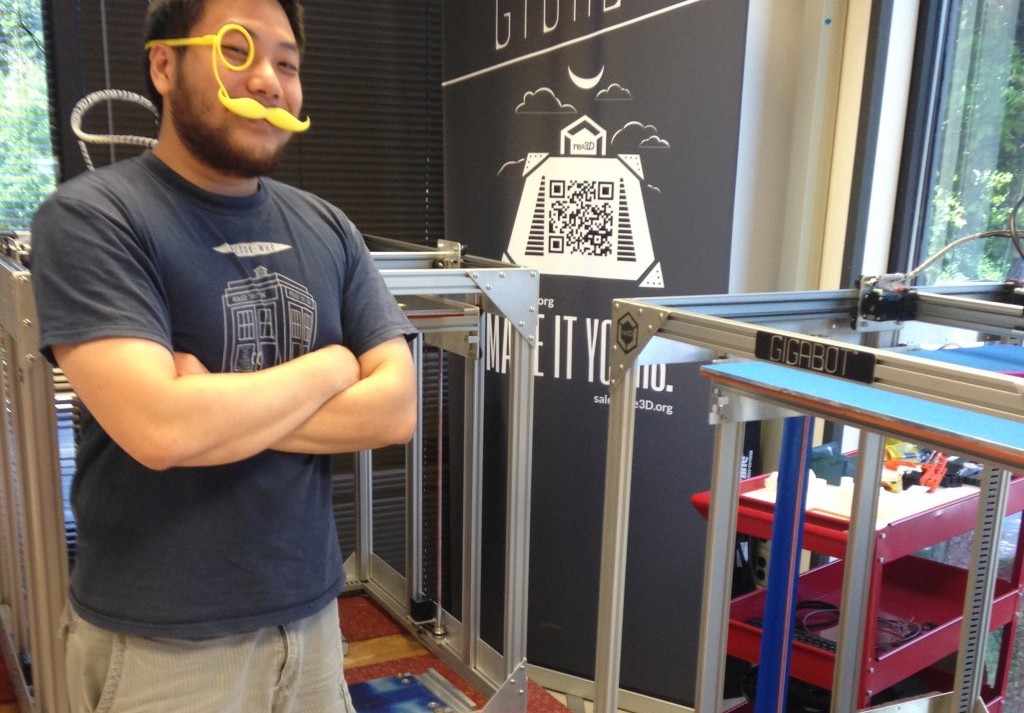

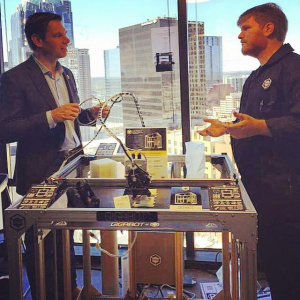

“The Future is Always Tomorrow,” the solo exhibition of artist Micah Ganske, was on display in May with the 101/Exhibit Gallery from Los Angeles at the Art Market San Francisco, a massive production in beautiful Fort Mason. Being the San Francisco-based member of the re:3D team, I was lucky enough to attend the show and see our talented Gigabot-owner Micah’s work in person.

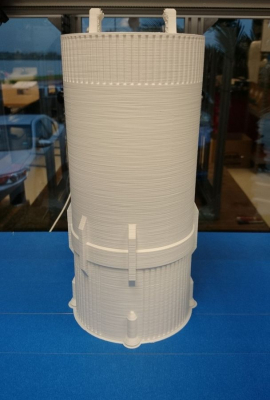

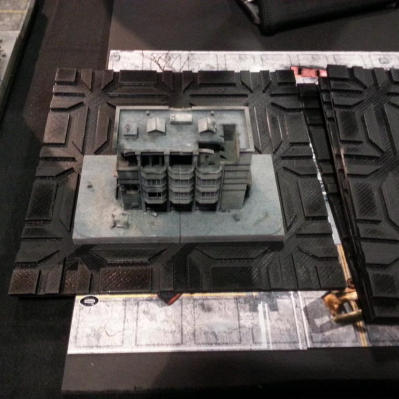

The exhibit revolves around the theme of a futuristic space habitat: a spinning disk called an O’Neill cylinder, with an interior based on the landscape of Centralia, PA, a near-ghost town whose population plummeted due to a coal fire which has been burning underground since 1962. As Micah puts it, Centralia was “felled by the very technology that once supported its population.”

