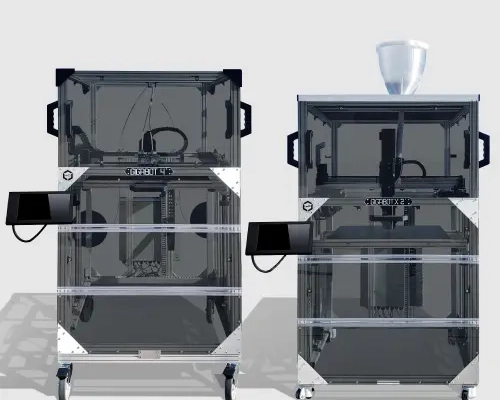

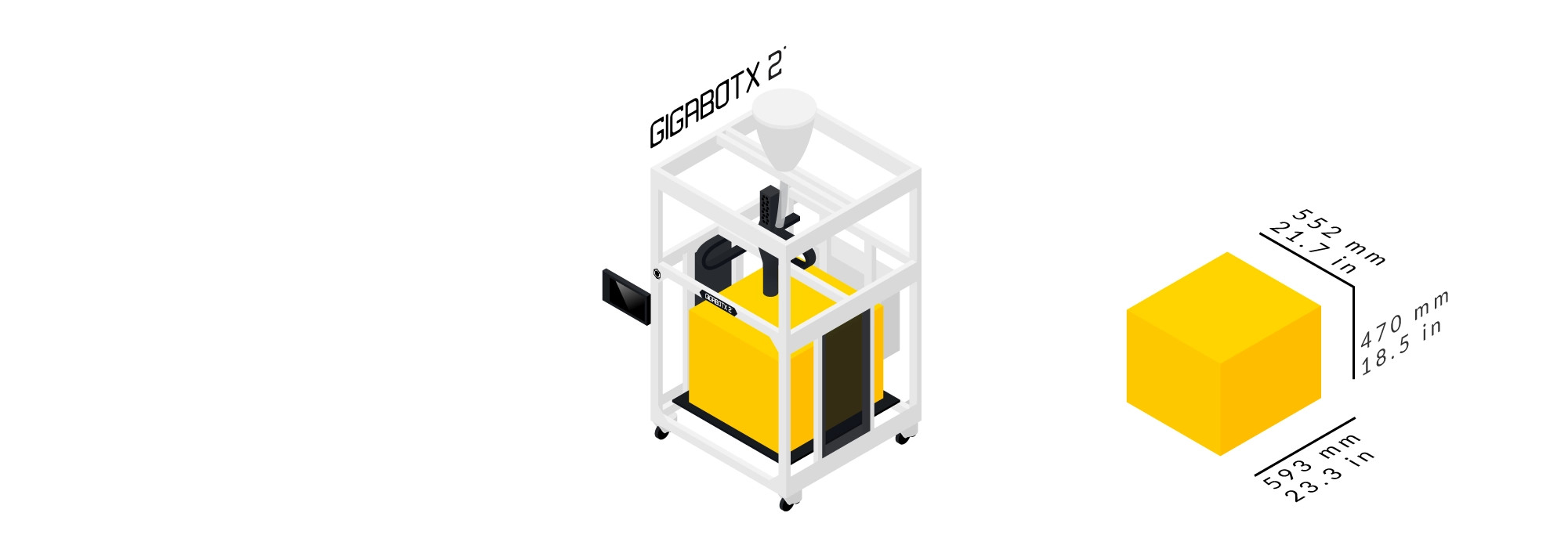

GigabotX 2

Three Zone Independently

Controlled Barrel Heaters

5/8" Extruder Screw with a

16:1 L/D Ratio and a0.4,

0.8, 1.75 or 3mm nozzle

4 Point Bed Leveling

NEMA 17 & 23

Stepper Motors

0.5" Aluminum Heated Bed

with PRINTinZ

Leveling Caster Wheels

Full Color 10"

LCD Touchscreen

with Mainsail for

Klipper interface

Optional Enclosure with

Removable Panels

Linear Rails on X & Y Axis

7.8 kg Hopper Capable

of 24h of Printing

Between Refills

32bit ArchiMajor

Control Board

The GigabotX 2 3D printer is the next evolution in 3D printing technology. These direct-drive pellet extrusion based printers, can print from virgin or recycled pellets, flake, or regrind – and bring us even closer to the dream of a circular economy.

