Our head of sales, Morgan, recently caught up with CJ Bryant, the Advanced Technologies Teacher and Coordinator for Phoenix Charter School, a 190 student high school in rural Oregon. Their program features Gigabot and has quickly become a hot item at the school. CJ tells the story below.

I’ve been here for about nine years. I started off as the transitions teacher, gearing students to be job- or college-ready when they graduated. It was about making sure that they wanted to go to college and had all the necessary things completed to do so. Then our technology coordinator left, and I moved into that position. I was teaching a few technology classes, but quite frankly, Microsoft Office is really boring to teach.

I talked to our Executive Director about getting a virtual reality simulator. We taught the class as a computer-based graphics and a programming class, and then you’re also designing buildings, which is geometry. Then about four years ago, when drones were in their infancy, I went to our Executive Director and said, “This is really cutting edge stuff. Soon there’s going to be hundreds or thousands of these things around; we could teach students to do useful things with them.” We were ahead of the curve.

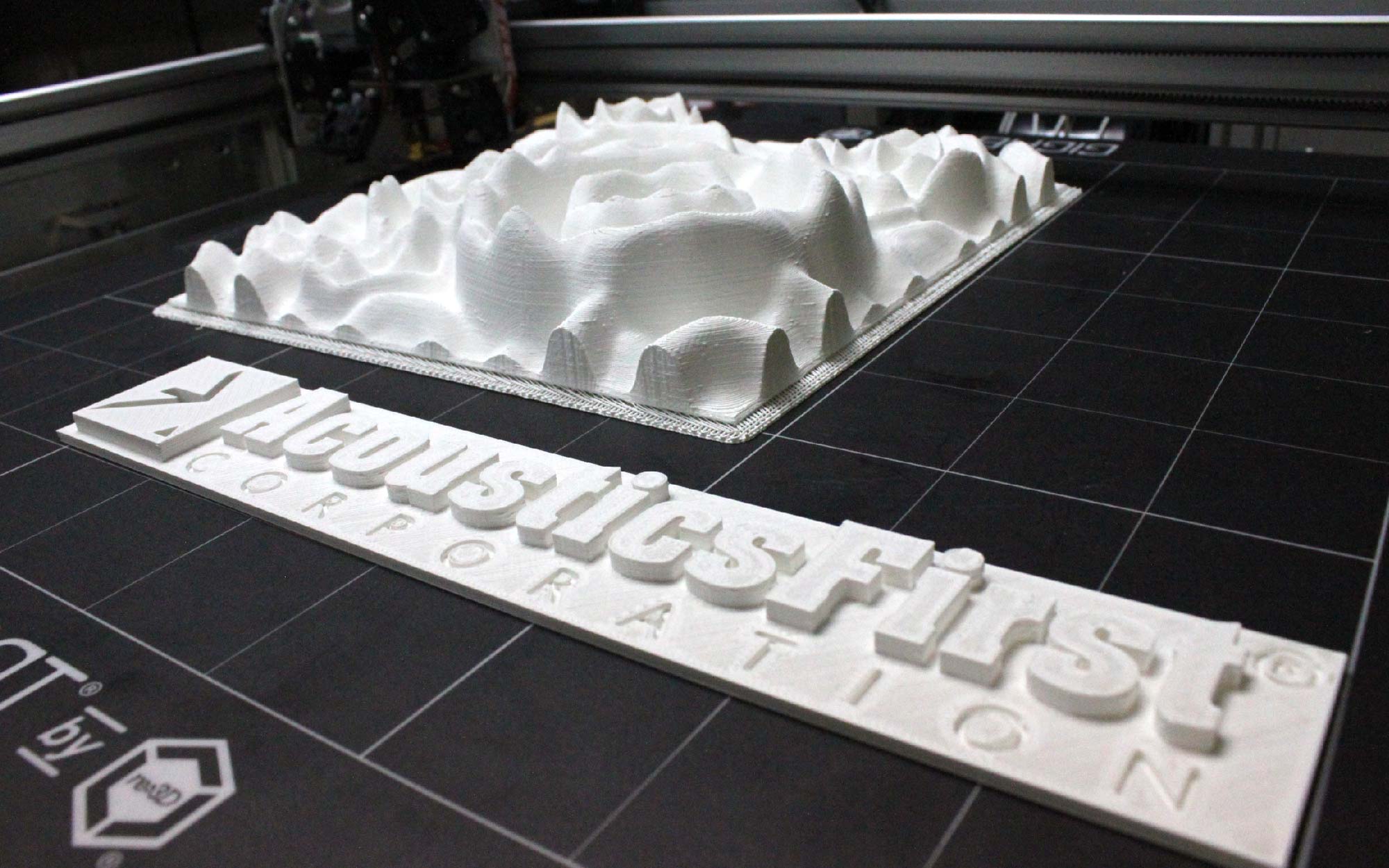

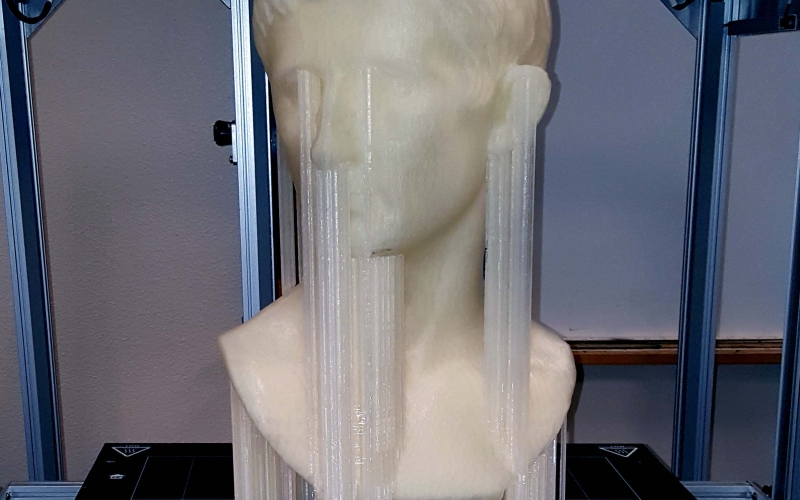

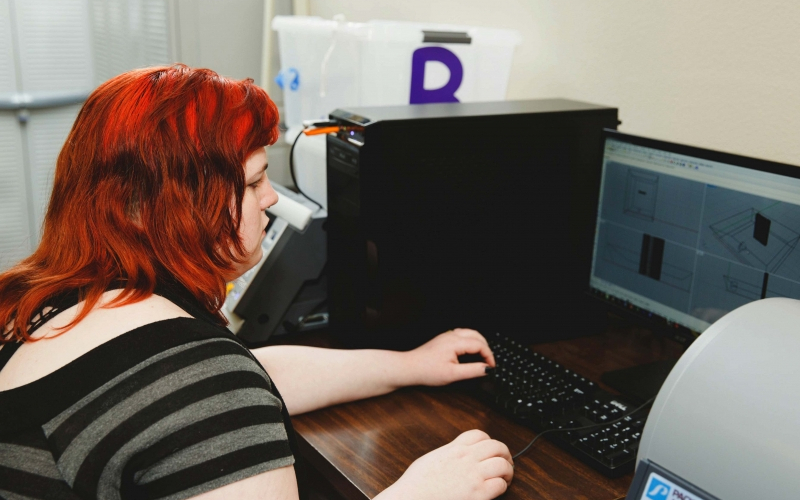

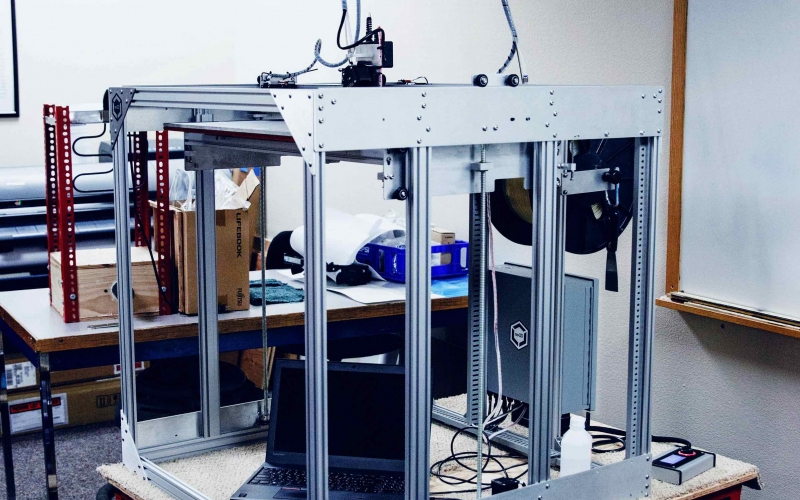

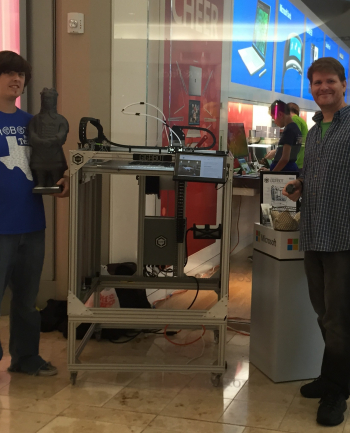

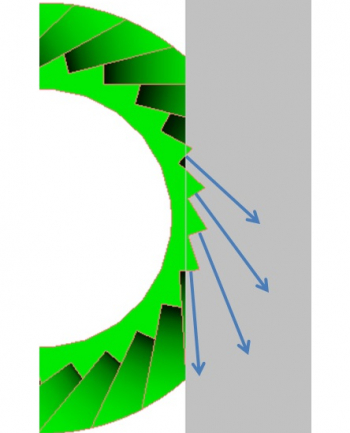

Being in western Oregon, our school has long-standing partnerships with the US Forest Service, and before I knew it, our quad rotor was in the woods with agency staff and students to learn if we could assist with tree vole nest surveys high up in the tree canopy. That experiment led to changes we needed to make in our quad rotor: it needed to be