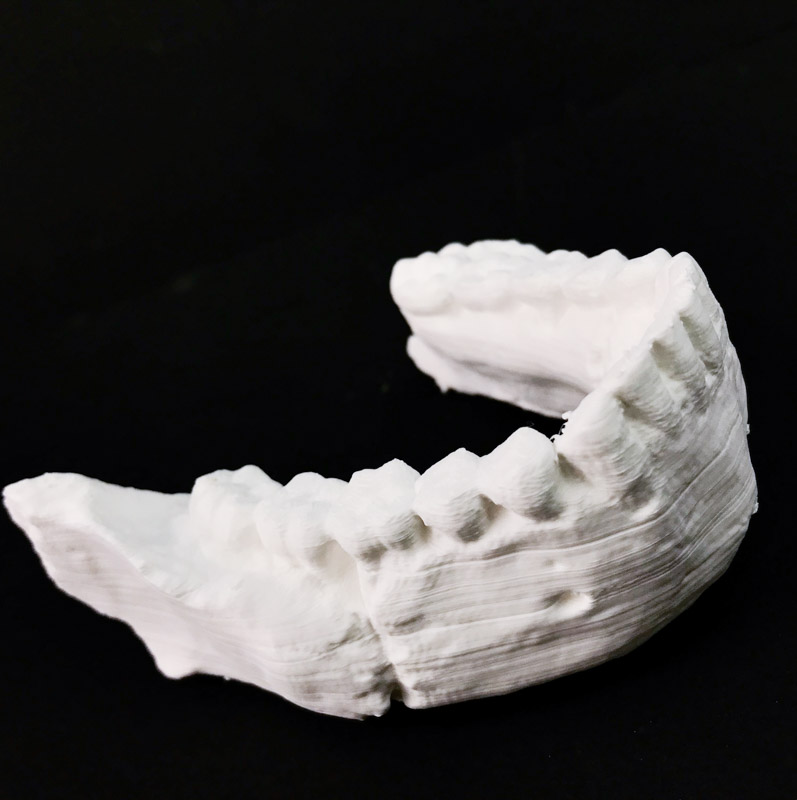

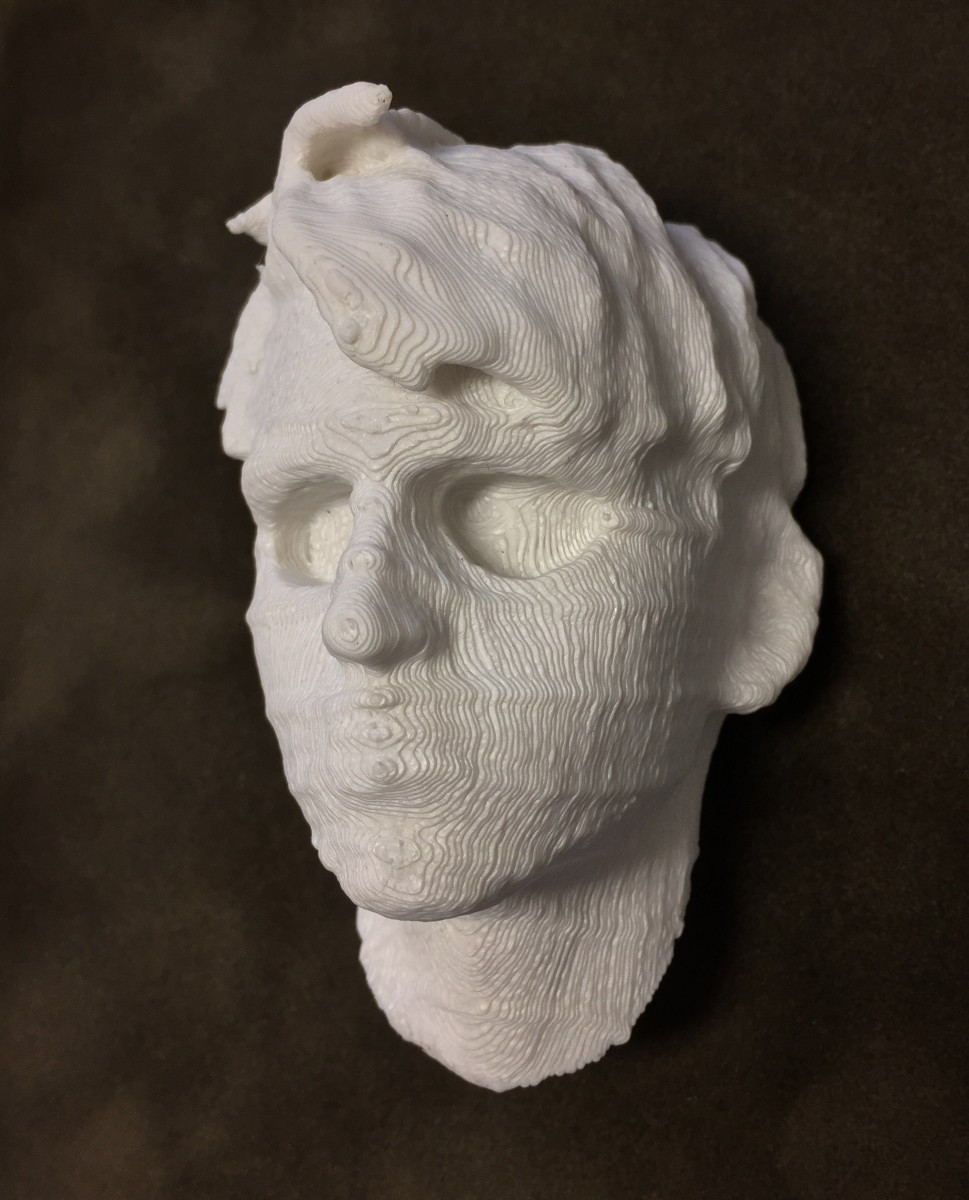

Maybe you’ve read our blog from several years back about improving a 3D print’s surface quality by reducing the triangle count of your STL file, or maybe you’ve just experienced some surface blobbing on a print and are looking for an explanation and a fix.

Well, you’ve come to the right place! This update blog will serve as both a complement to our original post, as well as a jumping off point for anyone experiencing issues described here.

