ReCreateIt, a net-zero manufacturing lab, is building a more circular economy by reducing landfill waste. Partnered with the Austin Habitat for Humanity ReStores, ReCreateIt enables low-income homeowners to design sustainable home goods 3D printed directly from recycled plastic waste.

ReCreateIt is building a more circular economy through the recycling and reuse of over 10,000 lbs of plastic waste otherwise destined for a landfill. This project brings together a collaborative team of researchers, manufacturers, and community leaders to creatively tackle plastic waste pollution.

The GigabotX large-format 3D printer manufacturers with pelletized and granulated plastics. The ReCreateIt Gigalab net-zero manufacturing lab, built sustainably from a modified shipping container, houses the 3D printers as well as a granulator for grinding up plastics and a dryer for removing moisture from material- all the equipment needed to create high value items from recycled plastic in low-income communities where it’s needed most.

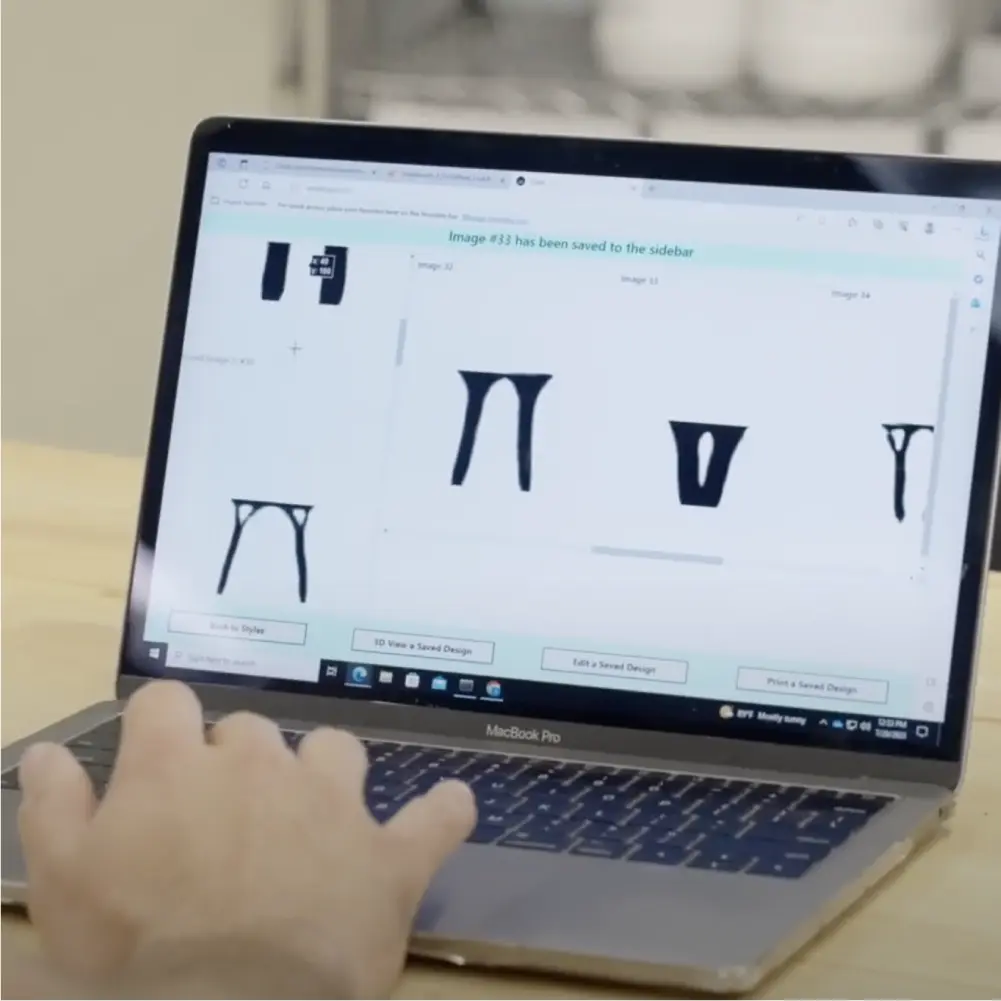

ReCreateIt customers work with Austin Habitat for Humanity ReStores to fabricate their own functional home goods from recycled materials. Using an interactive design tool, customers can select their favorite home goods or customize them with an intuitive, web-based interface that modifies and refines designs in real time in response to customer preferences. The tool is powered by machine learning algorithms that ensure structural integrity and tally sustainability benefits without requiring any engineering expertise from the customer.

A sustainability dashboard collects and communicates the environmental impacts of this work fabricating from locally-sourced recycled materials and expresses them in easily interpretable metrics, such as the number of water bottles saved from the landfill.

The team continually engages in polymer science and engineering research to enhance the printability of recycled materials while ensuring the structural integrity of 3D printed parts. For example, all of the prototype chairs and stools printed by the team to date, even those with apparent imperfections, support at least 500 lbs of weight. Research into combining different plastics together or adding naturally sourced additives to improve results is distributed in a public database, thereby contributing to the knowledge base that will transition industry to more sustainable manufacturing methods.

differentiators

By enabling 3D printing on site directly from granulated plastic waste, ReCreateIt minimizes the time and energy typically required in other resource intensive recycling systems. With the unique design tool allowing users to intuitively customize home goods, the innovation facilitates a path to circularity in a broad variety of communities, including those that typically do not have access to such technology. The ReCreateIt Gigalab is a flexible solution that can be built to adapt to location specific requirements. In pilot projects, Gigalabs are being built with both off-grid and grid connectable power solutions.

road map

In year 1 of NSF Convergence Accelerator Phase 2, the team will install the ReCreateIt Gigalab at Austin Habitat for Humanity ReStore, expand the design tool, integrate the sustainability dashboard, and conduct research on recycled polymers. In year 2, these tools and databases will be made publicly accessible, culminating in a pilot where ReStore staff are trained to transform waste plastics into valuable community assets. In year 3, ReCreateIt will develop a comprehensive database cataloging recycled material, detailing their structural properties and suitability for 3D printing. This invaluable resource will be published in an accessible format, enabling the generation of a public executive summary. By making these findings readily available, we aim to drive innovation and sustainability in the 3D printing industry, fostering informed decision-making and broader adoption of recycled materials.

partnerships

As the end user, Austin Habitat for Humanity (AHFH) has allowed research on their internal and external partners to direct the requirements of the ReCreateIt system within ReStore operations. Moving forward into Phase 2, AHFH will aid in the installation of the ReCreateIt Gigalab as well as provide staffing and training. The primary goal is enhanced revenue generation to support affordable housing throughout the Austin community while upskilling low-income workers and sharing the impact of sustainable manufacturing with the AHFH network.

Supporting AHFH in this project are the following partners, along with their technology focus areas:

Georgia Institute of Technology: Polymer science and human-centered design

re:3D, Inc.: Manufacturing and 3D printing from waste plastics

The University of Texas at Austin: Engineering design and life-cycle analysis

University of Wollongong Australia: Built environment building performance and life cycle analysis

Western Sydney University: Polymer science and engineering

ReCreateIt is part of the National Science Foundation’s Convergence Accelerator, Track I: Sustainable Materials for Global Challenges, and is funded by both NSF and their funding partner, CSIRO, Australia’s national science agency.

contact us

Contact us for more information about the ReCreateIt project