Rewind to late 2013.

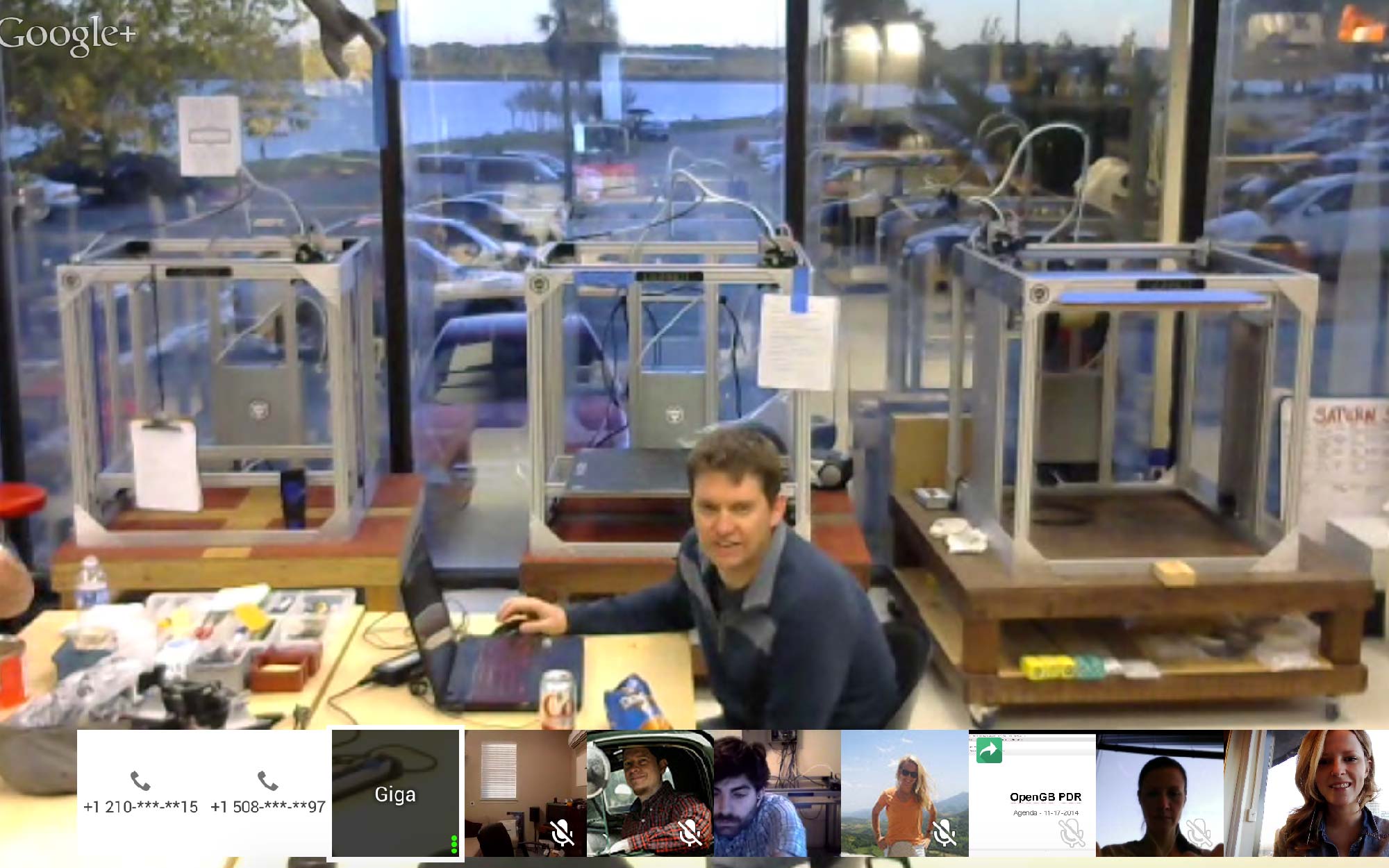

re:3D was in the middle of Kickstarter fulfillment, focusing on our backers, and building the core mechanics of our company, all the while introducing ourselves to the 3D printing community. The architecture community was one of our emerging markets for large format, affordable 3D printers, and through a fortunate introduction via Start-Up Chile during DemoDay, we had the honor of partnering with Arch Daily. Through the guidance of our rockstar designer, Lorena Quintana, the ArchDaily 3D Printing Challenge was born, and we yelled far and wide: “Calling all designers and architects – model your favorite masterpiece from modern architecture, and we will 3D print it on our Gigabot!”

The response was pretty impressive. ArchDaily has a very wide reach, and models from around the world came in to be judged by editors, Sketch-Fab, re:3D staff, and the global community via Internet voting. When all was said and done, 19 finalists with high quality .STL models of the most amazing buildings on the planet were waiting to be brought into the physical world.

