Karlos Miranda was in his first year at University Of Puerto Rico Mayagüez Campus when Hurricane Maria hit.

Bringing with it 150 mile-an-hour winds and several feet of rainfall, the storm devastated Puerto Rico, destroying homes and wiping out power across the island. But it was the destruction of the water system that made the biggest impression on Miranda, spurring him to action.

“I remember the first time I went out looking for water and saw the lines of people waiting for an oasis truck. It was a never-ending line of people desperate to fill their containers with water,” he recounts. “All these people – me included – were lucky to live in a place where water trucks were able to come, because there were others in more isolated areas or places with blocked roads who did not have access to water for a longer time.”

It jolted him that even the people who were seemingly well-equipped for such a natural disaster – homes with solar panels and backup generators – were crippled by the loss of running water. “After Maria, many Puerto Ricans started buying electric generators or moving to renewable energy to decrease the impact of a blackout, but when it comes to water there is not much to do in order to be more resilient.”

The relief effort was also woefully botched: who can forget the image of thousands of water bottle pallets left to expire on a hot runway in Ceiba?

“We saw a need after the hurricane: a need in water transportation, a need of micro-grids, and a gap in home-sustainability products,” Miranda says. “The need for an alternative water source – it was very obvious in that moment.”

Finding Solutions to Problems Exposed by Maria

As a student in the mechanical engineering program with a penchant for tinkering, Miranda often attended on-campus workshops for startups. One such event was put on by a local organization, Parallel18, which hosts a five-month program in San Juan that provides grants and mentorship to young companies in an accelerator-like format. Under the Parallel18 umbrella is Pre18, a program for even earlier-stage startups that may still be in the prototype phase.

Miranda pitched his idea and was accepted into Pre18’s second cohort.

That idea is now WATRIC Energy Resources, Miranda’s answer to the lack of off-the-grid systems for use in the event of a natural disaster, or simply to improve one’s carbon footprint. WATRIC’s mission is to develop home solutions, accessible to the average Puerto Rican, to extract potable water from the surroundings so that water security is never a concern.

“[Maria] has been in my mind since, and is what motivated me to start looking for future solutions in water access because…I am aware that this same situation could happen again to Puerto Rico, and any place prone to natural disasters like hurricanes.”

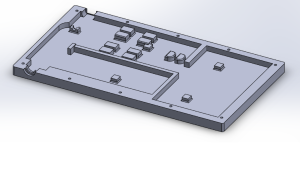

Miranda is working towards this solution through the creation of WALT, a wall-mounted device that condenses naturally-occurring moisture in the air, turning it into liquid water. Using the surrounding air, the technology makes use of the Peltier effect – in conjunction with software to allow the system to adapt in a wide range of environments – to generate one to two gallons of drinkable water a day.

“A technology like WALT could mean relief in a natural disaster that causes a water blackout,” Miranda explains. “We also think about WALT as part of the effort for achieving independence from the grid. We want to bring the same relief that people have when they can generate their own energy at home, but with water, and a future in which total home independence from the grid is a possibility.”

A Growing Startup Community in Puerto Rico

Over the course of about six months, Miranda was able to move rapidly from idea stage to workable prototype thanks to the help of a growing startup community in Puerto Rico, one which has blossomed from the rubble of Maria as local entrepreneurs sprang to action to create solutions to problems left exposed in the wake of the storm.

“Here in the island, this is – I would say – the first time that the startup community is really having growth,” Miranda muses.

One such entrepreneurial hub fueling this renaissance is Engine-4, which, at 24,000 square feet, is the largest coworking space in Puerto Rico. Housed in an old civil defense base, its mixed-use facilities are home to an array of equipment like soldering tools, oscilloscopes, and 3D printers. Miranda found himself at the space by way of Parallel18, where he met a fellow member – also part of the Engine-4 world – who introduced him.

He was blown away by the facility. “I didn’t know that they had so much resources in there for hardware prototyping and for hardware start-ups,” Miranda recollects. He was more accustomed to seeing young, software-focused companies, both in Puerto Rico and in the news in general. “Hardware start-ups are more difficult and less common in the island…so I was impressed that [Engine-4] had all these resources, 3D printing, everything.”

Both Parallel18 and Engine-4 host Gigabots for their members to use as a prototyping and design resource. Miranda took advantage of the two locations during the creation of WALT, printing full-scale models that dwarved the build volume of his desktop 3D printer at home.

“With these kinds of programs, we not only have the funds, we have an alternative to use resources directly,” he explains. Pre18 provided them with monetary grants, and, equally as beneficial, Engine-4 offered them access to machinery that would have otherwise been prohibitively expensive.

Miranda doesn’t know how WATRIC would have gotten to a final design without 3D printing.

He describes the early design stages, modeling the unit using CAD. “We thought that it was functional in that moment,” he recounts, “but it wasn’t until we had the physical prototype actually printed that we were able to improve it and to see what needed to be changed.” The phenomenon is all too common for product designers. A 3D design that seems watertight on a screen immediately gives up its flaws once its form enters the physical realm.

“Prototyping is our daily activity,” Miranda says. “3D printing is helping us to iterate. When we make our prototype, we see where we need to improve.”

The model they printed at Engine-4 clocked in at around 26 hours, designed specifically to allow them to move seamlessly from 3D printing into injection molding.

While WATRIC Energy Resources finishes the development and scaling of their drinking water product, they have created a smaller, spinoff version to get people a taste of their technology’s capabilities: a smart indoor plant watering system called WALTY. They will be launching a Kickstarter for this product, using funds raised to move forward with their larger mission of potable water-producing systems.

Follow WATRIC’s progress and get notified when their Kickstarter launches, at https://watric.com/

Morgan Hamel

Blog Post Author