rPET

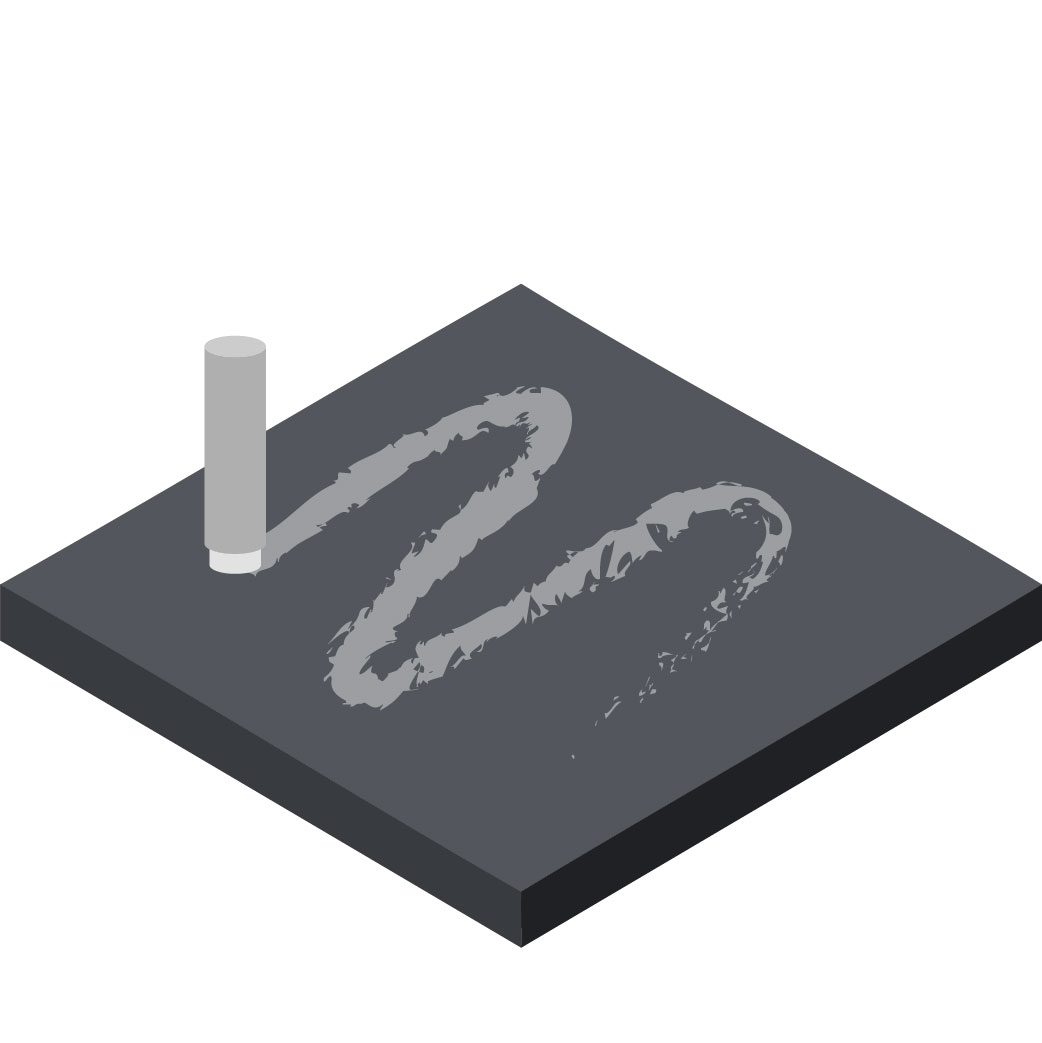

Polyethylene Terephthalate (PET) is a durable material with either a glossy appearance or opaque appearance depending on its crystallinity. PET is one of the most common plastics in the world, used in cases like sailcloth, water bottles, and clothes. In the world of 3D printing, PET is often used in the form of PETG which contains glycol. PET and PETG fill a role between PLA and ABS being a tough material and relatively easy to work with. With the rise of pellet printing, PET is growing in relevance as a 3D printing material. PET is also one of the most commonly recycled plastics, making its potential use in 3D printing even more attractive. For those looking for durable parts and a closed loop 3D printing solution, PET is a great material to use.

PET excels when you take advantage of its material properties and its prevalence. Its material properties allow it to perform well in a variety of applications. Its prevalence also makes it a great candidate for recycling and closed loop use cases.

- Containers

- Functional Parts

- Furniture

Glass Transition Temperature

~70 ºC

Density

1.38 g/cm3

Extrusion Temperatures

210 - 240 ºC

Top Temperature Zone

225 ºC

Middle Temperature Zone

220 ºC

Bottom Temperature Zone

185 ºC

Heated Bed Temperature

60 ºC

Bed Adhesion

Adhesive Needed

Enclosure

Do Not Use

Fans

-

Printing Speed

3,600 mm/min

PET is one of the most commonly used recyclable plastics, and often seen in the form of water bottles. The polymer chains that make up PET easily break apart at low temperatures, making PET an easy material to recycle. Being such a common material, there is great potential of recycling and reusing PET. One area of potential use is recycling PET as feedstock for pellet printers like Gigabot X. PET is easily recycled in most recycling centers, and an excellent choice for closed loop solutions due to its prevalence.