bigger, faster, smoother, and more stable. We thought, “If we had a 3D printer, we could print a new body and use all the components that we have.” I went to a couple different teacher workshops, and they had all these really small 3D printers, and to me, that was useless. I don’t want to make miniature chess pieces, I want to do something useful. I saw the Gigabot and went, “That’s it! Two feet cubed? That’s what I want.”

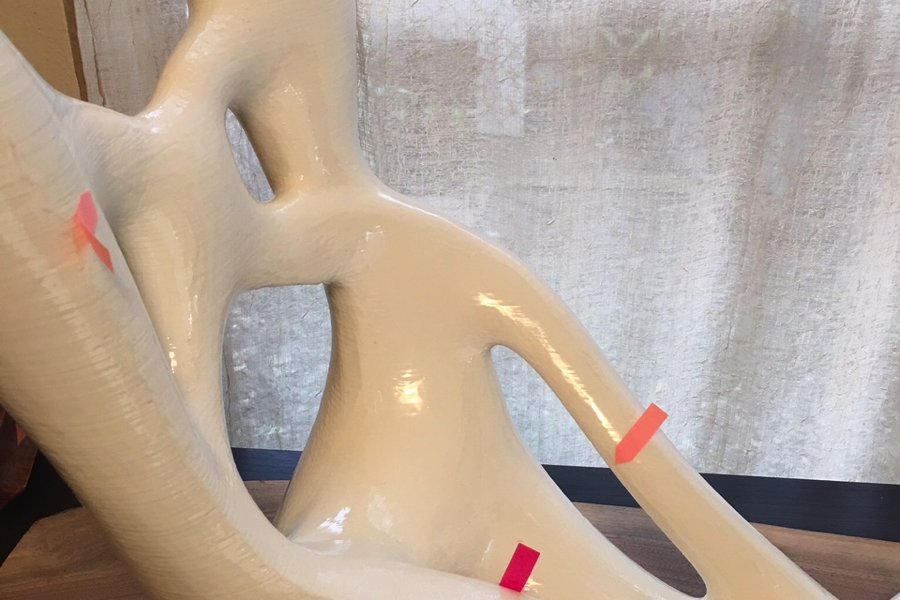

The most exciting thing I think we’ve done was when the symphony had a fundraiser at the school, the culinary arts department came to us wanting us to make chocolate molds for the fundraiser dessert. We printed out musical notes on Gigabot, and students built a vacuum former so we could make the molds in-house. It was a learning process. When we can do things like build a vacuum former, now we’ve taken what we can do with our Gigabot to the next level.

