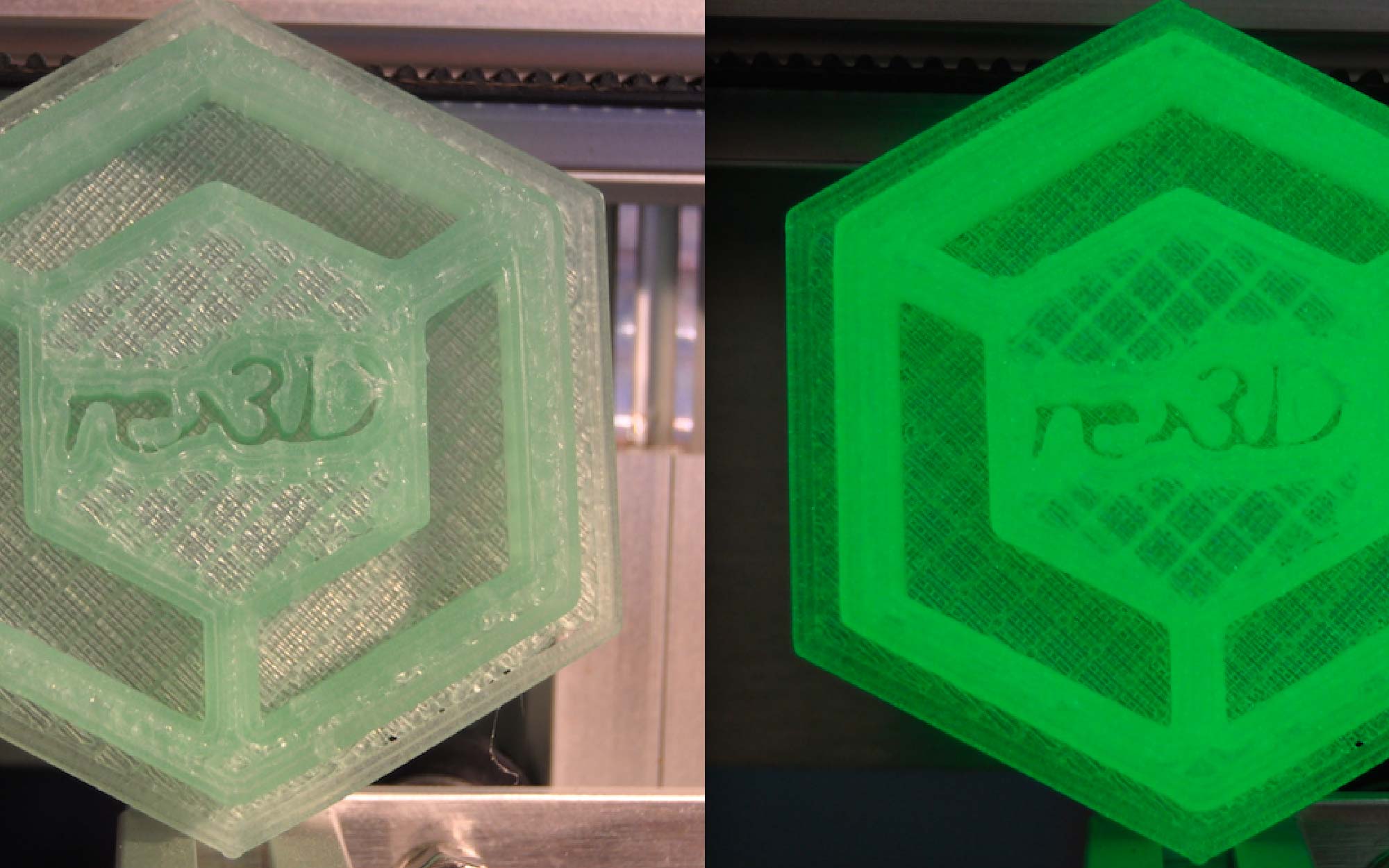

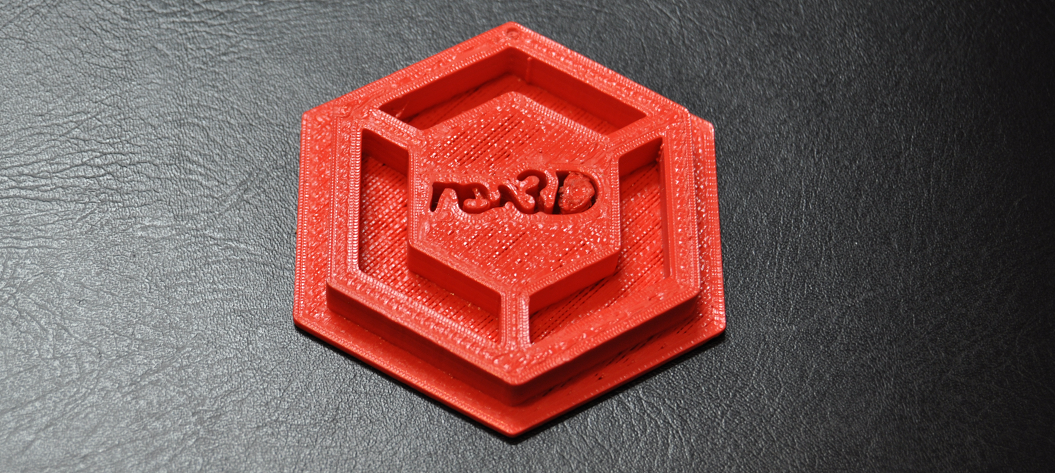

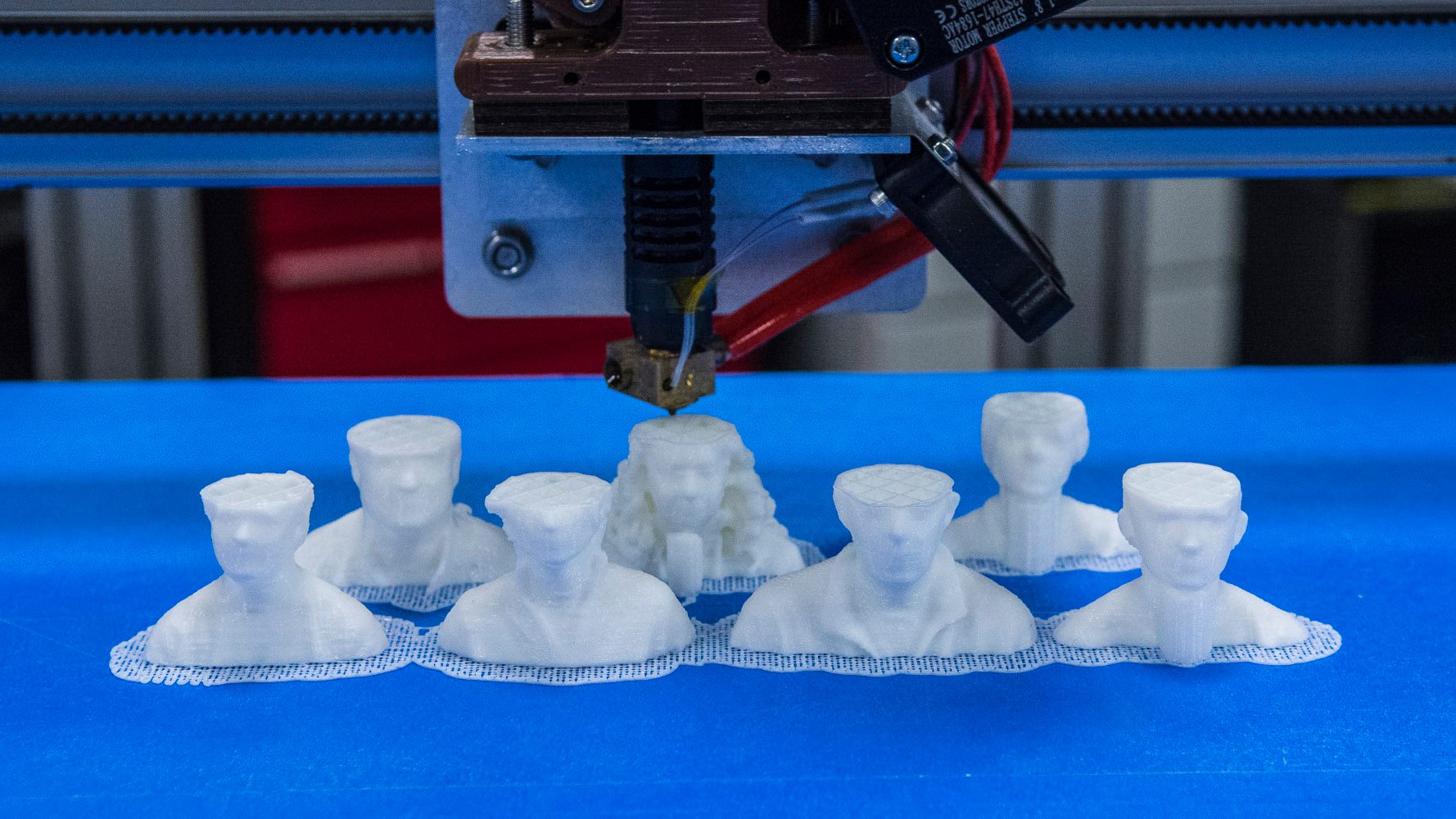

At re:3D we are constantly evaluating opportunities to integrate open platforms and philosophies into our company & products. From the firmware that interprets Gigabot’s G-code, to 3D Thursday Google hangouts with our Kickstarter backers, we recognize that the best way to operate is by partnering with our community. With that in mind, we are experimenting with an iteration of our Gigabot open source design with an eye toward the Maker, the Tinkerer, and the Educator. We want to enable home or school-based manufacturing in a way that reflects today’s trends of openness, iteration, and personalization while solving some challenges you have shared.

Throughout this process, we’re learning a lot. Not only about 3D printing, but about how people create things, and what their challenges are. So in the coming weeks we would like to share this experience of gathering user experiences, and solicit as much feedback as we can from the tinkerers who have ideas and thoughts to share. We are also researching different ways to approach manufacturing, so you may see some alternatives to our current, low-volume approach that you see today in Gigabot.

