The Gigaprize is a competition we run for every 100 bots we sell to donate a Gigabot to an organization that will use it for good. Scott Key originally saw the call for contest entries on Instagram.

He and his business partner, Sam Brisendine, thought the odds of them actually winning were pretty slim, but they decided to give it a shot anyway. That decision ended up paying off handsomely.

The winners of the 400th Gigabot are Good Works Studio, a Houston-based design firm specializing in products for refugees.

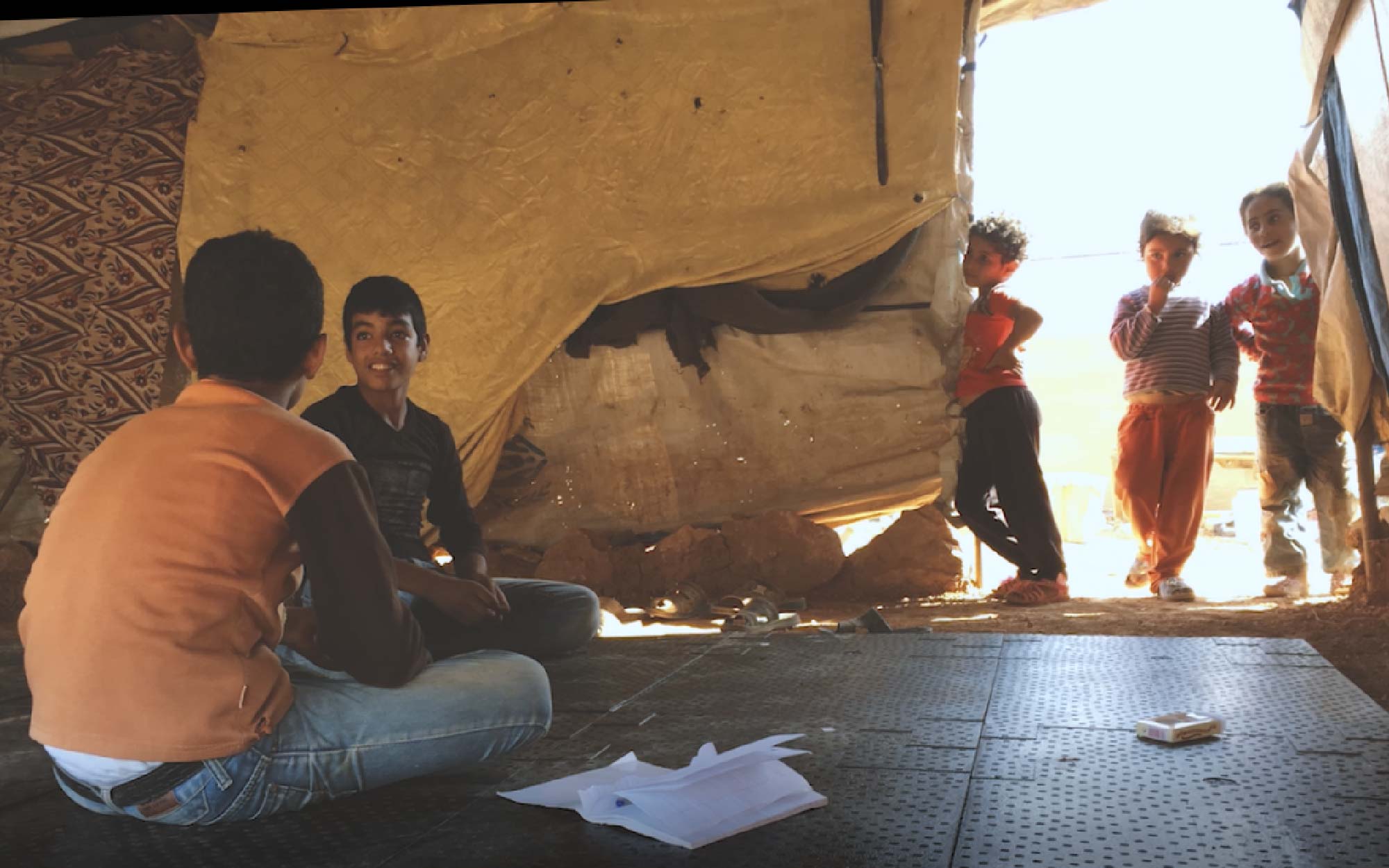

Sam and Scott met as students at the Rice University School of Architecture, where they developed a sort of Swiss Army Knife crate of supplies for refugees as a class project. The crate itself broke down and transformed into a floor, and as time went on, they came to realize that the most valuable part of the whole package was not the cache of supplies inside but the box itself. Emergency Floor was born.

Thus a school project gave birth to Good Works Studio, the company that the two cofounded specifically to develop products for the refugee space. Their first product, Emergency Floor, is a modular flooring system for refugee camps that can be quickly installed and configured to the varied layouts and sizes of different shelters.

