* Original post from mid 2013 *

Note: This post is adapted from an article written by Morgan Hamel for the Santiago-based magazine “I Love Chile.”

If you had told me a month ago that I would be leaving my hometown of Silicon Valley – the heart of all things tech – to come to Santiago, Chile to work with a startup making 3D printers, I would have thought you had taken one too many deep inhales of the Santiago smog. Yet here I am, gazing out the window at the Andes as I push a 3D printed model of the Chrysler Building and a structure of the inner ear out of my way to write this.

My knowledge of 3D printing before arriving was pretty minimal, so I’ll give you the low-down on how this futuristic technology works. In contrast to traditional subtractive manufacturing, whereby objects are fabricated by removing matter from a piece of raw material, 3D printing is known as additive manufacturing: objects are created by adding layers of material to form a desired shape. You start with a 3D image on the computer – modeled with digital modeling software or downloaded from a website with open-source designs, like Thingiverse. Using a special computer program, you then slice these images into layers that are readable by the 3D printer, and – voilá! – your printer can begin dispensing the layers while your once-two dimensional object comes to 3D life before your eyes. The impact of 3d printing in supply chain is also very fascinating and definitely worth investigating further.

Sounds like something straight from the year 3000, right? Surprisingly enough, this technology has been around for almost two decades. It has even helped to spark the fourth industrial revolution, which will have huge consequences for the business world. Drawing from the process of the then-recently-invented inkjet printer, 3D printing got its start in 1984 when Charles Hull invented stereolithography, a process by which 3D objects were created from digital data. Since its birth, 3D printing has brought us a working kidney (2002), a self-replicating printer (2008), a working car (2011), and a prosthetic jaw (2012). As the technology continues to flourish, we are now beginning to see 3D printers as household items, with the breadbox-sized MakerBot Replicator leading the pack in the desktop printer market.

