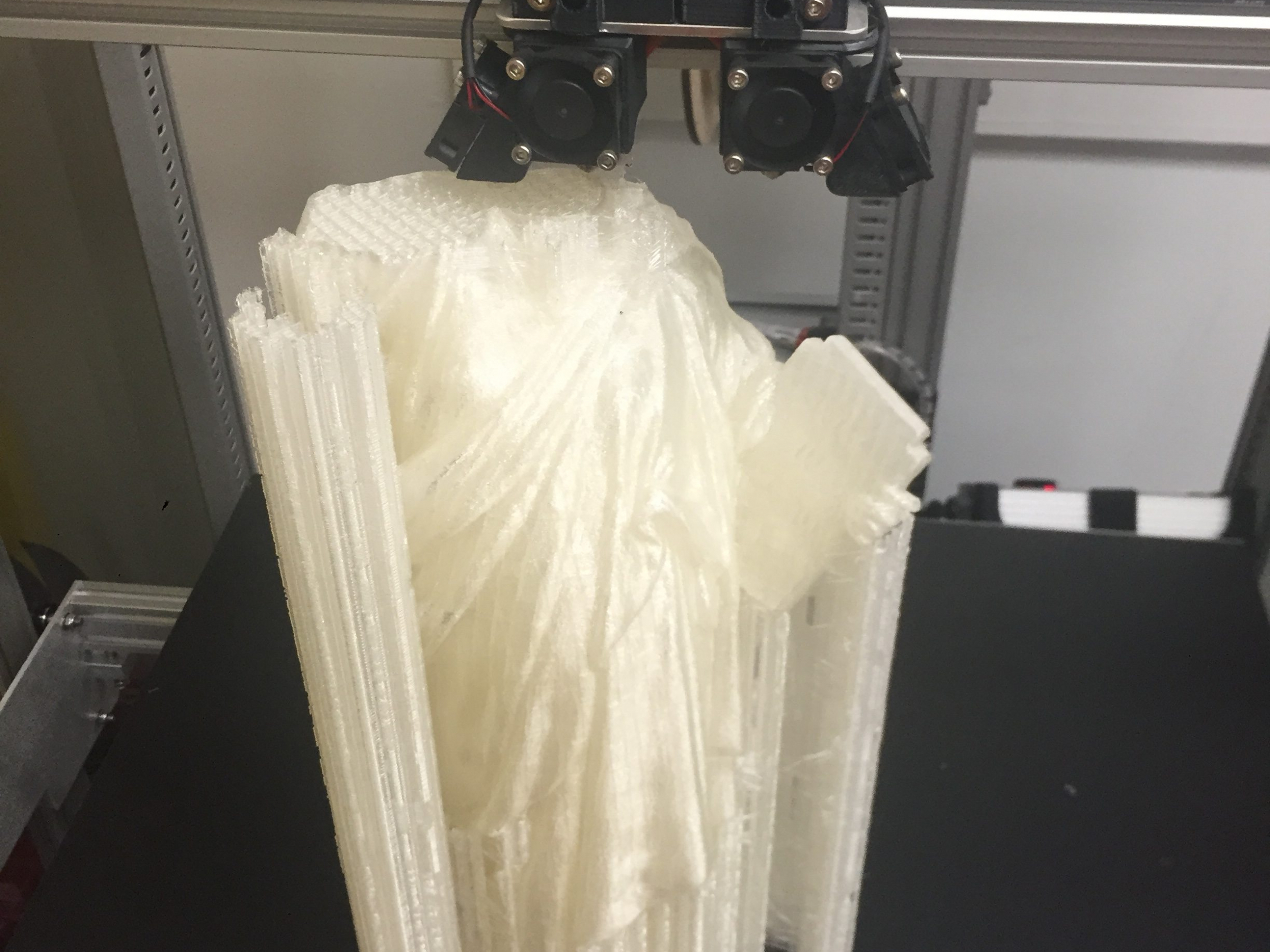

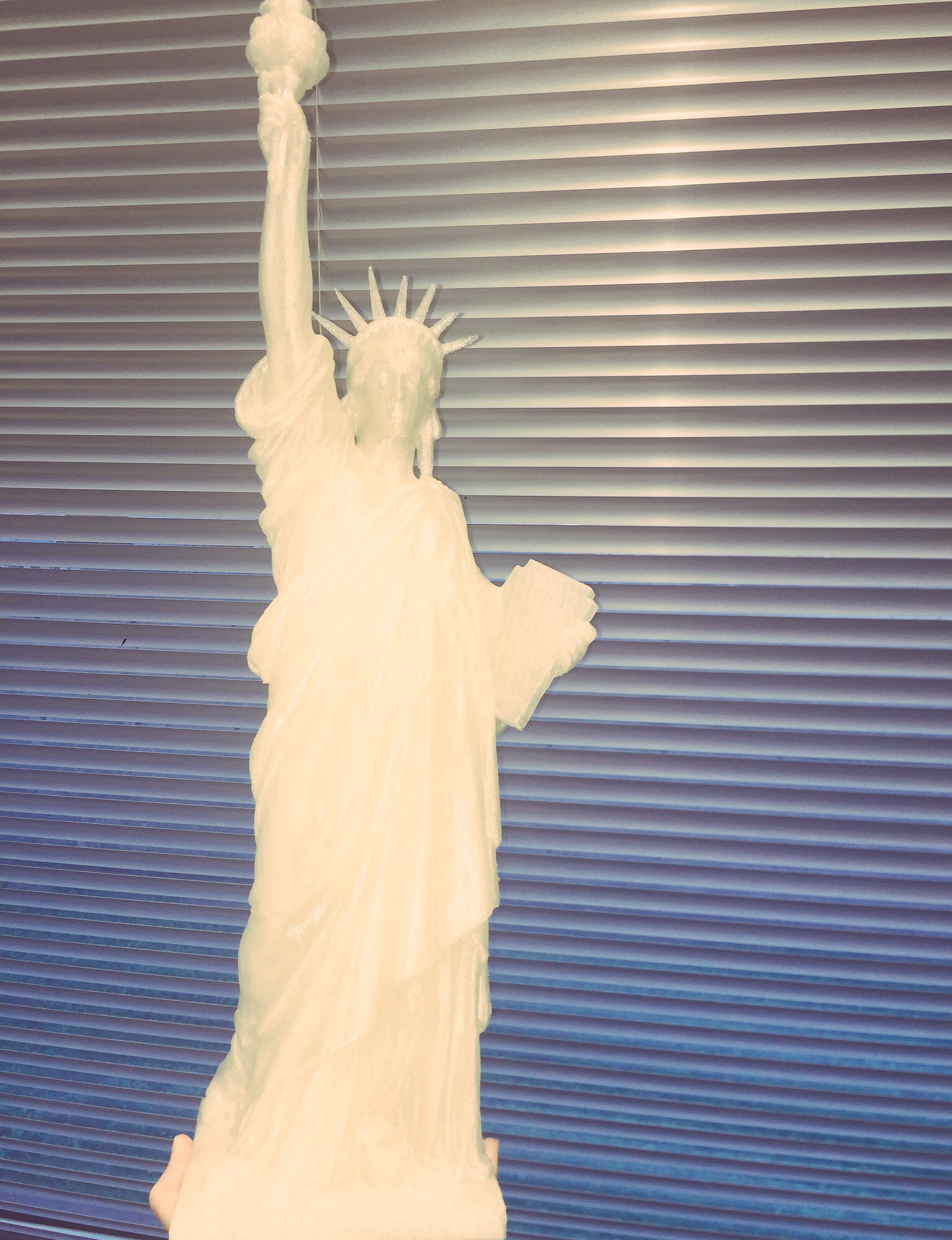

Here are a couple pictures from a recent experiment I did with Natureworks PLA 3D850 that claims increased crystallization with heat treat. I used a wall oven to heat treat the parts at 200F but please note that I did not verify with a second thermometer.

The three parts on the top row are not heat treated and the three on the bottom row are heat treated at 200F for 15 minutes. I placed the parts into a cold oven and let the oven heat to temp and maintained temp for 15 minutes then removed the parts to air cool. The color change and warping happened while the parts were in the oven not after they were removed.The top two parts were made with one perimeter (0.48mm width). The center two are two perimeters and the bottom two have three perimeters. Interestingly enough the part with two perimeters warped the least. I also heat treated a couple objects with more structural integrity and found little to no warping (small 5″ Moai statue and the re3D logo placard).

I think the next steps are to control the rate of heating to see if the amount of warping can be reduced. Would love to hear other’s experience with heat treating the PLA 3D850.

- Share your thoughts on the materials section of our forum:

- https://re3d.zendesk.com/hc/en-us/community/posts/206087383-Natureworks-3D850

Matthew Fiedler

Blog Post Author