Material Testing

Would you like help characterizing the best materials for your application? We can provide guidance on material compatibility testing to assess compatible build materials for adhesion or break away support. Send us your filament or pellets and we can print ASTM test samples to be assessed using our materials testing equipment. Once complete, we will send you a qualitative & quantitative report on:

- Compression and Tensile testing

- 3D point bending

- Analysis on how well the material prints

- Optimal print temperature, speeds and basic profile recommendations

- Layer bonding strength

Choose Your Material Testing & Validation

Filament Testing

Print Optimization

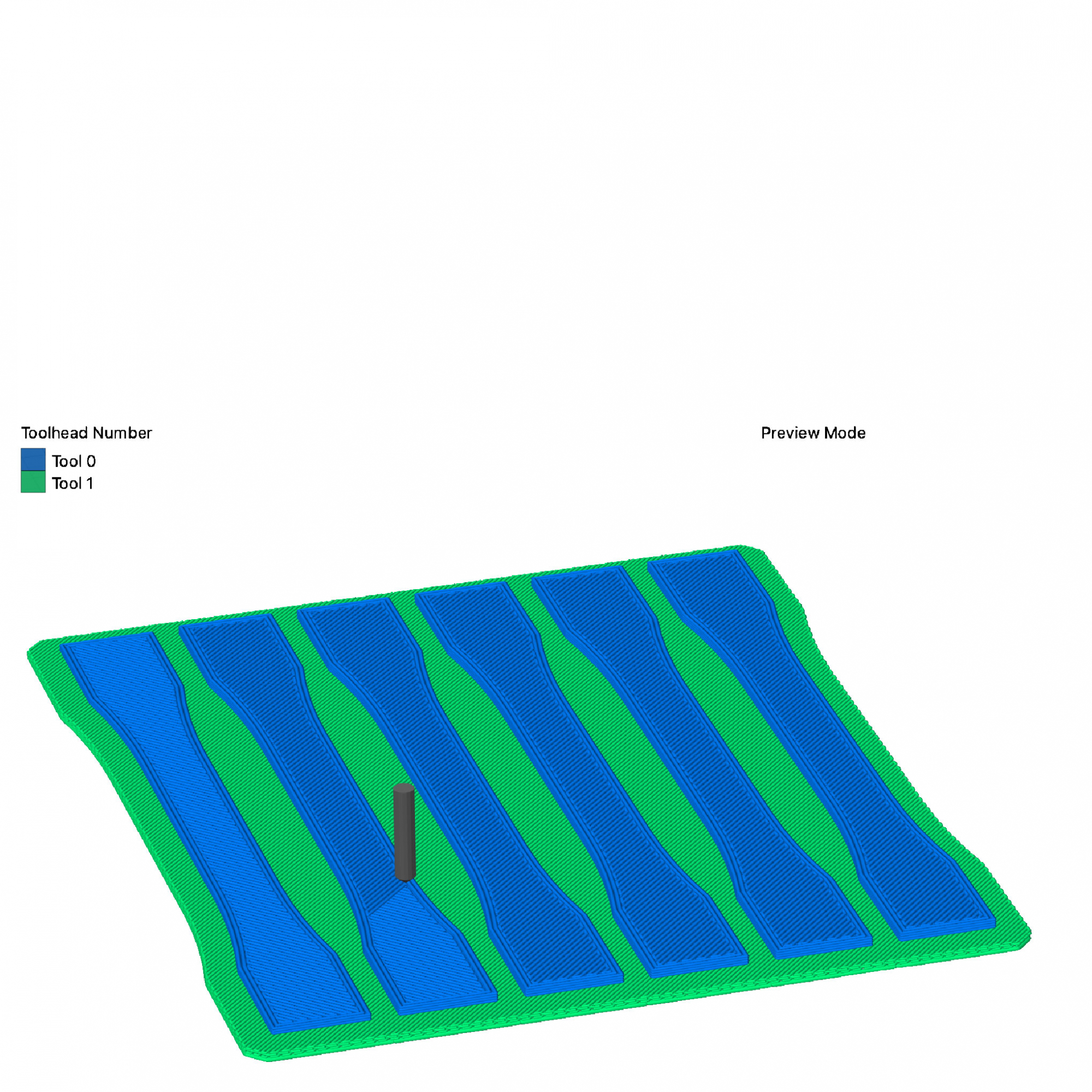

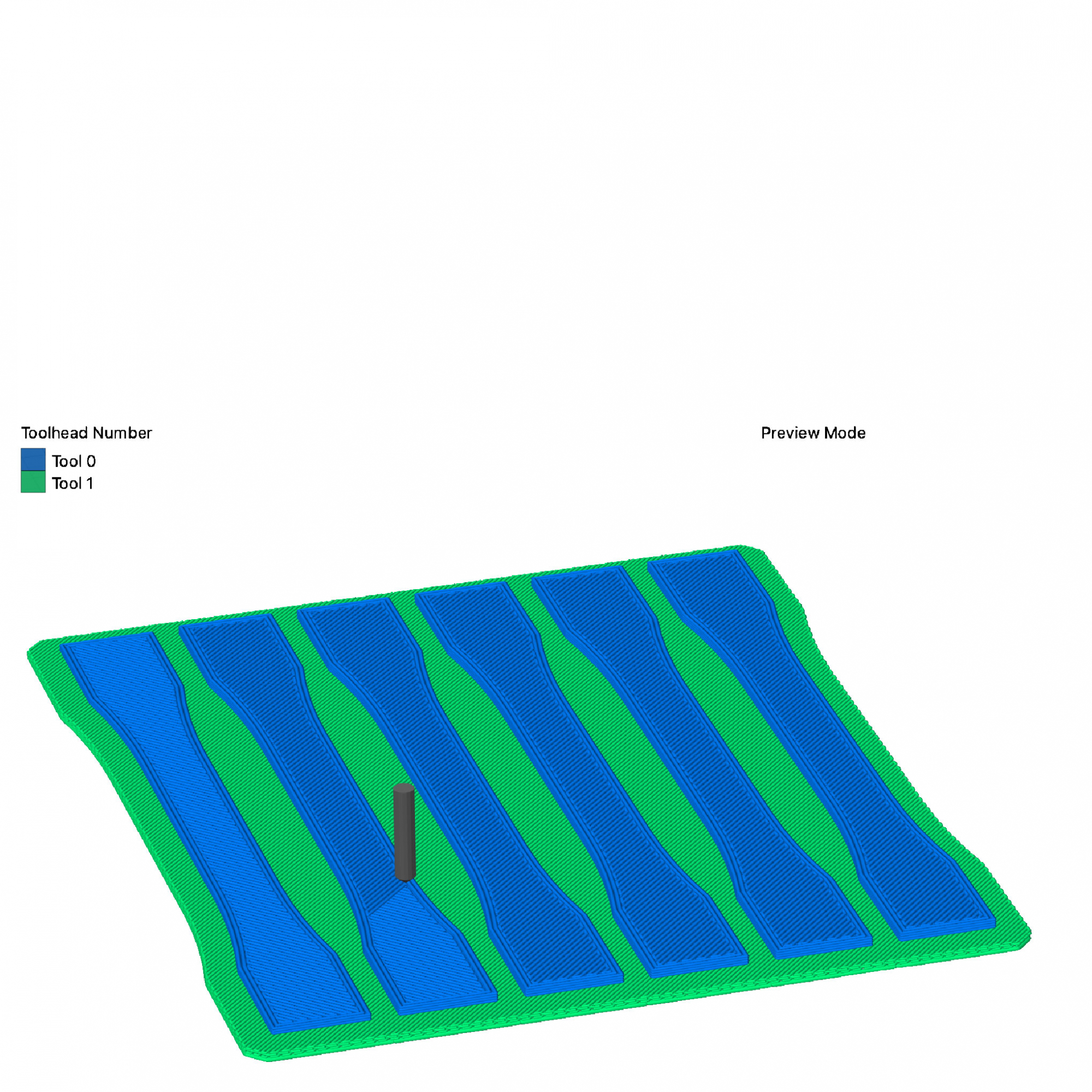

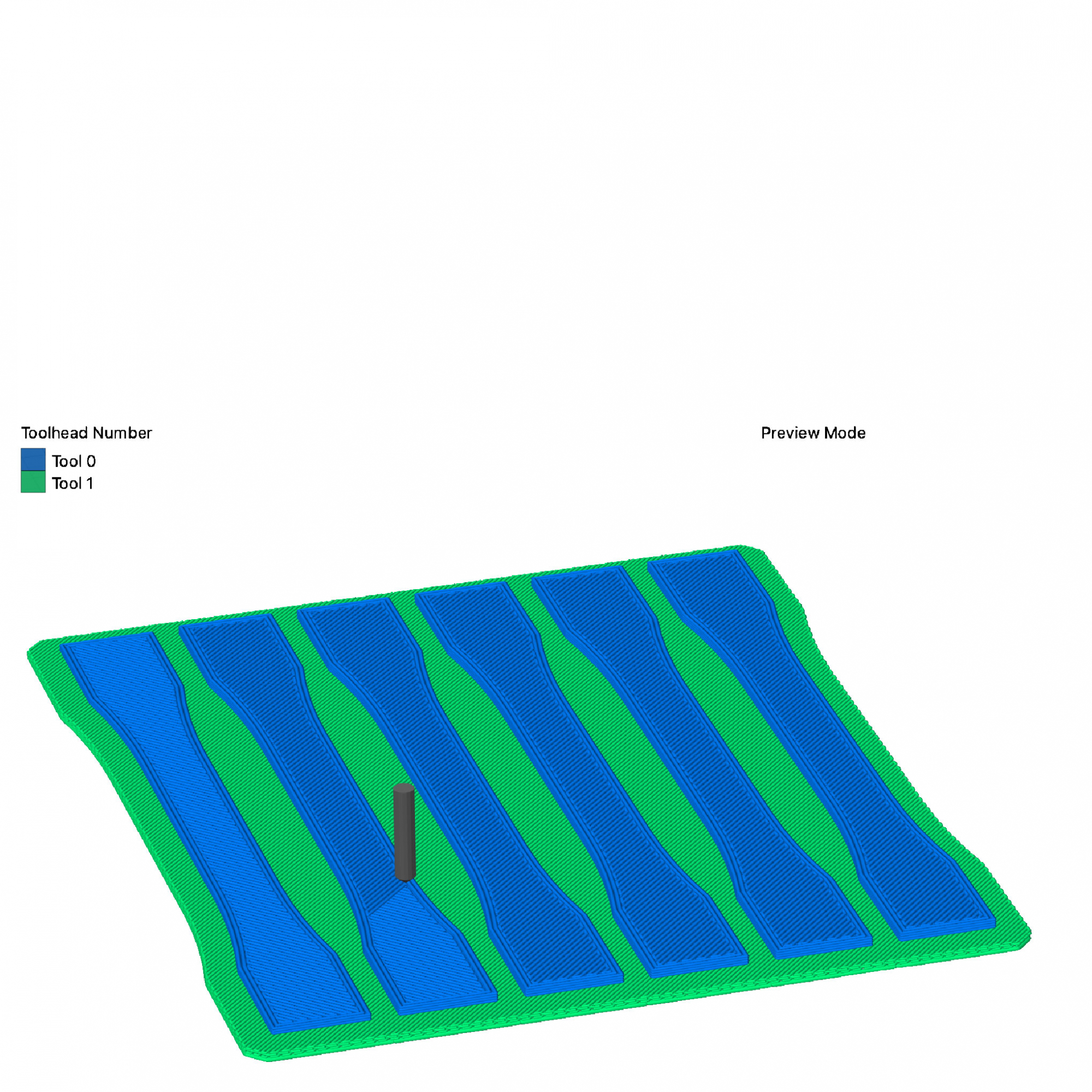

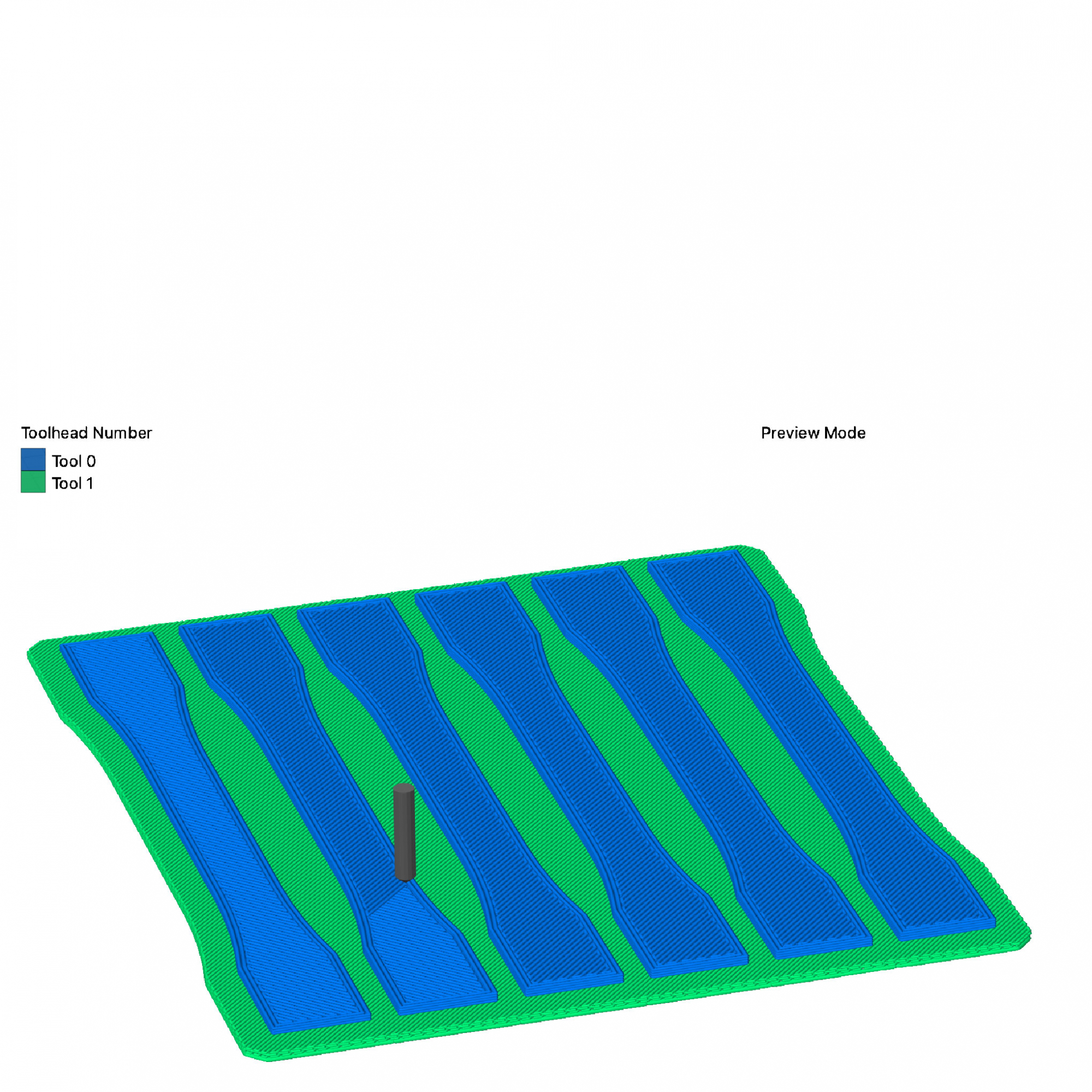

Print multiple test prints of increasing complexity to optimize print settings. A Simplify3D profile with optimized settings will be provided.

| $500

Material Properties

Use ASTM standards to conduct tensile, 3-point bending, or compression testing to establish material properties for industrial applications.

| $1,250

Custom Analysis

Custom tests can include multi material testing, various bed adhesives, heat treatment, or other technical tests.

| Contact us for Pricing

Mechanical Properties

Our Admet 50kN Universal Testing System is capable of finding the mechanical properties of 3D-printed materials using standardized test procedures: Tensile (ASTM D638), Flexural (ASTM D790), Flexural Fatigue (ASTM D7774) & more upon consultation