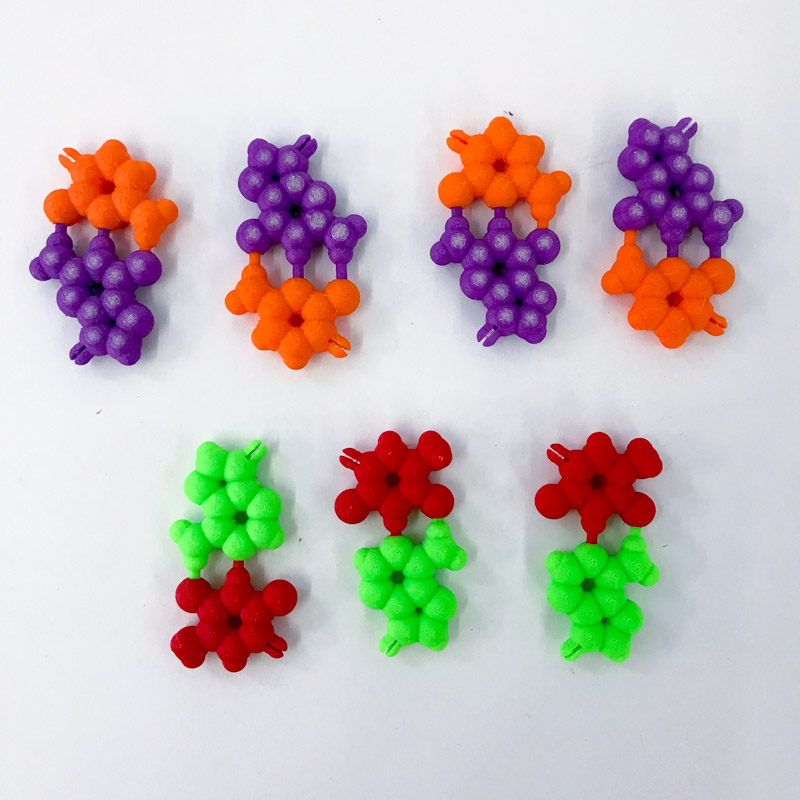

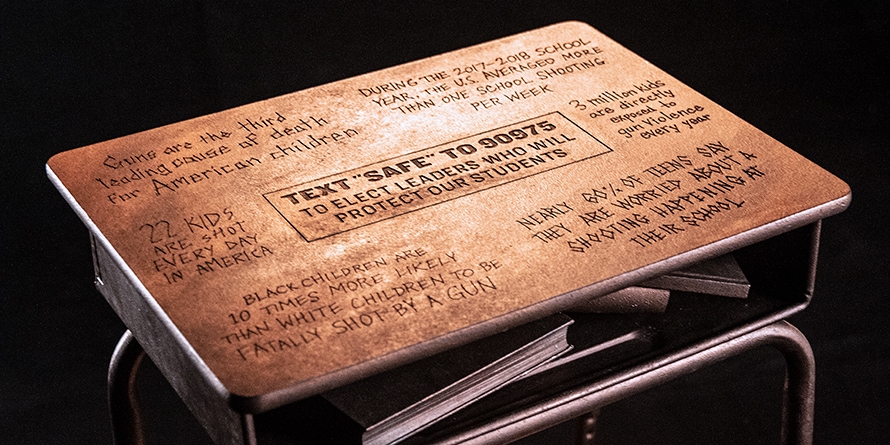