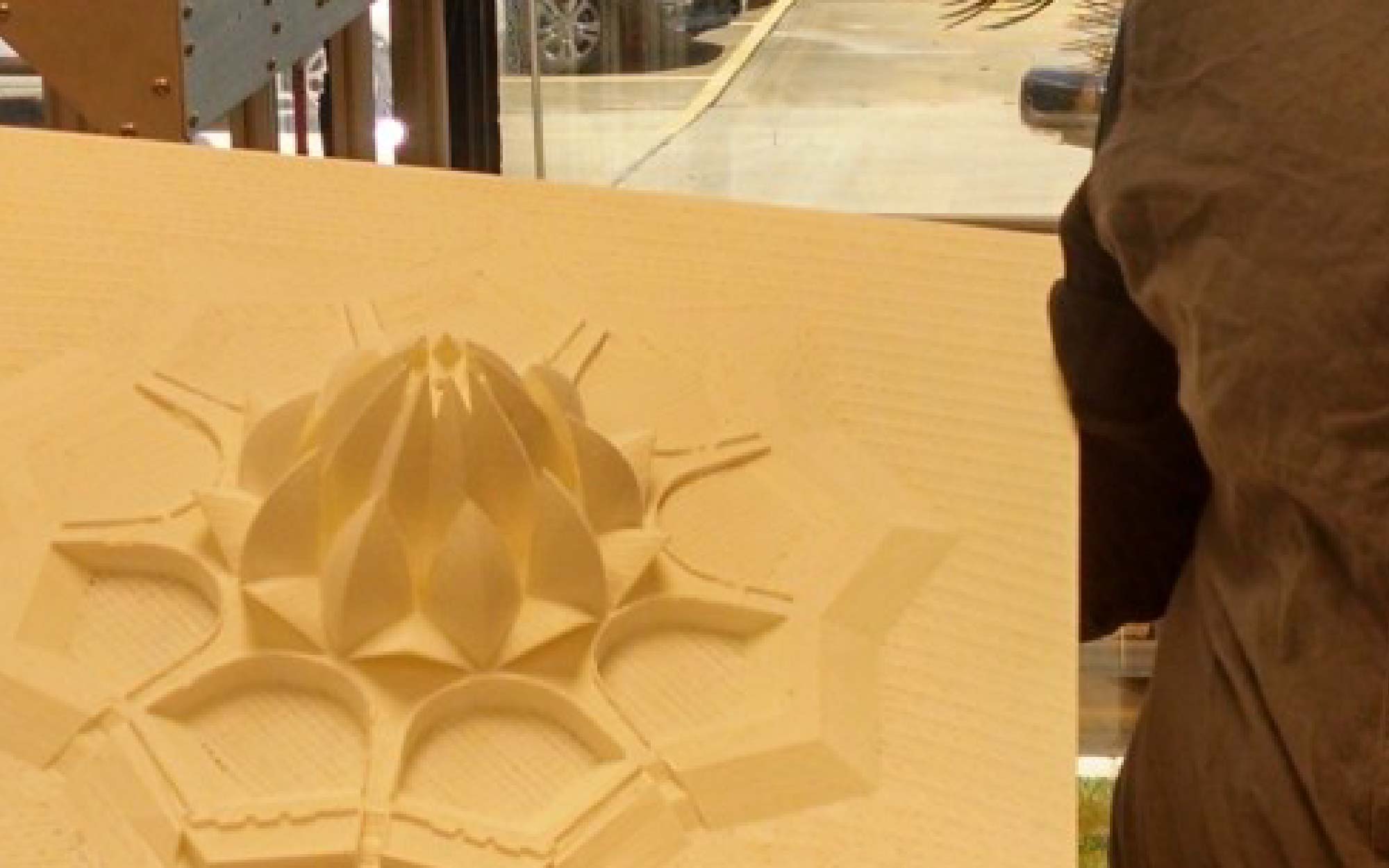

Our aim is to align this version of Gigabot with the philosophies of the new industrial revolution that we see ourselves within. Customizable – yet having standardized interfaces. Modifiable – yet with a clean design. We want “Your Gigabot” to continue to be a melting pot for multiple industries, but have some specialized features that really take advantage of the size, and the diversity of input material.

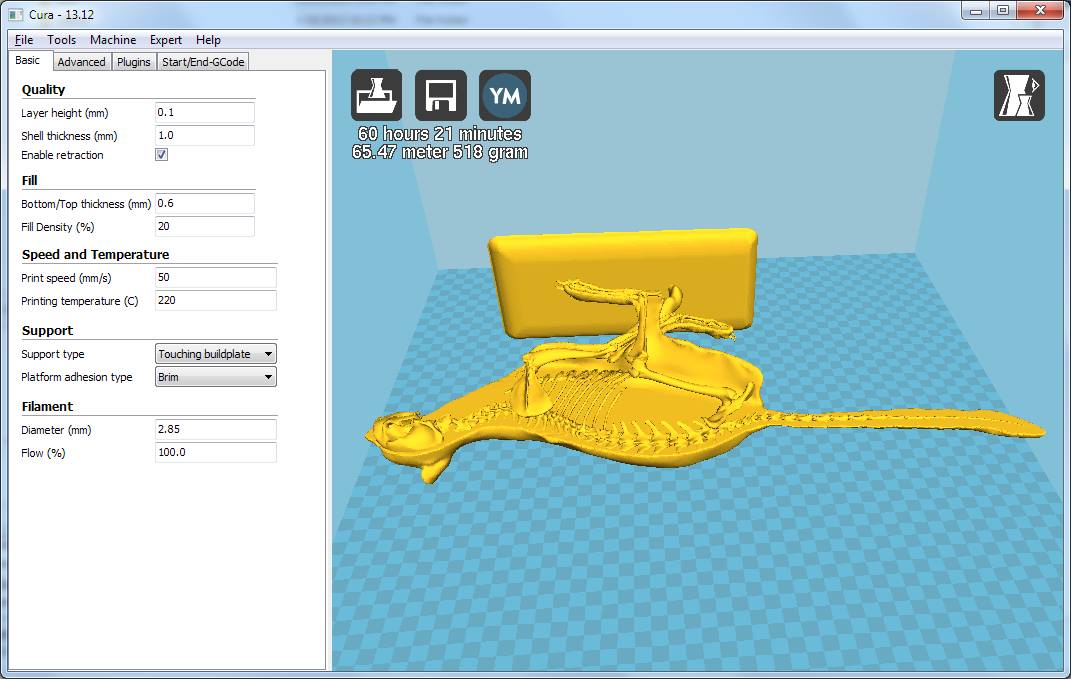

The “experimental version” of Gigabot which we are currently calling “OpenGB” is designed to be built with open source development boards like the Arduino, and Beagle Bone. It will also explore solutions to some challenges our home based users and those collaborating on 3D printing projects have shared. We think there might be a better name than OpenGB, but haven’t found it yet. We’re are hoping you will have some ideas.

This Gigabot has been inspired by the feedback & needs of our hobbyist hackers. As we adventure into an even more open Gigabot, we feel it is important to share our plans, and collect your inputs along the way. We invite you to check out our blog for project updates and to contact us directly with feedback at engineering@re3d.org!

Patrick Finucane

Blog Post Author