Clear Lake City, a community in the Bay Area of Greater Houston, is a name you might not immediately recognize, but it’s the site of a couple things you probably will.

Most notably the home of the historic NASA Johnson Space Center, its Mission Control can be picked out in famous scenes from the 1969 moon landing or movies like Apollo 13 and The Martian. It’s the Houston in “Houston, we have a problem.”

Also not to be forgotten in Clear Lake’s list of places you’d know is our very own office.

Just down the street from the re:3D Houston office is another place putting Clear Lake on the map for technological innovation, one which you might not expect: the Clear Lake City-County Freeman Branch Library.

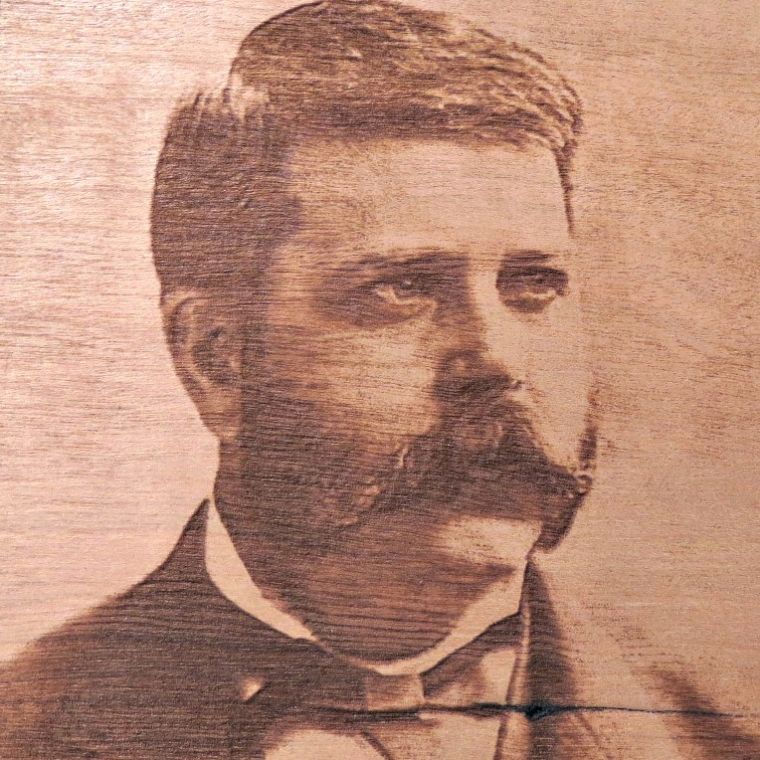

“This all started back in 2013 when we were notified that the library was named in a will: Mr. Jocelyn H. Lee’s, whose name is on the lab.”

Jim Johnson, Branch Manager of the library, explains how there came to be a tech innovation lab — complete with laser cutter and multiple 3D printers — in the middle of a library in Clear Lake.

“We had no expectation as to how much he might have left us. Once we did find out, I fell out of my chair. It was about $134,000.”

Evolving to Survive

The library as an institution has defied odds in the face of technology. Fighting the battle against obsolescence, libraries have made it through multiple threats to their livelihood, their survival owed to the nimbleness of their leadership.

“Largely because of technology, libraries, especially public libraries, have had to constantly adapt,” Jim explains. “Once computers became more prevalent and the internet started making headway, libraries as a rule had to adapt in order to stay alive, and not merely just for the sake of staying relevant, but staying relevant to what’s important to people in the way that they acquire information.”

The unexpected and extremely generous donation was an opportunity for the library to do just that.

“We started looking at some trends out there in public libraries around the country and found that makerspaces were beginning to catch interest in communities. Being such a strong engineering community in Houston — from aerospace to chemical — we thought that we probably had the space here to do that kind of thing. We didn’t really see how we could lose if we did it right.”

So they got to work, repurposing the library’s Quiet Room — “It’s hard to imagine a quiet room being needed in a library,” Jim adds — to accommodate some heavier machinery than most libraries are used to having. Next on the list was finding the right person to head the lab.

From Tinkering to Training

“I was a stay-at-home dad before this.”