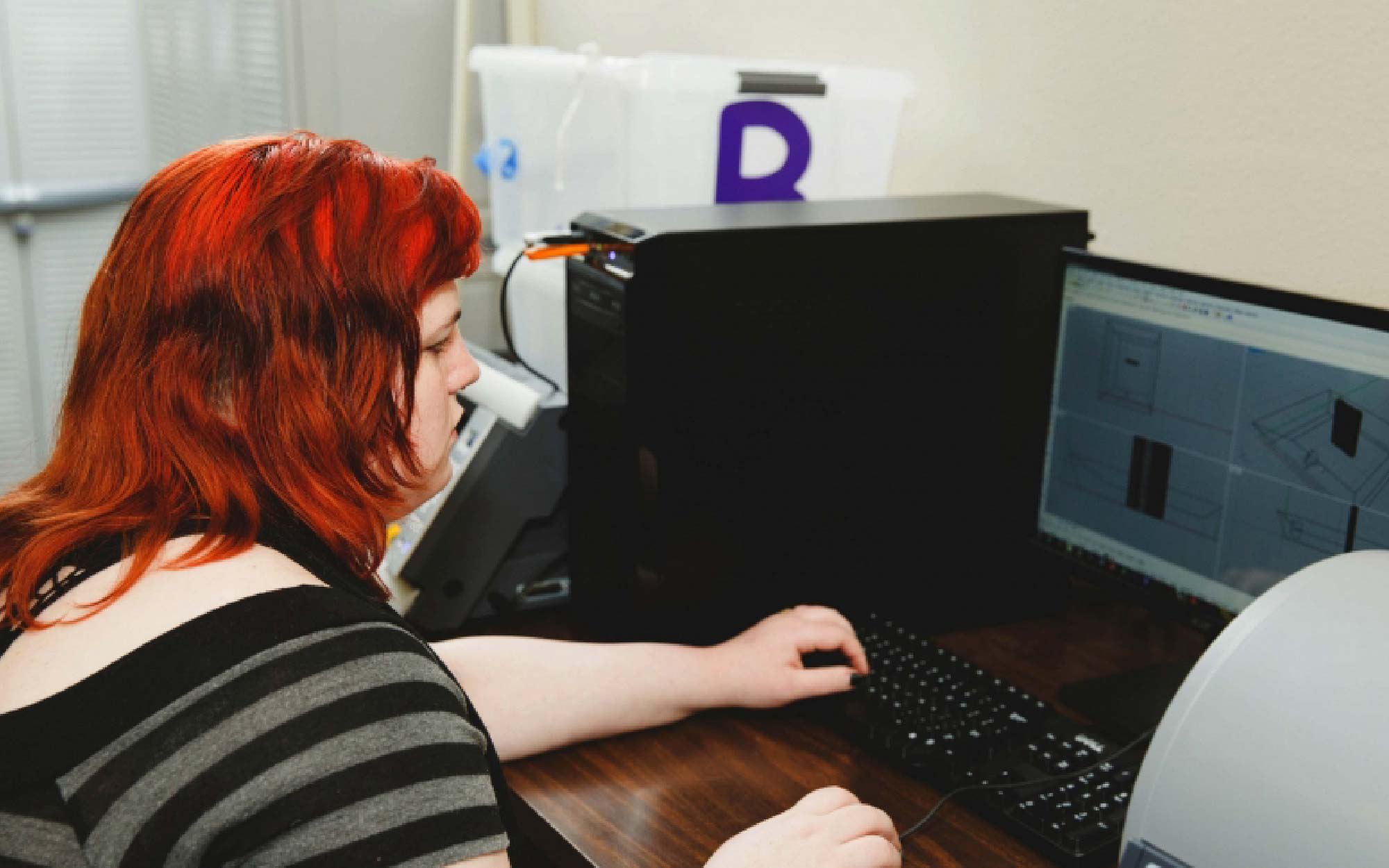

We call this project-based learning. Kids may be sitting in an algebra class thinking, “What would I ever need this for?” Then they come to my class to create something and go “Whoa, how did you do that?” In teaching them the math behind it, it clicks — this is what the math is for. What we are doing is using a real-world application to teach math. It’s far more engaging.

To get into teacher lingo: every state has standards that students have to meet. Rather than teaching standards using a textbook, worksheets, and tests, I cover the same standards with projects. Students can check off several standards in one project. Do the students know that they’re polishing off standards? Not so much. When do they find out? When they go through the list that they need in order to graduate, and they realize they’ve already checked all the boxes. Project-based learning has several distinct advantages, the largest being that students can take you step-by-step through their project. This ownership of their project makes education real, relevant, and lasting.

We are a charter school, and our target is to help with the community’s at-risk students — students at risk of not succeeding academically for whatever the reason. We have students who have not had success in any of the other schools in the county. What we do is teach them to be successful, to create that pattern of success. By the end of it, you’ve got juniors and seniors who are taking community college classes at the same time that they’re here. 75% of the students who graduate here go up to the community college and enroll.

This is enabling them to be successful. The job readiness skills they learn, the communication skills, the attention to detail, following instructions. The process is entertaining for us, it’s fun for them, and project outcomes make a meaningful difference in our school and community.