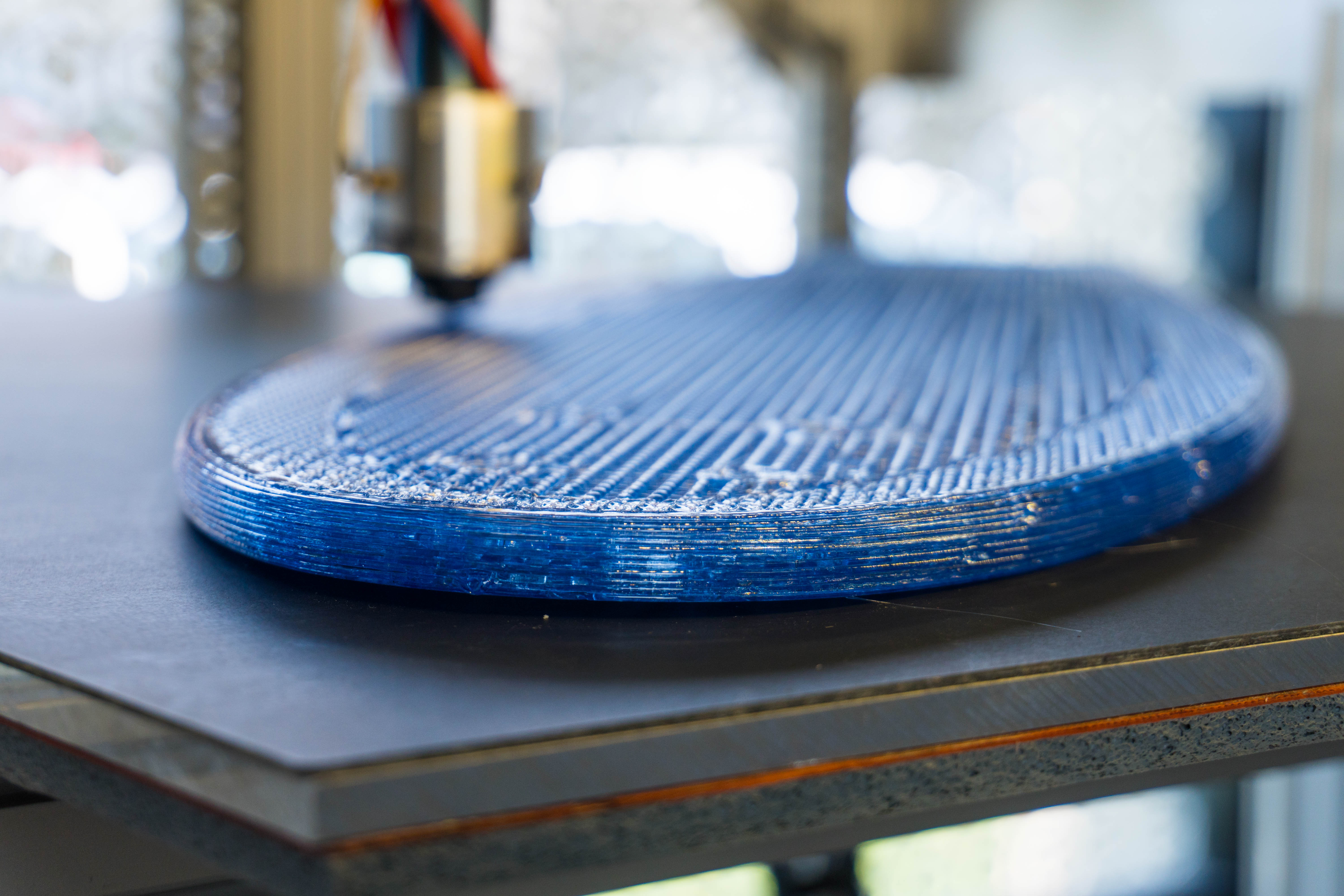

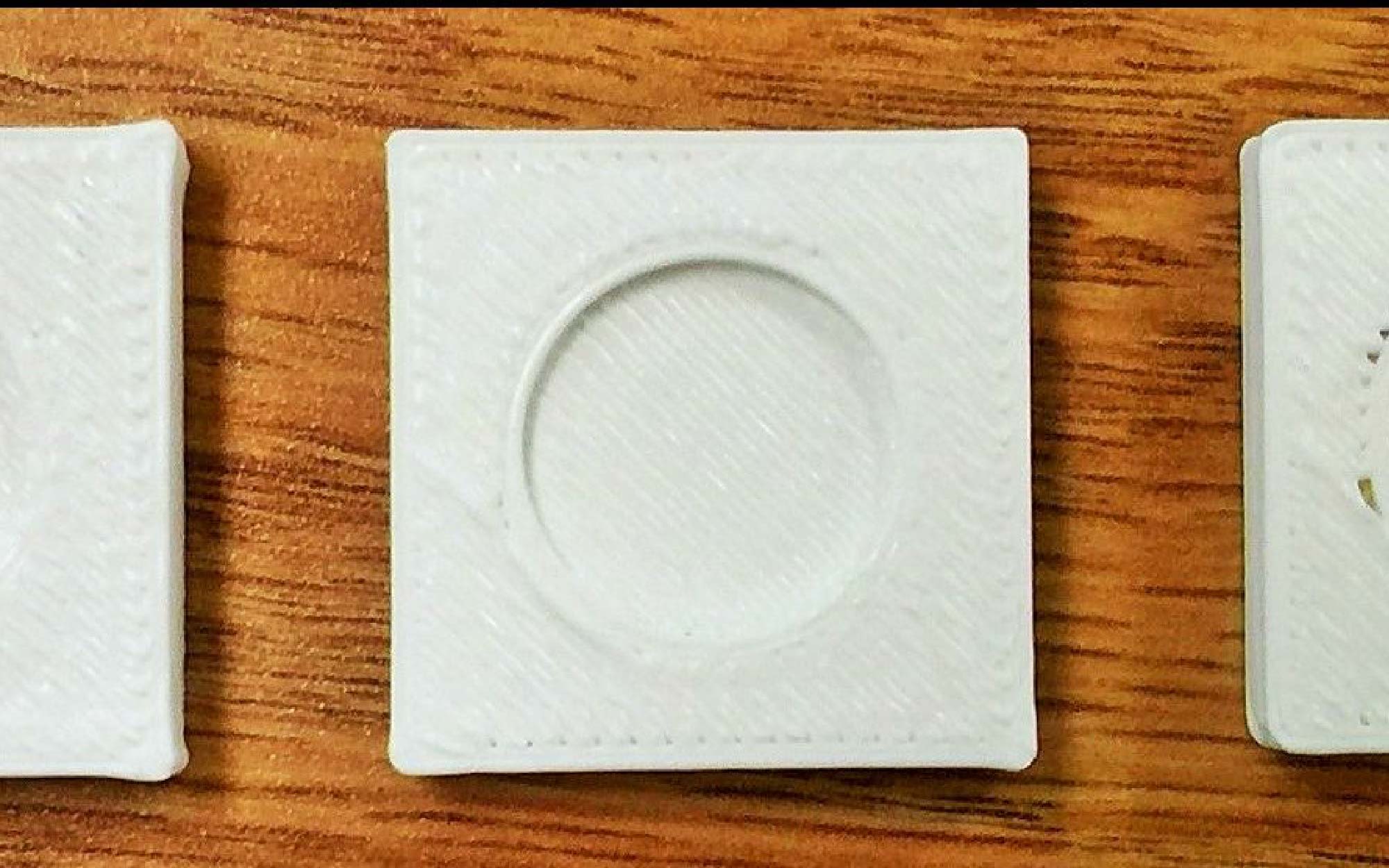

Have you ever had the problem of little filament blobs dotting the surface – like in the picture below – ruin an otherwise great print?

