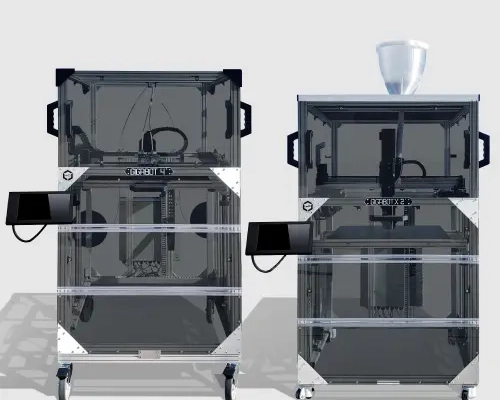

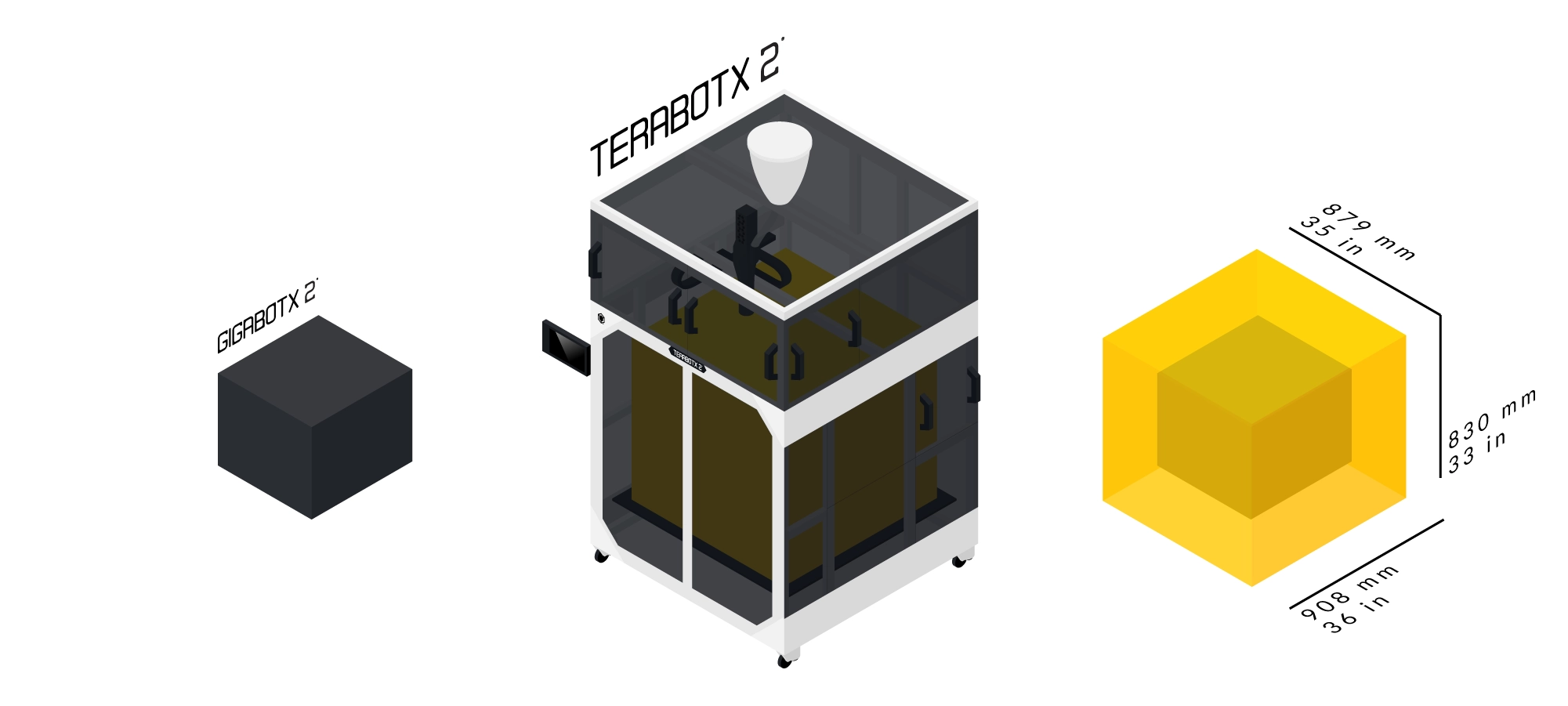

TerabotX 2

Three Zone Independently

Controlled Barrel Heaters

5/8" Extruder Screw with a

16:1 L/D Ratio and a0.4,

0.8, 1.75 or 3mm nozzle

9 Point Bed Leveling

NEMA 17 & 23

Stepper Motors

0.5" Aluminum Heated

Bed with PRINTinZ

Leveling Caster Wheels

Full Color 10"