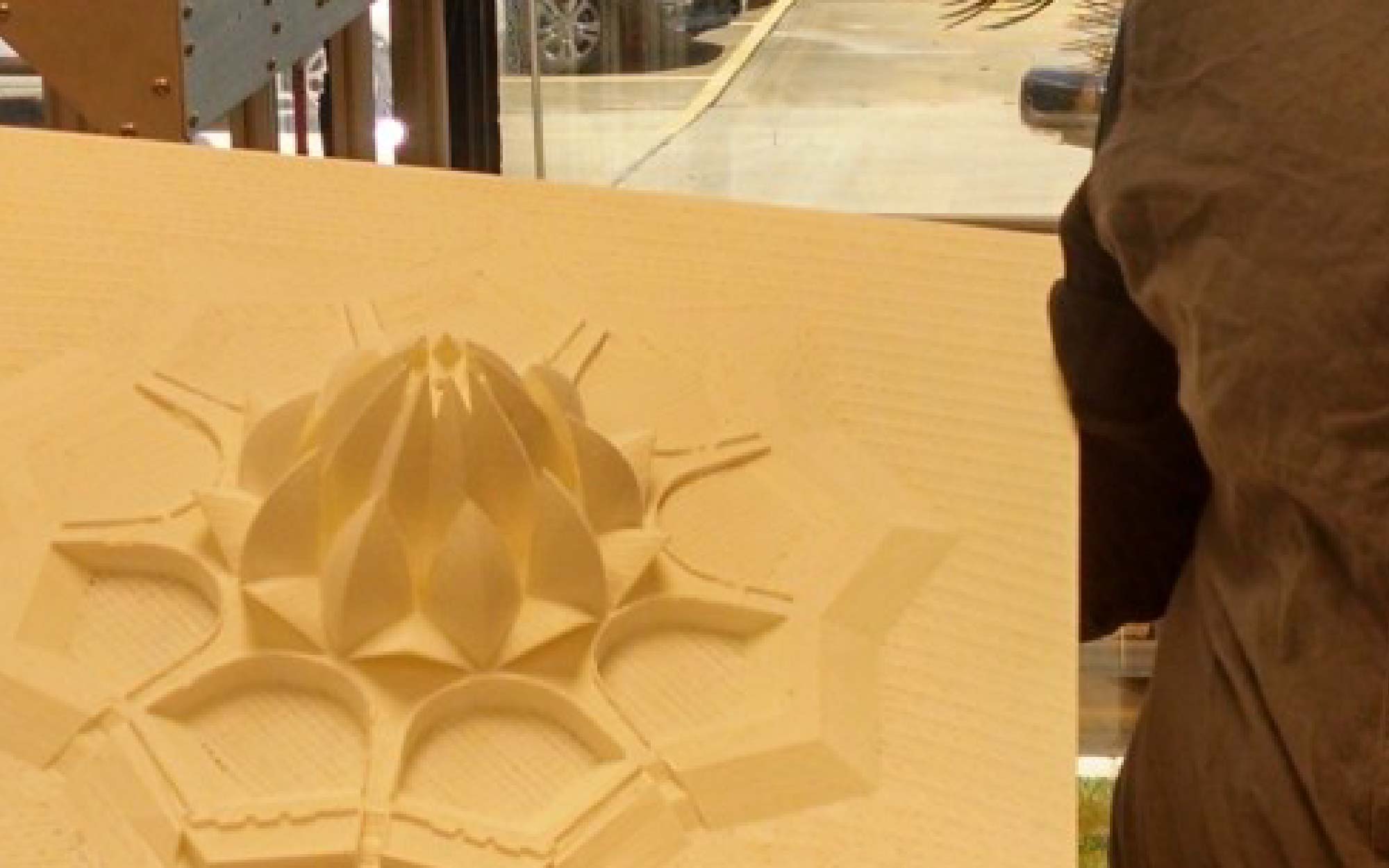

There were two winners who very deservedly were awarded large versions of their models. Elijah Wood created a model of the Lotus Temple in New Delhi, India which included the striking landscape surrounding the building, and Luisa Lense created a model of Villa Savoye, a nearly century-old basis of modern architecture near Paris, France.

I could easily and quite accurately end this blog post here, with “and we printed these great models for Eli and Luisa on the Gigabot”… but there is so much more of a story than that.