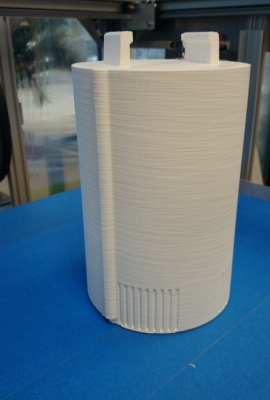

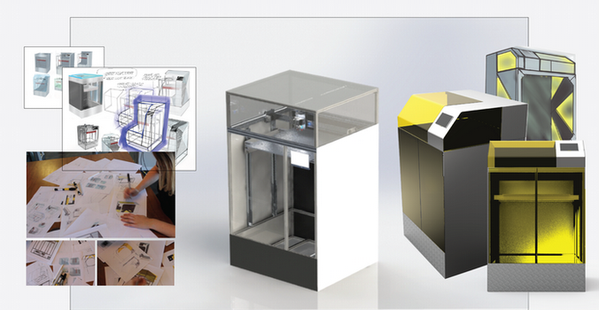

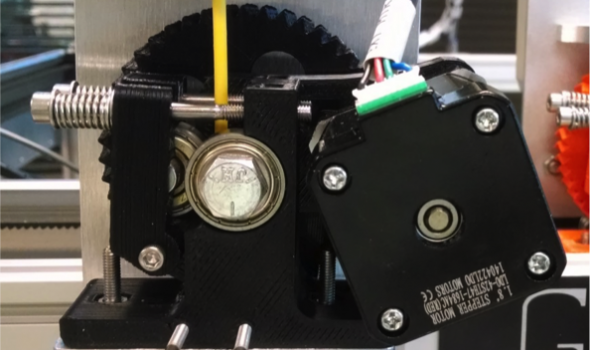

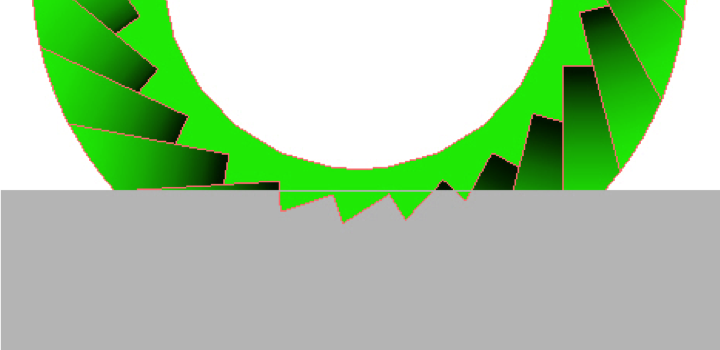

The exhibit is a mix of paintings, drawings, and sculptures, and the show-stealer is the command center of a spaceship, life-size, with joystick controllers that move. The entire piece, as well as his other sculptures, is 3D printed, in part by Gigabot and in part by Bold Machines. This sculpture is paired with an Oculus Rift, and the real fun begins when the headset goes on. With my hands grasping the controllers of the flight deck, the Oculus Rift transported me into the very world that Micah’s paintings and sculptures depict. Micah has created a fully-immersive experience, uniting his pieces in one masterfully-crafted virtual world.

Micah refers to this as “Augmented Virtual Reality,” a combination of Virtual Reality (virtual experiences which replace the real world) and Augmented Reality (virtual experiences incorporated into the real world, laid over your field of view). The joysticks of the flight deck serve the dual purpose of grounding the viewers in the real world and adding touch to the sensory experience while they soar through the virtual disk landscape and into outer space, while at the same time ensuring that they don’t involuntary tip over in the somewhat disorienting experience.

I was lucky enough to get to try out the experience before the crowds hit, and fortunately so, because once the show got into full swing there was a never-ending line to put on that Oculus Rift headset. Micah prefaced my experience with the disclaimer that this was his first foray into virtual reality work – it was my first time experiencing it too – but the forewarning was unnecessary; I was completely blown away.

The roughly five minute session felt like an eternity, in the best way possible. Floating through the air high above the interior of the space habitat, I slowly realized, like the VR newbie that I was, that if I swiveled my head around there was more virtual reality world to explore in my peripheries. Below my feet, above my head, 180º behind me – I started pivoting around like a madman, trying to soak in as much as I could. The purpose of the joysticks as a stabilizing handhold became apparent.

As I floated out of the circular landscape into what I can only describe as an airlock, I was sad to be leaving and didn’t want the experience to be over. To my surprise, I continued floating, a door opened, and suddenly I was suspended, floating through outer space.

This is where I really lost it. I’m a huge space junkie, and to truly have the feeling of being on a spacewalk was beyond cool. Ahead of me was a colorful nebula, floating nearby was one of the sculptures of Micah’s exhibit, below my feet was a moon. In that moment, I realized the potential that VR holds. This is a technology that will enable people to do and see things that are simply not otherwise possible. Wannabe astronauts can fulfill their dreams of walking on the moon, paralyzed athletes can climb mountains, aspiring Jacques Cousteaus can dive to the depths of the world’s oceans even with that sinus infection. Suddenly the technology became an enabler, rather than the introverted crutch I had previously seen it as.

The biggest shock was when the music came to a stop and the headset came off to reveal that I was still standing in the same spot, in the festival pavilion of Fort Mason. The feeling that came over me was akin to the post-movie depression that so many experienced after seeing Avatar in 3D. I had truly been on a journey to space and back in just five minutes. It really was an otherworldly experience.

Micah’s exhibit comes together with a uniting moral perspective: that we need to embrace our “techno-civilization” while also being “smarter about how we live.” He references Elon Musks’s new Powerwall batteries as an example: they are “something that can change the world today if we are proactive…made possible by smart engineering and responsible industry.”

Although Micah’s exhibit implies that humankind is not able to manage this feat, that we destroy our home planet and are forced to retreat to manmade modules floating in space, he is hopeful. “In the end I’m optimistic and confident that we will work things out and that the best members of society will make up for the worst,” he says. “My new sculptures and drawings combine express my hope that we will further use technology to improve and evolve our very selves. My vision of the future is one of cautious optimism.”

See more about Micah’s work: http://www.micahganske.com/

Check out the 101/Exhibit Gallery: http://www.101exhibit.com/

Read about Micah’s exhibit in the news:

Morgan Hamel

Blog Post Author