Here at re:3D, we are results driven and want to provide the best possible product for our customers. Before the release of the new Gigabot Firmware 4.2.0, we wanted to put the new feature, Linear Advance, to the test. Referenced from the Marlin website, Linear Advance allows users to print more dimensionally accurate parts. Under normal conditions, the extruder gear movement is a linear proportion to all other axes. However, the pressure buildup in the nozzle is not proportional to other axes and this leads to extra material being extruded at the end of each movement.

To solve this issue, linear advance changes the extrusion rate whenever the extruder slows down or speed up, creating an even extrusion line no matter the speed or change in direction. The K value has units of mm of filament compression needed per 1 mm/s extrusion speed [mm/(mm/s)]

The advantages of this feature are as follows:

- Better dimensional precision.

- Higher printing speeds are possible without any loss of print quality.

- Visible and tangible print quality is increased even at lower printing speeds.

- No need for high acceleration and jerk values to get sharp edges.

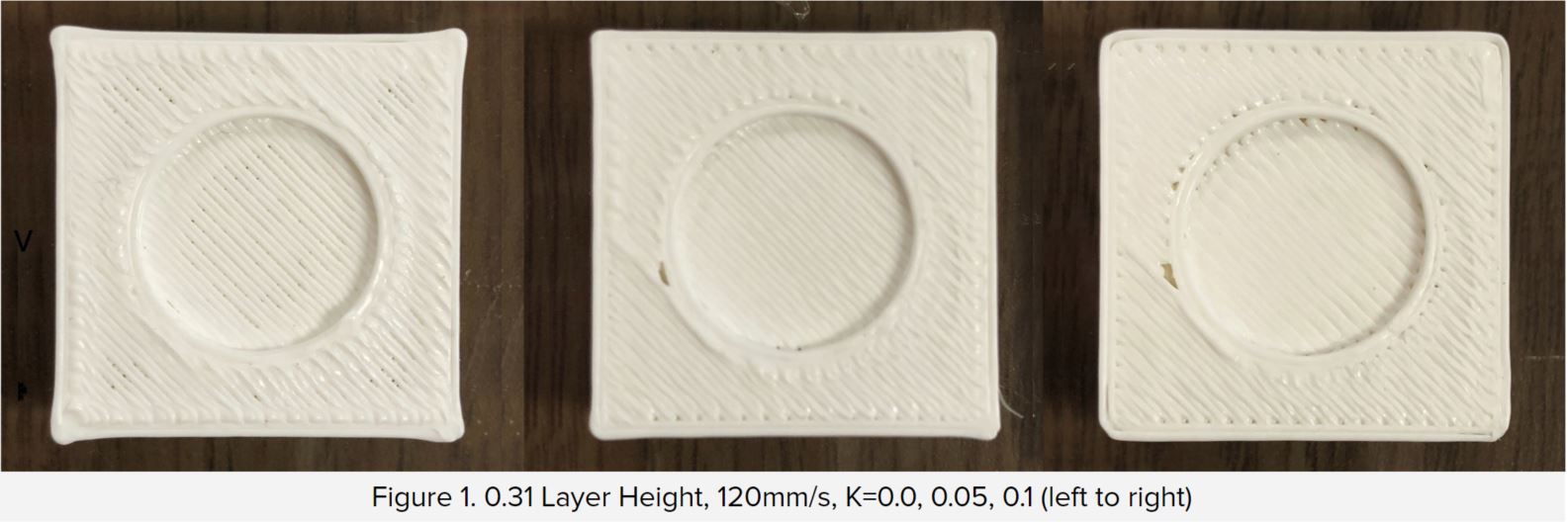

A total of 48 test specimens were printed at a different layer height, speed and K value. Each of the 25mm squares were printed individually to decrease the effects of other variables. A circular indentation was added to the middle of the model to increase the number of changes in travel direction, emphasizing the effects of Linear Advance. Shown in Figure 1, are a set of test pieces printed at 0.31 layer height, 120mm/s and a K value of 0.0, 0.05, 0.1, and 0.15 from left to right.

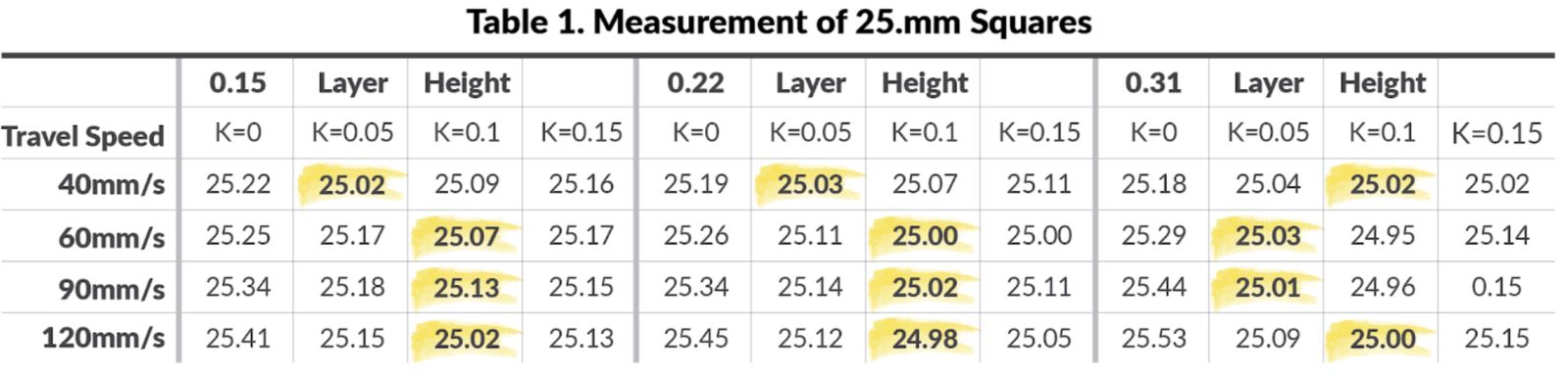

Each test specimen was measured with a caliper. In Table 1, the dimensions of all of the test squares are shown. The highlighted boxes show the test specimen that had the most accurate dimensional reading in its group. As linear advance decouples the extrusion motor from other axis, the print quality is visually and quantitatively improved. Shown in Figure 1, Linear Advance significantly reduces the extrusion of extra material on the outer edges at higher print speeds and larger layer heights. As print speed decreases, the addition of Linear Advance has less of an impact on the quality, however, it is still beneficial with a delta of 0.2 at 40mm/s and 0.15 layer height. These results showed to be consistent with expectations because as flow rate increases, the more buildup of pressure and potential for extra material to come out of the nozzle. With 8 test samples of 0.1 K value and 4 samples of 0.05 K value excelling in accuracy, a weighted average of K= 0.08 provides a good value to improve print quality across the board.

If you are interested in using this feature on your Gigabot, please visit the full feature list of the new Gigabot Firmware 4.2.0 here

Noah Pan

Blog Post Author