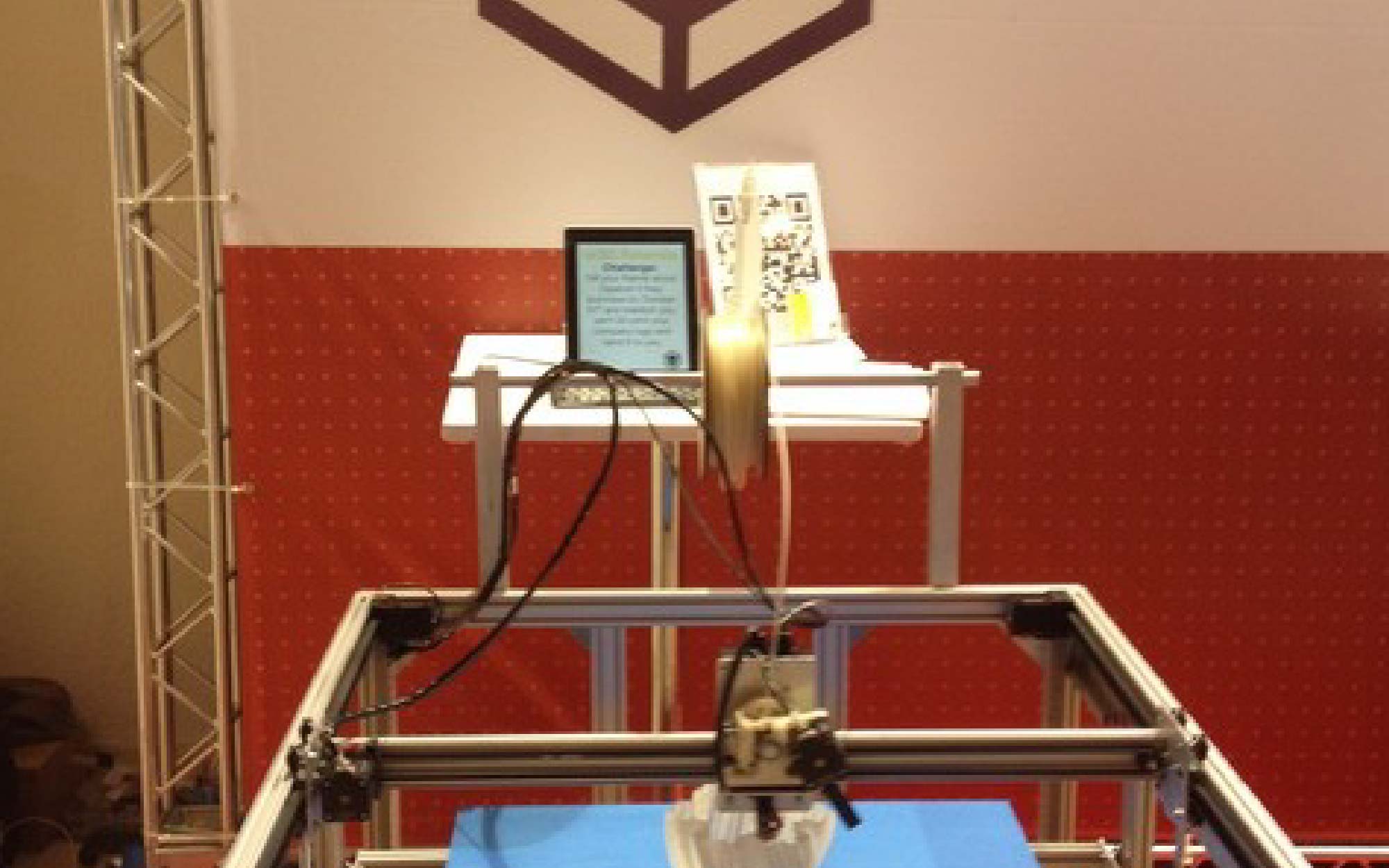

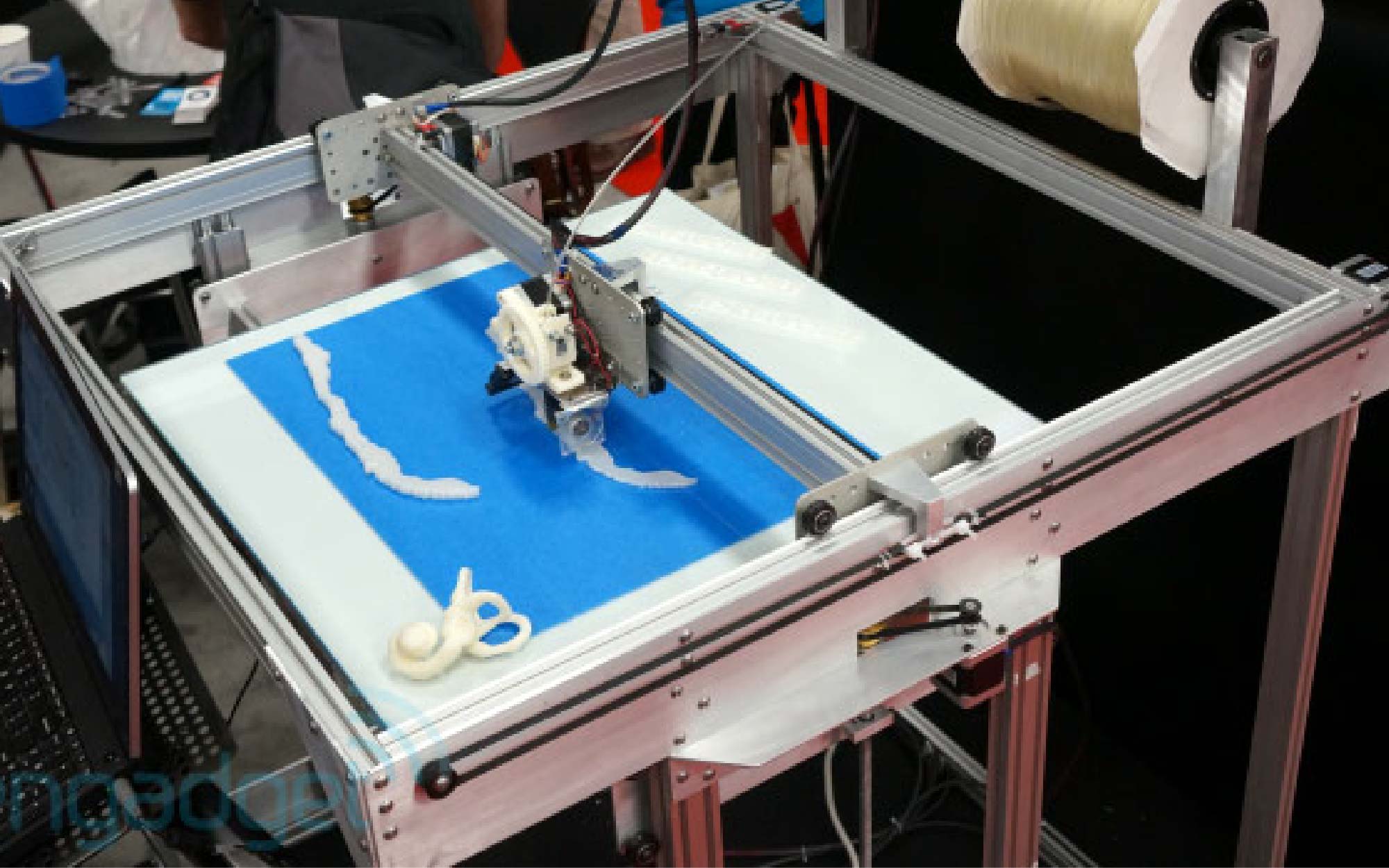

Right now, the marketplace is awash in desktop 3D printers – microwave-sized machines within the budget of a well-to-do hobbyist who enjoys printing handheld objects. But say you wanted to print something bigger, something like a chair? These printers don’t have the capacity to print something that large. This is where re:3D saw an opportunity. Addressing two of the main barriers to 3D printing – cost and scale – the team built their answer to this problem, and it goes by the name of Gigabot.

The Gigabot is currently the largest consumer printer on the market, boasting a build volume 30x larger than that of a standard desktop printer. The printer excelled in its Kickstarter campaign, meeting its fundraising goal in just over 24 hours and surpassing the target by more than sixfold. At $3,950 USD, it has applications in prototyping industries where the alternatives – like traditional injection molding – start in the tens of thousands of dollars. The team is already looking to become the forerunner in markets beyond the single consumer – aerospace, architecture, design, education, manufacturing, and medicine are just some of the industries where large-scale 3D printing is applicable and cost-effective.