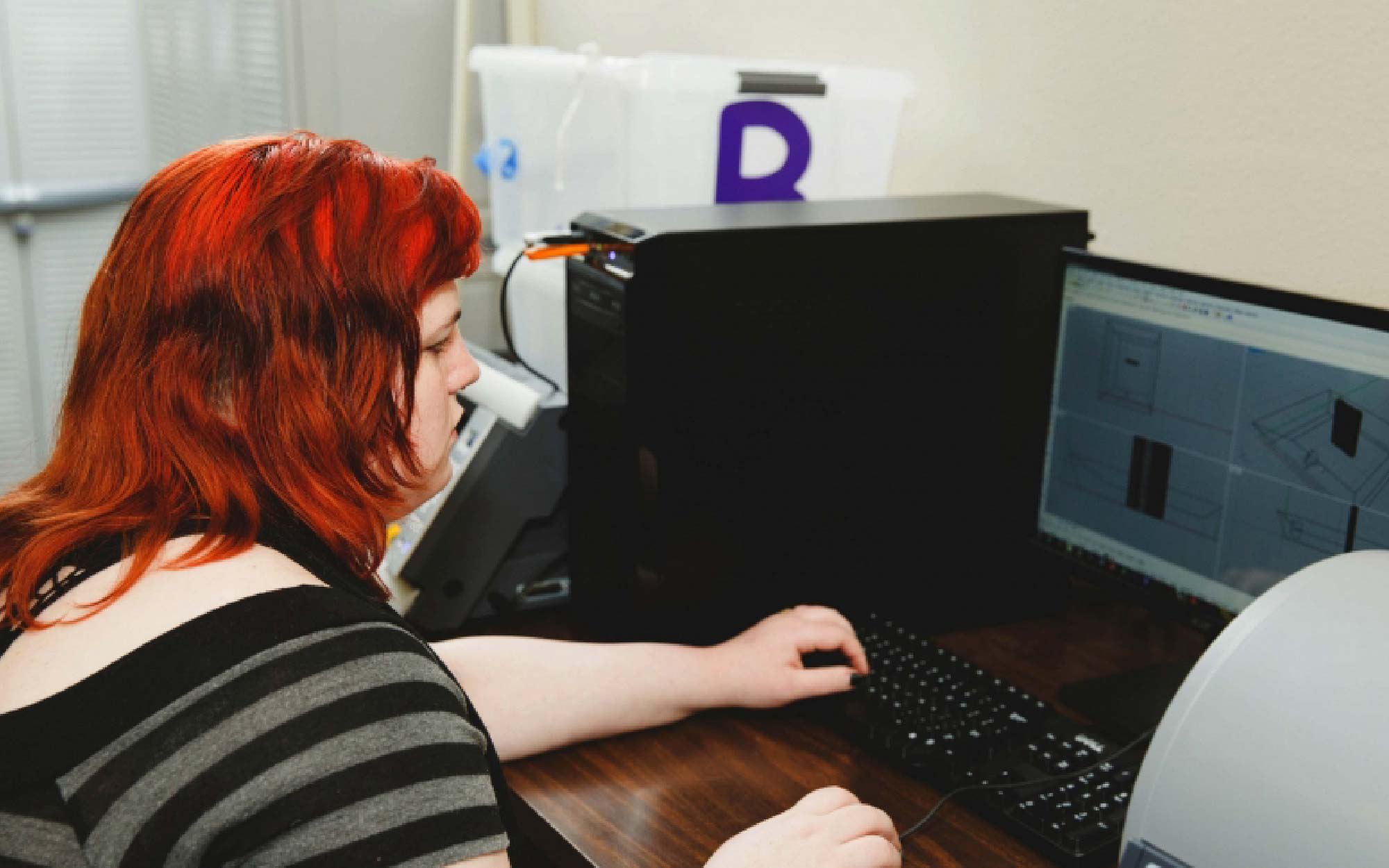

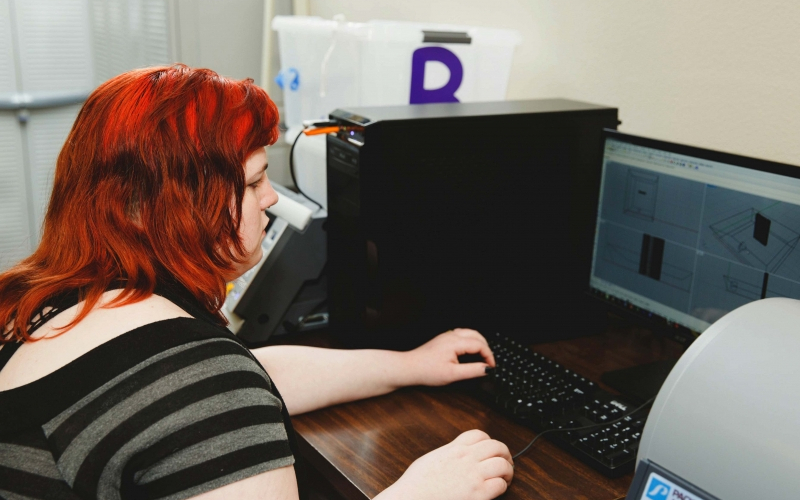

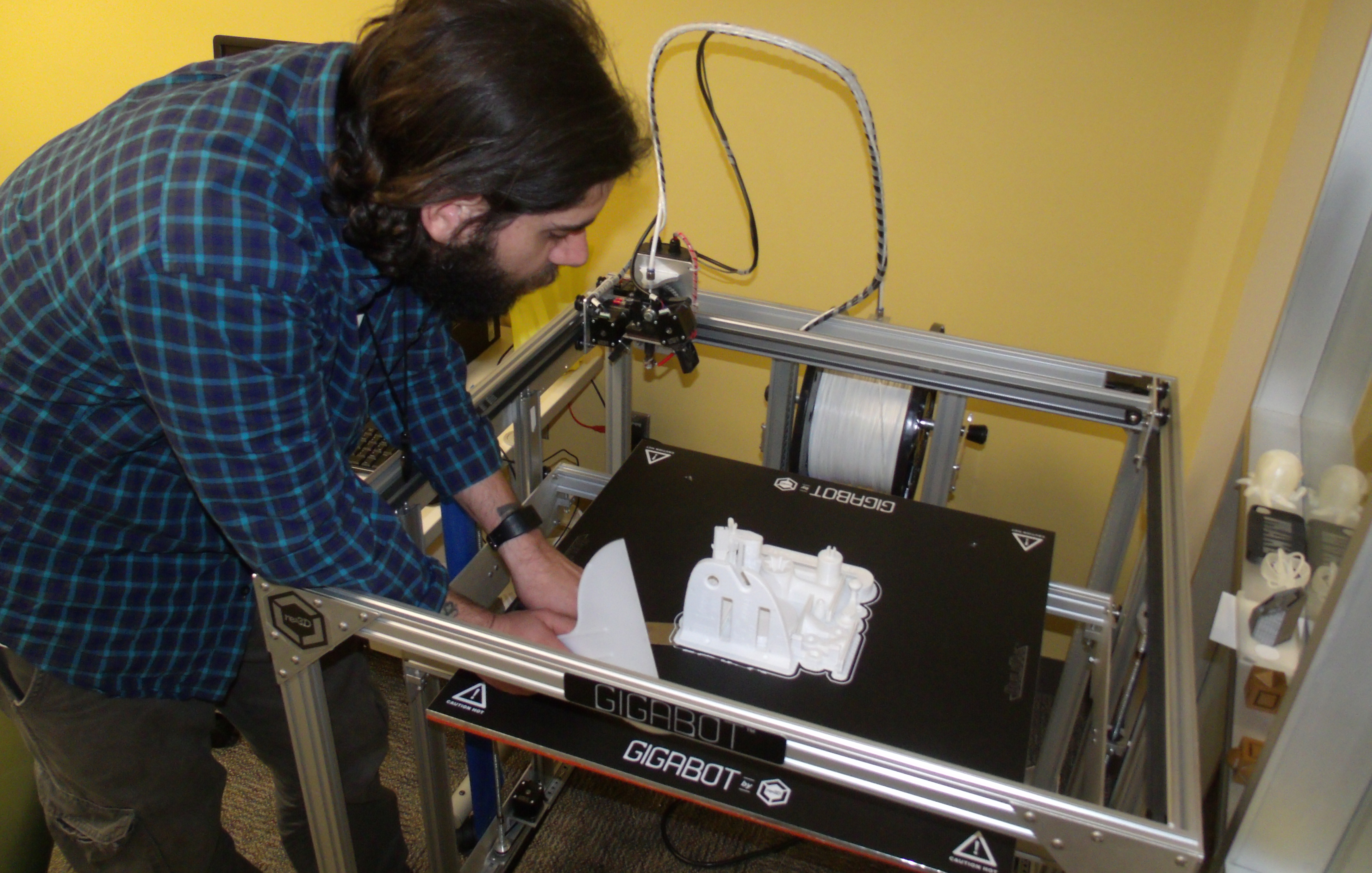

Patrick Ferrell was the man brought on for the job of Innovation Lab Trainer. “Before a year ago, the library was a place I brought the kids for storytime. I had never touched a 3D printer until after I found out I got this job.”

A natural tinkerer and hobbyist, Patrick’s professional background in mechanical engineering and physics lent itself well to what the library was looking to do. He now organizes and leads classes on everything from basic circuits and programming to robotics and structure-building with marshmallows and spaghetti.

“Whatever it looks like we need to do in order to cater to the audience we have,” he explains. “Since we’re the only space like this in the county system — and all of Southeast Texas as far as I know — I have a fair bit of latitude and freedom in what kind of classes we offer. Whatever I think looks like fun is what we do. If other people think it looks like fun too, then they come in and we keep offering it.”