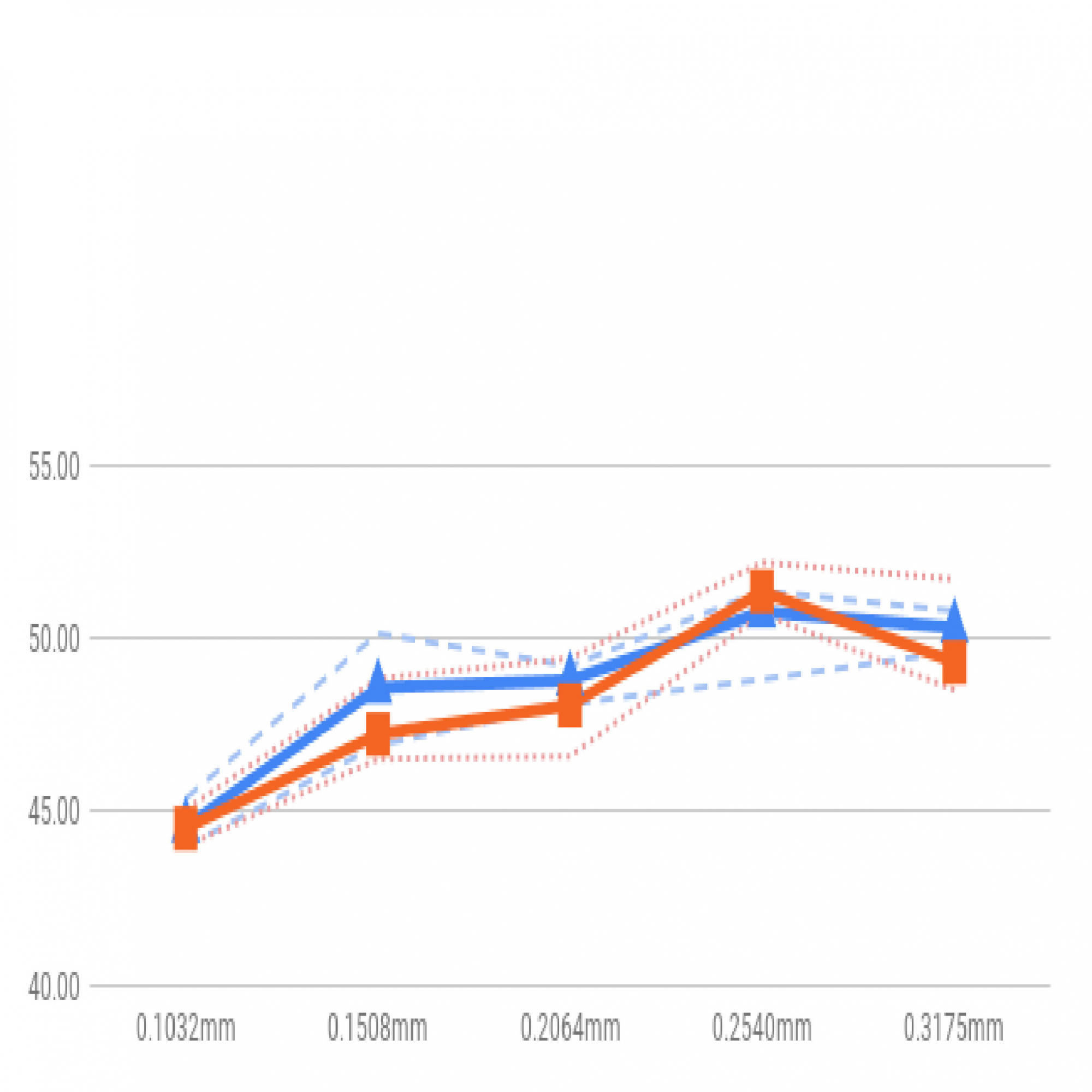

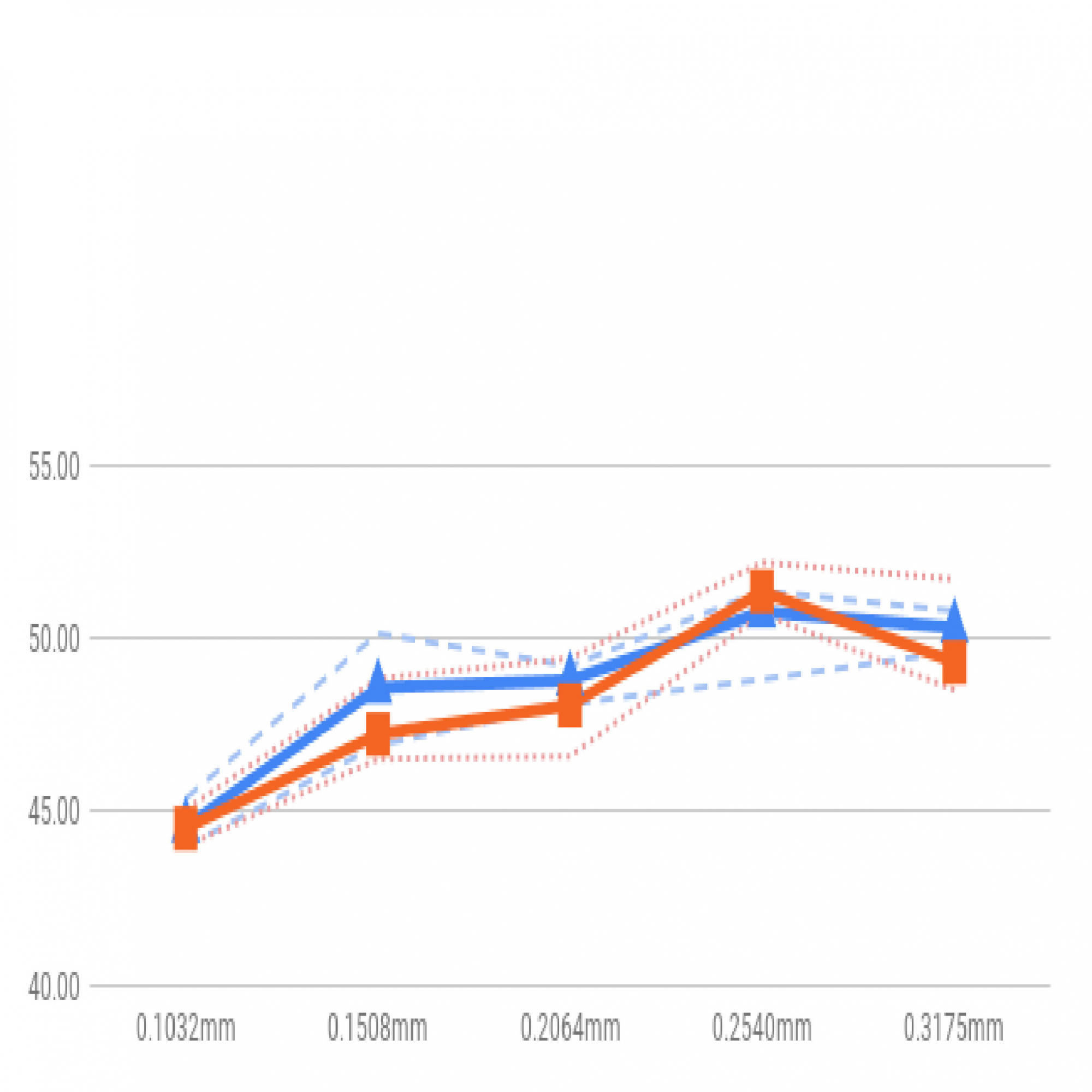

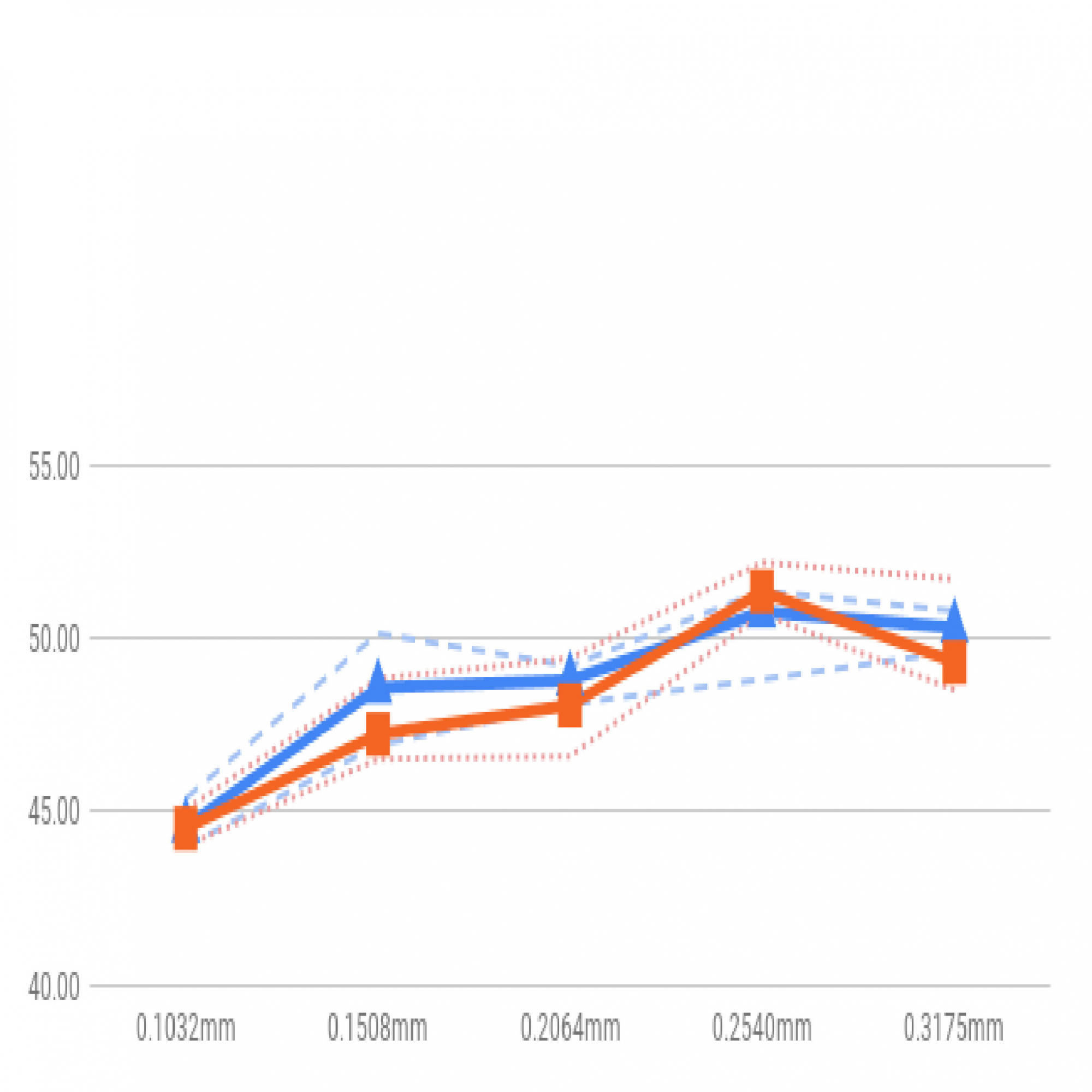

Data Analysis

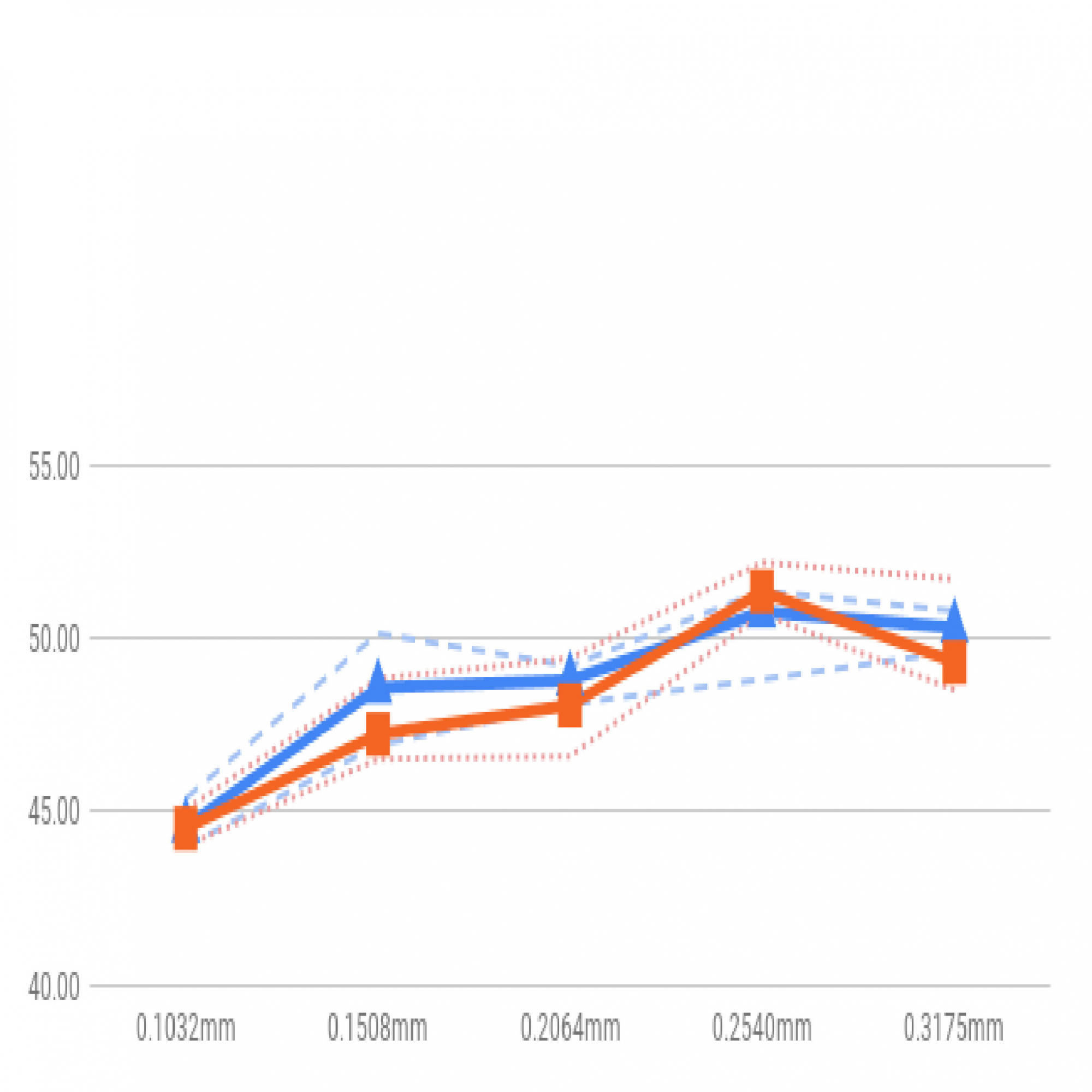

Aggregated stress data across all samples are given with average and standard deviation Stress-strain curves are given for each sample to show fracture characteristics