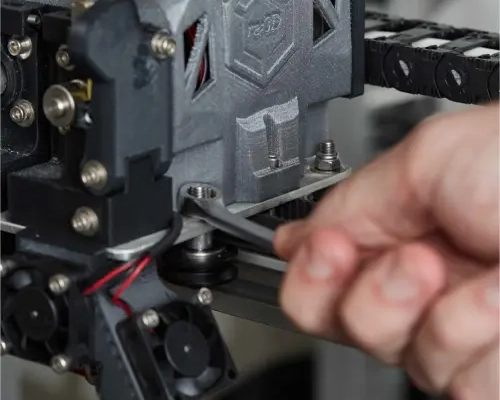

A ⅝” extruder screw with a 16:1 L/D ratio powered by a NEMA 23 motor enables 3D printing with 3-5mm plastic granules melting below 270ºC. With a larger 0.4, 0.8, 1.75 or 3mm nozzle, GigabotX 2 reduces the dependence on printing with filament while supporting plastic granule mixing, increasing printing speed and cost savings.

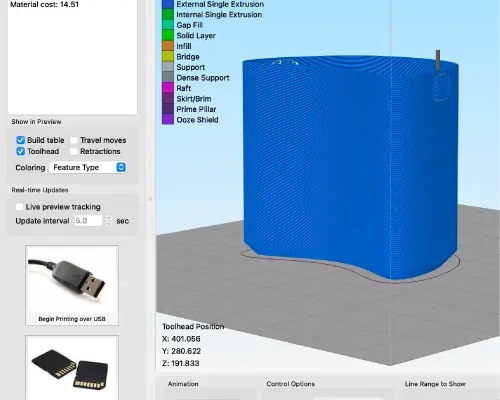

Your open-source industrial 3D printer is powered by a 32bit Ultimachine ArchiMajor control board and Klipper firmware run on a Raspberry Pi. Access GigabotX 2 controls via the Mainsail interface on either the 10” LCD touchscreen or a desktop or mobile web browser.

Hand-crafted in Texas by team re:3D to highly precise standards, your GigabotX 2 3D printer is modular, upgradable and backed by Lifetime Customer Support.

Technology

FGF

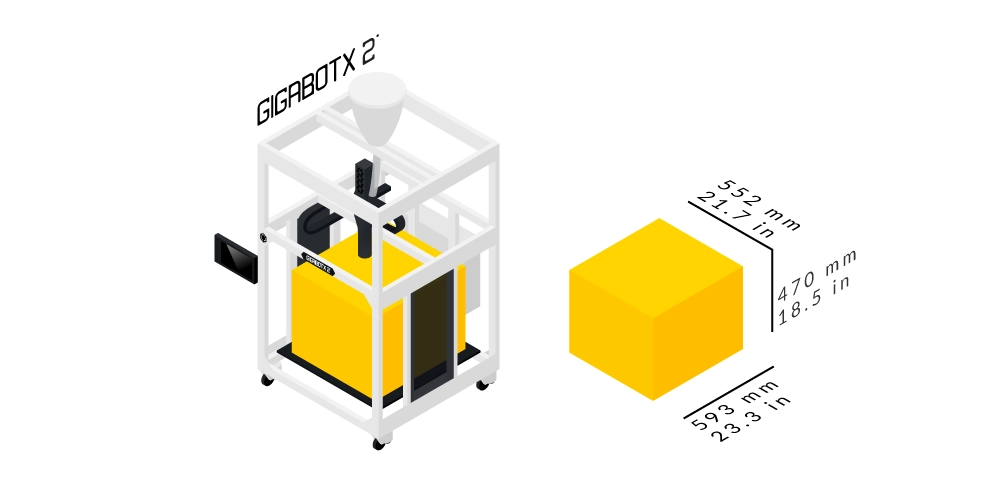

Build Volume

552 x 593 x 470 mm

Extruder

Steel 5/8" extruder screw with a 16:1 L/D ratio

Materials

Supports thermoplastics melting below 270 ºC

Granule Size

Supports 3 - 5 mm plastic granules & pellets

Layer Resolution

0.32 - 2.25 mm

Printing Speed

up to 60 mm/sec

Nozzle Diameter

0.4, 0.8, 1.75 or 3 mm

Design

Modular & upgradable construction

Construction

Robust aluminum cartesian frame

Build Plate

Cast aluminum blanchard ground flat 0.5” thick build plate

Stepper Motor

NEMA 17 & 23

Bot Control

Full color 10" LCD Touchscreen with Mainsail for Klipper interface

Connectivity

Optional network connecting for local monitoring & control

File Transfer Method

USB or Wifi

Open Source

Open source Klipper software stack

Upload File Type

G-code (.gcode) upload file type

Printing Workflow

Includes Simplify3D setting profiles

Power

110V 60Hz 20A or

220V 50Hz 10A

Extruder Temperature

Up to 270ºC

Build Surface Temperature

Up to 115ºC