His tactics have been working. As Jim put it, “Any success that the space has had is really largely due to Patrick’s influence.”

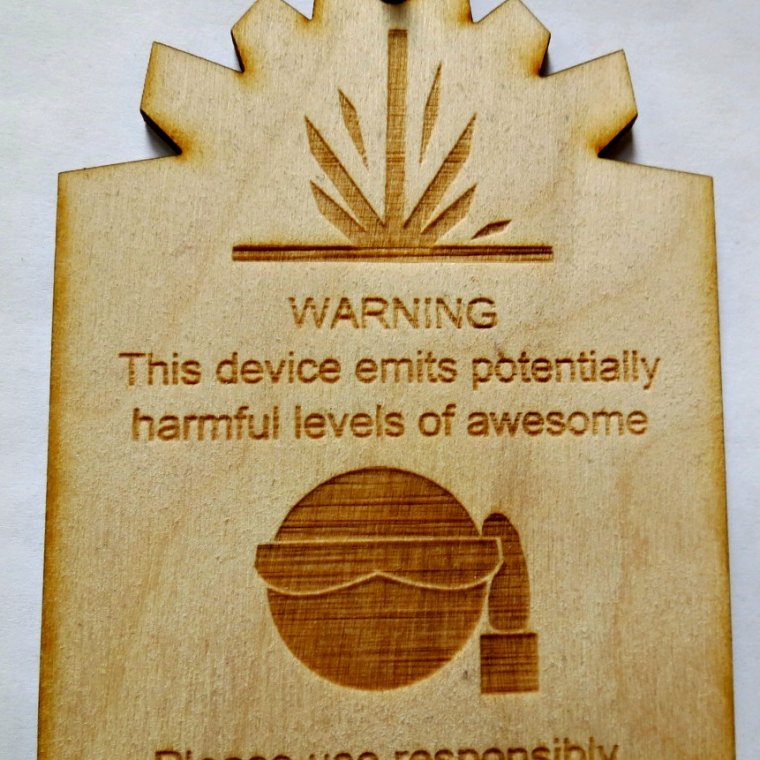

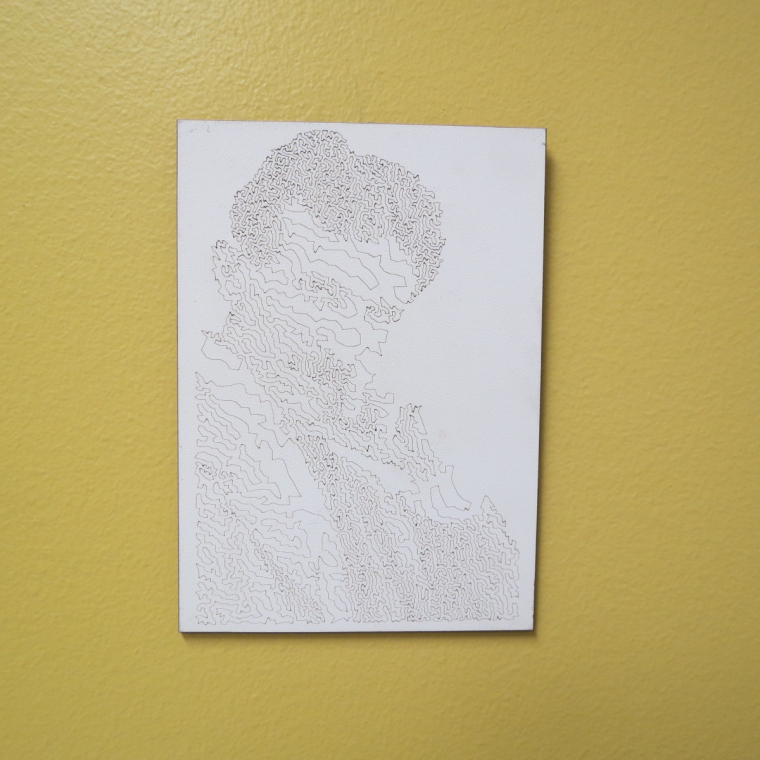

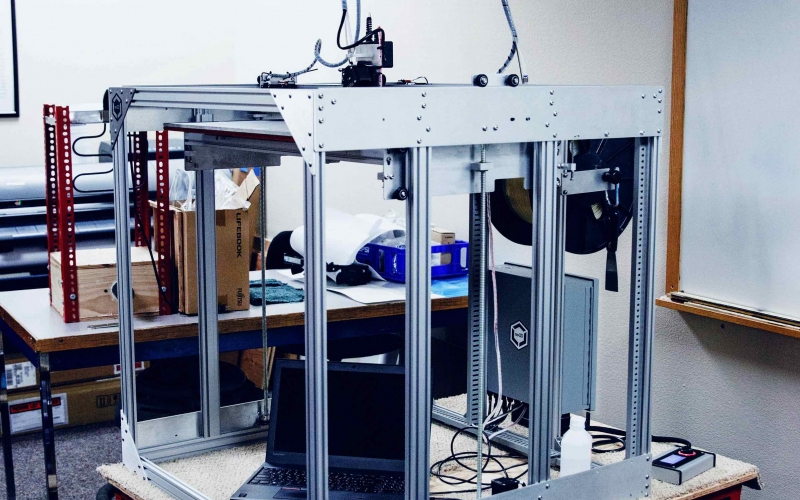

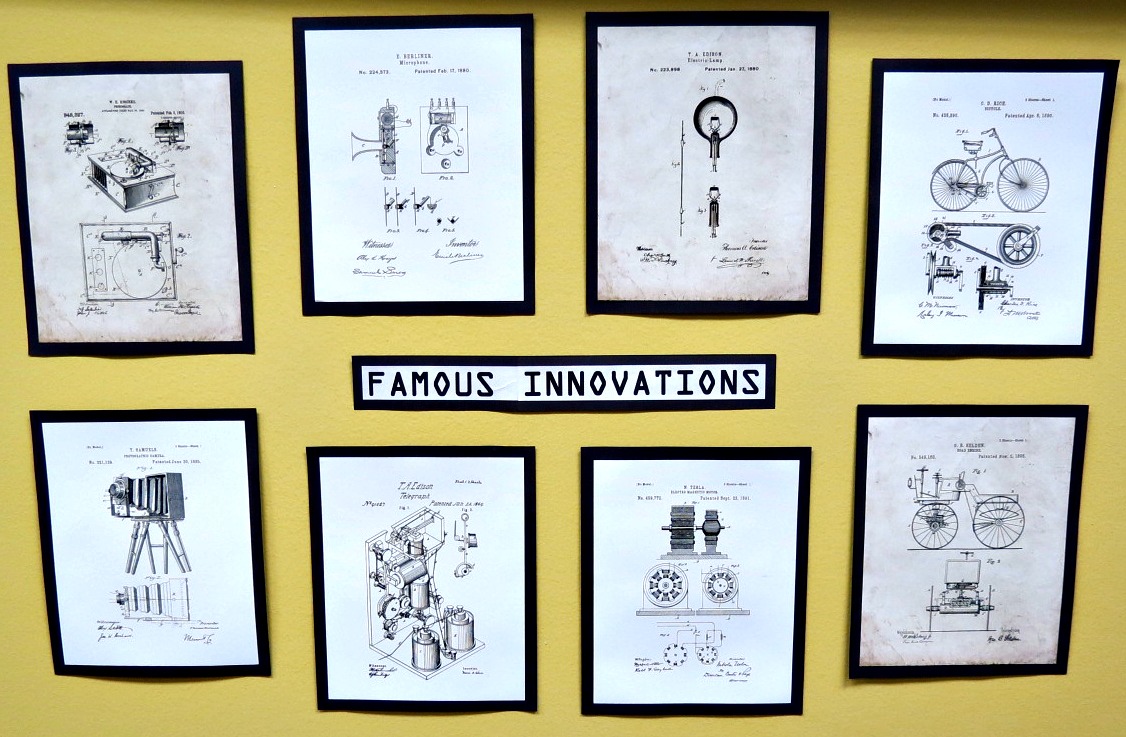

Walk into the lab and you’ll see what it’s all about. The walls are lined with eye-catching machinery and class creations. A “Cardboardosaurus” T-rex head hangs above their Gigabot in one corner; in another is an outer-space-themed piece of art made entirely using filament from abandoned and failed 3D prints, the masterpiece of one very creative library shelving assistant. Tribute to the original tech influence of the area you can find several NASA-themed 3D prints around the room, among them a several-foot-tall rocket and a model of the Orion space capsule. The laser cutter was my personal favorite — intricate wood, paper, and cardboard portraits adorned the wall next to the machine — proving that two-dimensions can still be cool.