Experimentation

Changes in slicing parameters or utilization of post-processing techniques (annealing, sterilization, smoothing) can be compared. Null hypothesis one-tailed tests are used to determine statistical significance of claims

Failure Analysis

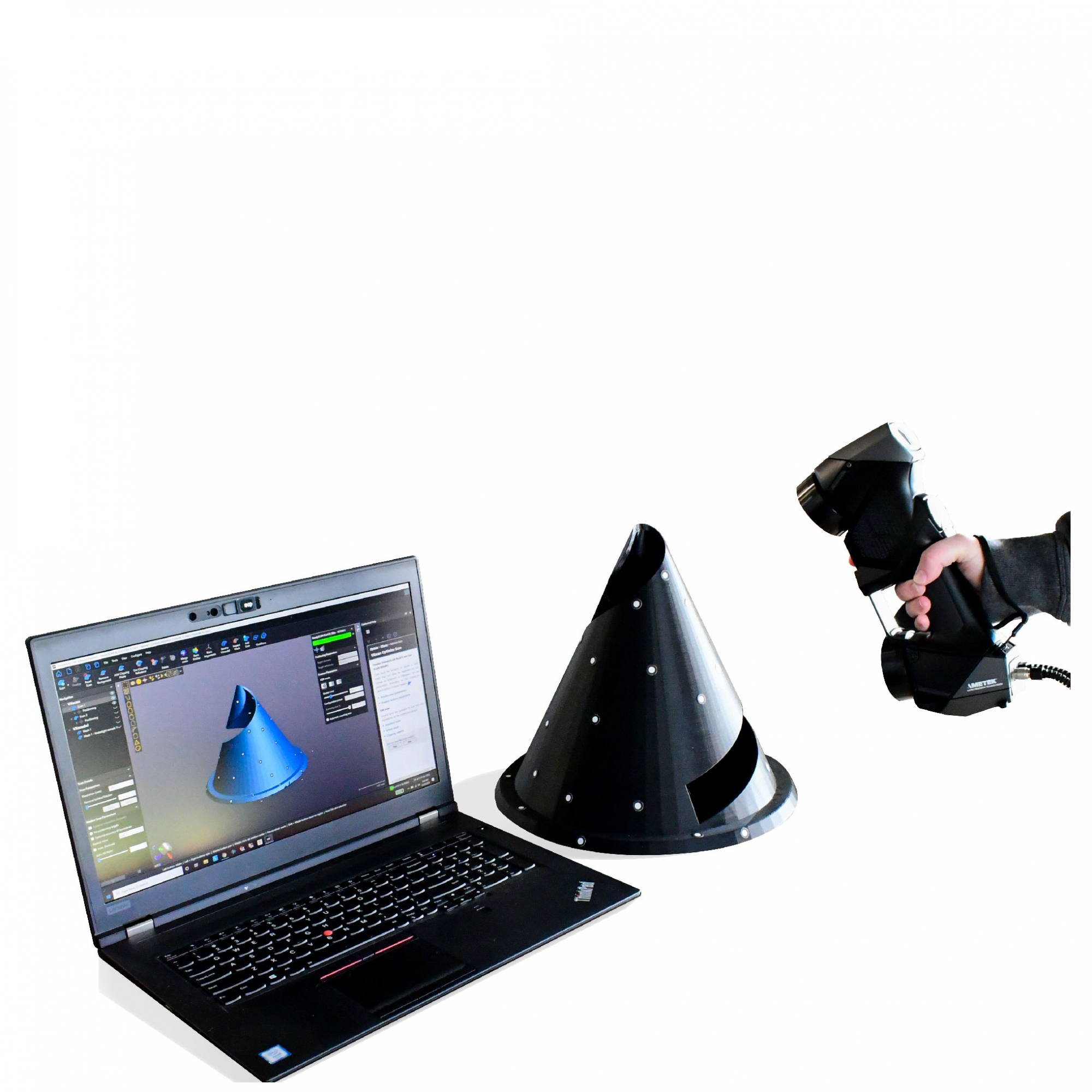

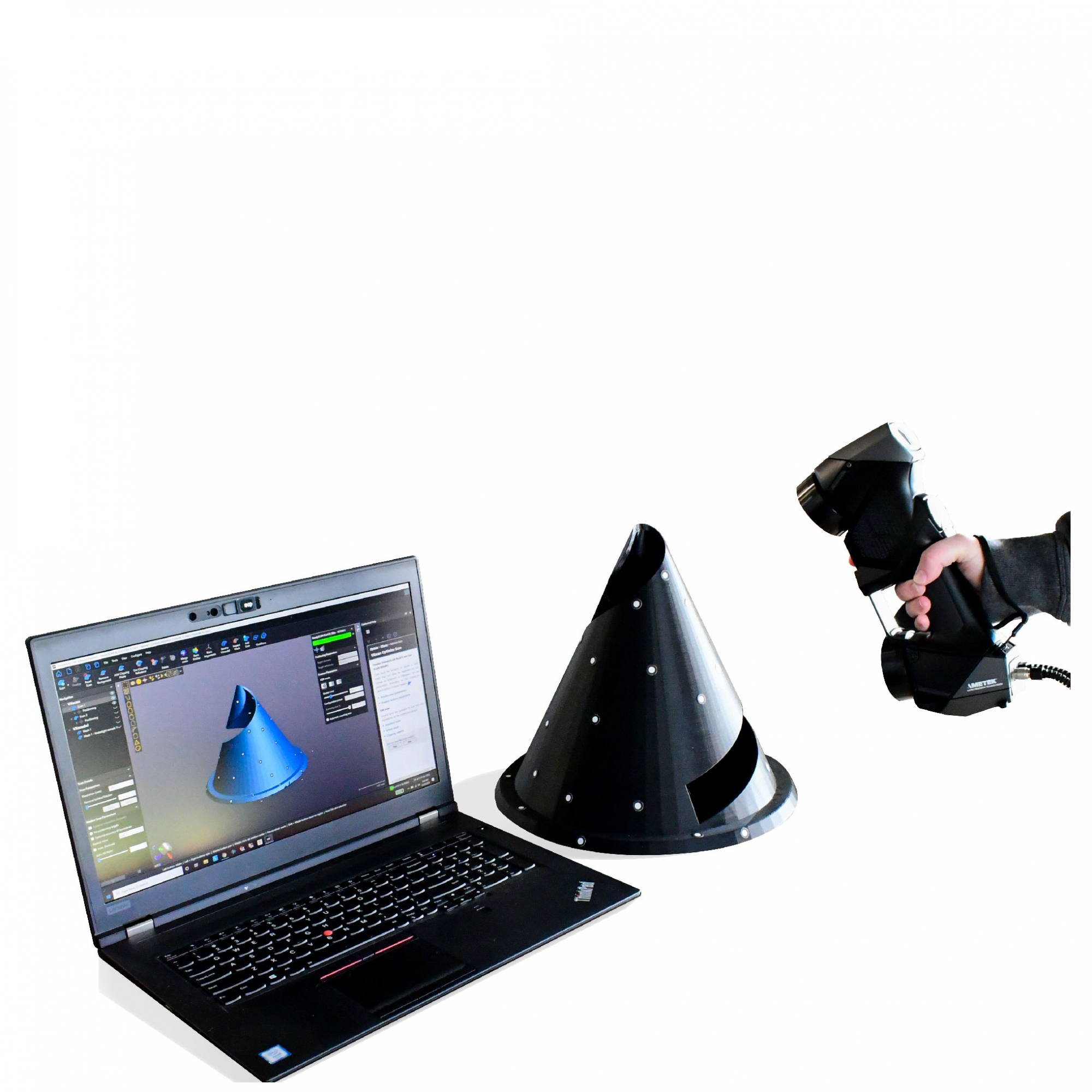

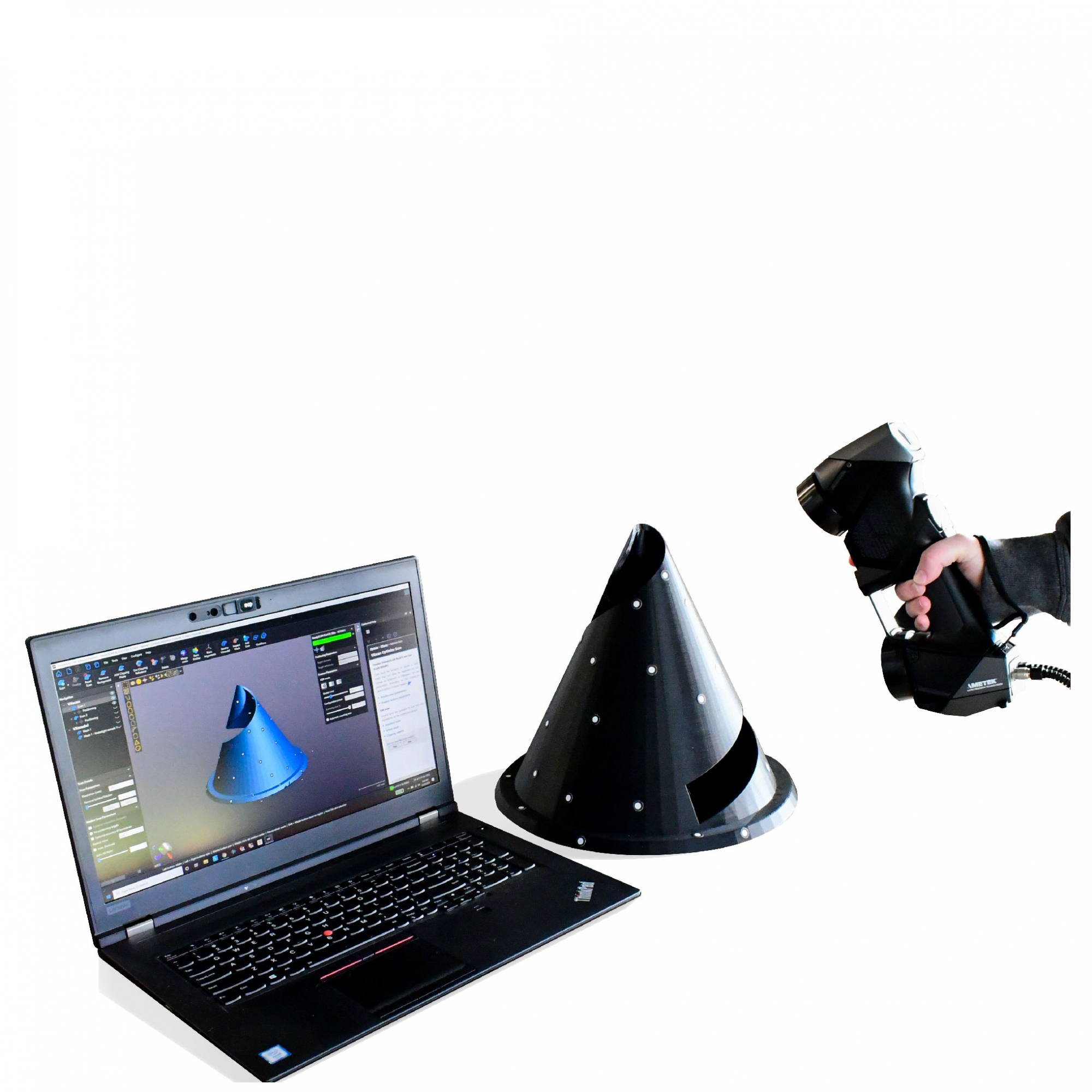

Test specimens can be 3D scanned at 0.025mm resolution to show deformation after testing. Fractures can be imaged with microscopy with 60x magnification

Mechanical Properties

Our Admet 50kN Universal Testing System is capable of finding the mechanical properties of 3D-printed materials using standardized test procedures: Tensile (ASTM D638), Flexural (ASTM D790), Flexural Fatigue (ASTM D7774) & more upon consultation

Data Analysis

Aggregated stress data across all samples are given with average and standard deviation Stress-strain curves are given for each sample to show fracture characteristics

