Article originally appeared on 3DPrint.com on August 31, 2017

One of the things that often surprises an organization that gets its first 3D printer is the unexpected uses that seem to pop out of the woodwork once it arrives.

Someone in one department will decide to get a 3D printer for a specific project, and once word of the new machine spreads through the organization, a line of people suddenly appears. “Do you think you might be able to help me with a project?” “What about this? Can you print that?”

I heard this story at Texas A&M University, where Veterinary Radiation Oncologist Michael Deveau originally got a Gigabot to 3D print components for a canine cancer treatment. Word of his success spread through the hospital, and he soon had colleagues from different departments knocking on his door to ask if he’d be able to help them out.

Deveau has since printed surgical models for neurologists and orthopedists, Ninjaflex models of canine inner ears to be implanted into toy stuffed animals on which students could practice ear exams, and devices to help a researcher with her studies on reducing bladder crystals in goats. He didn’t originally get the Gigabot to do any of those things — he didn’t even know about some of the projects prior to then — but once a solution presented itself, the applications came flowing.

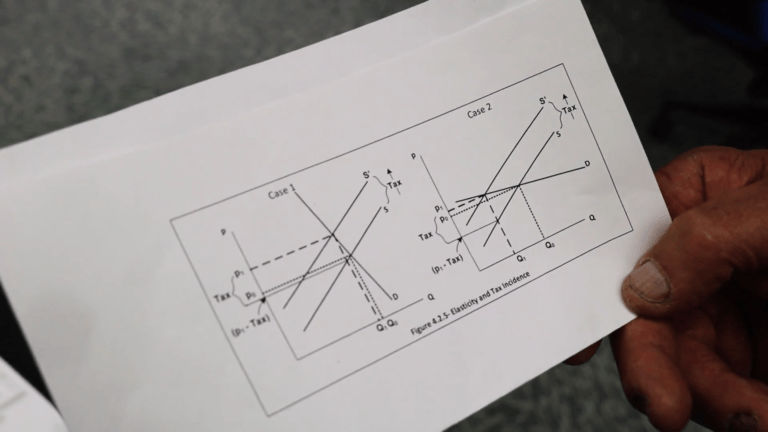

A similar story happened at Syracuse University in New York, where an economics professor was looking for a way to make his class accessible to a blind student. Anyone who’s taken an economics course will know: the subject matter can be very visual, relying on graphs to tell the story of data and trends.

The university had recently opened the doors to a brand-new makerspace, home to a few dozen 3D printers. The economics professor approached John Mangicaro, manager of the makerspace, to see if there might be a better solution for this student than what was already in place.