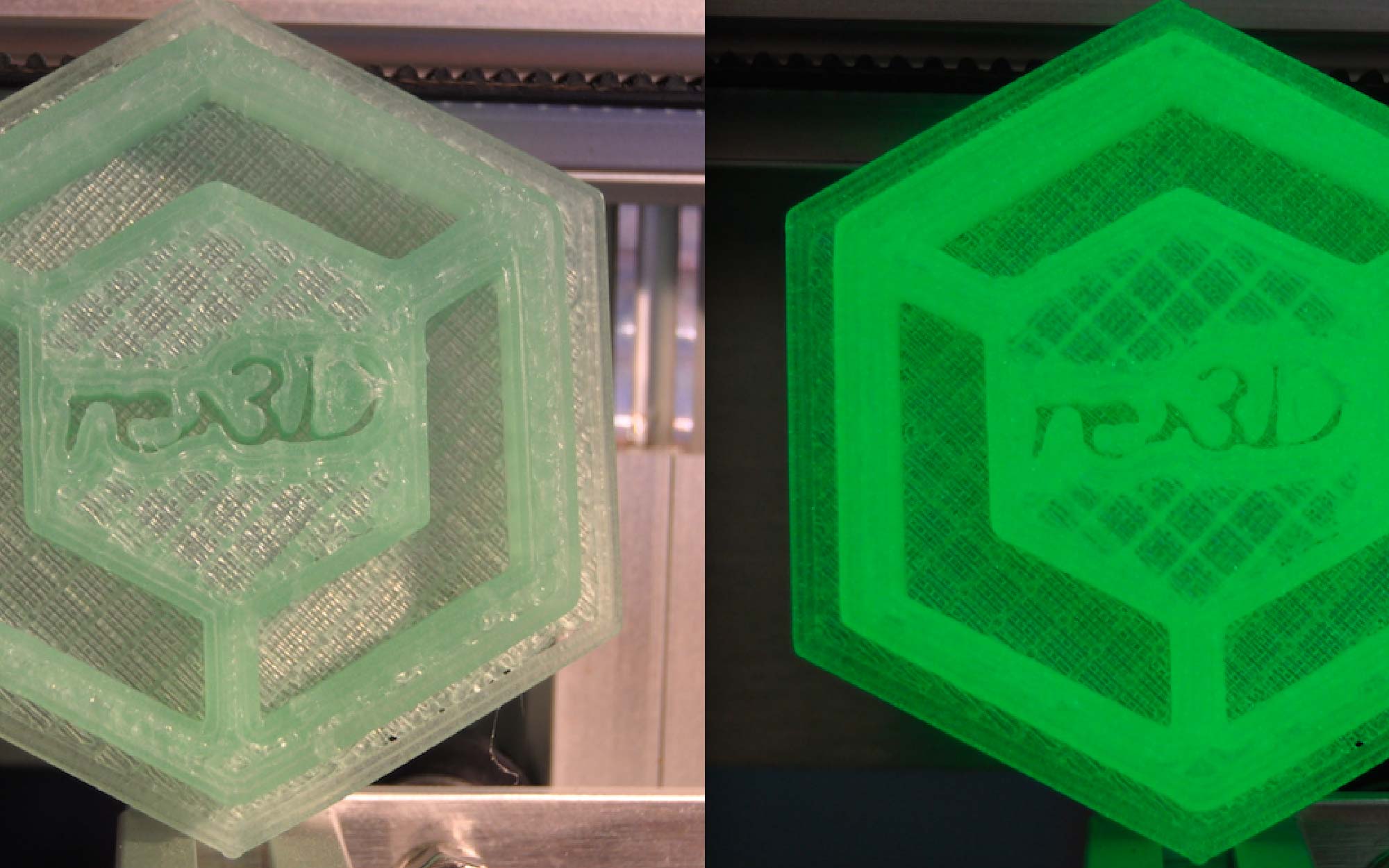

At the time of the challenge, re:3D was fulfilling a promise to Kickstarter backers that included a large 60cm x 60cm platform on their Gigabot, but not a heated bed. In fact, so much emphasis was on the Gigabot itself that the heated bed was a relatively low priority. Up until this point, we were printing enlarged models from the open source community: Large vases, skyscrapers, hand tools, and a thousand smaller items. We honestly did not print much that would push the limits of the highly forgiving PLA filament.

Enter into the mix a 2-foot square landscape surrounding the Lotus temple, containing 50,000 triangular faces and covering the entire bed. The results were challenging and stressful, to say the least! One night a co-founder (who shall remain nameless, but here’s a hint) slept next to an ongoing Lotus print in the Houston office so that she could stop it if it curled. It did, and she woke up immediately to the sound of crunching plastic. The direct result: heated bed development was accelerated, a feature that every backer and pre-order customer was asking for from day one. The heated bed today works like a charm – so powerful it can even make you breakfast!

Throughout the process of attempting to print the Lotus building and interfacing with the model’s designer, a wonderful thing happened — Eli Wood wanted to come to work with re:3D!!