Experimentation

Changes in slicing parameters or utilization of post-processing techniques (annealing, sterilization, smoothing) can be compared. Null hypothesis one-tailed tests are used to determine statistical significance of claims

Failure Analysis

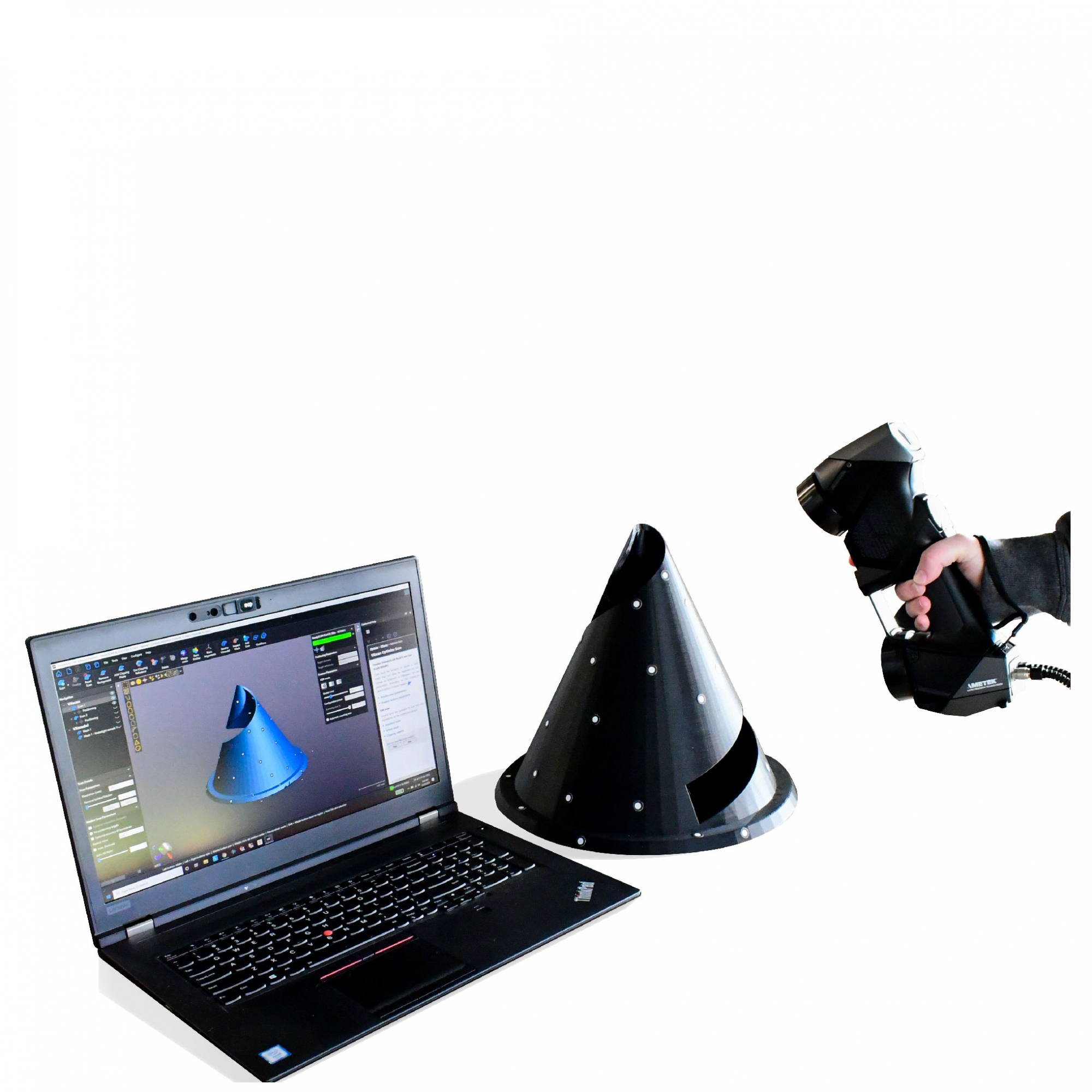

Test specimens can be 3D scanned at 0.025mm resolution to show deformation after testing. Fractures can be imaged with microscopy with 60x magnification

Pellets | Flake Testing

Tier 1 | Granulation

Granulate 5kg plastic waste into 4mm particles with our SHINI Low Speed Granulator

| $500

Tier 2 | Extrusion

Conduct particle size analysis, dry the material, & load it into Gigabot X to quantify the max extrusion rate. Establishes the initial print temperatures and identifies any extrusion issues.

| $1,000

Tier 3 | Print Optimization

Print multiple tests articles of increasing complexity to optimize print settings. A Simplify3D profile with optimized settings will be provided.

| $2,250

Tier 4 | Material Properties

Use ASTM standards to conduct tensile, 3-point bending, or compression testing to establish material properties for industrial applications.

| $1,250

Mechanical Properties

Our Admet 50kN Universal Testing System is capable of finding the mechanical properties of 3D-printed materials using standardized test procedures: Tensile (ASTM D638), Flexural (ASTM D790), Flexural Fatigue (ASTM D7774) & more upon consultation

Data Analysis

Aggregated stress data across all samples are given with average and standard deviation Stress-strain curves are given for each sample to show fracture characteristics

Experimentation

Changes in slicing parameters or utilization of post-processing techniques (annealing, sterilization, smoothing) can be compared. Null hypothesis one-tailed tests are used to determine statistical significance of claims

Failure Analysis

Test specimens can be 3D scanned at 0.025mm resolution to show deformation after testing. Fractures can be imaged with microscopy with 60x magnification

Mechanical Properties

Our Admet 50kN Universal Testing System is capable of finding the mechanical properties of 3D-printed materials using standardized test procedures: Tensile (ASTM D638), Flexural (ASTM D790), Flexural Fatigue (ASTM D7774) & more upon consultation

Data Analysis

Aggregated stress data across all samples are given with average and standard deviation Stress-strain curves are given for each sample to show fracture characteristics

Experimentation

Changes in slicing parameters or utilization of post-processing techniques (annealing, sterilization, smoothing) can be compared. Null hypothesis one-tailed tests are used to determine statistical significance of claims

Failure Analysis

Test specimens can be 3D scanned at 0.025mm resolution to show deformation after testing. Fractures can be imaged with microscopy with 60x magnification