Trend-Following to Trend-Setting

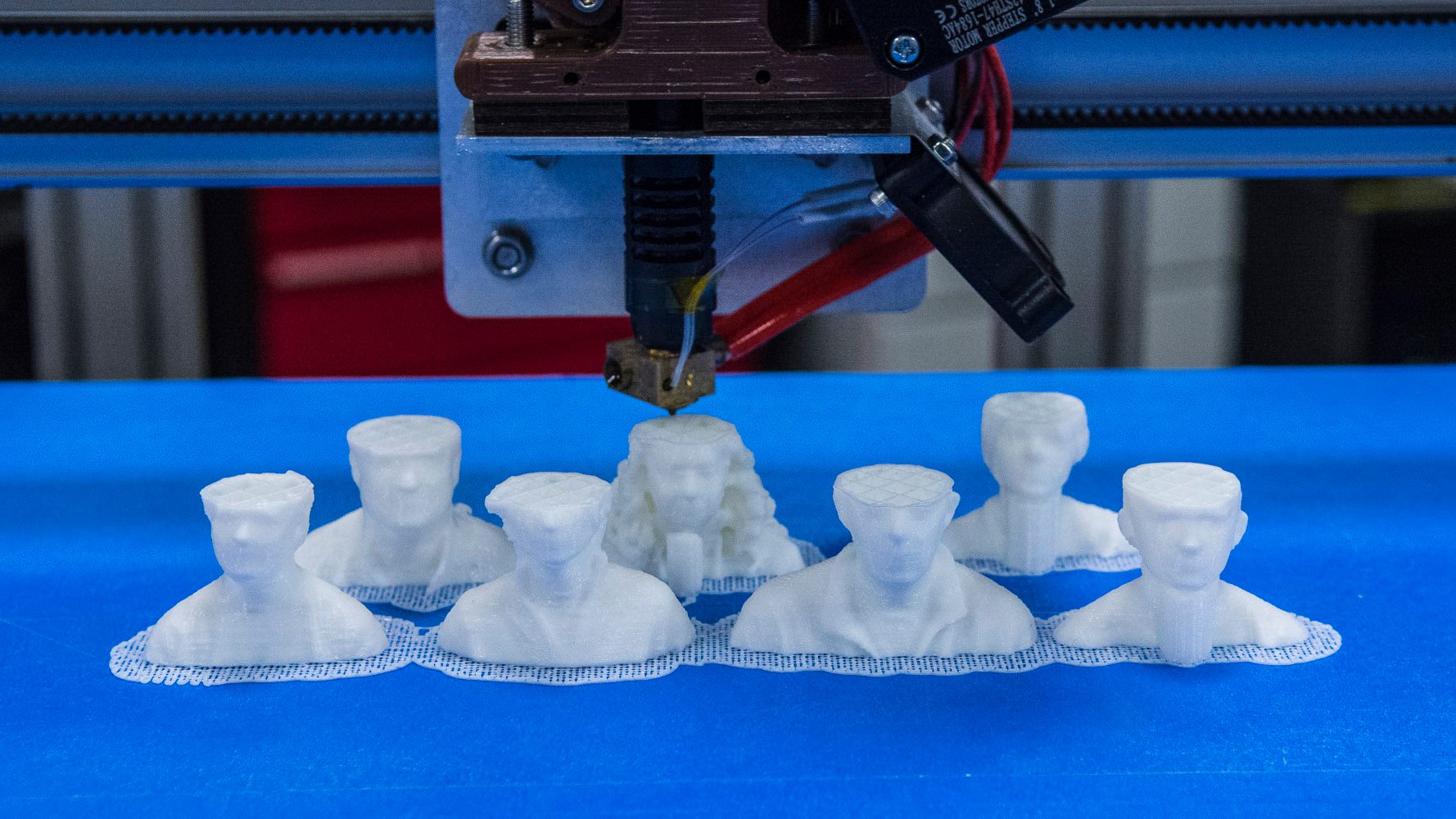

The recent boom in interest in desktop 3D printers allowed the library to tap into the trend and retain its relevancy in the community by getting several printers for the lab.

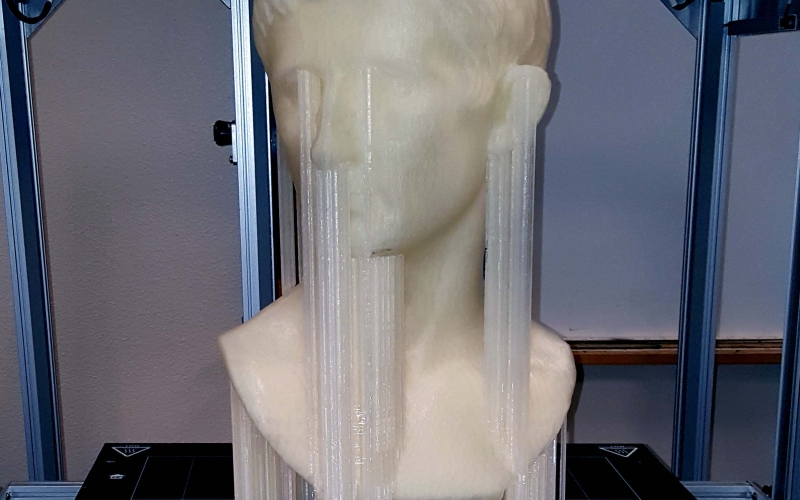

With a Gigabot in addition to two desktop-sized Makerbot Replicators, they also have the advantage of boasting a print volume unmatched by many local makerspaces. Because of this, they often get called on when a project has hit the size ceiling at another facility.

