Written by: Brendan J. Towlson

How do we encourage creators to explore new concepts? Give them something to create! When re:3D’s Community Liaison, Charlotte Craff was thinking of ways to spread the message that 3D printing is the future of manufacturing on Manufacturing Day, she came up with the idea of allowing visitors to build something out of 3D printed parts.“We build machines all day; why not provide our guests the opportunity to do so as well?” The wind-up car build was conceived. And the best part: you can print and build it yourself!

Attendees of re:3D’s Manufacturing Day Open House had the opportunity to tour the factory, touch and feel 3D prints from around the world, learn about the different skill sets involved in operating this unique hardware company, and finally take home their very own wind-up car. The challenge, though, was that the cars were not pre-assembled. If visitors wanted a car, they had to put it together themselves.

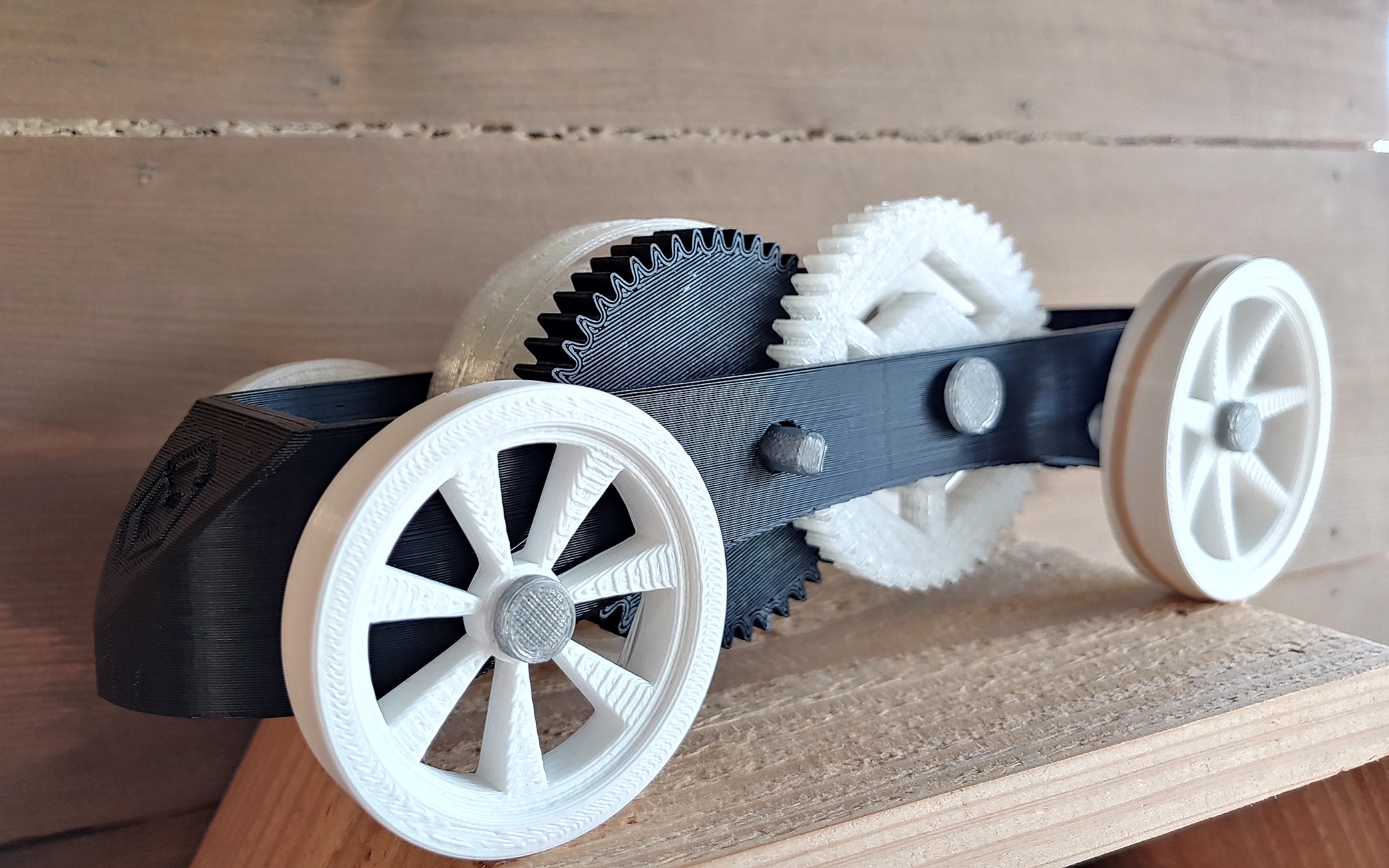

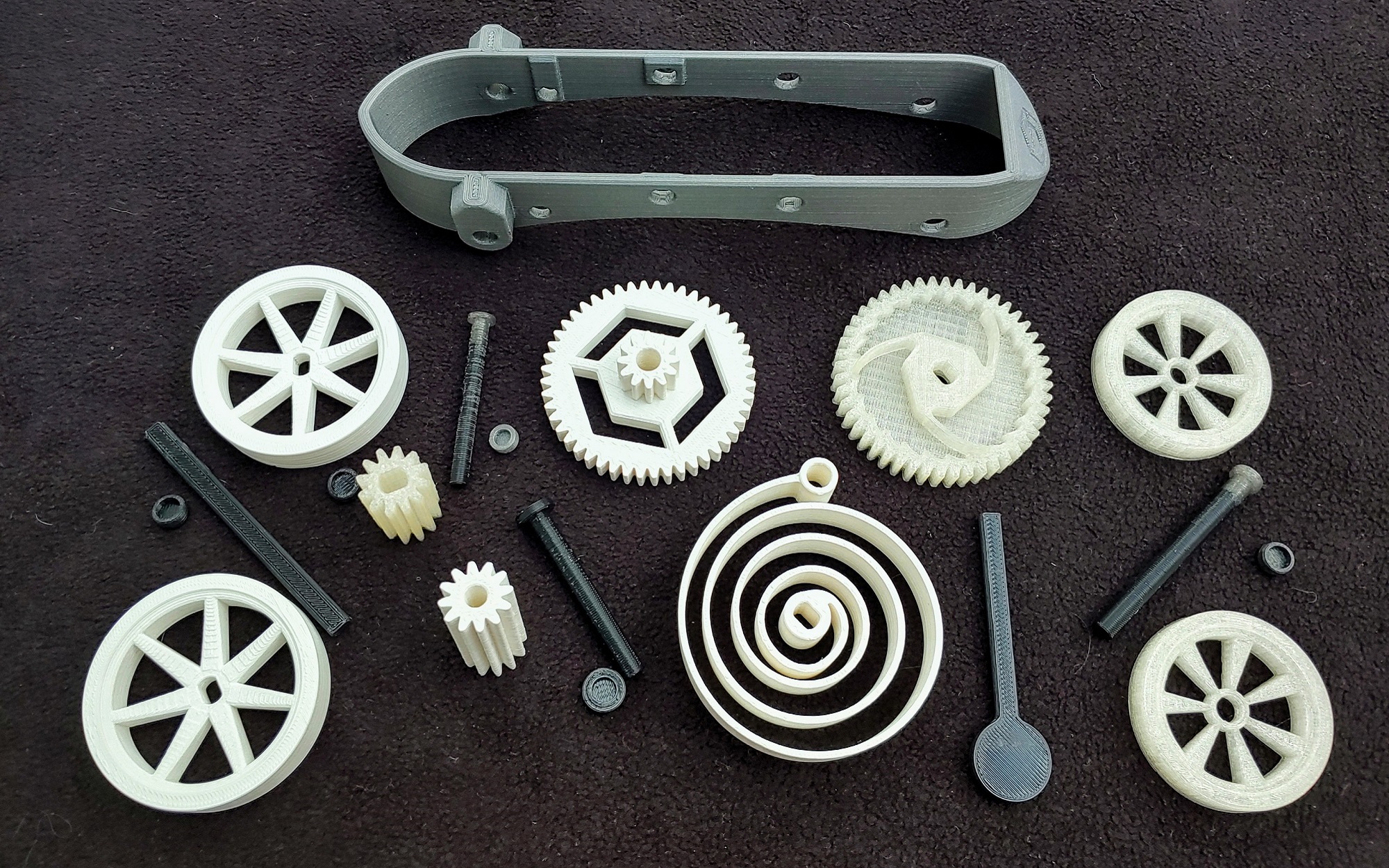

This wind-up car was designed by Mike Battaglia in Rhinoceros 3D software. It is made entirely of 3D printed parts, which is a difficult feat to get right. There are 21 parts, including four wheels, two axles, a gear system, and a spring with a hand crank. Once printed and assembled, you can crank the spring to store potential energy, and then release the car to watch as it converts potential to kinetic energy, and transfers it through the gears to the wheels that drive the car forward. It is a simple concept, but getting the parts to work together was a test of our 3D printing skills, and Mike spent time adjusting tolerances to get it just right.

The cars printed for Manufacturing Day were made of PLA. We learned a lot about this material while designing the cars. For example, white PLA is very pigment saturated, causing it to behave differently when melting and cooling. Tolerances on each part had to be adjusted accordingly. We used up to six of our Gigabot® 3+ workhorses at a time running 36 hour prints continually over a period of two weeks to complete the prints. In the end, for the Manufacturing Day event, printing 56 complete cars added up to 1,176 total parts, 420 hours of print time, and 28 pounds of material.

Challenging 3D print builds like this produce something that is more than just a toy. “It’s meant to demonstrate that even simple machines are complex, fun and buildable by people of all ages,” Charlotte said, “and it’s meant to inspire young people to look deeper into how machines function.” 3D print your own Wind-up car by downloading the design from Thingiverse or Cults!

Brendan J. Towlson

Blog Post Author