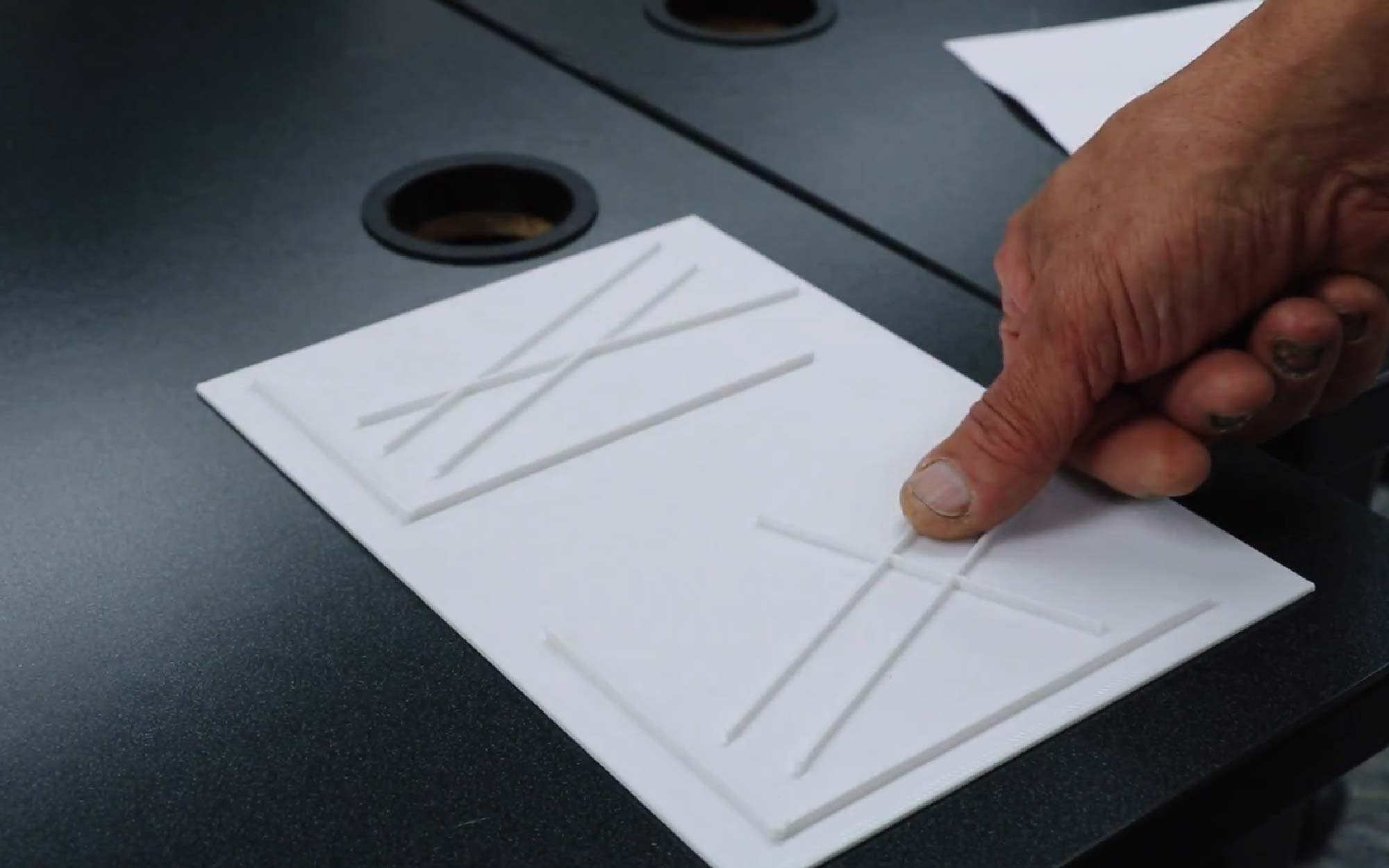

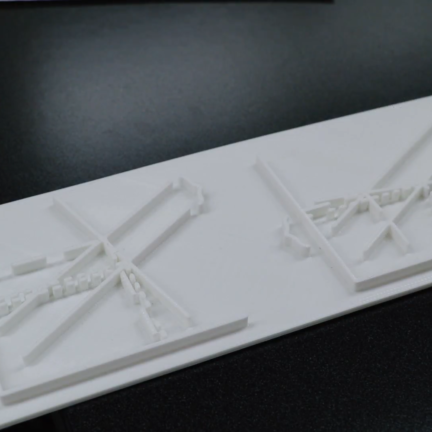

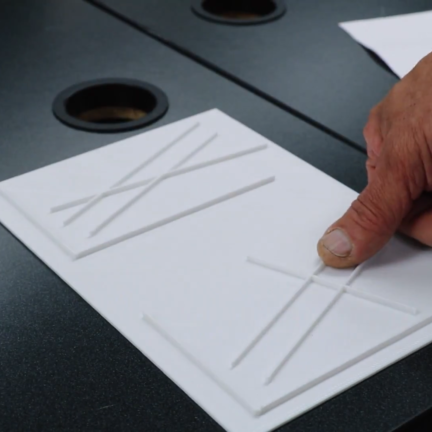

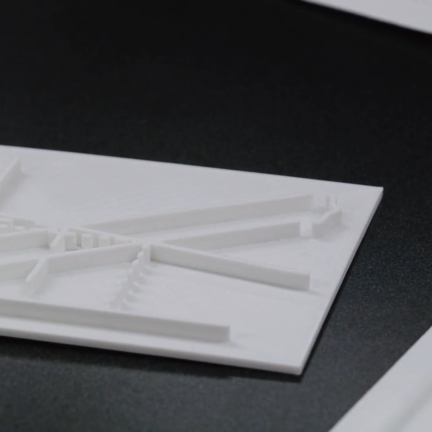

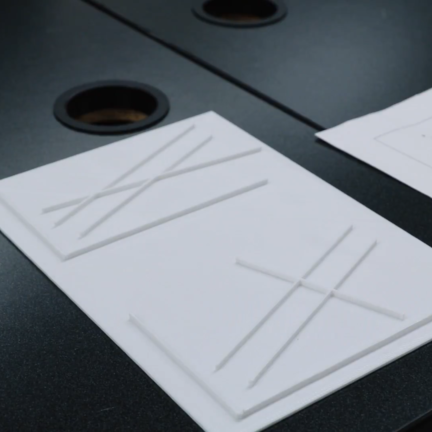

Mangicaro worked with the professor to convert graphs from the coursework into 3D CAD files which were then printed on the makerspace’s large-scale Gigabot. Based on feedback from the student, they tweaked print settings like layer height until the desired outcome was reached. By the end of it, the professor had a collection of Braille-esque graphs that his student could call on for homework and exams.

Syracuse didn’t originally build a lab to 3D print teaching aids to make their classes more accessible — it was a happy byproduct of making the right tools available on campus. And this is exactly one of the things that makes 3D printers so powerful: their ability to unlock previously unconsidered or impossible solutions to problems. Give people access to a tool with nearly limitless potential, and they might just surprise you.

So if your organization is thinking about getting a 3D printer, prepare yourself. You may find yourself working on product ideas you hadn’t considered, or printing off-the-wall solutions to problems that weren’t even on your radar, or you may unintentionally make yourself the new most popular person in the office.

To repurpose a famous quote: “If you can build it, they will come.”

Morgan Hamel

Blog Post Author