Specialty

Specialty materials are unique materials created for specific use cases. Sometimes, common materials like PLA or ABS cannot meet the demands of a specific application and a dedicated material is needed. Specialty materials have been created for casting, smooth surface finishes, flexible parts, high clarity, and support material. Due to the wide range of different applications, specialty materials are not easily classified into other common material categories. The chemical makeup of specialty materials is diverse as well, making each specialty material truly special. If you have a very specific demand for a material, there may be a specialty material to help you out!

Applications for specialty materials are almost entirely driven on the material’s design. Unlike common materials, specialty materials are often created for a specific application. Some of the most common specialty material use cases are given, but specialty materials exist for a wide variety of different applications.

- Casting

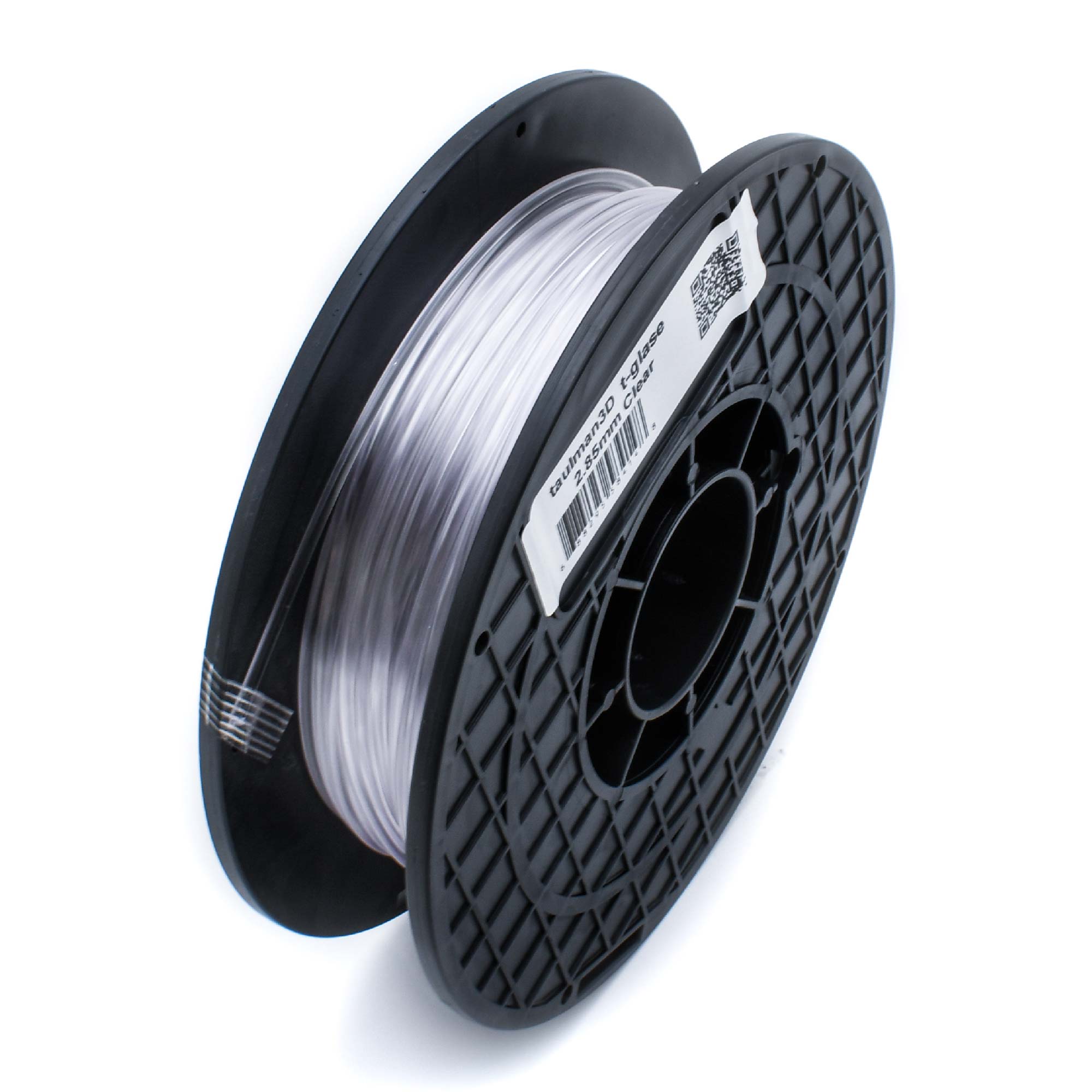

- Low Opacity

- Smooth Surface

Since specialty materials vary widely in properties and functions, no exact material property table can be given. It is recommended to consult the technical data sheet for a specific specialty material for material properties.

Much like for material properties, specialty materials also have a wide variety of different printer settings. It is recommended to consult the technical data sheet for a specific specialty material for printer settings.

The sustainability of specialty materials varies widely, though often they are not easily recycled at commercial centers. Safety data sheets of a specialty material can provide insight into proper ways to dispose of it properly.

MCPP

3DIAKON

MCPP

DURABIO

MCPP

Glassbend