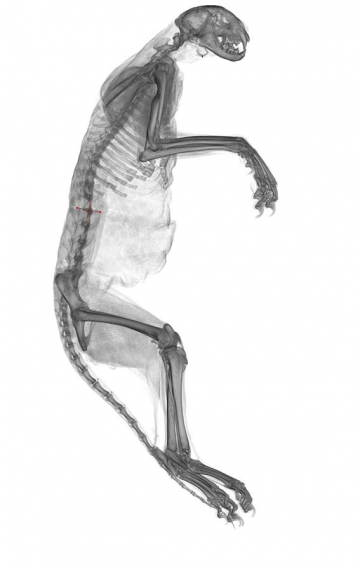

One of Patrick’s favorite projects so far was one by a local Houston teenager, Nicholas. He had been working with Techno Chaos, a local makerspace, the director of which knew that the library had a Gigabot.

“The director, Mike, called me up and said, ‘I’ve got this kid who’s designed a Freddy Fazbear costume and we’ve printed it on the MakerBot, but he wants to make it full-size. Do you think you could help him?’”

It was the longest print the library had taken on at the time.

“Just the head of the costume was a 44 hour print. But Nicholas was passionate about the project, and his persistence and perseverance enabled him to complete the entire thing successfully.”

What’s made it all worth it for Patrick is seeing success stories like Nicholas’s. “His parents would come in and say, ‘It’s good to see him excited about this kind of thing.’ Finding some outlet for him to be creative in that way was really great. Seeing him so excited, that’s what made it all so rewarding for me.”

And the sentiment is catching.

Patrick told the story of how Nicholas displayed his large-scale print at his booth at the local maker faire. “The director of the Harris County Public Library system was really impressed with his project. When it came time for budget talks, Nicholas and his dad went before the county commissioner’s court to say, ‘This is why libraries are important. This gives our son a place to go to use tools like this.’ The commissioners then asked, ‘How can I get one of these in my precinct?’ They see someone like Nicholas who’s passionate about this, excited about it, and they want to give more young people access to it.”

Challenges on the Front Lines of Innovation

Jim and Patrick have seen firsthand what doors the Innovation Lab has opened for the local community, and they understand the value that technologies like 3D printers can bring to the right people.

“Schools are starting to have the smaller printers, so if you’re doing a school project, that’s great,” Patrick explains. “But if you’re doing a personal project, then you’re kind of out of luck. You’re either sending your file off to Shapeways and paying outrageous amounts, or you have to find someone on Hubs, but it’s really hard to find somewhere that can print at the scale of what’s possible on Gigabot.”

On top of large-scale printing, there is another big selling point that sets the Innovation Lab apart from similar spaces in the area and around the country.

“What’s special about our makerspace is that we don’t charge dues or membership fees,” says Patrick. “The only thing you’re paying for is the material you use.”

The fact that the space remains open and accessible to the community is a core tenet of the library. The creative potential there is seemingly limitless — the machinery they have on hand coupled with its accessibility is a recipe for unbridled innovation. But being the first to tread through this territory means the library is crossing bridges as they go; the excitement of being on the front lines of innovation comes hand-in-hand with its challenges.