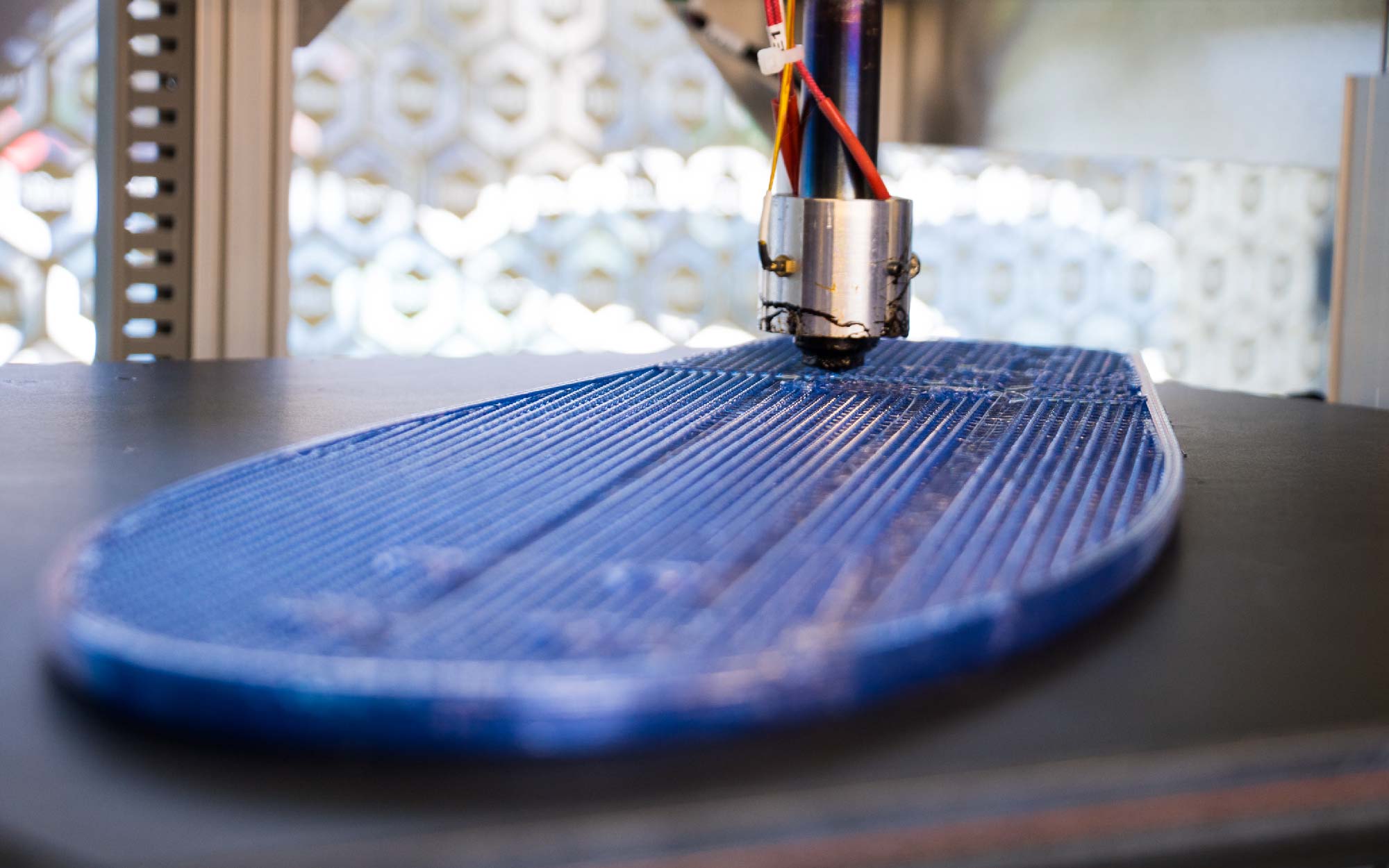

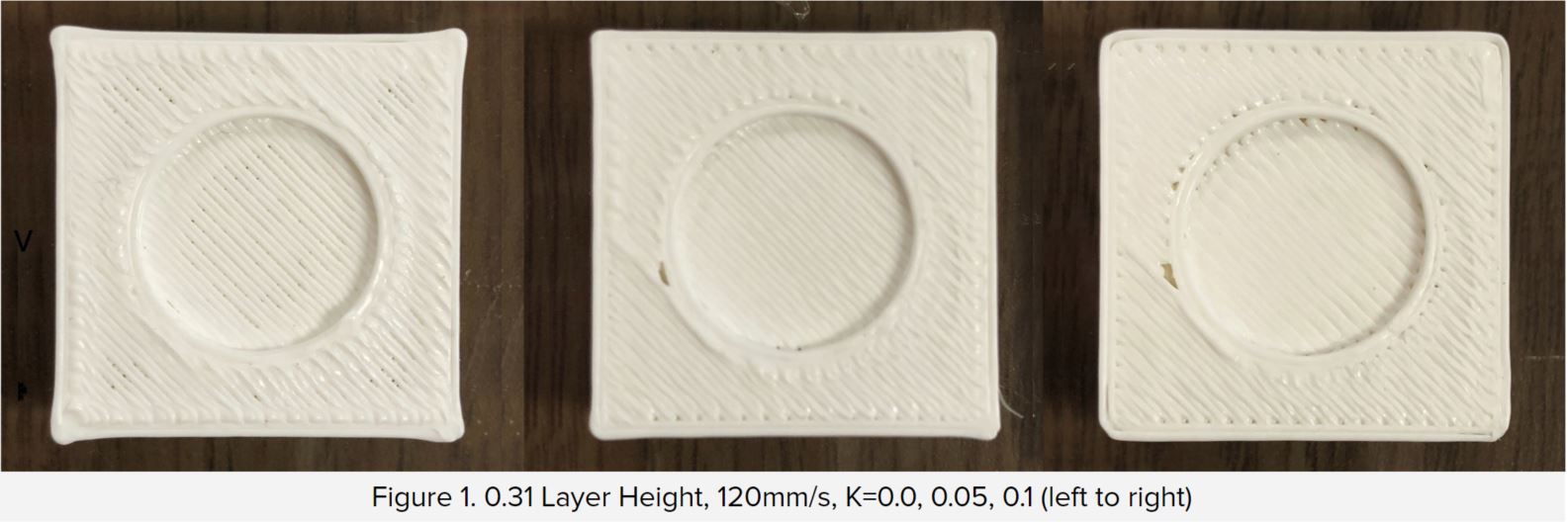

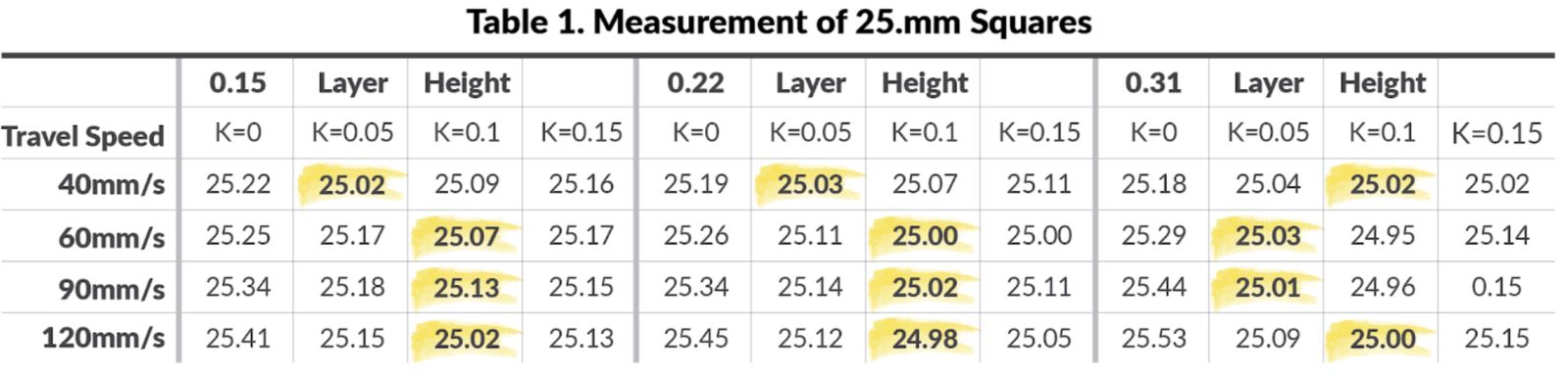

Those blobs are due to a buffering issue. There is a speed at which the board feeds the printer information and a number of commands it holds in the queue. It’s like a restaurant putting out orders for people to pick up. There’s speed at which they make the orders, and only so many spots for orders waiting on pickup.

If the printer comes to a bunch of really quick moves, it clears out all the stored commands and has to pause a second to wait for more. That pause lets some plastic ooze out and create one of these blobs. Having fewer triangles equals fewer commands to make the same shape, so the average move is longer. This is one solution to the blobbing problem.