Flooring for these refugee camps provides families with something more than just comfort: safety. The flooring acts as a thermal break between the cold nighttime temperature swings of places like Iraq and Lebanon, as well as a means to combat the higher rates of diarrhea and parasitic infections that come from living in the dirt.

Emergency Floor is just the first product that Scott and Sam have released to tackle problems faced by millions of refugees around the world, and they’ve got more in the works. However, the design and prototyping process that goes into developing products like these is not cheap, and Good Works Studio is a young, cash-strapped, two-man company whose founders work separate full-time jobs to pay the bills. They ran a crowdfunding campaign to get Emergency Floor off the ground, but they knew that the money and time needed to take future ideas from paper to product would be prohibitive.

Traditional manufacturing and tooling isn’t the most forgiving when it comes to the design process. Get a mold made and then decide you want to tweak something in your design, and you’ve just gotten yourself a $15,000 paperweight. Perfecting the design before moving on to manufacturing was imperative.

“Previously we had outsourced 3D printing and other prototyping methods,” Scott explained, but, as he went on, “It was just going to be an impossibility to do the amount of iterations we needed to get a product to where it needed to be.”

Having an in-house 3D printer was the dream.

For Scott and Sam, Gigabot is an enabler. Having a 3D printer of their own means getting well-designed products into the hands of people who need them more efficiently and effectively. They can send a design file to print in the morning, have a prototype in their hands by the afternoon, and start printing a modified version before they leave at the end of the day. This ability to iterate their designs quickly and in-house allows them to move through the prototyping process much faster and less expensively than any other avenue.

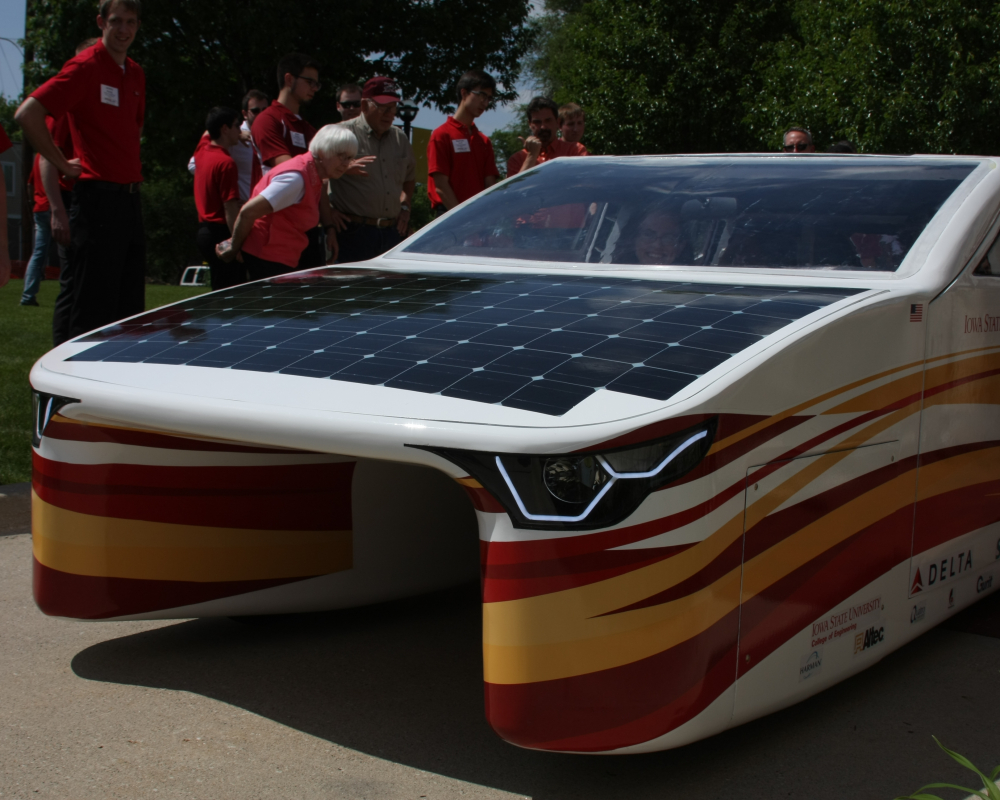

The overarching vision that drives Sam and Scott is a desire to help those in need around the world through design. The next product they’re working on is a device that can be installed into any shelter to act as an air conditioner – sans electricity – using the Venturi effect.

Our aim with Gigabot is to enable others to create products that make this world a better place, and the Gigaprize is our way of making this technology even more accessible to people who will do just that.

As Sam put it, “Design can do good for those who can’t afford it.” We couldn’t agree with him more.

Learn more about Good Works Studio and their first product, Emergency Floor:

Twitter: @EmergencyFloor

Instagram: @EmergencyFloor

Facebook: https://www.facebook.com/emergencyfloor/

Morgan Hamel

Blog Post Author