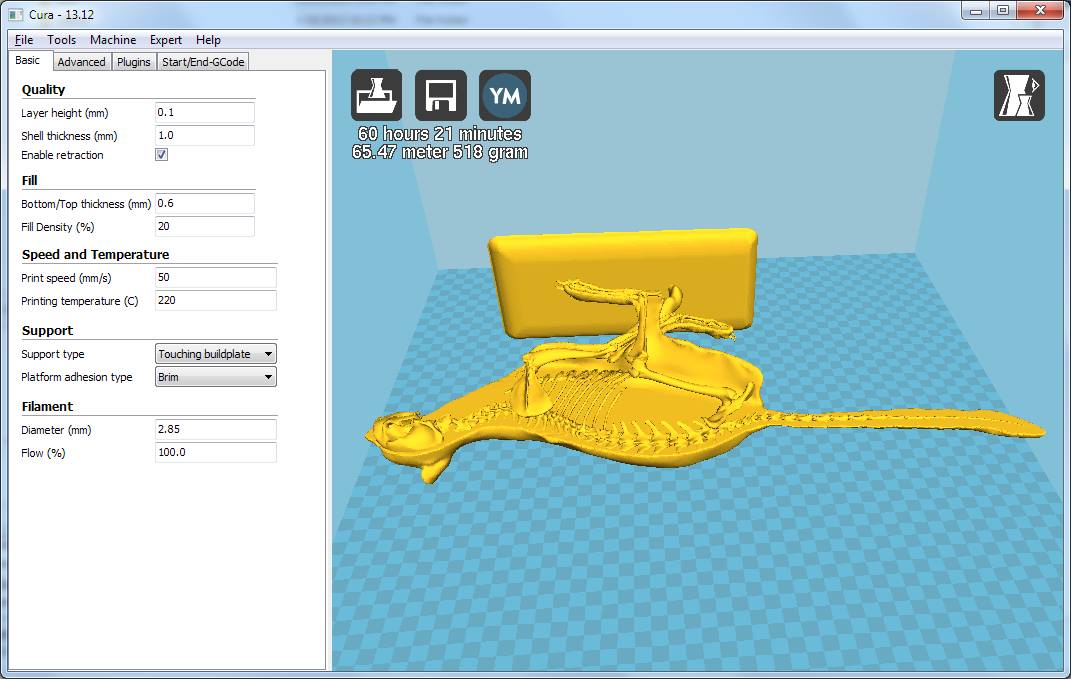

One thing they’ve encountered is the gap between the public’s general expectation of 3D printing and the reality of the technology.

“I don’t know, you mean I have to design it myself? Can’t you just design it for me? I have a picture, can’t we use that? What if I sketch it out on a piece of paper? I found this picture on the internet, is that good enough?” Patrick runs through the common questions he gets from some people when they first come in to 3D print. “Once we get over that hurdle, then people are more interested and they’ll start printing.”

Another thing they struggle with is demand for large-scale 3D printing, due in part to the gimmicky phase that desktop 3D printing is going through.

“Many people who come in are printing little trinkets. It satisfies the ‘Hey look, I 3D printed something’ desire, and they don’t need to go further,” says Patrick.

People are still figuring out how they can use 3D printing to make something practical. The intent in creating Gigabot was to serve just that purpose: a 3D printer at a scale large enough to print practical, real-world objects rather than just small trinkets.

Patrick speculates that the intimidation factor of the sheer size of a large-scale 3D printer adds to this tendency to avoid Gigabot in favor of their desktop printers. With a steep learning curve for 3D printing in general, expanding the build volume several orders of magnitude certainly can complicate things.

This is something that may prove to be the biggest challenge for libraries looking to open internal makerspaces: how do you tap into and attract the group of people who have a genuine need and use for these technologies? A long-term sustainable plan may not be able to rely on a stream of one-time visitors only there to print their name on a keychain and check a box on their bucket list, not to return again.

What spaces like this need are superusers, people who will return week after week, month after month, because they have a practical use for the machinery.

Lessons Learned for Libraries

At re:3D, we talk to a lot of people — inventors, entrepreneurs, tinkerers — with a clear use for large-scale 3D printing, but a lack of a budget with which to get one. To have access to a space where the only cost is a material fee would be the difference between bringing a product to market and never having the idea leave the drawing board.

A big reason 3D printing has flourished as a tool for businesses is its knack for prototyping. Companies can eliminate the need for third-party designers and injection mold do-overs, saving sizable chunks of time and money in the design and prototyping process. With a 3D printer, you could have a prototype made for as much money as it costs to do a few loads of laundry at the laundromat, in nearly the same amount of time. As Patrick explains, “Gigabot is great for designing a prototype which you want to market or show off to investors.”

Because of this, referrals have been a boon to the library, allowing them to offer their equipment to exactly these kinds of people: the garage entrepreneurs with plenty of ideas but not a lot of ways to make them a reality. Local makerspaces like the one that referred Nicholas — as well as the Houston Inventor’s Association, which also sends people their way who want to print big prototypes — have started to get the word out to their user bases.

In the meantime, the library is forging their own path in this new era of how communities interact with their local libraries. Jim is walking proof of the open and innovative mindset that must come with the librarian territory.

“I think that libraries are more about information and knowledge — a place to keep it and a place to use it — and I think makerspaces are a place to use information that you acquire. This is part of the reason why I think this is an excellent fit for libraries and allows them to remain relevant, not just for the sake of staying relevant, but as a practical place to learn something by doing. I think that hopefully, if other libraries catch on to this, you can easily have libraries remaining relevant not only as a place to absorb and acquire information, but also to use it in a practical way.

“This has changed my perspective on libraries being only about books.”

Do you or someone you know live in the area? Go check out the Jocelyn H. Lee Innovation Lab on the second floor of the Clear Lake City-County Freeman Branch Library.

Morgan Hamel

Blog Post Author