* Original post from March/April 2013 *

The re:3D Team cannot express enough how much we appreciate every single backer of our young enterprise! The past week has been a monumental one as we continued writing the history of the Gigabot, one milestone at a time. We are immensly humbled and filled with thanks each time we reflect on these past 12 days.

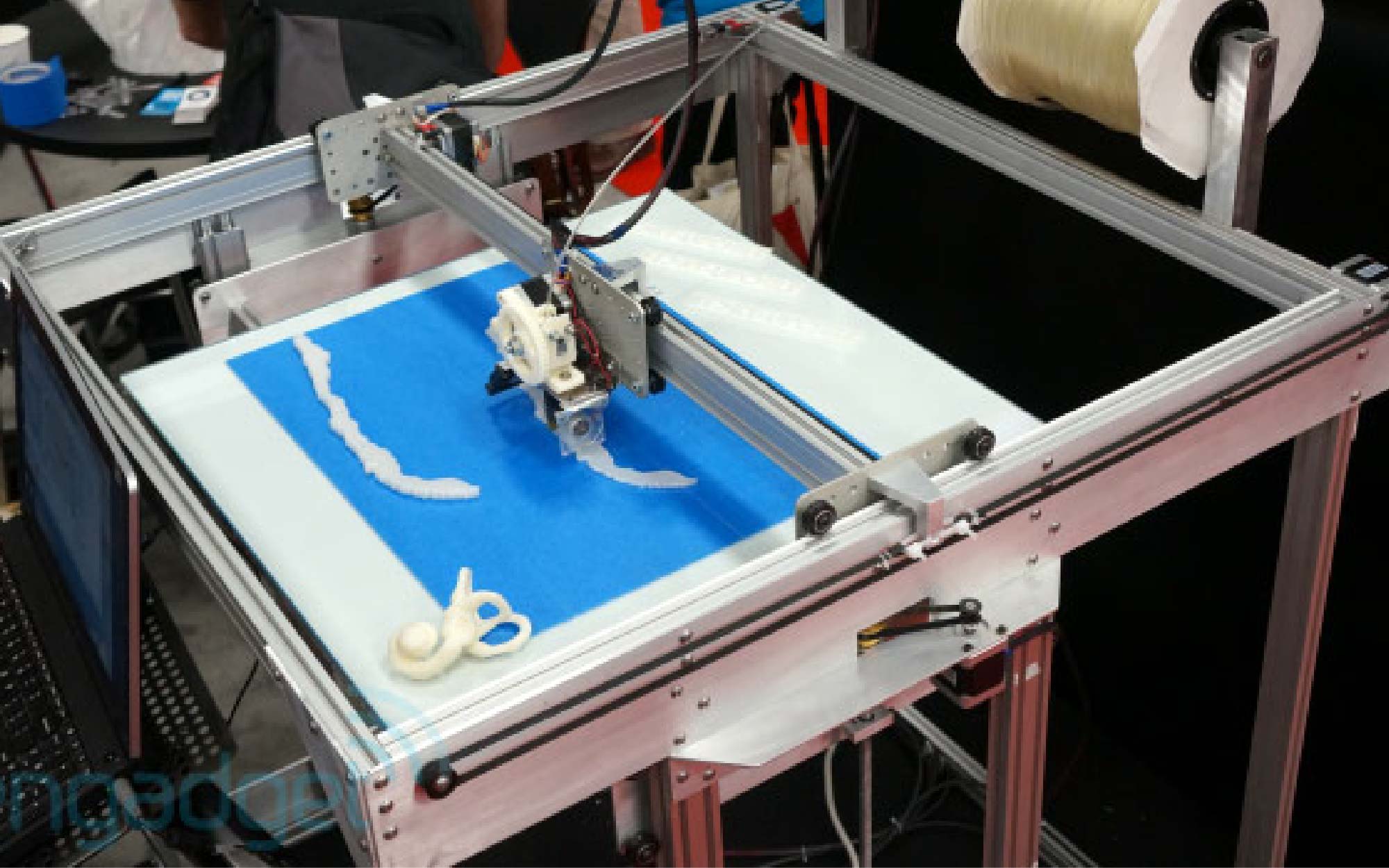

Many of you saw the Gigabot during its debut at South by Southwest Interactive in Austin, TX. Just days after packing up shop at the convention center, Chief Hacker Matthew packed himself, some tools, and the Gigabot on a commercial flight South, together with Doc Suzanne to join forces with Samantha in Santiago, Chile. After re-assembly in Samantha’s cozy apartment, we are proud to announce that we are printing LARGE in the southern hemisphere!

This success in packaging, transport, and the continuing validation of raw material sourcing for our kits has given us the confidence to “green-light” an exciting stretch goal for the Gigabot Project!

New Stretch Goal: $200K!

If we are successful in raising over $200K for our endeavor, we will integrate an LCD display into each and every Gigabot shipped to our Kickstarters. Why is this awesome? In addition to the insight that an added display provides during the build progress, this feature allows a print to occur independent of a dedicated laptop. This is useful for keeping the area clear surrounding the Gigabot, and also allows your laptop to be used for other purposes during giga-builds – like designing your next creation! Everyone who receives a kit of any level will receive the parts necessary to integrate the display – and if your Gigabot ships pre-assembled, so will the display.

Of course, we appreciate each and EVERY one of our backers, so if we meet this stretch goal of $200K, we will also throw a party in your honor during the weekend of the New York World Maker Faire! Each backer of the $5 level or more will allow you and a guest VIP entry to the Giga-Thanks Party, as we celebrate the kickoff of our shipping phase and plan for the future together as a community. There will of course be expectations of a Giga-Party to live up to its name, and we plan to deliver!

This $200K level will give us solid justification and capital to support a long-term manufacturing solution, and ensure that the best possible product is shipped to the first owners. It will also enable exciting development work on printing with recycled plastics.

This has been an amazing couple of weeks, and we can’t wait to see what we can create together by thinking globally, and printing big!

Sincerely,

The re:3D Team