But the team is not stopping there. The next project is already in the works at re:3D – a machine that converts plastic trash into 3D printer input material. This undertaking – a collaboration with Dr. Joshua Pearce of Michigan Tech University – will drive down costs while reducing landfill waste and global resource depletion, all while furthering the company’s vision of a future of sustainable 3D printing where individuals can have ownership over their entire supply chain. The applications range from the average consumer interested in operating a sustainable personal factory to isolated communities like Easter Island, where trash removal is a time-consuming and costly process.

So why Santiago? re:3D was accepted as one of the 103 companies in generation 6 of Startup Chile, an incubator program put on by the Chilean government. This CORFO initiative gives entrepreneurs around the world $40,000, office space, and mentorship under the condition that they move to Santiago for six months to build their companies. Gigabot is currently printing away in the ultra-cool workspace of the STGO MakerSpace (stgomakerspace.com) while the team explores the opportunities for 3D printing in the Latin American market.

While 3D printing has been hailed as the second industrial revolution many are still skeptical. But one needs to look past the knick-knacks and toys, towards the custom prosthetics and organs, the toilet in a developing country printed using the community’s plastic landfill, the astronauts fixing an unexpected breakage while on a mission. Only time will tell if 3D printing is the future, but until then I’ll be here in Santiago, somewhere between the Chrysler Building and inner ear.