LCD Touchscreen

with Mainsail for

Klipper interface

Linear Rails on All Axis

7.8 kg Hopper Capable

of 24h

of Printing

Between Refills

32bit ArchiMajor

Control Board

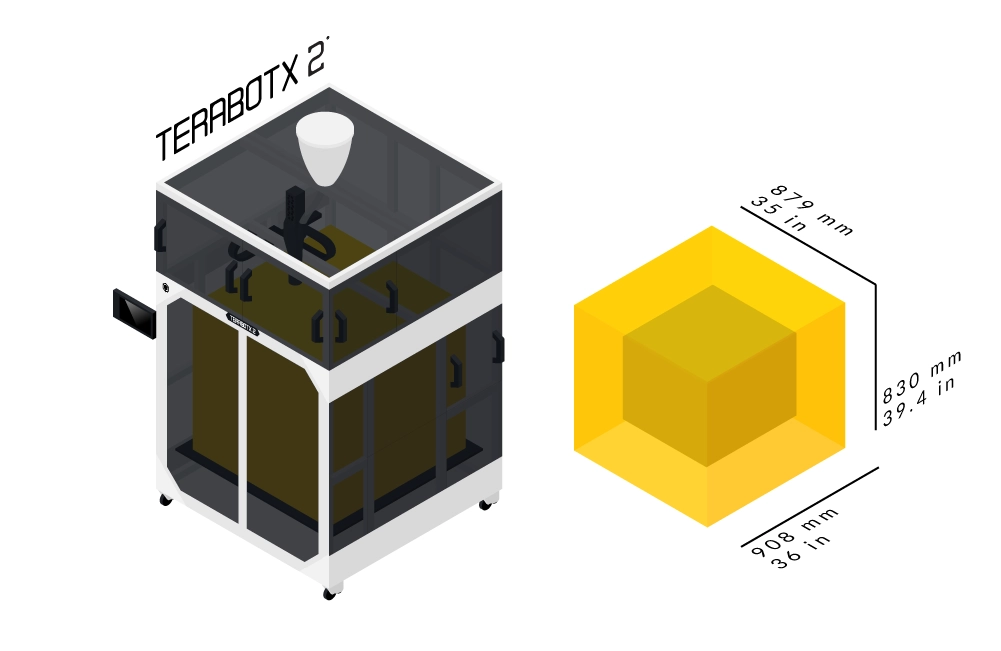

Fulfill your large-format FGF 3D printing needs with TerabotX 2, expanding the size of your build volume to 879 x 908 x 830mm. This direct-drive pellet extrusion based 3D Printer can print from virgin or recycled pellets, flake, or regrind – and bring us even closer to the dream of a circular economy.

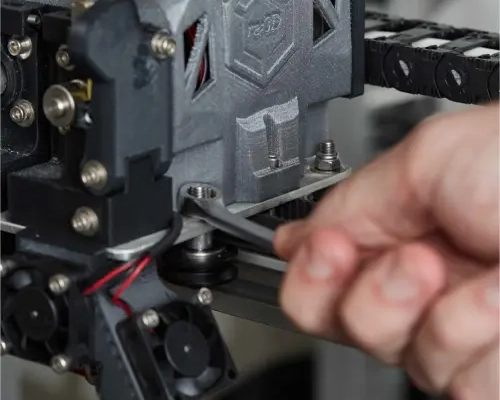

A ⅝” extruder screw with a 16:1 L/D ratio powered by a NEMA 23 motor enables 3D printing with 3-5mm plastic granules with melting temperatures below 270ºC. With a larger 0.4, 0.8, 1.75 or 3mm nozzle, TerabotX 2 3D printer reduces the dependence on printing with filament while supporting plastic granule mixing, increasing printing speed and cost savings.

Your open-source industrial 3D printer is powered by a 32bit Ultimachine ArchiMajor control board and Klipper firmware run on a Raspberry Pi. Access TerabotX 2 controls via the Mainsail interface on either the 10” LCD touchscreen or a desktop or mobile web browser.

Hand-crafted in Texas by team re:3D to highly precise standards, your TerabotX 2 3D printer is modular, upgradable and backed by Lifetime Customer Support.

Technology

FGF

Build Volume

879 x 908 x 830 mm

Extruder

Steel 5/8" extruder screw with a 16:1 L/D ratio

Materials

Supports thermoplastics melting below 270 ºC

Granule Size

Supports 3 - 5 mm plastic granules & pellets

Layer Resolution

0.32 - 2.25 mm

Printing Speed

up to 30 mm/sec

Nozzle Diameter

0.4, 0.8, 1.75 or 3 mm

Design

Modular & upgradable construction

Construction

Robust aluminum cartesian frame

Build Plate

Cast aluminum blanchard ground flat 0.5” thick build plate

Stepper Motor

NEMA 17 & 23

Bot Control

Full color 10" LCD Touchscreen with Mainsail for Klipper interface

Connectivity

Optional network connecting for local monitoring & control

File Transfer Method

USB or Wifi

Open Source

Open source Klipper software stack

Upload File Type

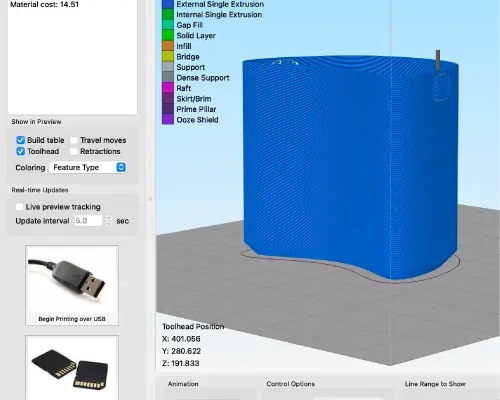

G-code (.gcode) upload file type

Printing Workflow

Includes Simplify3D setting profiles

Power

110V 60Hz 20A or

220V 50Hz 10A

Extruder Temperature

Up to 270ºC

Build Surface Temperature

Up to 115ºC