FOR IMMEDIATE RELEASE

re:3D installing Terabot and Terabot X at the Autodesk Technology Center in Boston, MA

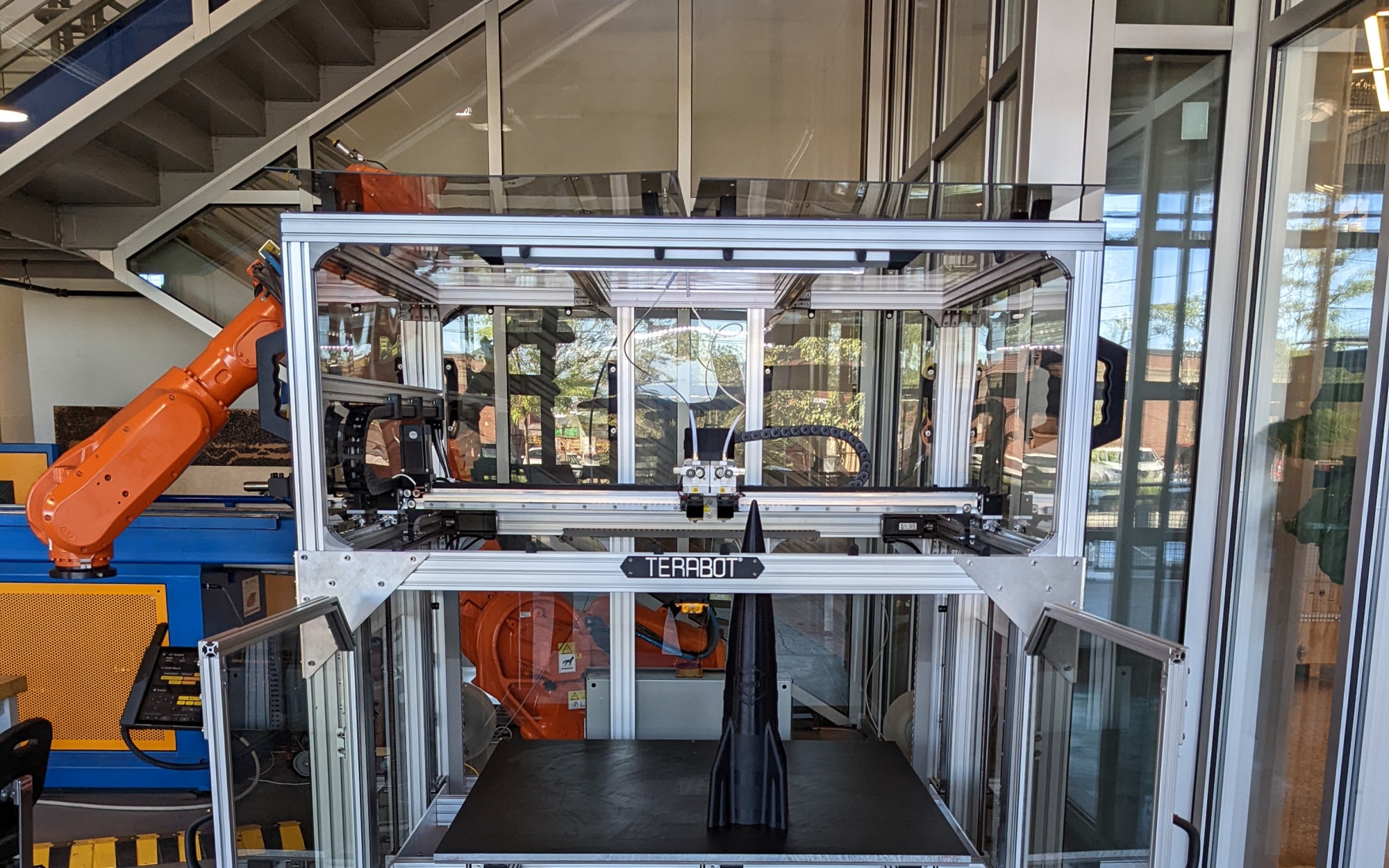

Boston, MA – re:3D, Inc. is delivering large-format filament, pellet and granule based 3D printing to the Autodesk Technology Center in Boston. A Texas and Puerto Rico based manufacturer, re:3D’s printers are beta units of Terabot 4, a filament extrusion 3D printer with a build volume of 915 x 915 x 1000mm (36” x 36”x 39.5”) and Terabot X 2, a pellet and granule extrusion 3D printer with a build volume of 892 x 908 x 830mm (35” x 35.75” x 32.75”). The 3D printers are available for residents of the Autodesk Technology Centers Outsight Network for large format 3D printing using both virgin and recycled or reground thermoplastics. Visitors to the Technology Center can view the Terabot 4 in action now after a successful installation over the last week. The Terabot X 2 installation is forthcoming.

As part of Autodesk Research, the Technology Centers catalyze new possibilities for making through the power of connection. They bring together a global network of innovation leaders, data-enabled fabrication workshops, curated experiences, and forward-thinking ideas to empower innovators in achieving the new possible, together.

The Outsight Network is Autodesk Research’s global innovation network. It includes resident teams from industry, academic, and entrepreneurial sectors who are passionate about accelerating and researching design and make processes. Teams in the network are connected with industry experts, the diverse and vibrant Technology Centers community, resources, and if applicable, have access to advanced fabrication machinery and training.

“We are thrilled to share this technology with Autodesk and its partners at the Boston Technology Center,” says re:3D Co-founder and Catalyst, Samantha Snabes. “Enabling 3D printing from waste plastics at scale has the capacity to make real-world impact and empower local communities. We’re excited the cutting-edge designers at Autodesk Technology Centers will be researching and innovating using re:3D 3D printers, putting sustainable 3D printing to great use.”

To learn more about how Terabot and all the 3D printers in re:3D’s portfolio are built, re:3D is offering live, monthly virtual tours of its Houston, TX factory. The next opportunity is Monday, September 19, at 10:00am CT. Attendees can register at the following link: https://www.eventbrite.com/e/3d-printer-factory-tour-virtual-edition-tickets-123094640383

About re:3D

re:3D, Inc. consists of a group of explorers committed to decimating the cost & scale barriers to industrial 3D printing. Having pioneered the world’s first and most affordable, human-scale industrial 3D printer, re:3D likewise is creating large scale, affordable 3D printers printing from pellets, regrind, and flake plastic waste. Beyond creating 3D printers for customers in over 50 countries, re:3D offers 3D printing contract services, consulting, design and education services. For more information on re:3D, visit www.re3d.org.

About Autodesk

Autodesk is changing how the world is designed and made. Our technology spans architecture, engineering, construction, product design, manufacturing, media and entertainment, empowering innovators everywhere to solve challenges big and small. From greener buildings to smarter products to more mesmerizing blockbusters, Autodesk software helps our customers to design and make a better world for all. For more information visit autodesk.com or follow @autodesk.

Charlotte craff

Blog Post Author