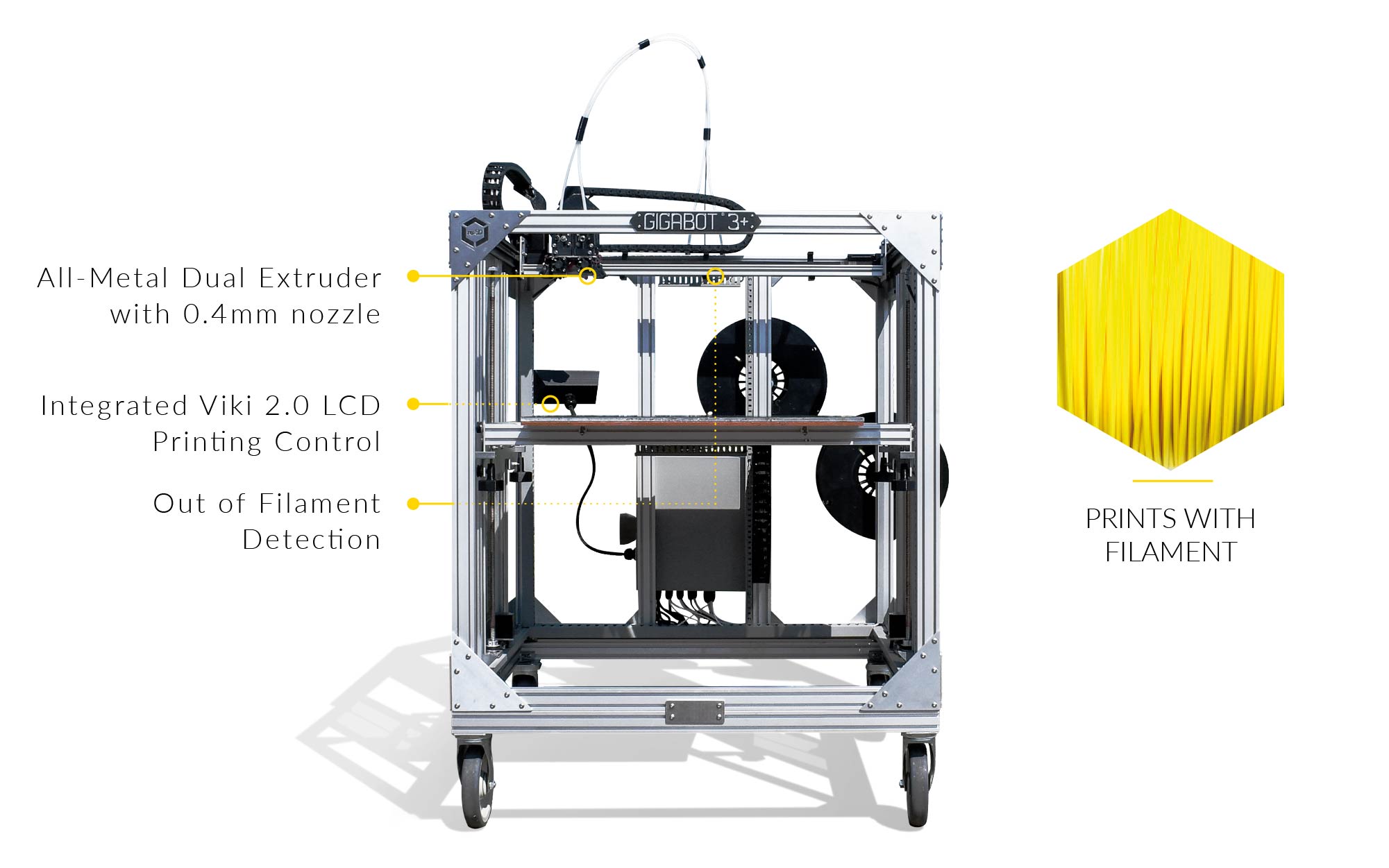

Another fix is to increase the buffer size (room for more pickup orders) or speed. We have been playing with buffer size since it is a setting in the firmware. The buffer speed depends on the capability of the board, so that would require a hardware upgrade to be faster.Lowering the mesh count on a model helps ensure that the printer can achieve its best performance for that print. You are modifying the part to match the capability of the printer. STL files are just a list of triangles that occupy a 3D space – curves are stored as a series of tangent triangular planes. Smaller triangles give a more accurate interpretation of the curve. So long as the facets are smaller than the printer can actually print, the result is a smooth curve. Technically you are degrading the mesh curvature. It’s the same as the transition from analog to digital. Analog is more information, but it overloads the system which makes digital better.

Morgan Hamel

Blog Post Author